A Rapid Detecting Method for Residual Flocculants in Water-Washed Manufactured Sand and Their Influences on Concrete Properties

Abstract

1. Introduction

2. Methods and Materials

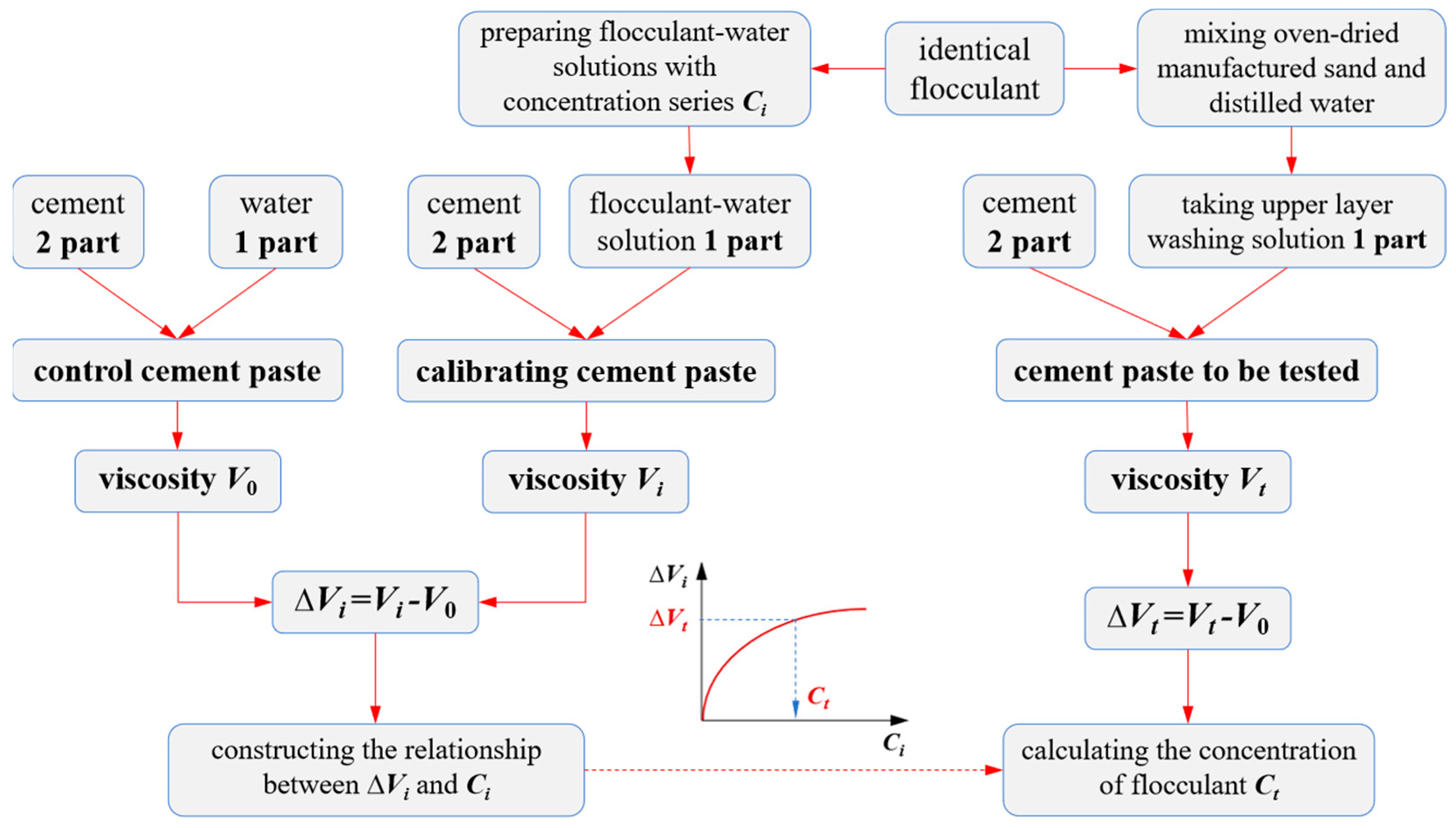

2.1. Detection of the Residual Flocculants Content in Manufactured Sand

2.2. Determination of the Threshold Content for Residual Flocculants in Manufactured Sand

2.3. Materials

2.4. Mixture Proportions

2.5. Experimental Procedures

3. Results and Discussion

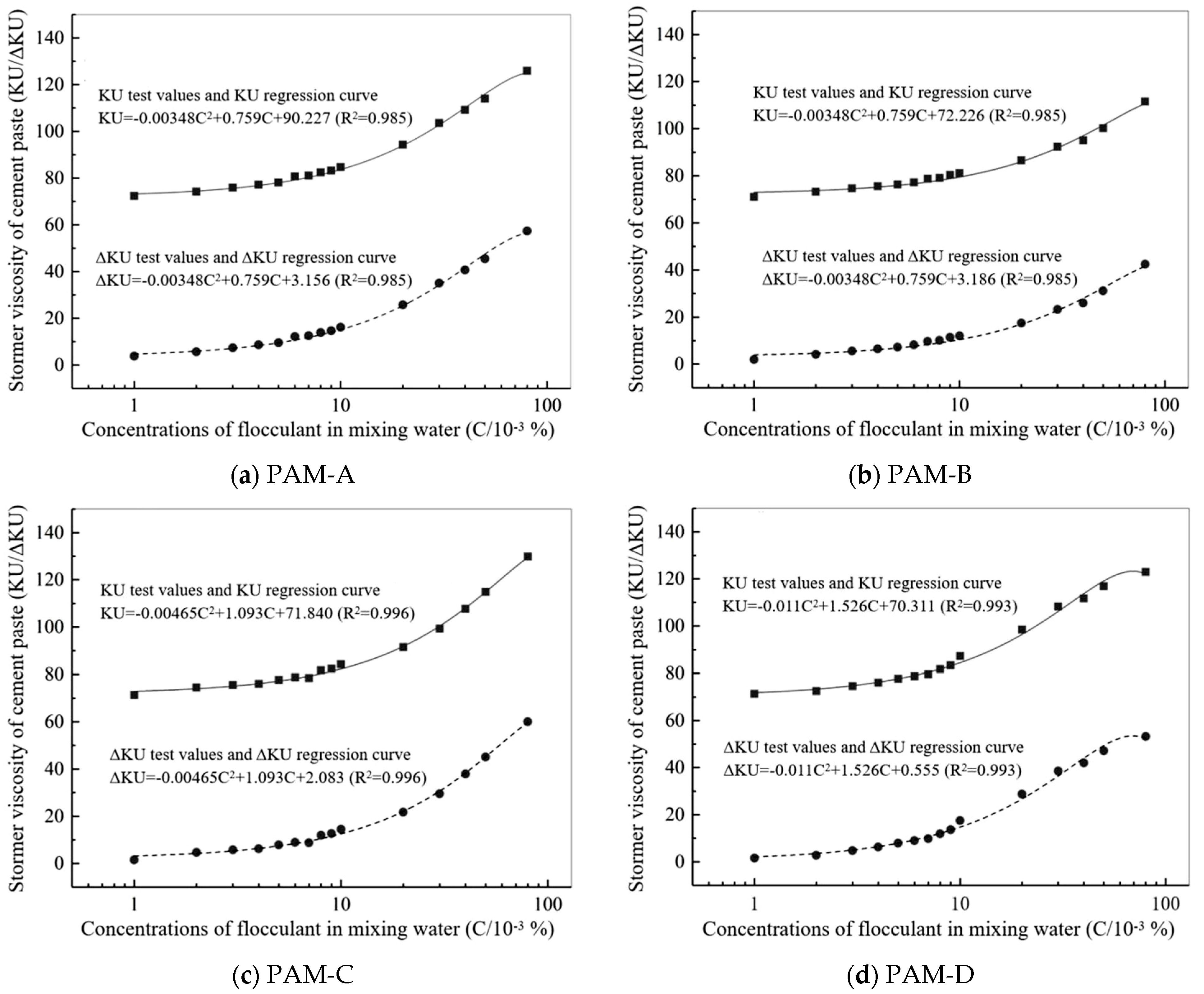

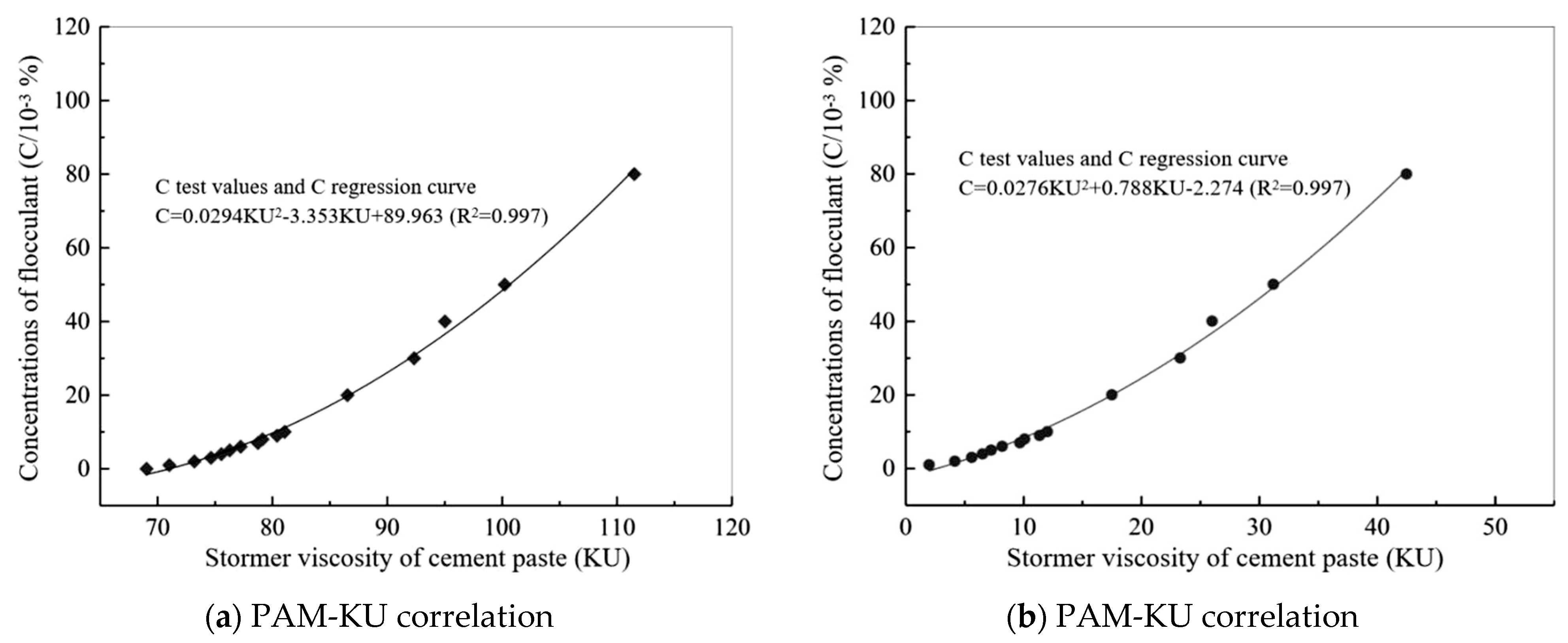

3.1. Relationship Between the Viscosity of the Cement Paste and the Concentration of PAM

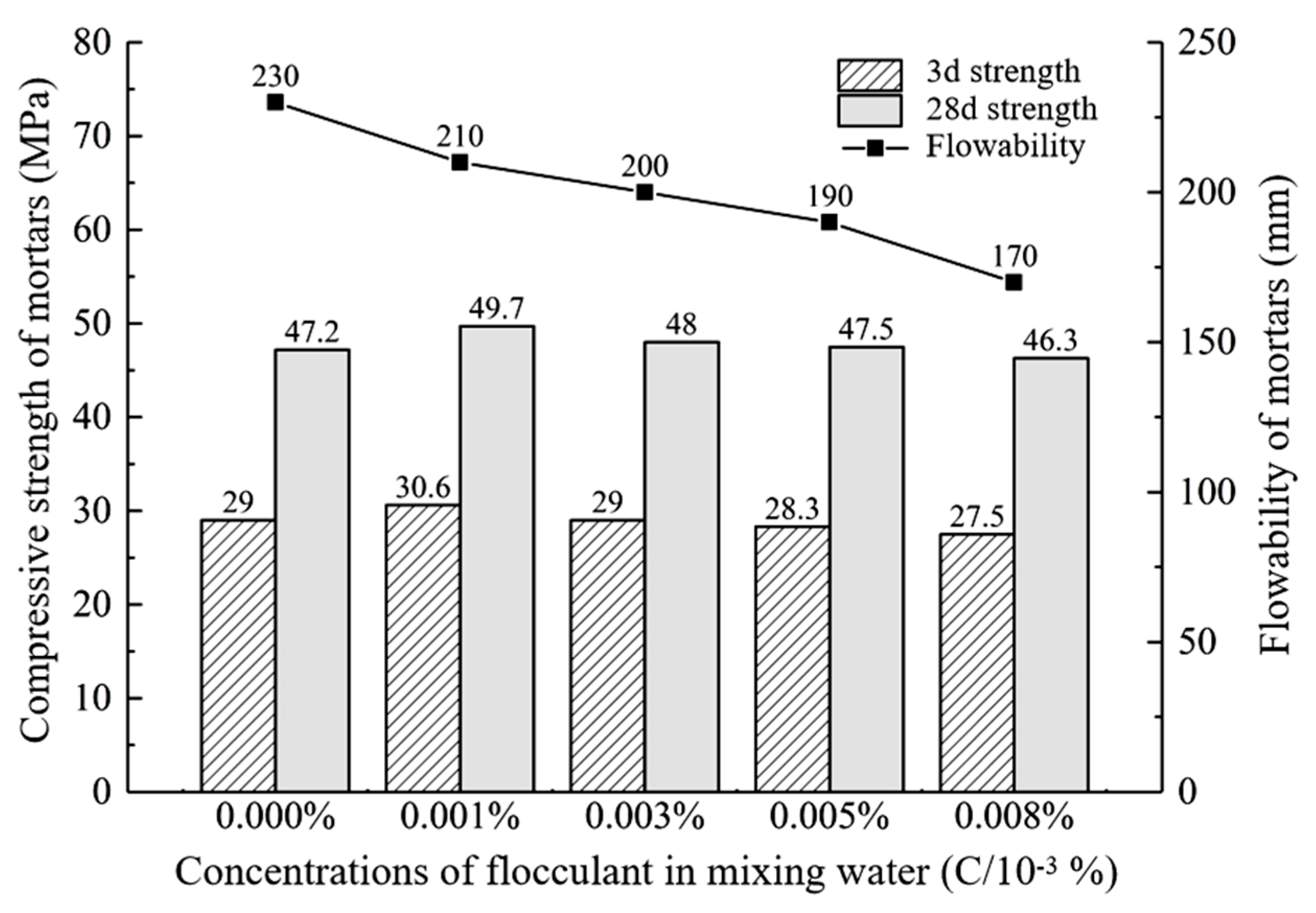

3.2. Influence of PAM Concentration on the Performance of Mortar

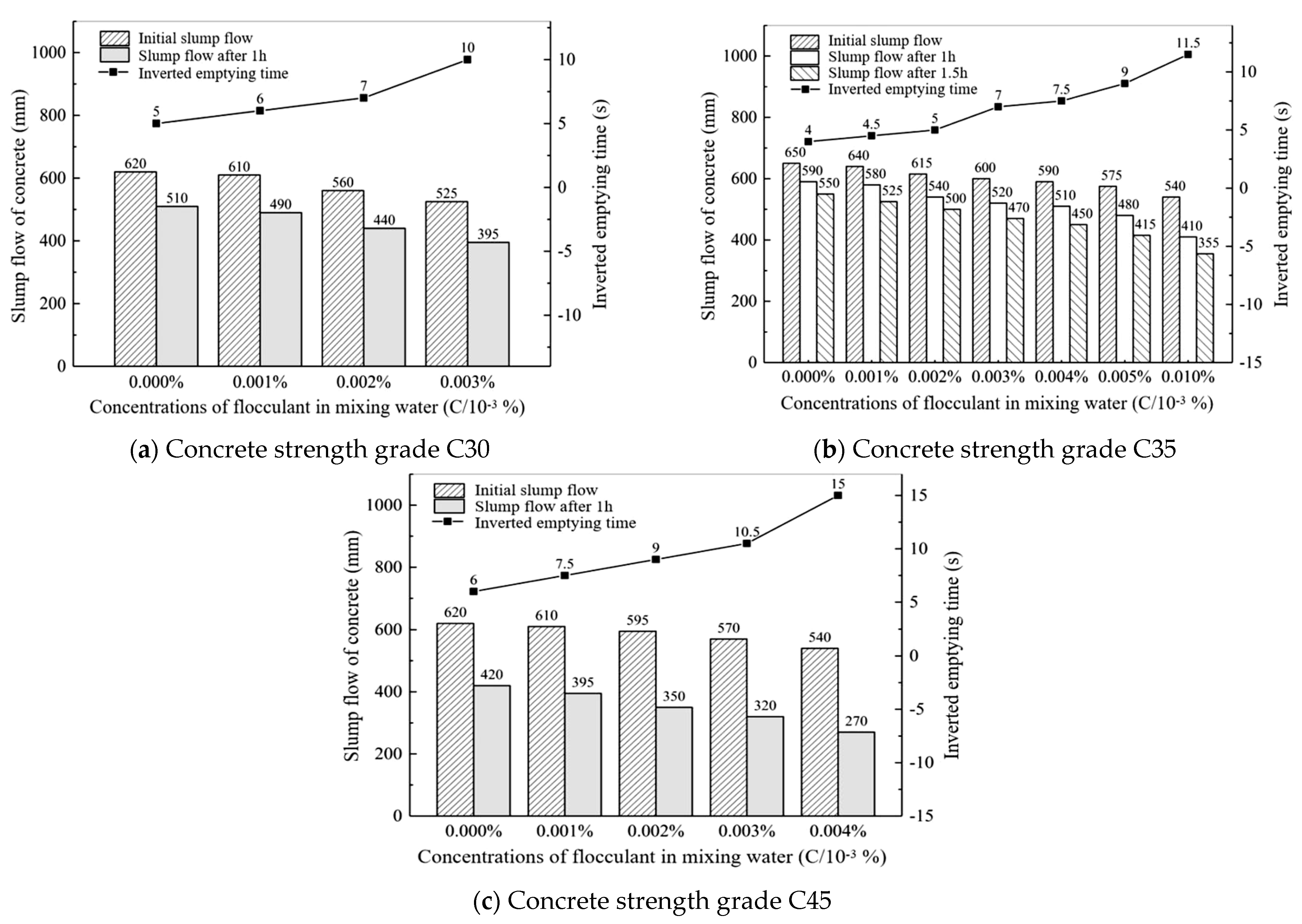

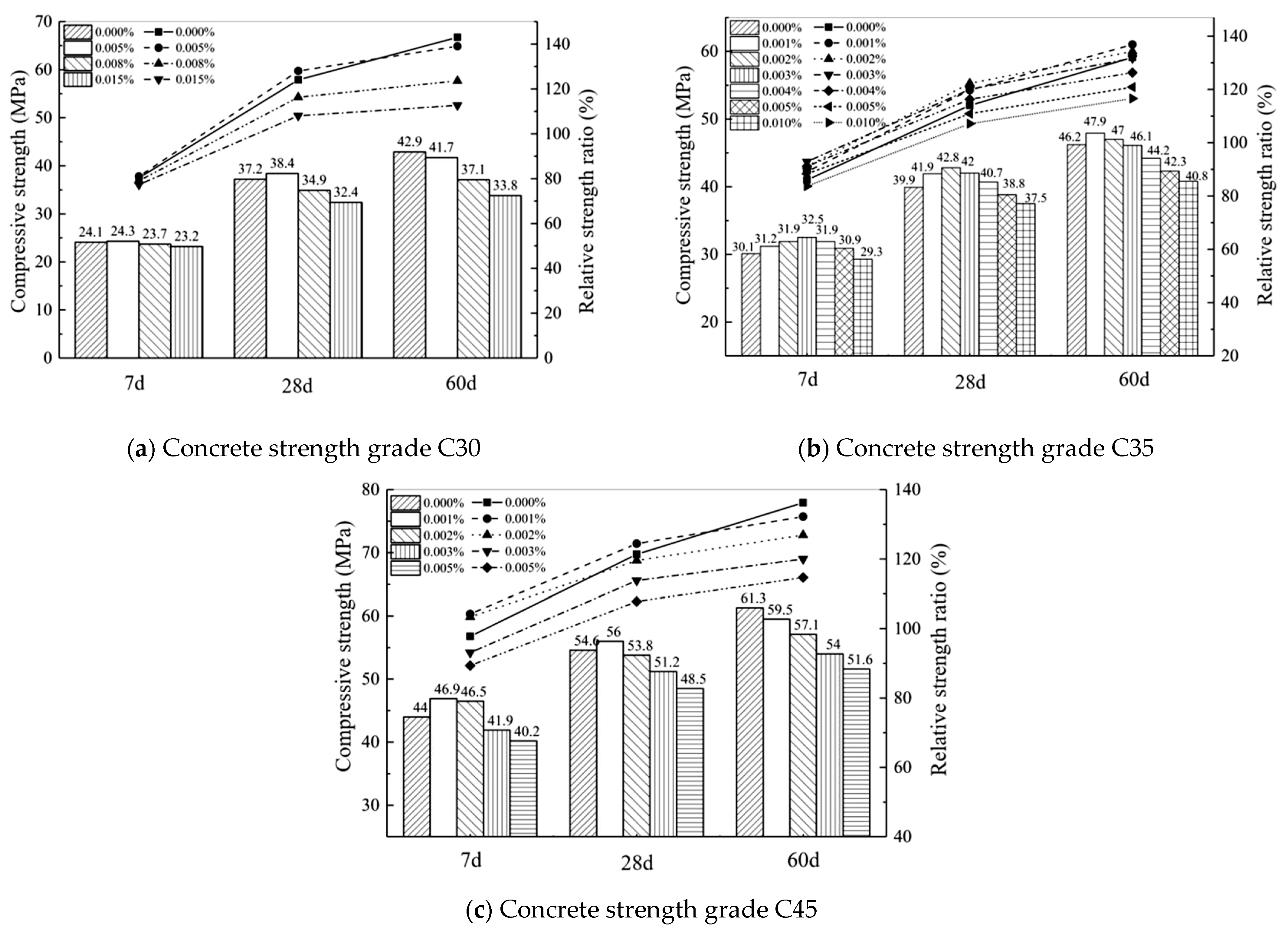

3.3. Influence of PAM Concentration on the Performance of Concrete

4. Conclusions

- The monomer type, molecular weight of PAM, and its concentration in the mixing water directly affected the Stormer viscosity of the cement paste. The viscosity of the cement paste presented a good positive correlation with the concentration of PAM in the mixing water. The experimental results showed that the correlation calibration equations can be used to determine the residual PAM concentration in manufactured sand by measuring the Stormer viscosity of the cement paste. This method can accurately and rapidly determine the residual PAM content in water-washed manufactured sand.

- The influence of intentional/occasional introduction of PAM on the performance of concrete was correlated with its content. When the concentration of PAM was less than 0.003%, PAM can play a role in thickening and water retention, improving the encapsulation property of the paste and enhancing the strength of concrete. When the PAM concentration was more than 0.003%, the workability and later-age strength of concrete would be negatively affected to varying degrees. The influence characteristic of PAM on the workability of concrete, mortar and cement paste have good consistency.

- Before the water-washed manufactured sand is used to mix concrete, it is recommended to use the method proposed in this study to rapidly detect the PAM content in the sand leachate, and set an acceptable upper limit of PAM concentration based on its influence on the properties/performance of concrete. If necessary, measures such as controlling the moisture content of manufactured sand and secondary flushing can be taken to reduce the residual PAM concentration to ensure the quality of concrete batched with manufactured sand.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WWMS | Water-washed manufactured sand |

| PAM | Polyacrylamide |

| PAC | Polyaluminium Chloride |

| W | Mixing water for cement paste/mortar/concrete |

| WRA | Water-reducing agent (Superplasticizer) |

| FA | Fly ash |

| OPC | Ordinary Portland cement |

| GBFS | Ground granulated blast furnace slag (powder) |

| LG | Larger gravel |

| SG | Smaller gravel |

| MS | Manufactured sand |

| NS | Natural sand |

| MK | Metakaolin (powder) |

| SS | Chinese ISO standard sand |

| KU | Stormer viscosity with Krebs Unit |

| ΔKU | Stormer viscosity difference with Krebs Unit |

| C | Concentrations of flocculant in mixing water |

Appendix A

Appendix A.1

Appendix A.2

References

- Zhang, C.H.; Song, S.M.; Liu, F. Review on the present situation of preparing sand aggregate from mine waste rock. Fly Ash Compr. Util. 2023, 86, 55–63. [Google Scholar]

- Zhuang, S.R.; Torres, A.; Chen, R.S. Trends, challenges, and mitigation strategies for the use of sand and gravel resources in China. J. East China Norm. Univ. 2022, 23, 137–147. [Google Scholar]

- Han, Z. Research on Design, Performance and Mechanism of High Performance Concrete Based on Manufactured Sand Morphology; Lanzhou University of Technology: Lanzhou, China, 2023; Available online: https://kns.cnki.net/kcms2/article/abstract?v=mA0k7fYtKv41uYDOX19SsI72aHVAXxnnl_P3fPXn8rTQ7vWhHuZ6Cyjq1klyD-kezRLhMSFlk4uogYH81iI7iu62291m_0oApPww2jESSl9rE4NBSdllO78KhhQJA-5hwH4SPtd1vUmJq1AE8seut1HykE6IaNMP1x4PVHVpq5CDV2N9AZfrrQtYaumrwTSc&uniplatform=NZKPT&language=CHS (accessed on 16 September 2025).

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is running out for sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef]

- María, C.P.-M.; Inês, F.-C.; Jorge, B. The use of stone waste as fine aggregate or cement replacement in cement-based mortars: A review. J. Build. Eng. 2025, 106, 112503. [Google Scholar] [CrossRef]

- Yu, L.J.; Tong, X. Optimization of key components of impact crusher based on “rock bed” mechanism. Mech. Adv. Mater. Struct. 2020, 29, 321–329. [Google Scholar] [CrossRef]

- Zhu, W.; Liu, C.; Zhang, Y.; Zhang, Y.; Wang, Y.; Wang, T. Rheological performance regulation and material optimization of manufactured sand concrete in 3D printing. Constr. Build. Mater. 2025, 483, 141735. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Y.; Liu, Z.; Qiao, H.; Ye, F.; Lei, Z. Research on carbon emission reduction of manufactured sand concrete based on compressive strength. Constr. Build. Mater. 2023, 403, 133101. [Google Scholar] [CrossRef]

- Peng, W.B.; Zhang, R.H.; Wu, X. Experimental study on the preparation of poor concrete with high-quality manufactured sand. China Concr. 2021, 32, 56–60. [Google Scholar]

- Wu, J.Z.; Shan, G.C.; Chen, J. Application of flocculant in manufactured sand and its effect on the dispersion of plasticizer. New Build. Mater. 2021, 48, 53–55. [Google Scholar]

- Feng, W.K.; Xie, Y.C.; Xu, Q. Influence of flocculant in manufactured aggregate on the quality of ready-mixed concrete. Ready-Mix. Concr. 2020, 26, 22–26. [Google Scholar]

- Yang, L.; Li, C.H. Effect of flocculant (PAM) on performance of cement (cementitious material) paste and concrete. China Concr. 2021, 32, 80–83. [Google Scholar]

- Duan, S.S. A brief discussion on the application of manufactured sand in concrete. Ready-Mix. Concr. 2017, 11, 2–7. [Google Scholar]

- Feng, A.L.; Qin, W.Z.; Wang, Z.Y. Comparison of some kinds of wadding congeal that influence the property of non-scattering concrete. Pet. Eng. Constr. 2022, 4, 6–10. [Google Scholar]

- Yu, X.; Cao, T.C.; Bai, L.L.; Rui, C.M. Effect of polyacrylamide on the properties of cement stabilized sand. J. Hebei Univ. Eng. (Nat. Sci. Ed.) 2023, 40, 65–70. [Google Scholar]

- Ye, C.F. Effect of polyacrylamide on properties of steel slag concrete. China Concr. Cem. Prod. 2023, 8, 88–92. [Google Scholar]

- GB/T 17671; Test Method of Cement Mortar Strength (ISO Method). State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 14685; Pebbles and Crushed Stones for Construction. State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 14684; Sand for Construction. State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2022.

- GB/T 50081; Standard for test methods of concrete physical and mechanical properties. State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2019.

- GB/T 8077; Test methods for homogeneity of concrete admixtures. State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

- GB/T 50080; Standard test methods for properties of ordinary concrete mixtures. State Administration for Market Regulation & Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- Meng, Q.; Mao, Y.; Zhang, J.; Zhou, D.; Yang, Y.; Wang, T. Effect of flocculant in circulating washing crushed sand on concrete performance. New Build. Mater. 2022, 49, 65–68. [Google Scholar]

- Yin, J.L. Study on the effect of flocculants in washed manufactured sand on the performance of concrete. China Concr. 2023, 50, 14–18. [Google Scholar]

- Yang, G.S.; Du, S.P.; Luo, X.D.; Wang, S.L. Effect of flocculants on workablity and strength of C30 strength class concrete. Ready-Mix. Concr. 2019, 11, 53–56. [Google Scholar]

- Zou, S.; Sun, Z.; Lu, Z.; Yang, H.; Li, H.; Fan, S.; Deng, X.; Yang, J. Fresh and hardened properties of cement paste under the synergistic influence of polycarboxylate superplasticizer and anionic polyacrylamide. Case Stud. Constr. Mater. 2024, 21, e03895. [Google Scholar] [CrossRef]

- Bessaies-Bey, H.; Khayat, K.H.; Palacios, M.; Schmidt, W.; Roussel, N. Viscosity modifying agents: Key components of advanced cement-based materials with adapted rheology. Cem. Concr. Res. 2022, 152, 106646. [Google Scholar] [CrossRef]

- Lai, Z.F.; Wang, W.J.; Leng, F.G.; Feng, X.Y. Study on the effect of sulfonation β-cyclodextrin as an impedance flocculant in concrete. New Build. Mater. 2023, 50, 74–77. [Google Scholar]

- Xu, W.B.; Tian, M.M.; Li, Q.L. Time-dependent rheological properties and mechanical performance of fresh cemented tailings backfill containing flocculants. Miner. Eng. 2020, 145, 106064. [Google Scholar] [CrossRef]

- Xie, W.X. Exploration of stable use of manufactured sand in concrete. Guangdong Build. Mater. 2022, 38, 11–12, 14. [Google Scholar]

- Zhang, Y.A. Analysis on the influence of washing sand with flocculant on concrete performance. New Technol. New Prod. China 2022, 27, 123–125. [Google Scholar]

- Shi, L.P.; Su, Q.J. Study on the effect of compound flocculants on the settlement of fine coal slime waste. Coal Process. Compr. Util. 2024, 33, 26–30, 36. [Google Scholar]

- Zhu, F.R. Study on Preparation and Flocculation Efficiency of Inorganic-Organic Hybrid Polymer Flocculant; Northeast Petroleum University: Daqing, China, 2023; pp. 1–14. Available online: https://kns.cnki.net/kcms2/article/abstract?v=mA0k7fYtKv6-pWR7-_7eO0U8WFb06dlV6A931XWEO67CCMLzA37RtziG78_e8JimcYzE_7K4mEWAjSIEstfxEJsP7SPAXojtp9kg4L_64Rg01WCt9X6K46cZFknvIVhziFWIwWs0xb6XaZ-bG-gqaOEuQSRqSs0ba7scK2zOBQvxCnR27wkNYYJnUpCYmTVg&uniplatform=NZKPT&language=CHS (accessed on 16 September 2025).

- Wang, Z.; Li, L.; He, Y.; Ru, J.; Yu, R.; Yu, Z.; Yin, T.; Li, K.; Xu, L. Molecular dynamics simulation of PAM and PCE adsorption sites on sodium montmorillonite surface. J. Mater. Sci. Eng. 2023, 41, 397–403. [Google Scholar]

- Fan, W.; Lv, B.; Jiao, Y.; Deng, X.; Fang, C.; Xing, B. Preparation and application of composite magnetic flocculants for wastewater treatment: A review. J. Environ. Manag. 2025, 377, 124626. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.P.; Wang, P.; Guo, H.P.; Lou, R.R.; Ye, W.D.; Liu, Y.; Liu, K. Effect of dry process manufactured sands dust on the mechanical property and durability of recycled concrete. J. Build. Eng. 2024, 87, 108942. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, T. Preparation of recycled sand from WRSG and compressive and flexural behavior of recycled aggregate concrete. Construct. Build. Mater. 2024, 414, 134944. [Google Scholar] [CrossRef]

- Bayesteh, H.; Sharifi, M.; Haghshenas, A. Effect of stone powder on the rheological and mechanical performance of cement-stabilized marine clay/sands. Construct. Build. Mater. 2020, 262, 120792. [Google Scholar] [CrossRef]

- Lu, L.; Yang, Z.X.; Lin, Y. Partial replacement of manufactured sands with homologous granite powder in mortar: The effect on porosity and capillary water absorption. Construct. Build. Mater. 2023, 376, 131031. [Google Scholar] [CrossRef]

- Li, H.J.; Huang, F.L.; Cheng, G.Z. Effect of granite dust on mechanical and some durability properties of manufactured sands concrete. Construct. Build. Mater. 2016, 109, 41–46. [Google Scholar] [CrossRef]

- Ding, X.X.; Li, C.Y.; Xu, Y.Y. Experimental study on long-term compressive strength of concrete with manufactured sands. Construct. Build. Mater. 2016, 108, 67–73. [Google Scholar] [CrossRef]

- Jiang, Z.W. Production of manufactured sands Green High-Performance Concrete with Manufactured Sands. Construct. Build. Mater. 2022, 114, 13–46. [Google Scholar]

- ASTM D562; Standard Test Method for Consistency of Paints Measuring Krebs Unit (KU) Viscosity Using a Stormer-Type Viscometer. ASTM International: West Conshohocken, PA, USA, 2018.

| Oxide Composition (wt%) | Cementitious Materials | |||

|---|---|---|---|---|

| OPC | FA | GBFS | MK | |

| SiO2 | 17.27 | 37.00 | 26.08 | 45.12 |

| Al2O3 | 6.63 | 31.88 | 13.51 | 42.40 |

| Na2O | 0.25 | 0.66 | 0.26 | 0.15 |

| CaO | 58.25 | 9.11 | 45.66 | 9.11 |

| Fe2O3 | 6.38 | 8.35 | 0.45 | 0.76 |

| MgO | 2.69 | 1.16 | 8.53 | 0.09 |

| TiO2 | 0.51 | 1.81 | 0.67 | 1.37 |

| K2O | 0.74 | 1.29 | 0.41 | 0.19 |

| Mixture | Quantities of Raw Materials (g) | ||||

|---|---|---|---|---|---|

| MK | OPC | SS 1 | W 2 | WRA 3 | |

| Cement paste | 25 | 475 | --- | 250 | --- |

| Mortar | --- | 500 | 1350 | 225 | 5.0 |

| Mixture Proportions (kg/m3) | Concrete Strength Grade 1 (Mixture ID) | ||

|---|---|---|---|

| C30 | C35 | C45 | |

| ordinary Portland cement (OPC) | 230 | 270 | 320 |

| fly ash (FA) | 35 | 40 | 60 |

| ground blast furnace slag (GBFS) | 80 | 80 | 70 |

| larger gravel (LG) | 880 | 830 | 870 |

| smaller gravel (SG) | 110 | 125 | 130 |

| manufactured sand (MS) | 550 | 540 | 560 |

| natural sand (NS) | 250 | 280 | 160 |

| water (W) | 170 | 165 | 165 |

| water-reducing agent (WRA) | 6.9 | 7.4 | 8.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, C.; Chen, Z.; Gan, X. A Rapid Detecting Method for Residual Flocculants in Water-Washed Manufactured Sand and Their Influences on Concrete Properties. Constr. Mater. 2025, 5, 71. https://doi.org/10.3390/constrmater5040071

Jiang C, Chen Z, Gan X. A Rapid Detecting Method for Residual Flocculants in Water-Washed Manufactured Sand and Their Influences on Concrete Properties. Construction Materials. 2025; 5(4):71. https://doi.org/10.3390/constrmater5040071

Chicago/Turabian StyleJiang, Chenhui, Zefeng Chen, and Xuehong Gan. 2025. "A Rapid Detecting Method for Residual Flocculants in Water-Washed Manufactured Sand and Their Influences on Concrete Properties" Construction Materials 5, no. 4: 71. https://doi.org/10.3390/constrmater5040071

APA StyleJiang, C., Chen, Z., & Gan, X. (2025). A Rapid Detecting Method for Residual Flocculants in Water-Washed Manufactured Sand and Their Influences on Concrete Properties. Construction Materials, 5(4), 71. https://doi.org/10.3390/constrmater5040071