Alternative Fine Aggregates to Natural River Sand for Manufactured Concrete Ensuring Circular Economy

Abstract

1. Introduction

2. Materials and Methods

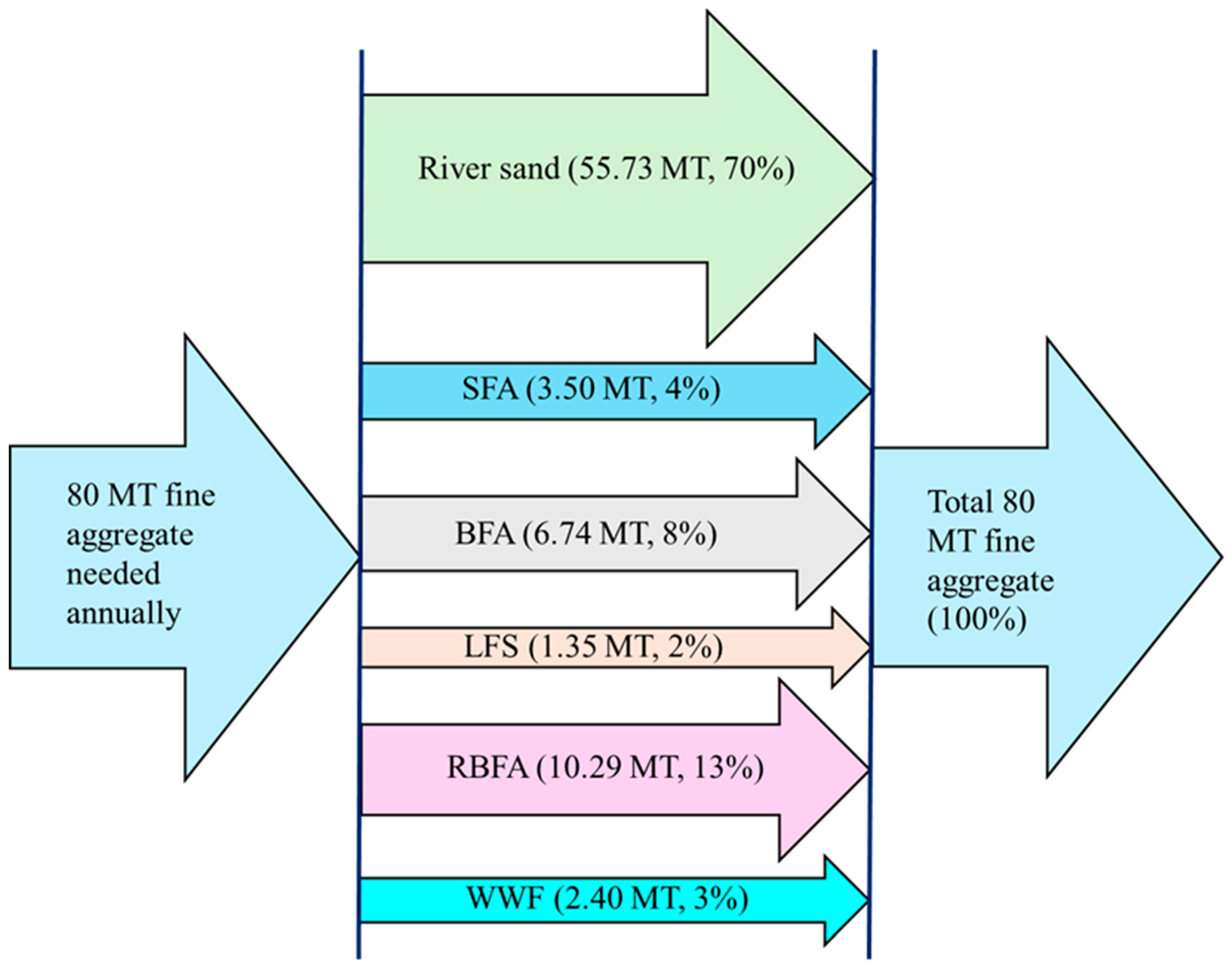

2.1. Materials

2.1.1. Stone Fine Aggregate (SFA)

2.1.2. Brick Fine Aggregate (BFA)

2.1.3. Ladle-Refined Furnace Slag Fine Aggregate (LFS)

2.1.4. Recycled Brick Fine Aggregate (RBFA)

2.1.5. Washed Waste Fine Aggregate (WWF)

2.2. Methods

3. Results and Discussions

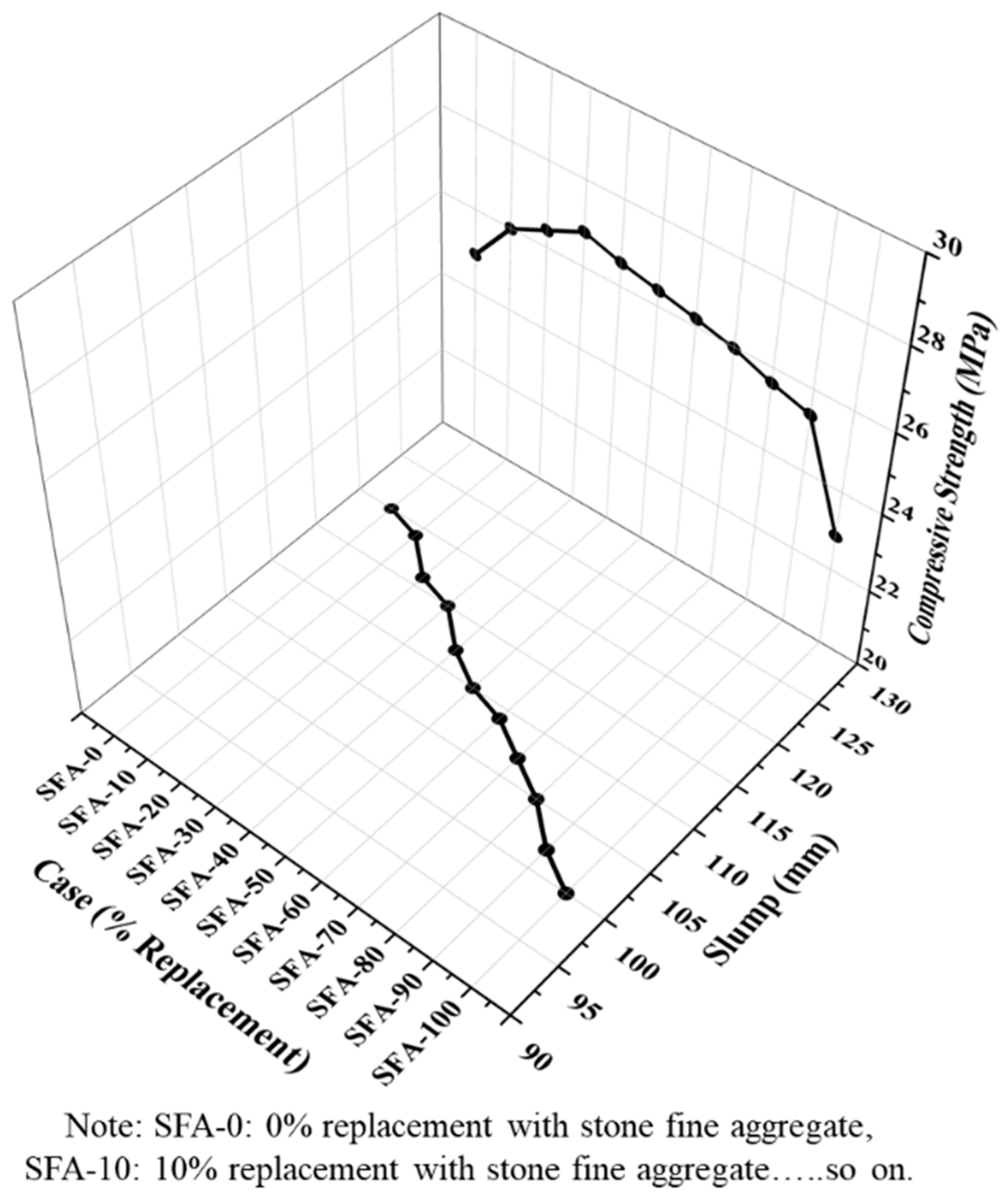

3.1. Stone Fine Aggregate (SFA) Concrete

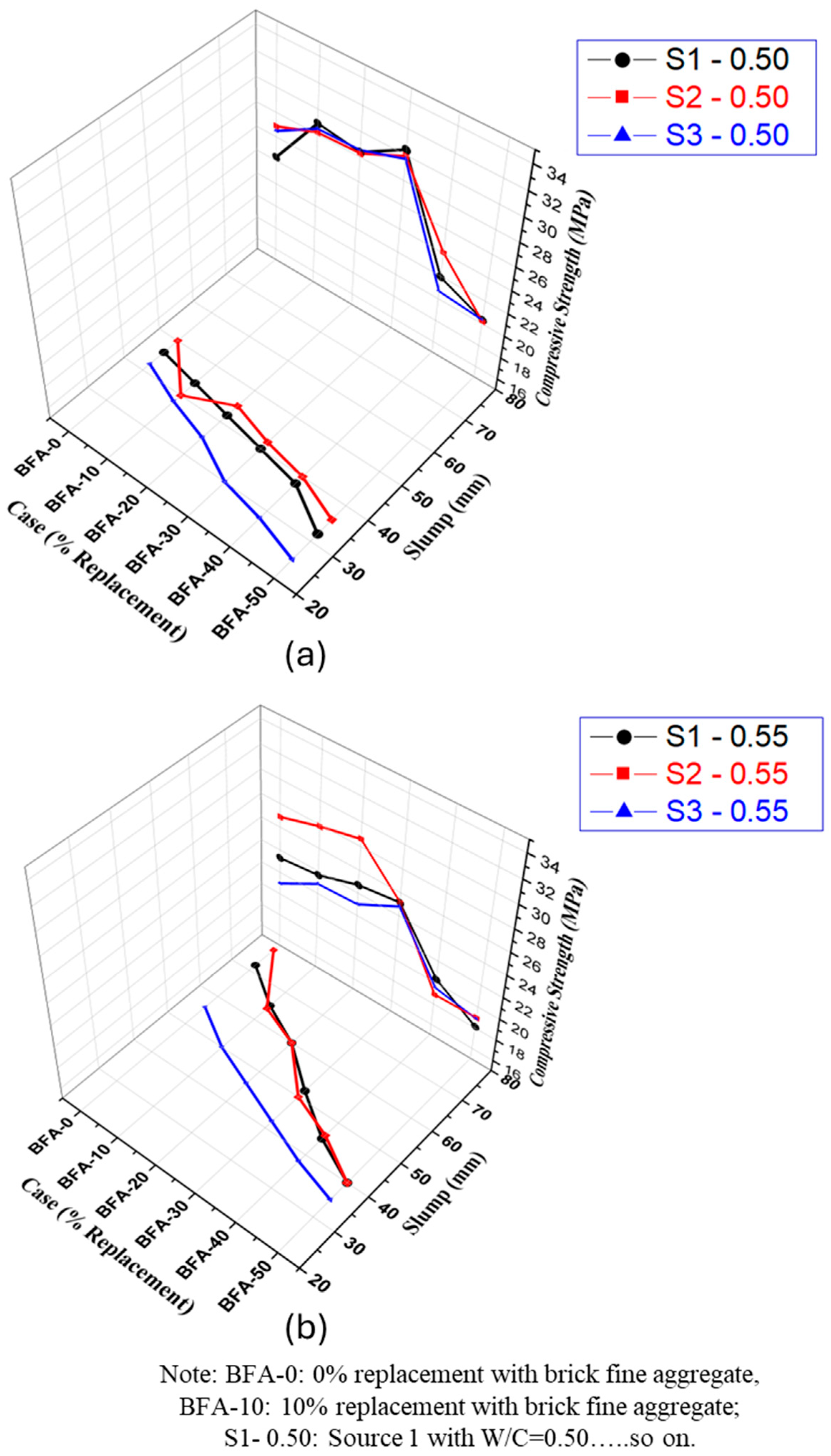

3.2. Brick Fine Aggregate (BFA) Concrete

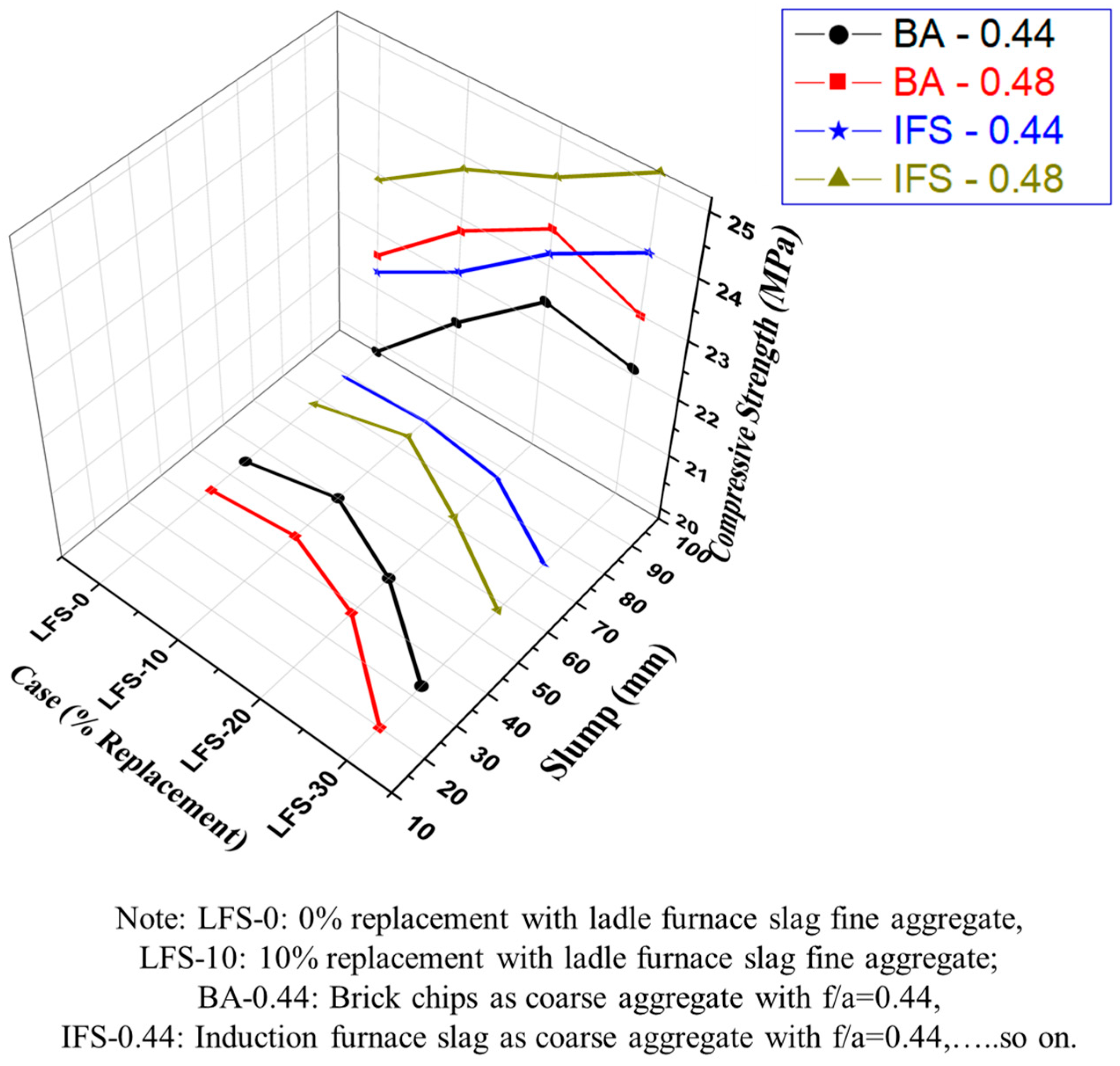

3.3. Ladle-Refined Furnace Slag Fine Aggregate (LFS) Concrete

3.4. Recycled Brick Fine Aggregate (RBFA) Concrete

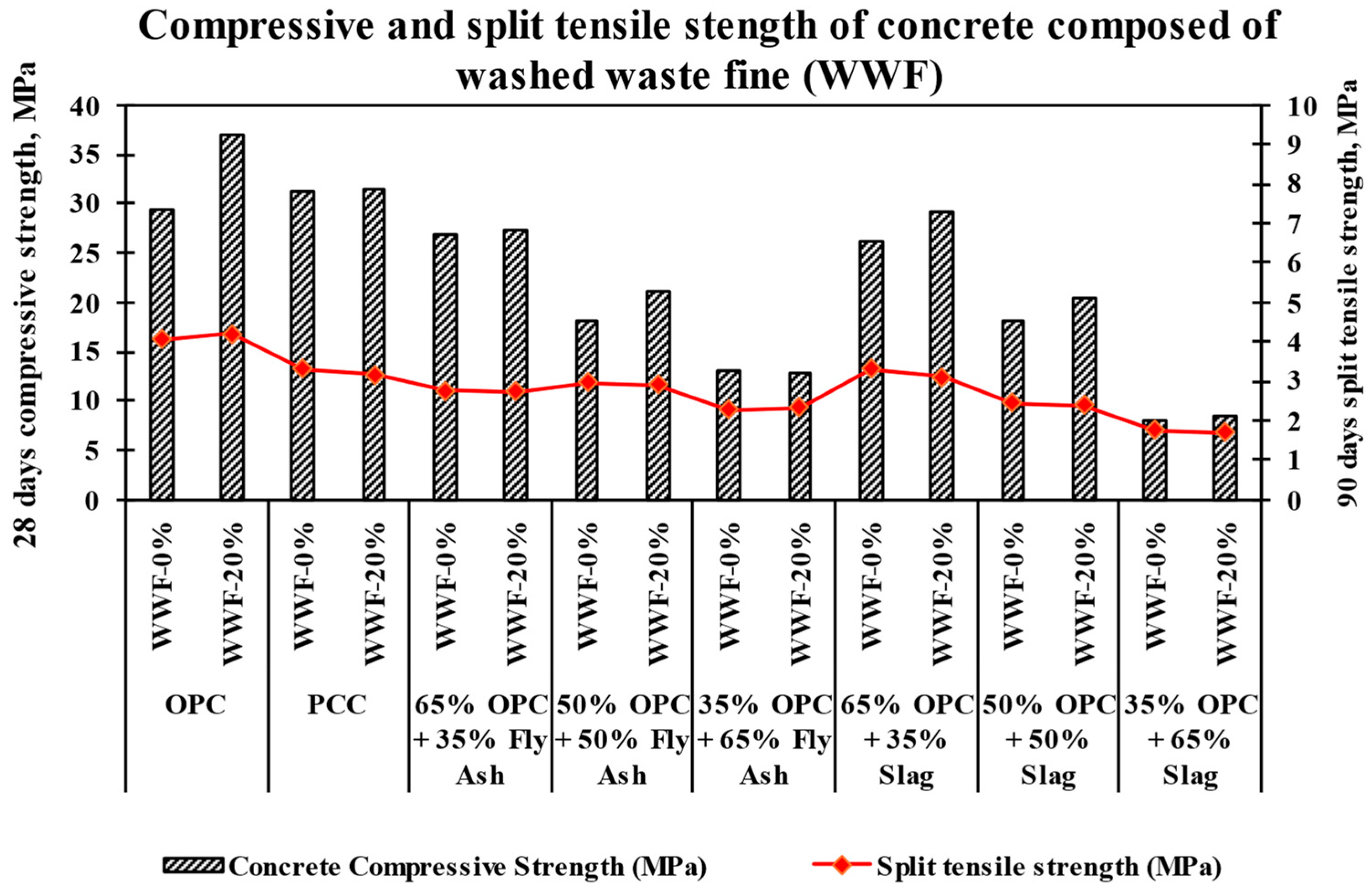

3.5. Washed Waste Fine Aggregate (WWF) Concrete

4. Circular Economy

5. Conclusions

- To achieve the optimum mechanical properties of concrete, natural sand can be replaced by 30% of BFA or SFA. In the case of LFS, the optimum replacement of natural river sand was 20%. Concrete can be produced by 100% replacement of RBFA and 20% replacement of WWF without sacrificing its compressive strength.

- Utilizing these alternative fine aggregates can reduce the consumption of natural river sand by 30%.

- These alternative materials, fine aggregates, can be utilized to ensure the circular economy, i.e., to attain the goals of SDG12 (Ensure sustainable consumption and production patterns).

- Future research may investigate other alternative waste materials available in Bangladesh and their mechanical and durability studies for replacing concrete fine aggregate with such alternatives.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirchherr, J.; Yang, N.-H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour. Conserv. Recycl. 2023, 194, 107001. [Google Scholar] [CrossRef]

- Barros, M.V.; Salvador, R.; Do Prado, G.F.; De Francisco, A.C.; Piekarski, C.M. Circular Economy as a Driver to Sustainable Businesses. Clean. Environ. Syst. 2021, 2, 100006. [Google Scholar] [CrossRef]

- Heyes, G.; Sharmina, M.; Mendoza, J.M.F.; Gallego-Schmid, A.; Azapagic, A. Developing and Implementing Circular Economy Business Models in Service-Oriented Technology Companies. J. Clean. Prod. 2018, 177, 621–632. [Google Scholar] [CrossRef]

- United Nations Environment Programme Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources. 2019. Available online: https://unepgrid.ch/storage/app/media/documents/Sand_and_sustainability_UNEP_2019.pdf (accessed on 20 July 2024).

- The Concrete Sustainability Council SDG 12: Responsible Consumption and Production–Concrete Sustainability Council. 2024. Available online: https://csc.eco/sdg-12-responsible-consumption-and-production/ (accessed on 20 July 2024).

- Statista Cement Production Global 2023\Statista. Available online: https://www.statista.com/statistics/1087115/global-cement-production-volume/ (accessed on 6 August 2024).

- International Association of Certified Home Inspectors Constituent Materials of Concrete-InterNACHI®. Available online: https://www.nachi.org/constituent-materials-concrete.htm (accessed on 8 September 2024).

- Nguyen, T.T.H.; Tu, Y.-T.; Diep, G.L.; Tran, T.K.; Tien, N.H.; Chien, F. Impact of Natural Resources Extraction and Energy Consumption on the Environmental Sustainability in ASEAN Countries. Resour. Policy 2023, 85, 103713. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Mahmood, A.H.; Zunaied-Bin-Harun, M.; Joy, J.A.; Ahmed, M.A. Destructive and Non-Destructive Evaluation of Concrete for Optimum Sand to Aggregate Volume Ratio. Front. Struct. Civ. Eng. 2021, 15, 1400–1414. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Bin Harun, M.Z.; Joy, J.A. Effect of Sand-to-Aggregate Volume Ratio on Durability of Concrete. Innov. Infrastruct. Solut. 2022, 7, 318. [Google Scholar] [CrossRef]

- Singh, S.; Nagar, R.; Agrawal, V.; Rana, A.; Tiwari, A. Sustainable Utilization of Granite Cutting Waste in High Strength Concrete. J. Clean. Prod. 2016, 116, 223–235. [Google Scholar] [CrossRef]

- Ministry of Water Resources, Ministry of Land and Resources, and Ministry of Transport. Notice from the Ministry of Water Resources, Ministry of Land and Resources, and Ministry of Transport Regarding Strengthening of Management of Sand Mining in Rivers 2015. Available online: http://www.mwr.gov.cn/zw/tzgg/tzgs/201702/t20170213_858612.html (accessed on 20 June 2024).

- Bari, E.; Haque, S.E. Legal and Illicit Sand Mining Practice in Bangladesh: Exploring Supply Chain and Its Value. J. Illicit. Econ. Dev. 2022, 4, 44–57. [Google Scholar] [CrossRef]

- Rahman, M.A. An Overview of the Cement Industry in Bangladesh. 2023. Available online: https://emergingrating.com/wp-content/uploads/2023/11/An-Overview-of-the-Cement-Industry-in-Bangladesh.pdf (accessed on 20 June 2024).

- Cordeiro, G.C.; De Alvarenga, L.M.S.C.; Rocha, C.A.A. Rheological and Mechanical Properties of Concrete Containing Crushed Granite Fine Aggregate. Constr. Build. Mater. 2016, 111, 766–773. [Google Scholar] [CrossRef]

- Galetakis, M.; Soultana, A. A Review on the Utilisation of Quarry and Ornamental Stone Industry Fine By-Products in the Construction Sector. Constr. Build. Mater. 2016, 102, 769–781. [Google Scholar] [CrossRef]

- Nagabhushana; Bai, H. Use of Crushed Rock Powder as Replacement of Fine Aggregate in Mortar and Concrete. Indian J. Sci. Technol. 2011, 4, 917–922. [Google Scholar]

- Pofale, D.A.D.; Quadri, S.R. Effective Utilization of Crusher Dust in Concrete Using Portland Pozzolana Cement. Int. J. Sci. Res. Publ. 2013, 3, 415. [Google Scholar]

- Tiwari, A.; Singh, S.; Nagar, R. Feasibility Assessment for Partial Replacement of Fine Aggregate to Attain Cleaner Production Perspective in Concrete: A Review. J. Clean. Prod. 2016, 135, 490–507. [Google Scholar] [CrossRef]

- Almeida, N.; Branco, F.; De Brito, J.; Santos, J.R. High-Performance Concrete with Recycled Stone Slurry. Cem. Concr. Res. 2007, 37, 210–220. [Google Scholar] [CrossRef]

- Assis, S.R.H.D.; Queiroz, B.O.D.; Araújo, C.C.; Nunes, K.K.F.; Melo, R.A.D.; Lucena, L.C.D.F.L. Evaluation of Limestone Crushed Dust Aggregates in Hot Mix Asphalt. Constr. Build. Mater. 2017, 148, 659–665. [Google Scholar] [CrossRef]

- Han, M.-C.; Han, D.; Shin, J.-K. Use of Bottom Ash and Stone Dust to Make Lightweight Aggregate. Constr. Build. Mater. 2015, 99, 192–199. [Google Scholar] [CrossRef]

- Ahmed, A.A.M.; Mahzuz, H.M.A.; Yusuf, M.A. Minimizing the Stone Dust through a Sustainable Way: A Case Study of Stone Crushing Industry of Sylhet. Intl. Conf. Environ. Asp. Bangladesh 2010, Japan, 215–218. [Google Scholar] [CrossRef]

- Nagpal, L.; Dewangan, A.; Dhiman, S.; Kumar, S. Evaluation of Strength Characteristics of Concrete Using Crushed Stone Dust as Fine Aggregate. Int. J. Innov. Technol. Explor. Eng. 2013, 2, 102–104. [Google Scholar]

- Sravani, T.; Anitha, A.; Kumar, D. Experimental studies on concrete replacing fine aggregate with quarry dust wastes. Int. J. Prog. Civ. Eng. 2014, 1, 2394–4684. [Google Scholar]

- Haque, S.E.; Shahriar, M.M.; Nahar, N.; Haque, M.S. Impact of Brick Kiln Emissions on Soil Quality: A Case Study of Ashulia Brick Kiln Cluster, Bangladesh. Environ. Chall. 2022, 9, 100640. [Google Scholar] [CrossRef]

- Adamson, M.; Razmjoo, A.; Poursaee, A. Durability of Concrete Incorporating Crushed Brick as Coarse Aggregate. Constr. Build. Mater. 2015, 94, 426–432. [Google Scholar] [CrossRef]

- Bektas, F.; Wang, K.; Ceylan, H. Effects of Crushed Clay Brick Aggregate on Mortar Durability. Constr. Build. Mater. 2009, 23, 1909–1914. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical Properties of Brick Aggregate Concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with Recycled Concrete Aggregate and Crushed Clay Bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- IDLC Finance Limited The Steel Industry Of Bangladesh: Constructing A Compact Foundation Of Growth Amidst Economic Instability 2023. Available online: https://idlc.com/mbr/article.php?id=568, (accessed on 20 June 2024).

- Chen, Z.; Wu, S.; Wen, J.; Zhao, M.; Yi, M.; Wan, J. Utilization of Gneiss Coarse Aggregate and Steel Slag Fine Aggregate in Asphalt Mixture. Constr. Build. Mater. 2015, 93, 911–918. [Google Scholar] [CrossRef]

- Kockal, N.U. Investigation about the Effect of Different Fine Aggregates on Physical, Mechanical and Thermal Properties of Mortars. Constr. Build. Mater. 2016, 124, 816–825. [Google Scholar] [CrossRef]

- Kothai, P.S.; Malathy, D.R. Utilization Of Steel Slag In Concrete As A Partial Replacement Material for Fine Aggregates. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 3, 124–136. [Google Scholar]

- Pellegrino, C.; Cavagnis, P.; Faleschini, F.; Brunelli, K. Properties of Concretes with Black/Oxidizing Electric Arc Furnace Slag Aggregate. Cem. Concr. Compos. 2013, 37, 232–240. [Google Scholar] [CrossRef]

- Qasrawi, H.; Shalabi, F.; Asi, I. Use of Low CaO Unprocessed Steel Slag in Concrete as Fine Aggregate. Constr. Build. Mater. 2009, 23, 1118–1125. [Google Scholar] [CrossRef]

- Sezer, G.İ.; Gülderen, M. Usage of Steel Slag in Concrete as Fine and/or Coarse Aggregate. Indian J. Eng. Mater. Sci. 2015, 22, 339–344. [Google Scholar]

- Singh, G.; Siddique, R. Strength Properties and Micro-Structural Analysis of Self-Compacting Concrete Made with Iron Slag as Partial Replacement of Fine Aggregates. Constr. Build. Mater. 2016, 127, 144–152. [Google Scholar] [CrossRef]

- Adolfsson, D.; Robinson, R.; Engström, F.; Björkman, B. Influence of Mineralogy on the Hydraulic Properties of Ladle Slag. Cem. Concr. Res. 2011, 41, 865–871. [Google Scholar] [CrossRef]

- John, A.; John, E. Study on the Partial Replacement of Fine Aggregate Using Induction Furnace Slag. Am. J. Eng. Res. 2014, 4, 1–5. Available online: https://www.ajer.org/papers/rase-2-2013/Volume-4/AV220130105.pdf (accessed on 20 June 2024).

- Mazhar, M.A.; Alam, P.; Ahmed, S.; Khan, M.S.; Adam, F.A. Sustainable Usage of Demolished Concrete Waste as a Sub-Base Material in Road Pavement. Front. Sustain. 2023, 4, 1060878. [Google Scholar] [CrossRef]

- Zega, C.J.; Villagrán-Zaccardi, Y.A.; Di Maio, A.A. Effect of Natural Coarse Aggregate Type on the Physical and Mechanical Properties of Recycled Coarse Aggregates. Mater. Struct. 2010, 43, 195–202. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Properties of Concrete Prepared with Crushed Fine Stone, Furnace Bottom Ash and Fine Recycled Aggregate as Fine Aggregates. Constr. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hasnat, A.; Awal, M.; Bosunia, S. Recycling of Brick Aggregate Concrete as Coarse Aggregate. J. Mater. Civ. Eng. 2014, 27, B4014005. [Google Scholar] [CrossRef]

- Correia, S.L.; Souza, F.L.; Dienstmann, G.; Segadães, A.M. Assessment of the Recycling Potential of Fresh Concrete Waste Using a Factorial Design of Experiments. Waste Manag. 2009, 29, 2886–2891. [Google Scholar] [CrossRef]

- Ferrari, G.; Miyamoto, M.; Ferrari, A. New Sustainable Technology for Recycling Returned Concrete. Constr. Build. Mater. 2014, 67, 353–359. [Google Scholar] [CrossRef]

- Rughooputh, R.; Rana, J.O.; Joorawon, K. Possibility of Using Fresh Concrete Waste in Concrete for Non Structural Civil Engineering Works as a Waste Management Strategy. KSCE J. Civ. Eng. 2017, 21, 94–99. [Google Scholar] [CrossRef]

- Anastasiou, E.; Papachristoforou, M.; Anesiadis, D.; Zafeiridis, K.; Tsardaka, E.-C. Investigation of the Use of Recycled Concrete Aggregates Originating from a Single Ready-Mix Concrete Plant. Appl. Sci. 2018, 8, 2149. [Google Scholar] [CrossRef]

- Chatveera, B.; Lertwattanaruk, P.; Makul, N. Effect of Sludge Water from Ready-Mixed Concrete Plant on Properties and Durability of Concrete. Cem. Concr. Compos. 2006, 28, 441–450. [Google Scholar] [CrossRef]

- Kou, S.; Zhan, B.; Poon, C. Feasibility Study of Using Recycled Fresh Concrete Waste as Coarse Aggregates in Concrete. Constr. Build. Mater. 2012, 28, 549–556. [Google Scholar] [CrossRef]

- Saha, D. Use of Stone Fine Aggregate for Making Concrete. Master’s Thesis, University of Asia Pacific, Dhaka, Bangladesh, 2014. [Google Scholar]

- Mohammed, T.U.; Hassan, M.M.; Rahman, M.N.; Apurbo, S. Brick Fine Aggregate and Ladle Furnace Slag as Alternative to Natural River Sand. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 14–17 July 2019; pp. 139–151. [Google Scholar]

- Mohammed, T.U.; Khan, A.Z.; Mahmood, A.H. Recycling of Demolished Concrete as Coarse and Fine Aggregate. In Proceedings of the International Conference on the Regeneration and Conservation of Concrete Structures, Nagasaki, Japan, 1–3 June 2015; pp. 1–12. [Google Scholar]

- C09 Committee ASTM International. Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM international: West Conshohocken, PA, USA, 2023. [Google Scholar] [CrossRef]

- C01 Committee ASTM International. Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-Mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- C09 Committee ASTM International. Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- C09 Committee ASTM International. Test Method for Slump of Hydraulic-Cement Concrete; ASTM international: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- ACI Committee 363 State of the Art Report on High-Strength Concrete. ACI J. Proc. 1984, 81, 364–411. [CrossRef]

- Adegoke, H.A.; Ikumapayi, C.M. Effects of Induction Furnace Slag on the Durability Properties of Concrete. Constr. Build. Mater. 2024, 419, 135263. [Google Scholar] [CrossRef]

- Uddin, M.A.; Jameel, M.; Sobuz, H.R.; Islam, M.S.; Hasan, N.M.S. Experimental Study on Strength Gaining Characteristics of Concrete Using Portland Composite Cement. KSCE J. Civ. Eng. 2013, 17, 789–796. [Google Scholar] [CrossRef]

- United Nations Goal 12\Department of Economic and Social Affairs. Available online: https://sdgs.un.org/goals/goal12 (accessed on 6 August 2024).

- Bendixen, M.; Iversen, L.L.; Best, J.; Franks, D.M.; Hackney, C.R.; Latrubesse, E.M.; Tusting, L.S. Sand, Gravel, and UN Sustainable Development Goals: Conflicts, Synergies, and Pathways Forward. One Earth 2021, 4, 1095–1111. [Google Scholar] [CrossRef]

- The Daily Star Construction Aggregate Market Grows Sevenfold in a Decade\The Daily Star. Available online: https://www.thedailystar.net/business/economy/news/construction-aggregate-market-grows-sevenfold-decade-3370861 (accessed on 6 August 2024).

- Puri, V.; Kumar, S.; Grover, K.; Sharma, M. Development of Eco-Friendly Bricks for Sustainable Construction. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1248, 012109. [Google Scholar] [CrossRef]

- The Daily Star Bangladesh Steel Industry Top Producers 2024\Four Steelmakers Control 53% of the Market: Study. Available online: https://www.thedailystar.net/business/news/four-steelmakers-control-53-the-market-study-3613811 (accessed on 6 August 2024).

- The Daily Star Cement Consumption to Grow Steadily\The Daily Star. Available online: https://www.thedailystar.net/business/cement-consumption-grow-steadily-1581961 (accessed on 6 August 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, T.U.; Rony, M.A.; Zunaied Bin Harun, M.; Uddin, N.; Saha, D.; Rahman, M.N.; Mahmood, A.H. Alternative Fine Aggregates to Natural River Sand for Manufactured Concrete Ensuring Circular Economy. Constr. Mater. 2024, 4, 640-654. https://doi.org/10.3390/constrmater4040035

Mohammed TU, Rony MA, Zunaied Bin Harun M, Uddin N, Saha D, Rahman MN, Mahmood AH. Alternative Fine Aggregates to Natural River Sand for Manufactured Concrete Ensuring Circular Economy. Construction Materials. 2024; 4(4):640-654. https://doi.org/10.3390/constrmater4040035

Chicago/Turabian StyleMohammed, Tarek Uddin, Md. Aktaruzzaman Rony, Mohammad Zunaied Bin Harun, Naba Uddin, Debasish Saha, Md. Nafiur Rahman, and Aziz Hasan Mahmood. 2024. "Alternative Fine Aggregates to Natural River Sand for Manufactured Concrete Ensuring Circular Economy" Construction Materials 4, no. 4: 640-654. https://doi.org/10.3390/constrmater4040035

APA StyleMohammed, T. U., Rony, M. A., Zunaied Bin Harun, M., Uddin, N., Saha, D., Rahman, M. N., & Mahmood, A. H. (2024). Alternative Fine Aggregates to Natural River Sand for Manufactured Concrete Ensuring Circular Economy. Construction Materials, 4(4), 640-654. https://doi.org/10.3390/constrmater4040035