Effect of Process Parameters on the Physical and Mechanical Properties of Cornstarch-Based Construction Materials

Abstract

:1. Introduction

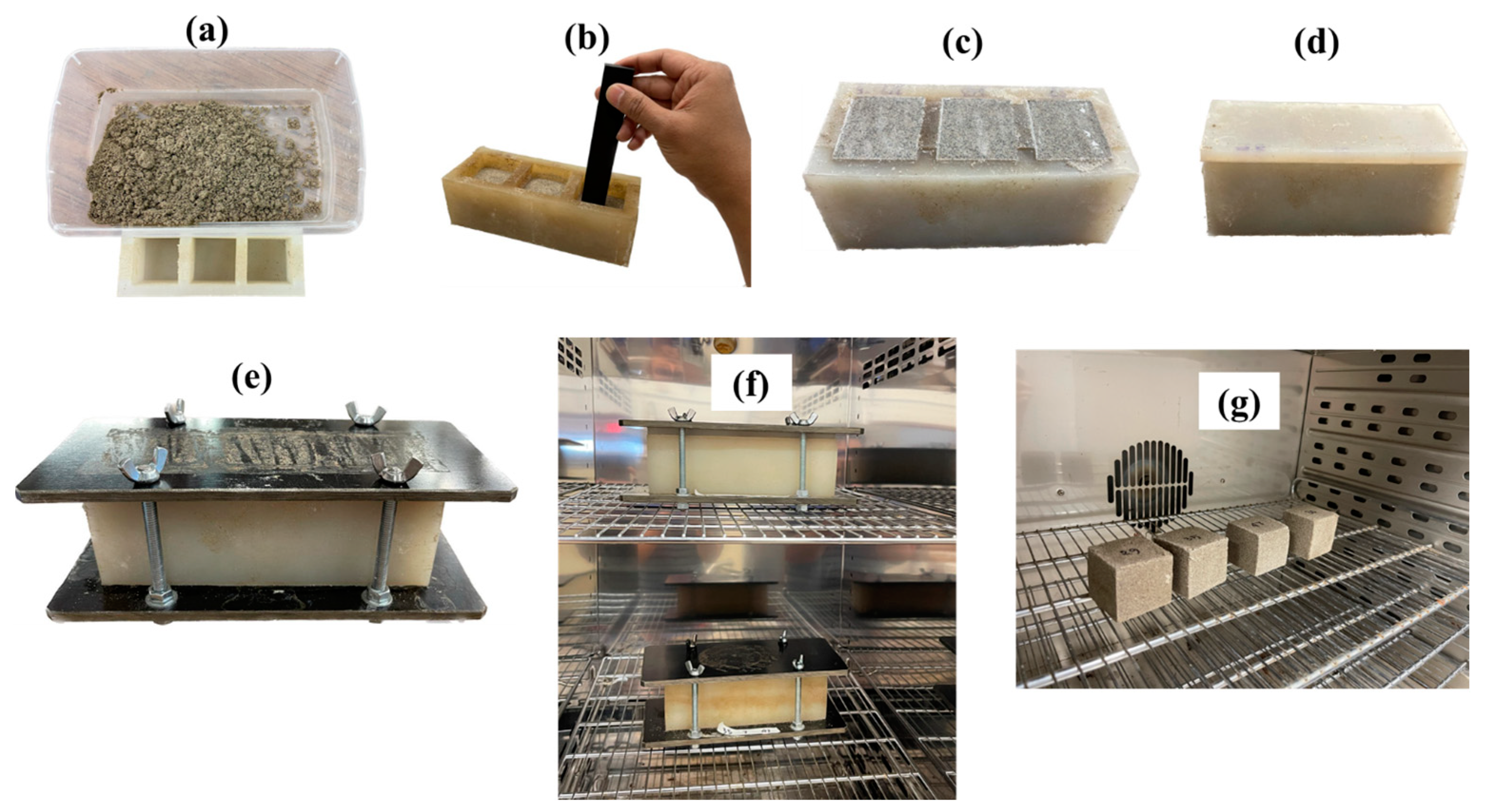

2. Materials and Methods

2.1. Materials and Preliminary Study

2.2. Experimental Design

2.3. Sample Preparation for Testing

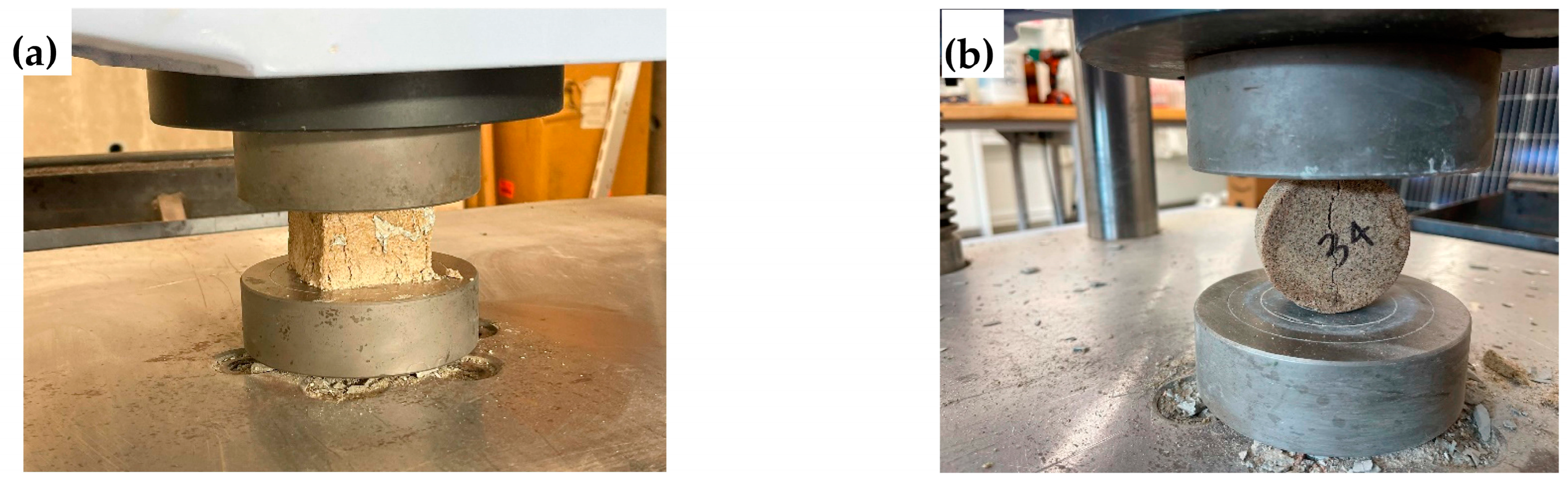

2.4. Mechanical Strength Measurement

2.5. Scanning Electron Microscopy

2.6. X-ray Micro-Computed Tomography (microCT)

2.7. Statistical Analysis

3. Results and Discussion

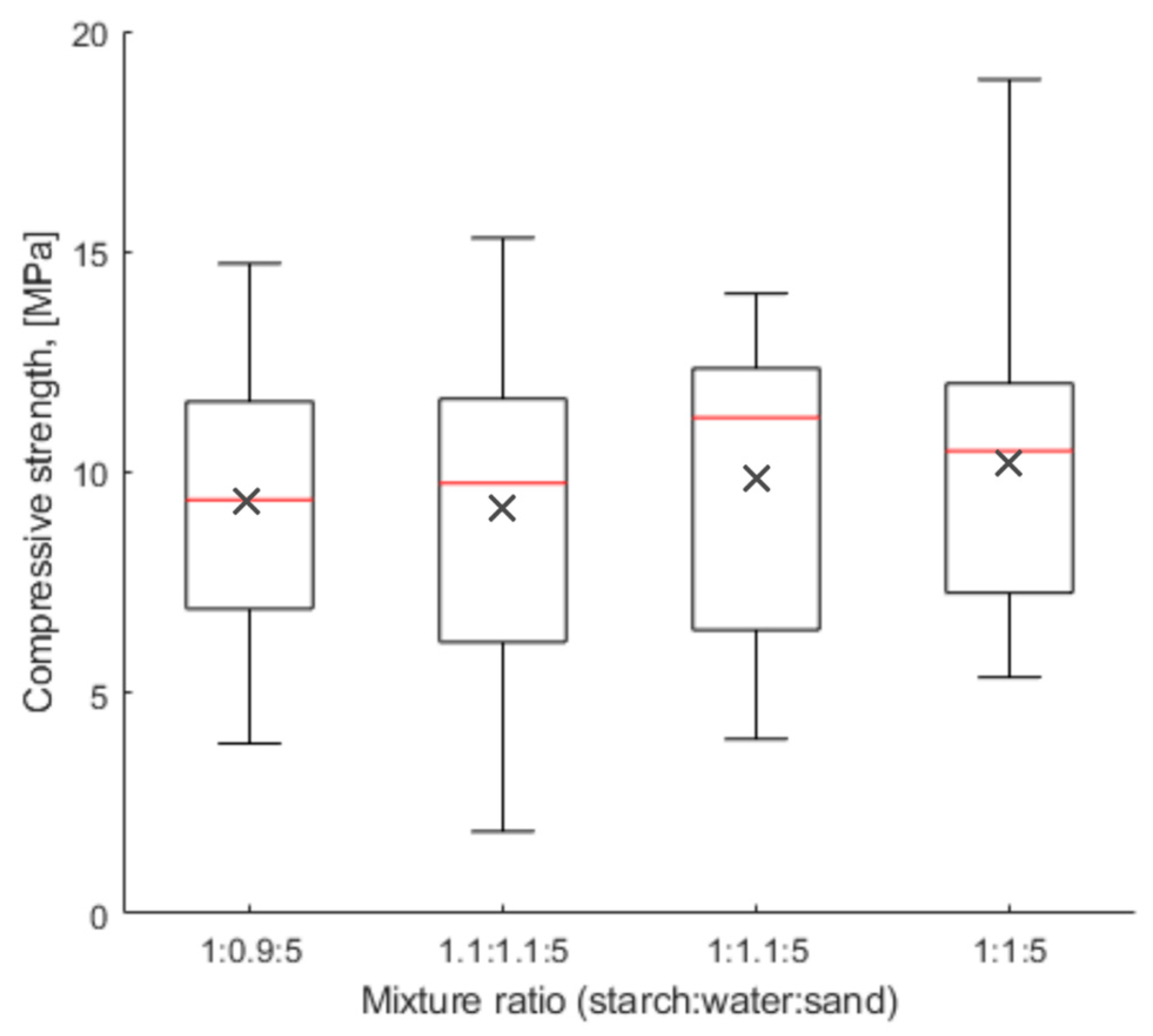

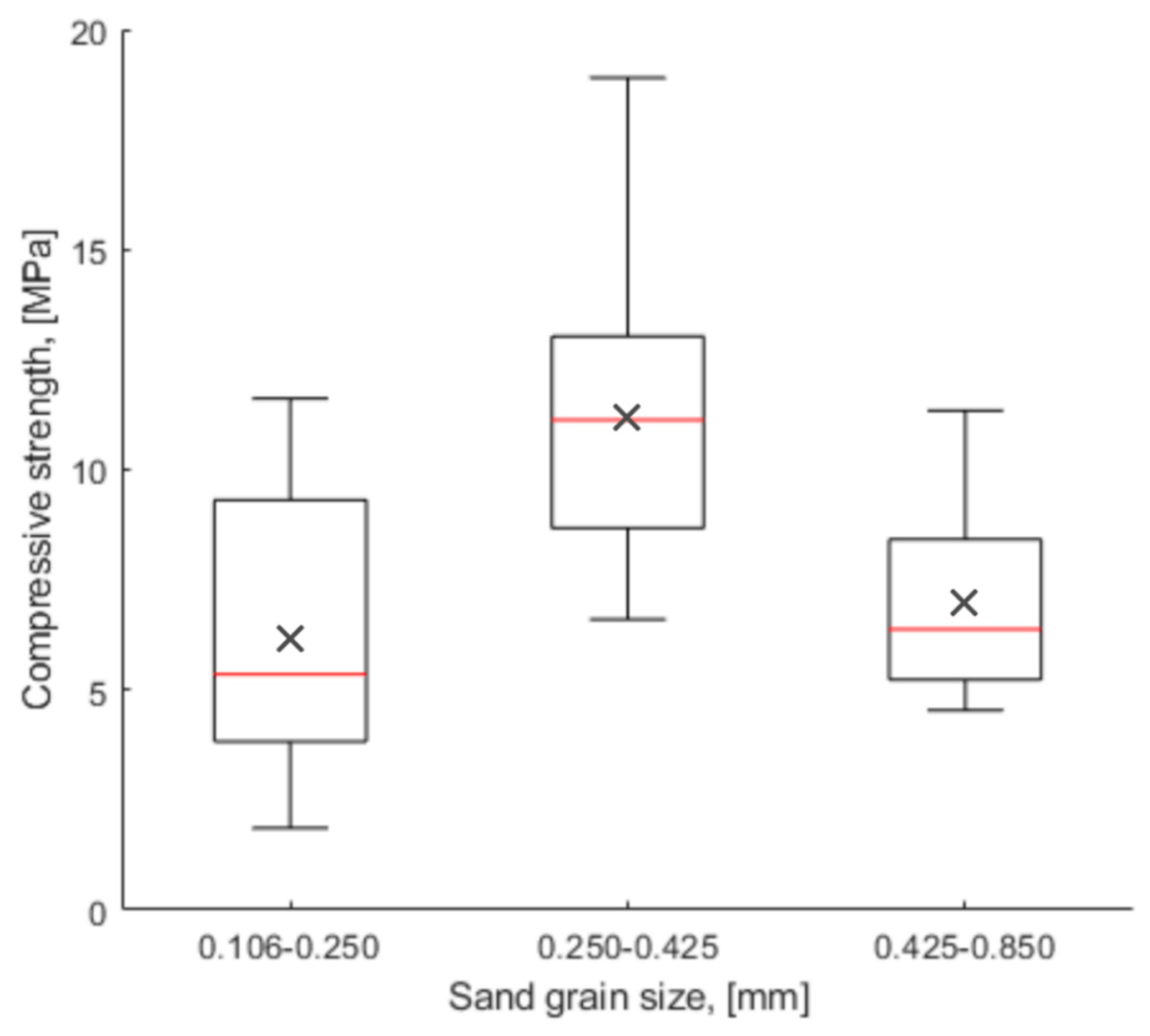

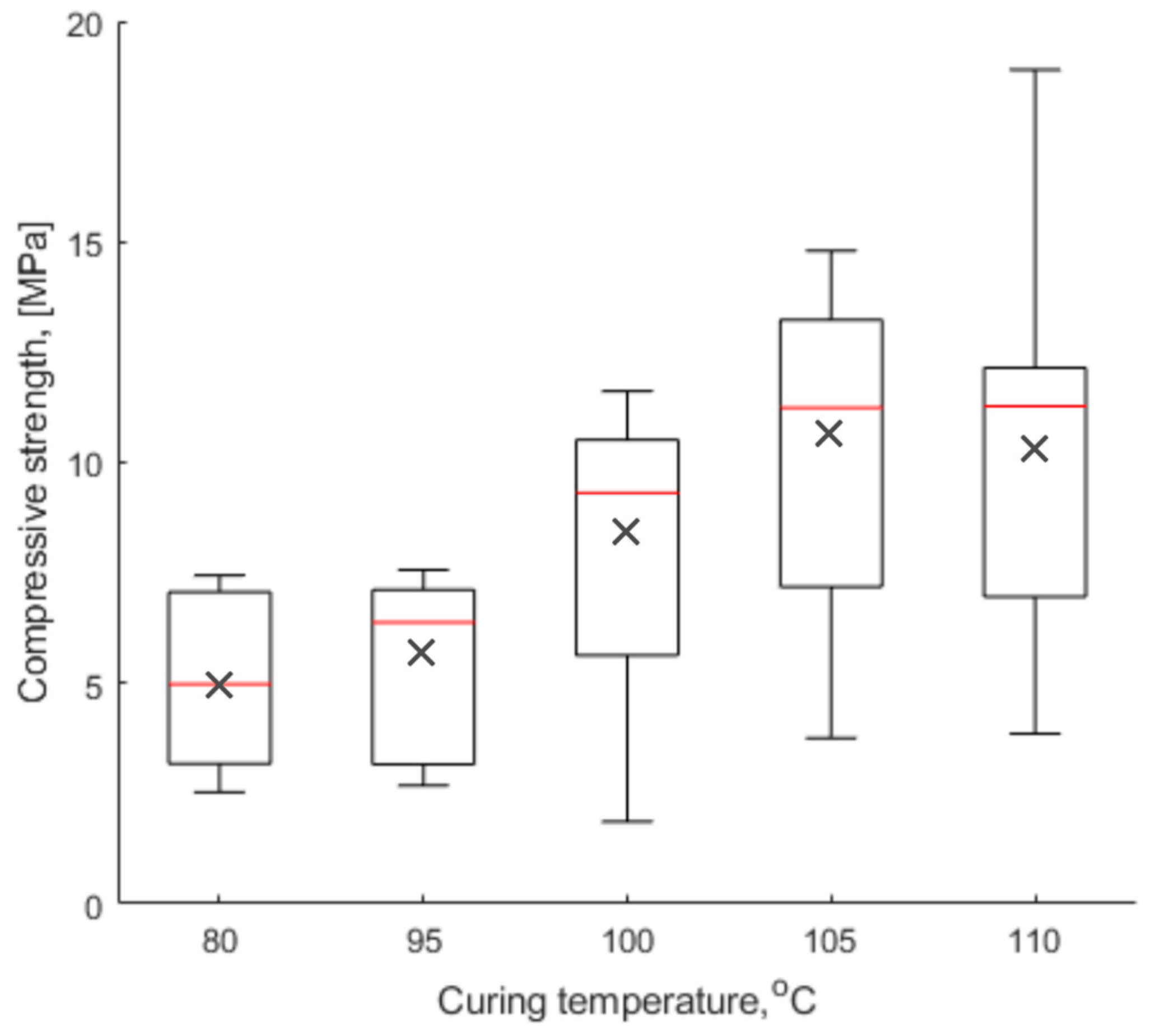

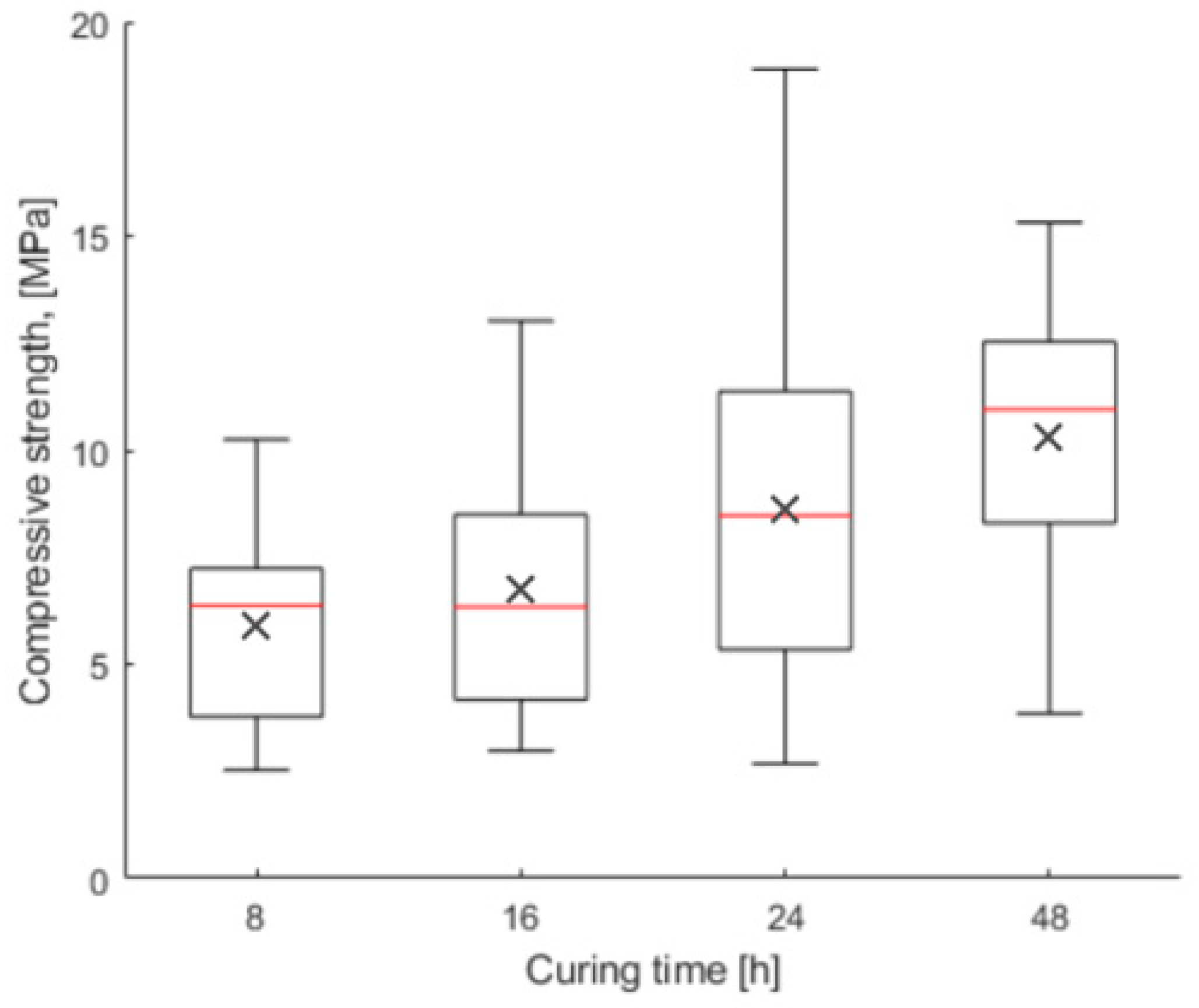

3.1. The Effect of Different Factors on the Compressive Strength of CoRncrete

3.2. Tensile Strength Analysis

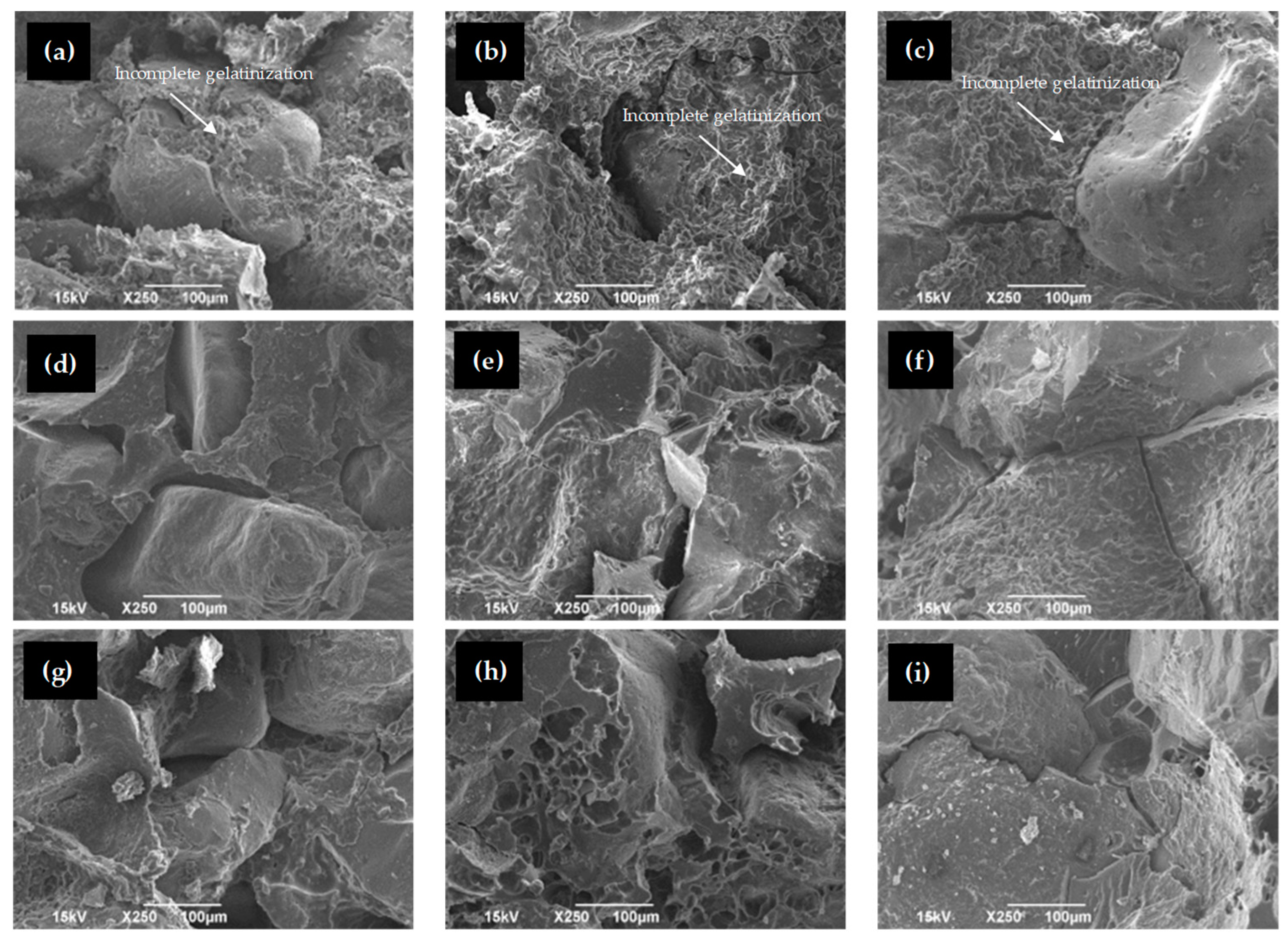

3.3. Microstructural Analysis Using Scanning Electron Microscopy (SEM)

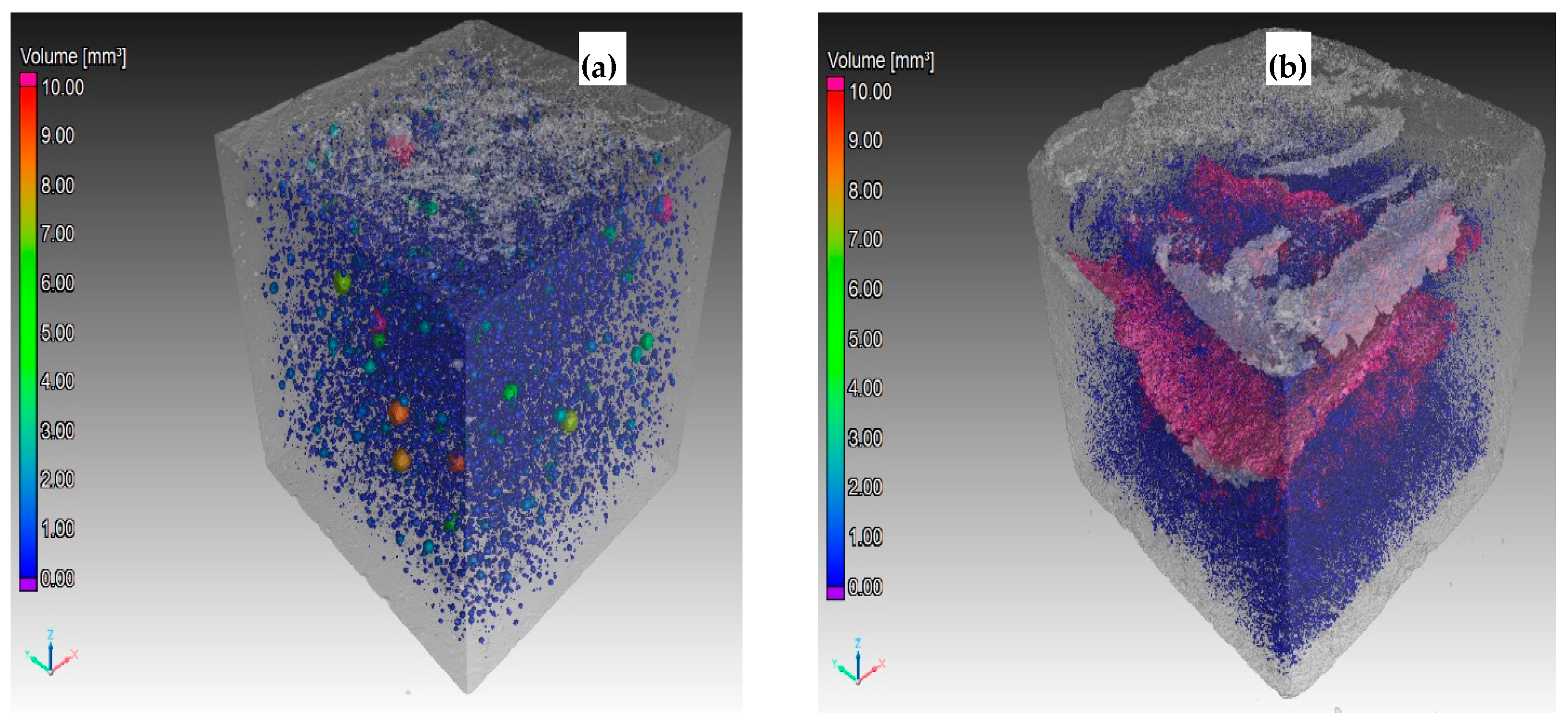

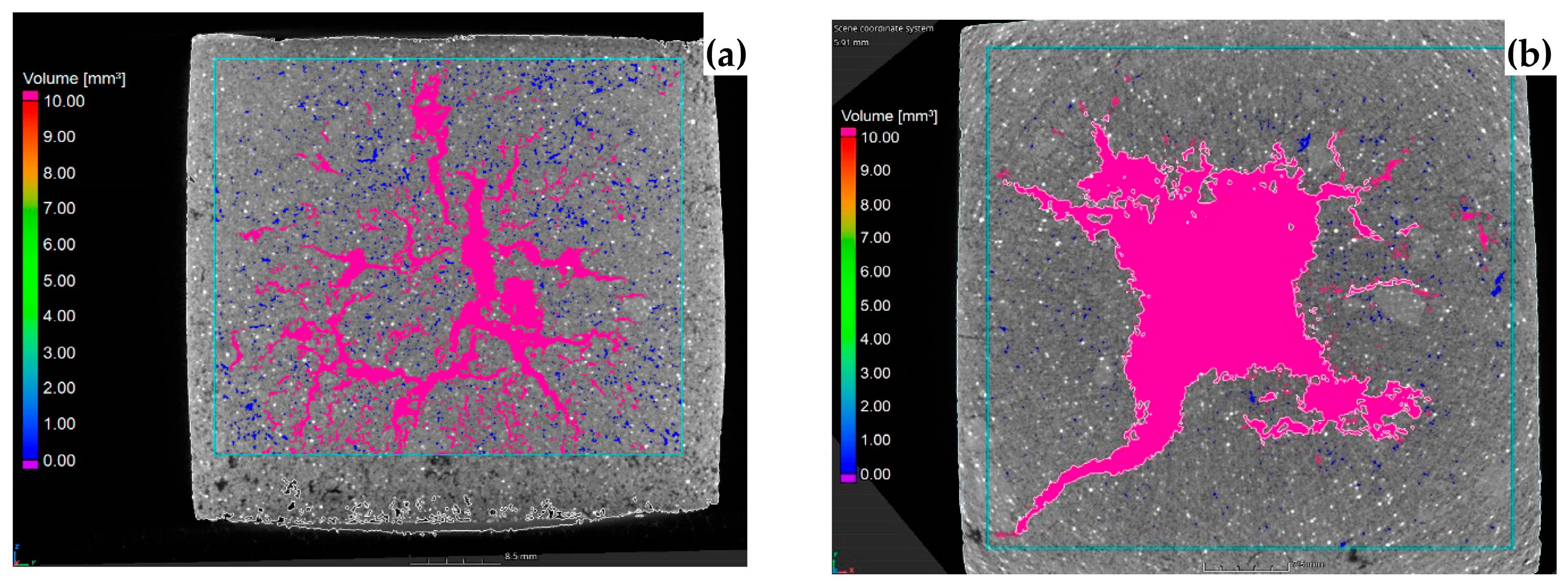

3.4. Internal Structure Analysis Using X-ray Micro-Computed Tomography (microCT)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flower, D.J.M.; Sanjayan, J.G. Greenhouse gas emissions due to concrete manufacture. Handb. Low Carbon Concr. 2017, 12, 1–16. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily implementable techniques can cut annual CO2 emissions from the production of concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Statista. Cement Production in the United States from 2010 to 2020. 2020. Available online: https://www.statista.com/statistics/219343/cement-production-worldwide/ (accessed on 15 February 2022).

- Mehta, P.; Monteiro, P.J. Concrete: Microstructure, Properties, Materials; McGraw-Hill, T.: New York, NY, USA, 2006. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Asia Pte. Ltd.: Singapore, 2011. [Google Scholar]

- Rajendran, R.; Sathishkumar, A.; Perumal, K.; Pannirselvam, N.; Lingeshwaran, N.; Madavarapu, S. An experiment on concrete replacing binding material as waste glass powder. Mater. Today Proc. 2021, 47, 5447–5450. [Google Scholar] [CrossRef]

- Rashwan, M.A.; Al-Basiony, T.M.; Mashaly, A.O.; Khalil, M.M. Behaviour of fresh and hardened concrete incorporating marble and granite sludge as cement replacement. J. Build. Eng. 2020, 32, 101697. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Fapohunda, C.; Akinbile, B.; Shittu, A. Structure and properties of mortar and concrete with rice husk ash as partial replacement of ordinary portland cement—A review. Int. J. Sustain. Built Environ. 2017, 6, 675–692. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Müller, P.; Kapin, É.; Fekete, E. Effects of preparation methods on the structure and mechanical properties of wet conditioned starch/montmorillonite nanocomposite films. Carbohydr. Polym. 2014, 113, 569–576. [Google Scholar] [CrossRef]

- Afroz, S.; Manzur, T.; Borno, I.B.; Hasanuzzaman, M.; Hossain, K.M.A. Potential of Starch as Organic Admixture in Cementitious Composites. J. Mater. Civ. Eng. 2021, 33, 1–10. [Google Scholar] [CrossRef]

- ONI, D.O.; Mwero, J.; Kabubo, C. Experimental investigation of the physical and mechanical properties of cassava starch modified concrete. Open Constr. Build. Technol. J. 2019, 13, 331–343. [Google Scholar] [CrossRef]

- Abd, S.M.; Hamood, Q.Y.; Khamees, A.S.; Ali, Z.H. Effect of using corn starch as concrete admixture. Int. J. Engg. Res. Sci. Tech. 2016, 5, 35–44. [Google Scholar]

- Liu, H.; Guan, Y.; Wei, D.; Gao, C.; Yang, H.; Yang, L. Reinforcement of injectable calcium phosphate cement by gelatinized starches. J. Biomed. Mater. Res. Part B Appl. Biomater. 2016, 104, 615–625. [Google Scholar] [CrossRef]

- Akindahunsi, A.A.; Uzoegbo, H.C.; Iyuke, S.E. Use of starch modified concrete as a repair material. In Concrete Repair, Rehabilitation and Retrofitting III; CRC Press: Boca Raton, FL, USA, 2012; pp. 361–362. [Google Scholar]

- Kulshreshtha, Y.; Schlangen, E.; Jonkers, H.M.; Vardon, P.J.; van Paassen, L.A. CoRncrete: A corn starch based building material. Constr. Build. Mater. 2017, 154, 411–423. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Starch-sandstone materials in the construction industry. Results Eng. 2020, 8, 100182. [Google Scholar] [CrossRef]

- ASTM, C 109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D 3967-08; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2008.

- Liu, H.; Yu, L.; Xie, F.; Chen, L. Gelatinization of cornstarch with different amylose/amylopectin content. Carbohydr. Polym. 2006, 65, 357–363. [Google Scholar] [CrossRef]

- Bertrand, R.; Holmes, W.; Orgeron, C.; McIntyre, C.; Hernandez, R.; Revellame, E.D. Rapid estimation of parameters for gelatinization of waxy corn starch. Foods 2019, 8, 556. [Google Scholar] [CrossRef]

- Coral, D.F.; Pineda-Gómez, P.; Rosales-Rivera, A.; Rodriguez-Garcia, M.E. Determination of the gelatinization temperature of starch presented in maize flours. J. Phys. Conf. Ser. 2009, 167, 012057. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Tzetzis, D. Starch sandstones in building bio-materials. MATEC Web Conf. 2020, 318, 01046. [Google Scholar] [CrossRef]

- Zoumaki, M.; Tsongas, K.; Tzetzis, D.; Mansour, G. Corn starch-based sandstone sustainable materials: Sand type and water content effect on their structure and mechanical properties. Sustainability 2022, 14, 8901. [Google Scholar] [CrossRef]

- da Silva, A.; Dionísio, A.; Coelho, L. Flexible-lean processes optimization: A case study in stone sector. Results Eng. 2020, 6, 100129. [Google Scholar] [CrossRef]

- Li, D.; Wong, L.N.Y. The brazilian disc test for rock mechanics applications: Review and new insights. Rock Mech. Rock Eng. 2013, 46, 269–287. [Google Scholar] [CrossRef]

- Newman, J.; Choo, B.S. Strength-testing machines for concrete. In Advanced Concrete Technology; Elsevier: Oxford, UK, 2003; pp. 1–9. [Google Scholar]

- Sari, M. Investigating relationships between engineering properties of various rock types. Glob. J. Earth Sci. Eng. 2018, 5, 1–25. [Google Scholar] [CrossRef]

- Yang, B.; He, M.; Deng, B.; Zhang, Z. Correlation between the tensile to compressive strength ratio and mechanical parameters of rock based on a nonlinear M-C criterion. Arab J Geosci. 2022, 15, 982. [Google Scholar] [CrossRef]

- Plessis, A.D.; Olawuyi, B.J.; Boshoff, W.P.; le Roux, S.G. Simple and fast porosity analysis of concrete using X-ray computed tomography. Mater. Struct. 2016, 49, 553–562. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, Z.; Ren, W.; Liu, G.; Zhang, C. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray Computed Tomography images using damage plasticity model. Int. J. Solids Struct. 2015, 67–68, 340–352. [Google Scholar] [CrossRef]

- Huang, Y.; Yan, D.; Yang, Z.; Liu, G. 2D and 3D homogenization and fracture analysis of concrete based on in-situ X-ray Computed Tomography images and Monte Carlo simulations. Eng. Fract. Mech. 2016, 63, 37–54. [Google Scholar] [CrossRef]

| Factors | Levels | Level Names |

|---|---|---|

| Sand grain size | 2 | 0.106–0.250 (mm) |

| 0.250–0.425 (mm) | ||

| Mixture ratio (starch: water: sand) | 4 | 1:1:5 |

| 1:0.9:5 | ||

| 1:1.1:5 | ||

| 1.1:1.1:5 | ||

| Curing Temperature (convection oven) | 3 | 100 °C |

| 105 °C | ||

| 110 °C | ||

| Curing time | 2 | 24 h |

| 48 h |

| Factors | Levels | Level Names |

|---|---|---|

| Sand grain size | 3 | 0.106–0.250 (mm) |

| 0.250–0.425 (mm) | ||

| 0.425–0.850 (mm) | ||

| Curing Temperature | 3 | 80 °C |

| 95 °C | ||

| 110 °C | ||

| Curing time | 3 | 8 h |

| 12 h | ||

| 24 h |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean of Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Sand grain size | 1 | 240.3 (39.4%) | 240.250 | 32.79 | 0.000 |

| Mixture ratio | 3 | 7.4 | 2.457 | 0.34 | 0.800 |

| Curing temperature | 2 | 56.8 (9.3%) | 28.408 | 3.88 | 0.029 |

| Curing time | 1 | 12.2 | 12.223 | 1.67 | 0.204 |

| Error | 40 | 293.1 (48.1%) | 7.327 | - | - |

| Total | 47 | 609.7 | - | - | - |

| Factors | Levels | N | Mean | Grouping * |

|---|---|---|---|---|

| Sand grain size (mm) | 0.250–0.425 | 24 | 11.88 | A |

| 0.106–0.250 | 24 | 7.41 | B | |

| Mixture ratio (starch:water:sand) | 1:1:5 | 12 | 10.24 | A |

| 1:1.1:5 | 12 | 9.75 | A | |

| 1:0.9:5 | 12 | 9.36 | A | |

| 1.1:1.1:5 | 12 | 9.23 | A | |

| Curing temperature (°C) | 110 | 16 | 10.54 | A |

| 105 | 16 | 10.28 | A | |

| 100 | 16 | 8.11 | B | |

| Curing time (h) | 24 | 24 | 9.14 | A |

| 48 | 24 | 10.15 | A |

| Source of Variation | Degree of Freedom | Sum of Squares | Mean of Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Sand grain size | 2 | 143.9 (40.3%) | 71.9 | 22.07 | 0.000 |

| Curing temperature | 2 | 128.3 (35.9%) | 64.2 | 19.68 | 0.000 |

| Curing time | 2 | 20.2 (5.7%) | 10.1 | 3.09 | 0.068 |

| Error | 20 | 65.2 (18.2%) | 2.1 | - | - |

| Total | 26 | 357.5 | - | - | - |

| Factors | Levels | N | Mean | Grouping * |

|---|---|---|---|---|

| Sand grain size (mm) | 0.250–0.425 | 9 | 9.45 | A |

| 0.425–0.850 | 9 | 7.205 | A | |

| 0.106–0.250 | 9 | 3.835 | B | |

| Temperature (°C) | 110 | 9 | 9.90 | A |

| 95 | 9 | 5.559 | B | |

| 80 | 9 | 5.035 | B | |

| Curing time (h) | 24 | 9 | 7.94 | A |

| 16 | 9 | 6.72 | A | |

| 8 | 9 | 5.833 | A |

| Sand Grain Size (mm) | Mixture Ratio (Starch:Water:Sand) | Curing Temperature (°C) | Curing Time (h) | Compressive Strength (MPa) | Tensile Strength (MPa) | Ratio (Tensile/ Compressive) |

|---|---|---|---|---|---|---|

| 0.106–0.250 | 1.1:1.1:5 | 110 | 48 | 9.33 | 1.88 | 0.201 |

| 1:1:5 | 80 | 8 | 2.53 | 0.38 | 0.152 | |

| 1:1:5 | 95 | 24 | 2.68 | 0.52 | 0.193 | |

| 1:1:5 | 110 | 24 | 8.475 | 1.81 | 0.214 | |

| 0.250–0.425 | 1:1:5 | 110 | 24 | 18.90 | 0.85 | 0.045 |

| 1.1:1.1:5 | 110 | 24 | 15.31 | 0.86 | 0.056 | |

| 1.1:1.1:5 | 100 | 24 | 9.32 | 0.45 | 0.049 | |

| 1:1:5 | 110 | 16 | 13.02 | 0.65 | 0.050 | |

| 1:1:5 | 95 | 24 | 6.60 | 0.39 | 0.060 | |

| 1:1:5 | 100 | 24 | 9.49 | 0.66 | 0.070 | |

| 0.425–0.850 | 1:1:5 | 95 | 8 | 6.37 | 0.34 | 0.054 |

| 1:1:5 | 110 | 24 | 11.338 | 0.53 | 0.046 |

| - | Compressive Strength (MPa) | Sand Grain Size (mm) | Curing Temperature/Media | Curing Time | Density (kg/m3) | % Porosity |

|---|---|---|---|---|---|---|

| CoRncrete | 11.34 | 0.425–0.850 | 110 °C | 24 h | 1592 | 32.5 |

| 18.90 | 0.250–0.425 | 110 °C | 24 h | 1562 | 26.9 | |

| 8.13 | 0.106–0.250 | 110 °C | 24 h | 1437 | 9.6 | |

| 5.19 | 0.106–0.250 | 100 °C | 24 h | 1322 | 6.5 | |

| 1.86 | 0.106–0.250 | 100 °C | 48 h | 1392 | 11.0 | |

| Traditional concrete | 42.90 | 0.425–0.850 | water | 7 days | 2026 | 2.1 |

| 42.88 | 0.250–0.425 | water | 7 days | 1982 | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tulip, S.; Sarker, N.; Nahar, N.; Yang, M.; Monono, E. Effect of Process Parameters on the Physical and Mechanical Properties of Cornstarch-Based Construction Materials. Constr. Mater. 2023, 3, 320-336. https://doi.org/10.3390/constrmater3030021

Tulip S, Sarker N, Nahar N, Yang M, Monono E. Effect of Process Parameters on the Physical and Mechanical Properties of Cornstarch-Based Construction Materials. Construction Materials. 2023; 3(3):320-336. https://doi.org/10.3390/constrmater3030021

Chicago/Turabian StyleTulip, Shibli, Niloy Sarker, Nurun Nahar, Mijia Yang, and Ewumbua Monono. 2023. "Effect of Process Parameters on the Physical and Mechanical Properties of Cornstarch-Based Construction Materials" Construction Materials 3, no. 3: 320-336. https://doi.org/10.3390/constrmater3030021

APA StyleTulip, S., Sarker, N., Nahar, N., Yang, M., & Monono, E. (2023). Effect of Process Parameters on the Physical and Mechanical Properties of Cornstarch-Based Construction Materials. Construction Materials, 3(3), 320-336. https://doi.org/10.3390/constrmater3030021