Impact of Crushed Natural and Recycled Fine Aggregates on Fresh and Hardened Mortar Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. µCT Imaging and Particle Shape Characterization

2.3. Design of Experiment and Laboratory Tests

- Blend the aggregates and 2/3 of the total amount of water and mix for 30 s at low speed.

- Wait for 570 s for the aggregates to saturate.

- Add the remaining water, limestone powder, and cement within 30 s.

- Mix for 60 s at low rotational speed and 30 s at high rotational speed.

- Wait and clean the mixer for 90 s.

- Mix at high rotational speed for 60 s.

2.4. Statistical Methods

3. Results and Discussion

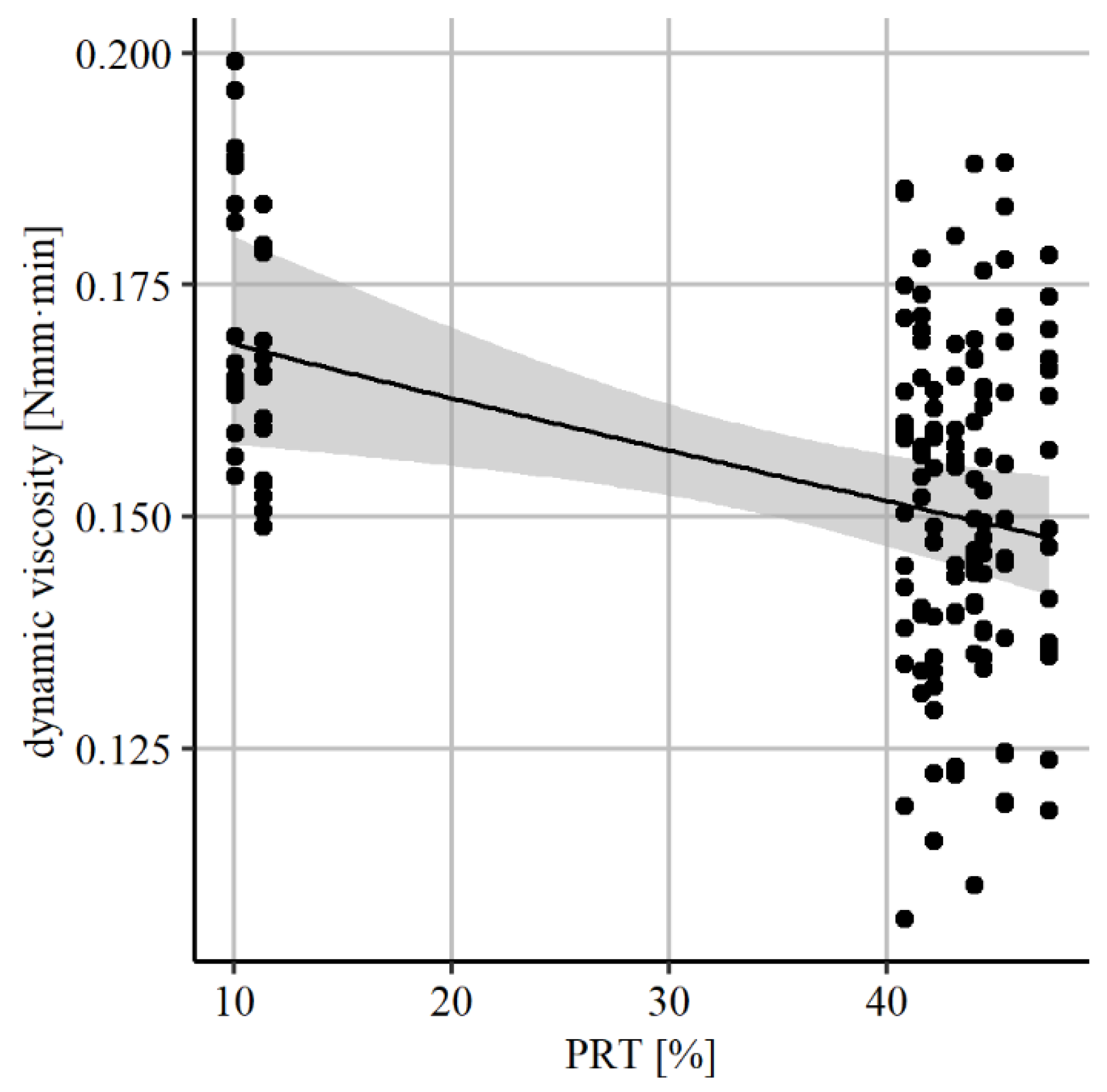

3.1. Dynamic Viscosity

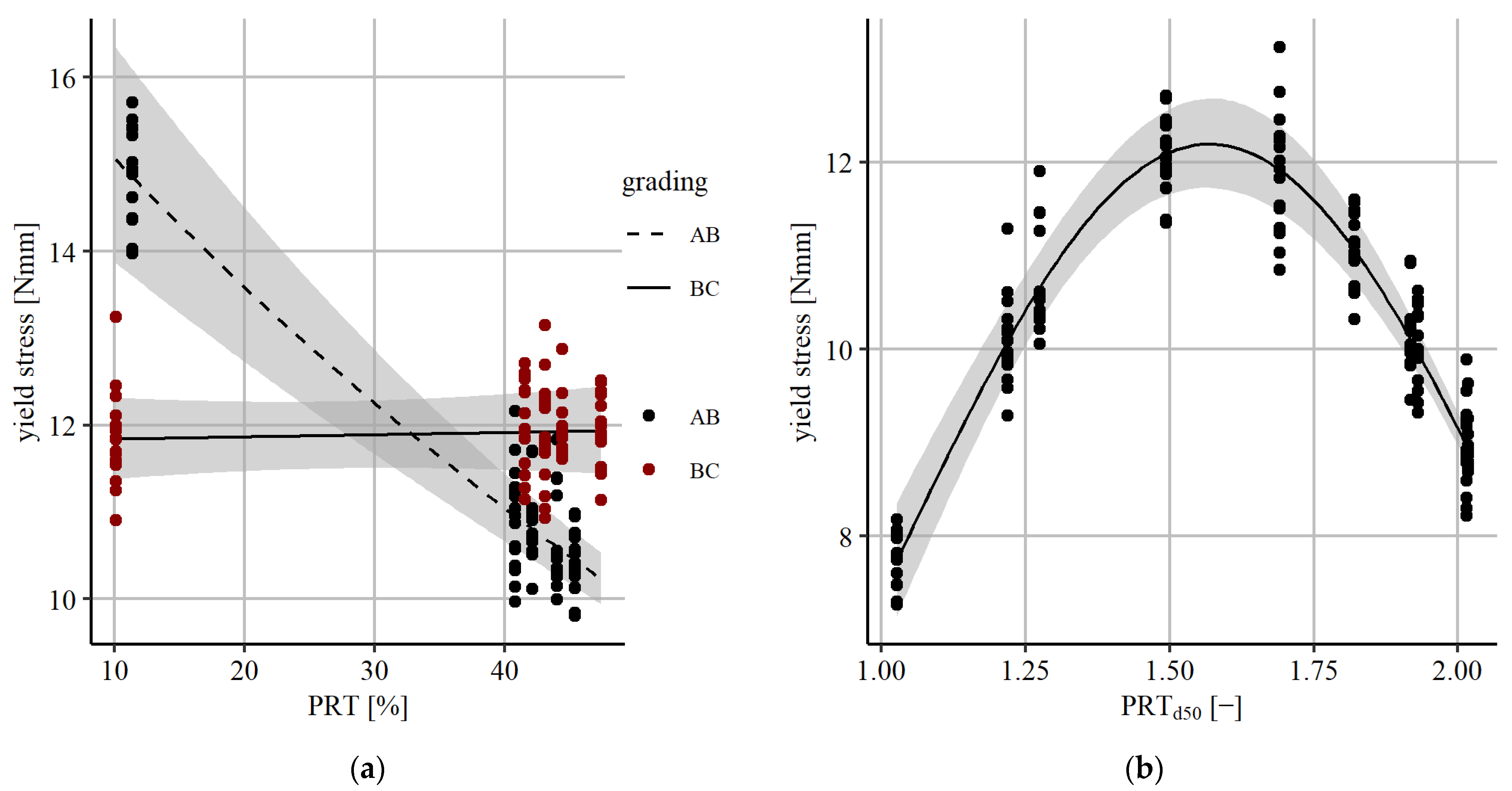

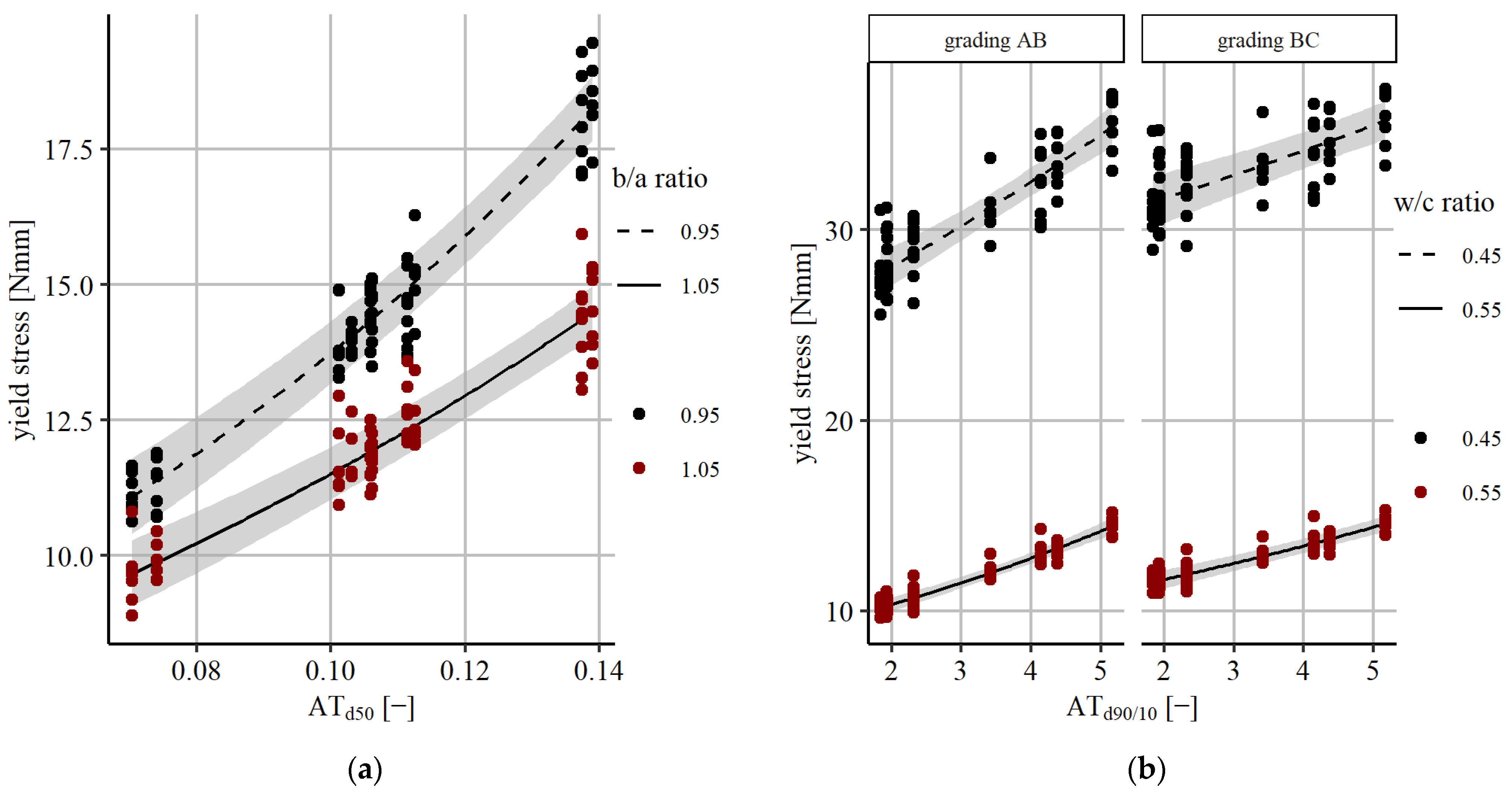

3.2. Yield Stress

3.3. Compressive Strength

3.4. Flexural Strength

4. Conclusions

- With an increasing number of prolate particles, a decrease in the dynamic viscosity was observed within this study. If reducing the risk of segregation of a mixture is the aim of optimization, a reduction in the number of prolate particles could therefore lead to an increase in dynamic viscosity. If an improvement in workability is the aim of optimization, an increase in the number of prolate particles could be beneficial. With respect to angularity, a strong increase in dynamic viscosity was observed for mixtures with a high w/c ratio with increasing angularity. To reduce the risk of segregation for mixtures with a high w/c ratio, it might be beneficial to include higher numbers of angular particles, like recycled fine aggregates. For mortar mixtures with a low w/c ratio, no strong impact of angularity on dynamic viscosity was observed.

- The interaction between shape and angularity characteristics, mortar composition properties, and the yield stress of mortar mixtures was quite complex. For grading curves with low fine aggregate content (AB), decreasing yield stress was observed for increasing numbers of prolate particles, whereas there was no impact for grading curves with high fine aggregate content (BC). As severe scatter and large confidence intervals are associated with this observation, a follow-up study with additional experimental tests would be required to examine this impact in greater detail. In addition, a moderate increase in the degree of l/t ratio resulted in higher yield stresses, whereas very high degrees of l/t ratio seemed to result in decreasing yield stress values. Thus, to improve the workability of mortar, the incorporation of prolate particles for grading curves with low fine aggregate content could be suitable. With increasing angularity, yield stress increased as well. From a practical point of view, reducing the number of angular particles as well as the degree of angularity could lead to mortar mixtures with improved workability.

- For compressive strength, an increase was observed with increasing angularity of natural aggregates. Increasing the number of fine crushed natural aggregates with higher angularity in comparison to weathered fine aggregates resulted in higher compressive strength values for mortar. However, when fine recycled aggregates were incorporated into mortar mixtures, a different impact on compressive strength was observed, associated with large confidence intervals that showed the uncertainty related to this observation. Independent of angularity, a lower compressive strength was observed for mortar mixtures with recycled aggregates in comparison to mixtures with natural aggregates. For a reliable interpretation of results, additional experimental tests covering a larger range of angularity and texture characteristics for recycled aggregate samples is required.

- With increasing angularity and texture, an increase in flexural strength was observed independent of the use of natural or recycled fine aggregates. The results show a comparably large number of unexplained variance, which could have been caused by the test setup used. Incorporating crushed natural or recycled aggregates into mortar mixtures with increased angularity and texture in comparison to natural aggregates therefore had a potential positive effect on flexural strength.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 2D | Two-dimensional |

| 3D | Three-dimensional |

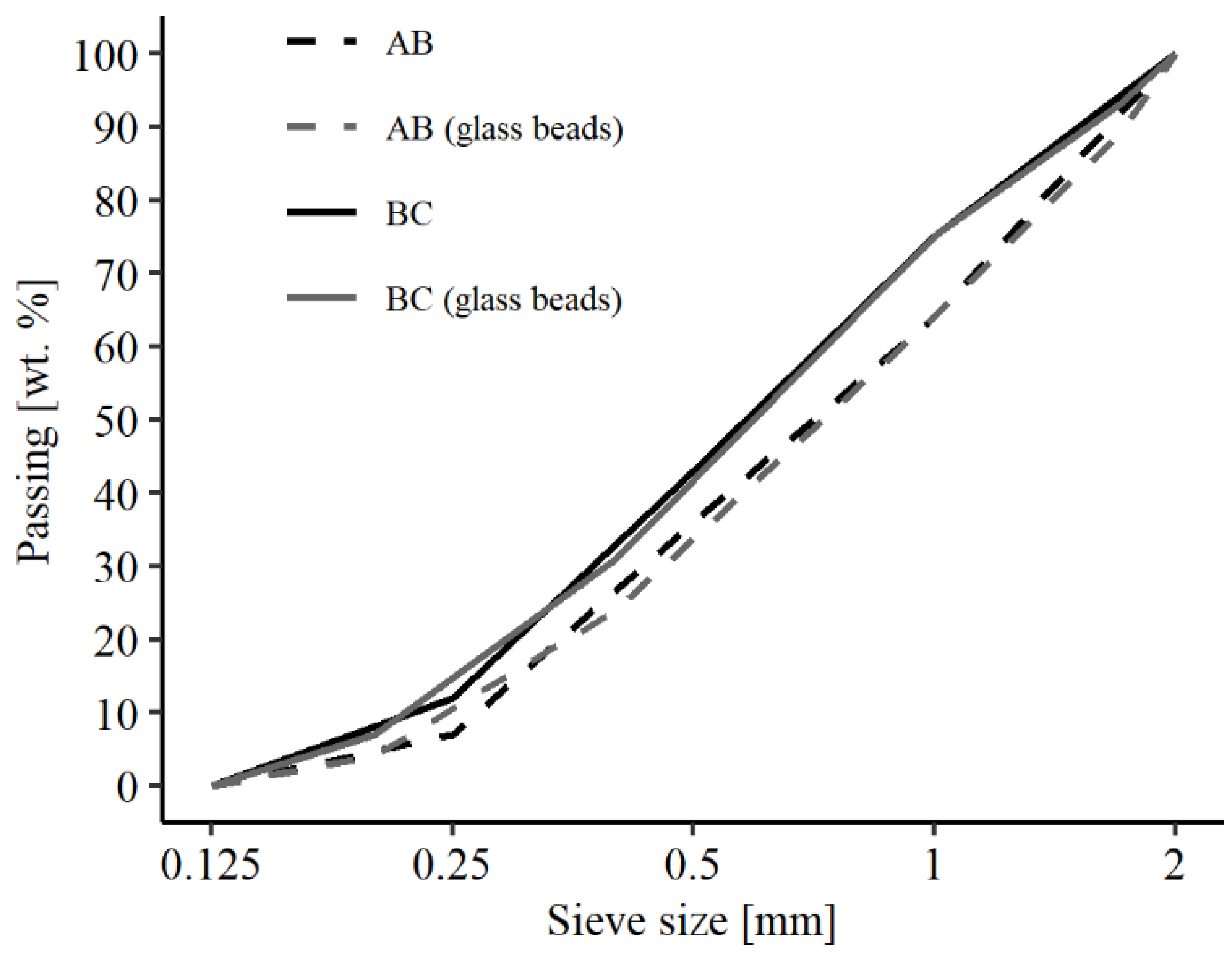

| AB | Grading curve with a larger coarse aggregate fraction |

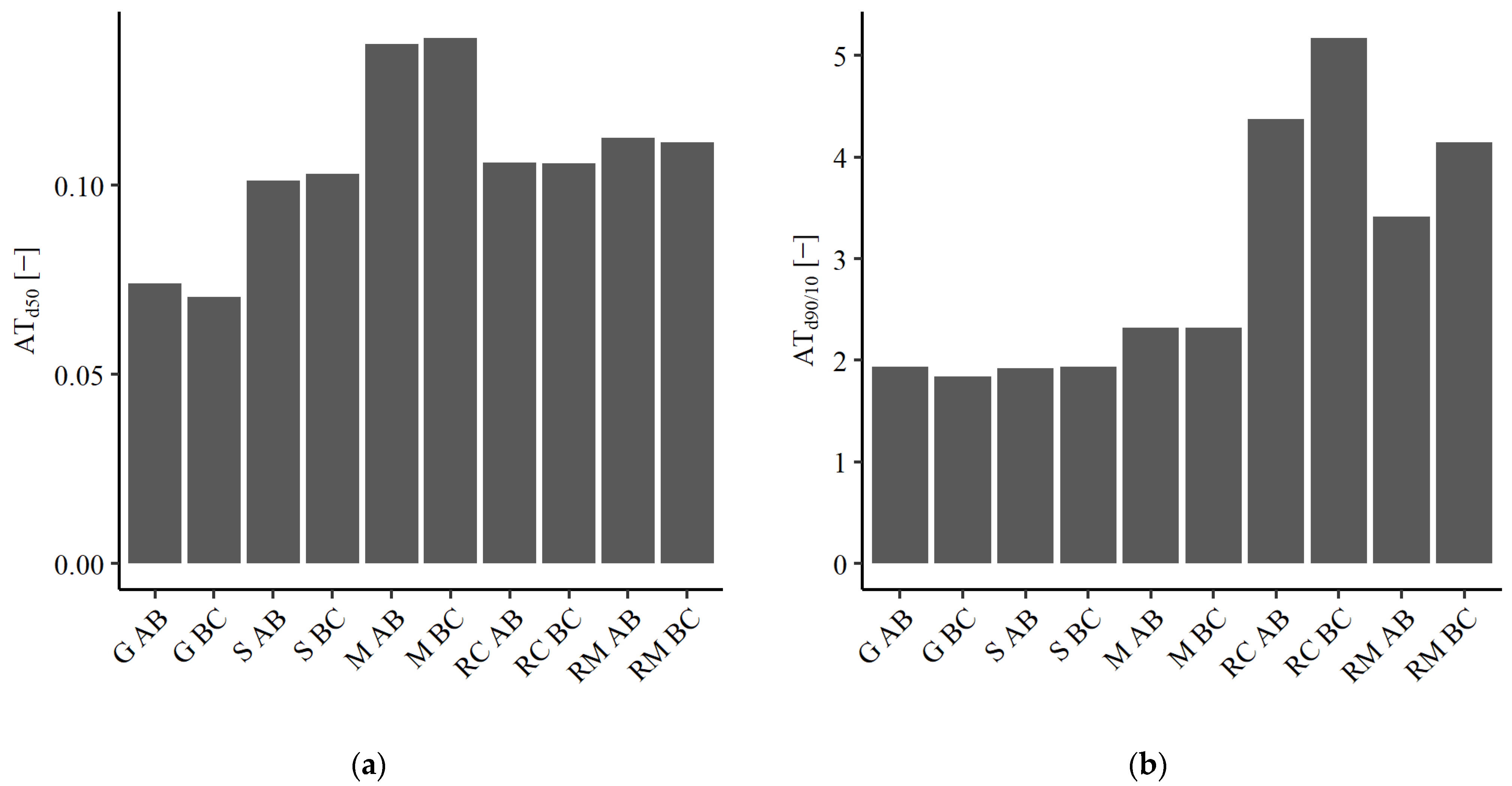

| Median value of AT for a particle sample | |

| Ratio of the AT value at a cumulative volume passing of 90% to 10% | |

| b/a ratio | Binder–aggregate ratio |

| BC | Grading curve with a larger number of fine aggregates |

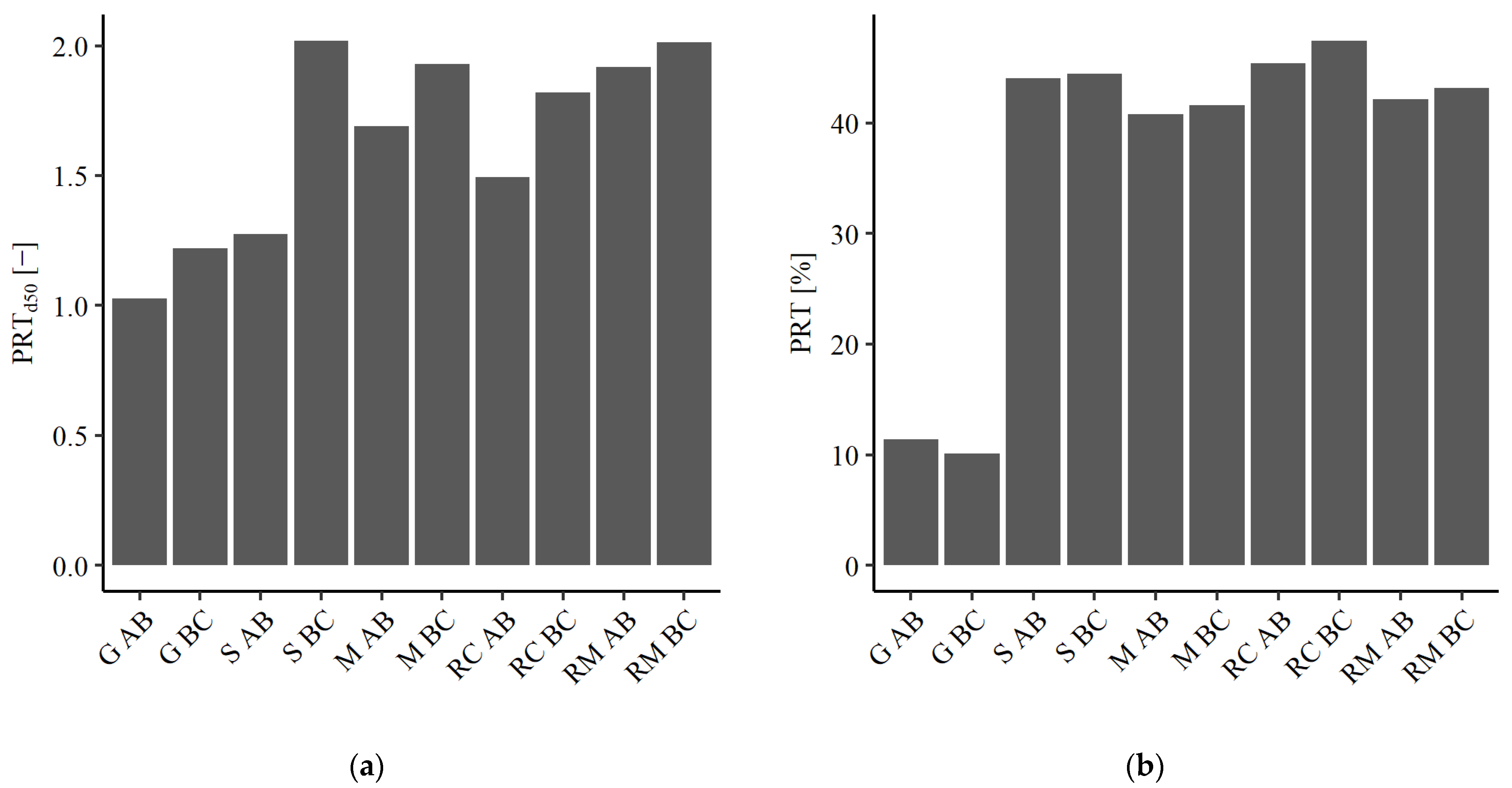

| G | Glass beads |

| l | Particle length |

| µCT | Micro-computed tomography |

| M | Crushed microdiorite |

| N | Natural material origin |

| PRT | Number of prolate particles in comparison to the total number of Particles |

| Median of the ratio of l/t of all particles classified as prolate | |

| R | Recycled material origin |

| RC | Recycled concrete |

| RM | Recycled masonry |

| S | Natural sand |

| SA | Surface area |

| Surface area of the convex hull | |

| t | Particle thickness |

| w | Particle width |

| w/c ratio | Water–cement ratio |

References

- Torres, A.; Brandt, J.; Lear, K.; Liu, J. A looming tragedy of the sand commons: Increasing sand extraction, trade and consumption pose global sustainability challenges. Science 2017, 357, 970–971. [Google Scholar] [CrossRef] [PubMed]

- Rentier, E.S.; Cammeraat, L.H. The environmental impacts of river sand mining. Sci. Total Environ. 2022, 838, 155877. [Google Scholar] [CrossRef] [PubMed]

- United Nations Environment Programme. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Geneva, Switzerland, 2019. [Google Scholar]

- United Nations Environment Programme. Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis; United Nations Environment Programme: Geneva, Switzerland, 2022. [Google Scholar]

- Westerholm, M.; Lagerblad, B.; Silfwerbrand, J.; Forssberg, E. Influence of fine aggregate characteristics on the rheological properties of mortars. Cem. Concr. Compos. 2008, 30, 274–282. [Google Scholar] [CrossRef]

- Khatib, J. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Ren, Q.; Tao, Y.; Jiao, D.; Jiang, Z.; Ye, G.; De Schutter, G. Plastic viscosity of cement mortar with manufactured sand as influenced by geometric features and particle size. Cem. Concr. Compos. 2021, 122, 104163. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; de Alvarenga, L.M.S.C.; Rocha, C.A.A. Rheological and mechanical properties of concrete containing crushed granite fine aggregate. Constr. Build. Mater. 2016, 111, 766–773. [Google Scholar] [CrossRef]

- Aissoun, B.M.; Hwang, S.-D.; Khayat, K.H. Influence of aggregate characteristics on workability of superworkable concrete. Mat. Constr. 2016, 49, 597–609. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, Y.; Zhu, L.; Wang, Y.; Jin, Z. Characterization of coarse aggregate morphology and its effect on rheological and mechanical properties of fresh concrete. Constr. Build. Mater. 2021, 286, 122940. [Google Scholar] [CrossRef]

- Donza, H.; Cabrera, O.; Irassar, E. High-strength concrete with different fine aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

- Polat, R.; Yadollahi, M.M.; Sagsoz, A.E.; Arasan, S. The correlation between aggregate shape and compressive strength of concrete: Digital image processing approach. Int. J. Struct. Civ. Eng. Res. 2013, 2, 62–80. [Google Scholar]

- DIN EN 933-3; Tests for Geometrical Properties of Aggregates: Part 3: Determination of Particle Shape—Flakiness Index. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2012.

- DIN EN 933-4; Tests for Geometrical Properties of Aggregates: Part 4: Determination of Particle Shape—Shape Index. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2015.

- Garboczi, E.J.; Liu, X.; Taylor, M.A. The 3-D shape of blasted and crushed rocks: From 20 μm to 38 mm. Powder Technol. 2012, 229, 84–89. [Google Scholar] [CrossRef]

- Cepuritis, R.; Garboczi, E.J.; Jacobsen, S.; Snyder, K.A. Comparison of 2-D and 3-D shape analysis of concrete aggregate fines from VSI crushing. Powder Technol. 2017, 309, 110–125. [Google Scholar] [CrossRef]

- Erdoğan, S.T.; Garboczi, E.J.; Fowler, D.W. Shape and size of microfine aggregates: X-ray microcomputed tomography vs. laser diffraction. Powder Technol. 2007, 177, 53–63. [Google Scholar] [CrossRef]

- Estephane, P.; Garboczi, E.J.; Bullard, J.W.; Wallevik, O.H. Three-dimensional shape characterization of fine sands and the influence of particle shape on the packing and workability of mortars. Cem. Concr. Compos. 2019, 97, 125–142. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X.; Zhao, Y. Investigation of the shape, size, angularity and surface texture properties of coarse aggregates. Constr. Build. Mater. 2012, 34, 330–336. [Google Scholar] [CrossRef]

- DIN EN 933-1; Tests for Geometrical Properties of Aggregates: Part 1: Determination of Particle Size Distribution—Sieving method. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2012.

- DIN 1045-2; Concrete, Reinforced and Prestressed Concrete Structures: Part 2: Concrete. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2023.

- DIN EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates: Part 6: Determination of Particle Density and Water Absorption. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2013.

- Kim, J.; Zi, G.; Lange, D.A. Measurement of water absorption of very fine particles using electrical resistivity. ACI Mater. J. 2017, 114, 957–965. [Google Scholar] [CrossRef]

- DIN EN 1097-3; Tests for Mechanical and Physical Properties of Aggregates: Part 3: Determination of Loose Buld Density and Voids. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 1998.

- Burgmann, S.; Godehardt, M.; Schladitz, K.; Breit, W. Influence of voxel size for µCT imaging of particles on measurement accuracy. Constr. Build. Mater. 2021, 289, 123148. [Google Scholar] [CrossRef]

- DIN EN ISO 15708-3; Non-Destructive Testing—Radiation Methods for Computed Tomography: Part 3: Operation and Interpretation. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2018.

- Burgmann, S.; Godehardt, M.; Schladitz, K.; Breit, W. Separation of sand and gravel particles in 3D images using the adaptive h-extrema transform. Powder Technol. 2022, 404, 117468. [Google Scholar] [CrossRef]

- Blott, S.J.; Pye, K. Particle shape: A review and new methods of characterization and classification. Sedimentology 2008, 55, 31–63. [Google Scholar] [CrossRef]

- Eckert, M.; Oliveira, M. Mitigation of the negative effects of recycled aggregate water absorption in concrete technology. Constr. Build. Mater. 2017, 133, 416–424. [Google Scholar] [CrossRef]

- DIN EN 196-1; Methods of Testing Cement: Part 1: Determination of Strength. DIN German Institute for Standardization. Beuth Verlag GmbH: Berlin, Germany, 2016.

- Banfill, P.F.G. Rheology of fresh cement and concrete. Rheol. Rev. 2006, 61–130. [Google Scholar]

- Bingham, E.C. Fluidity and Plasticity, 1st ed.; McGraw-Hill Book Company: New York, NY, USA, 1922. [Google Scholar]

- Banfill, P.F.G. The rheology of fresh mortar. Mag. Concr. Res. 1991, 43, 13–21. [Google Scholar] [CrossRef]

- R Core Team. R.; R Foundation for Statistical Computing: Vienna, Austria, 2022. [Google Scholar]

- Harrell, F.E. Regression Modeling Strategies: With Applications to Linear Models, Logistic Regression, and Survival Analysis, 1st ed.; Springer: New York, NY, USA, 2001; ISBN 978-1-4419-2918-1. [Google Scholar]

- Schwarz, G. Estimating the dimensions of a model. Ann. Stat. 1978, 6, 461–464. [Google Scholar] [CrossRef]

- Dormann, C.F.; Elith, J.; Bacher, S.; Buchmann, C.; Carl, G.; Carré, G.; Marquéz, J.R.G.; Gruber, B.; Lafourcade, B.; Leitão, P.J.; et al. Collinearity: A review of methods to deal with it and a simulation study evaluating their performance. Ecography 2013, 36, 27–46. [Google Scholar] [CrossRef]

- Shapiro, S.S.; Wilk, M.B. An analysis of variance test for normality (complete samples). Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Breusch, T.S.; Pagan, A.R. A simple test for heteroscedasticity and random coefficient variation. Econometrica 1979, 47, 1287–1294. [Google Scholar] [CrossRef]

- Popovics, S. Aggregate grading and the internal structure of concrete. Highw. Res. Rec. 1973, 56–64. [Google Scholar]

- de Larrard, F. Concrete Mixture Proportioning: A Scientific Approach, 1st ed.; E & FN Spon/Routledge: London, UK, 1999; ISBN 0419235000. [Google Scholar]

- Zou, R.P.; Yu, A.B. Evaluation of the packing characteristics of mono-sized non-spherical particles. Powder Technol. 1996, 88, 71–79. [Google Scholar] [CrossRef]

- Hafid, H.; Ovarlez, G.; Toussaint, F.; Jezequel, P.H.; Roussel, N. Effect of particle morphological parameters on sand grains packing properties and rheology of model mortars. Cem. Concr. Res. 2016, 80, 44–51. [Google Scholar] [CrossRef]

- Wright, P.J.F.; Garwood, F. The effect of the method of test on the flexural strength of concrete. Mag. Concr. Res. 1952, 4, 67–76. [Google Scholar] [CrossRef]

| Material | Grading Curve | Bulk Density (g/cm³) | Apparent Density (g/cm³) | Water Absorption (%) |

|---|---|---|---|---|

| Glass beads | AB | 1.62 | 2.49 | 0.00 |

| (G) | BC | 1.61 | 2.49 | 0.00 |

| Natural sand | AB | 1.53 | 2.62 | 1.28 |

| (S) | BC | 1.52 | 2.63 | 1.71 |

| Crushed microdiorite | AB | 1.46 | 3.07 | 1.80 |

| (M) | BC | 1.47 | 3.11 | 2.70 |

| Recycled concrete | AB | 1.08 | 2.67 | 15.10 |

| (RC) | BC | 1.07 | 2.67 | 16.50 |

| Recycled masonry | AB | 1.17 | 2.64 | 13.70 |

| (RM) | BC | 1.22 | 2.71 | 13.70 |

| Variable | Coefficient | Standard Error | p-Value |

|---|---|---|---|

| Intercept | −1.4932 | 0.0744 | 0.000 |

| w/c (0.55) | −1.4745 | 0.0991 | 0.000 |

| PRT | −0.0035 | 0.0012 | 0.005 |

| −0.8300 | 0.8245 | 0.3157 | |

| w/c (0.55): | 5.3572 | 0.9042 | 0.000 |

| −0.0706 | 0.0126 | 0.000 | |

| w/c (0.55): | 0.1249 | 0.0161 | 0.000 |

| Variable | Coefficient | Standard Error | p-Value |

|---|---|---|---|

| Intercept | −0.7436 | 0.2489 | 0.003 |

| w/c (0.55) | −1.0630 | 0.0181 | 0.000 |

| b/a (1.05) | −0.0407 | 0.0347 | 0.242 |

| Grading (BC) | −0.2648 | 0.0433 | 0.000 |

| PRT | −0.0103 | 0.0009 | 0.000 |

| Grading (BC):PRT | 0.0105 | 0.0011 | 0.000 |

| 4.8630 | 0.4029 | 0.000 | |

| −1.5497 | 0.1212 | 0.000 | |

| 7.2711 | 0.4510 | 0.000 | |

| b/a (1.05): | −1.3641 | 0.3218 | 0.000 |

| 0.0736 | 0.0079 | 0.000 | |

| w/c (0.55): | 0.0322 | 0.0057 | 0.000 |

| Grading (BC): | −0.0352 | 0.0078 | 0.000 |

| Variable | Coefficient | Standard Error | p-Value |

|---|---|---|---|

| Intercept | 52.13 | 1.56 | 0.000 |

| w/c (0.55) | −11.76 | 0.99 | 0.000 |

| b/a (1.05) | 0.98 | 0.37 | 0.008 |

| Origin (R) | 84.06 | 21.39 | 0.000 |

| Origin (R): | −891.03 | 181.74 | 0.000 |

| −1.49 | 0.85 | 0.082 | |

| w/c (0.55): | 1.30 | 0.31 | 0.000 |

| Variable | Coefficient | Standard Error | p-Value |

|---|---|---|---|

| Intercept | −0.27 | 0.45 | 0.55 |

| w/c (0.55) | 0.39 | 0.17 | 0.02 |

| 53.74 | 4.07 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burgmann, S.; Breit, W. Impact of Crushed Natural and Recycled Fine Aggregates on Fresh and Hardened Mortar Properties. Constr. Mater. 2024, 4, 37-57. https://doi.org/10.3390/constrmater4010003

Burgmann S, Breit W. Impact of Crushed Natural and Recycled Fine Aggregates on Fresh and Hardened Mortar Properties. Construction Materials. 2024; 4(1):37-57. https://doi.org/10.3390/constrmater4010003

Chicago/Turabian StyleBurgmann, Sophie, and Wolfgang Breit. 2024. "Impact of Crushed Natural and Recycled Fine Aggregates on Fresh and Hardened Mortar Properties" Construction Materials 4, no. 1: 37-57. https://doi.org/10.3390/constrmater4010003

APA StyleBurgmann, S., & Breit, W. (2024). Impact of Crushed Natural and Recycled Fine Aggregates on Fresh and Hardened Mortar Properties. Construction Materials, 4(1), 37-57. https://doi.org/10.3390/constrmater4010003