Self-Compacting Cementitious Composites with Heavy Fuel Fly Ash Replacement

Abstract

1. Introduction

2. State of the Art on the Use of Fly Ash in Concrete

3. Materials and Methods

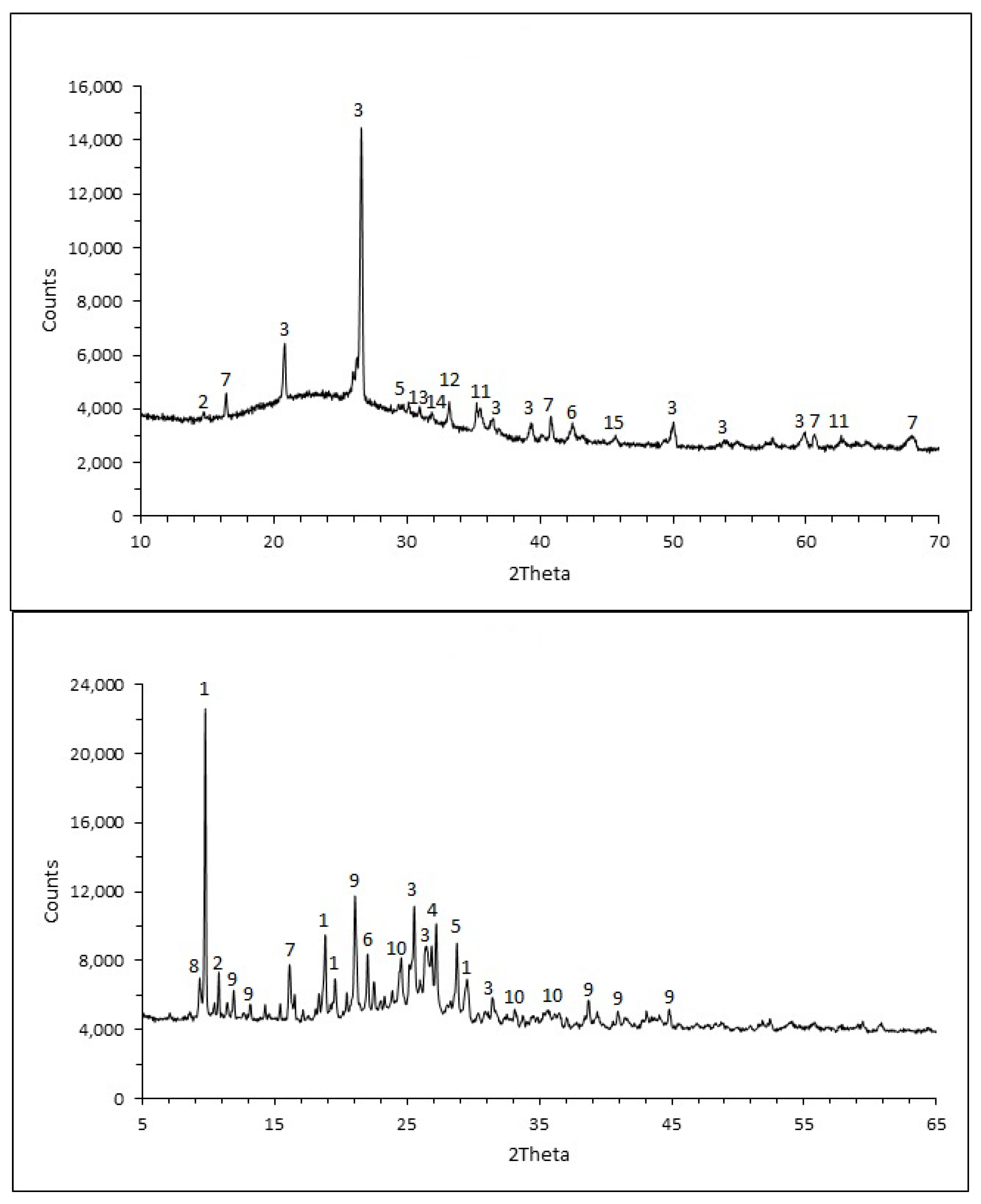

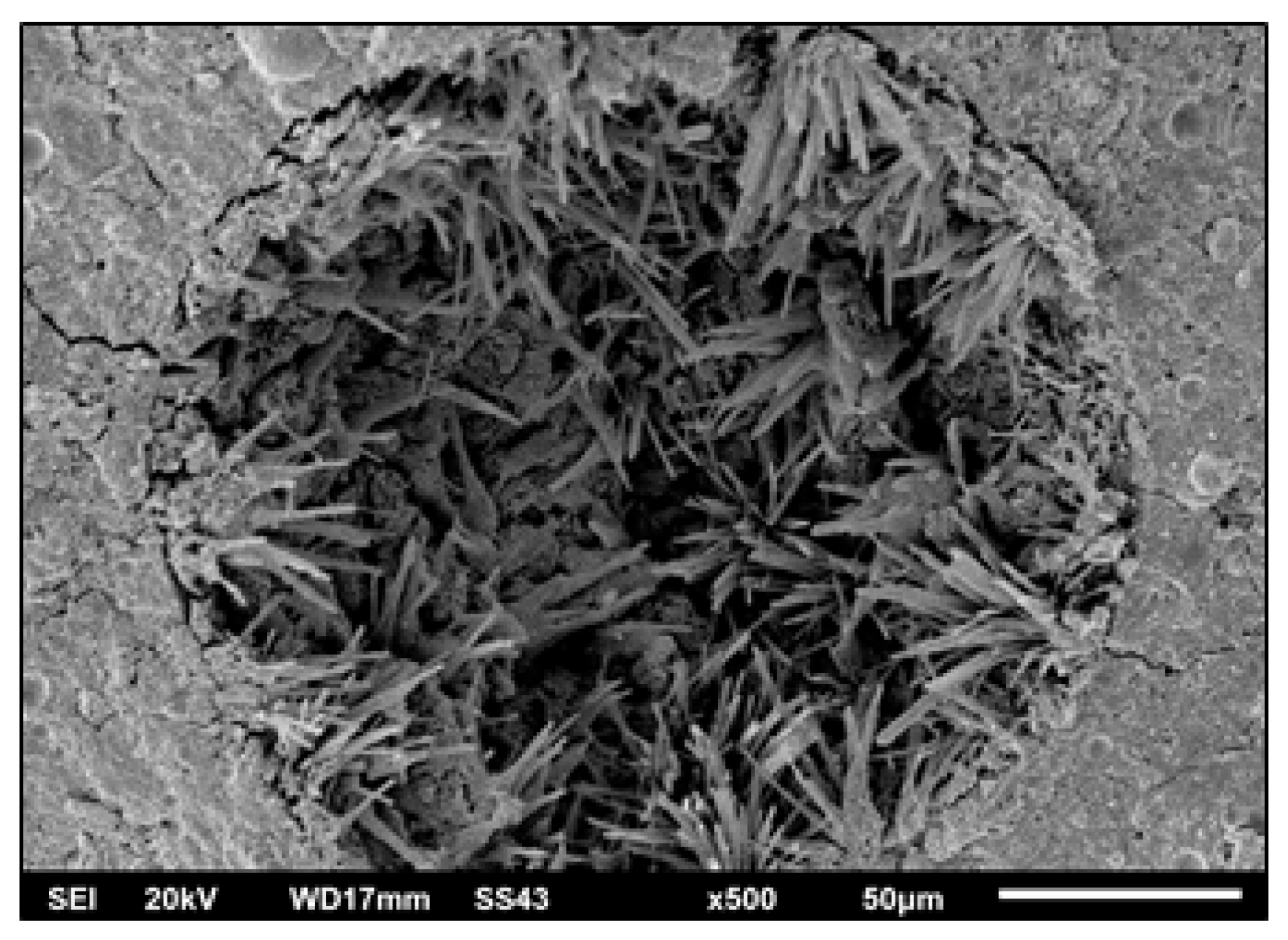

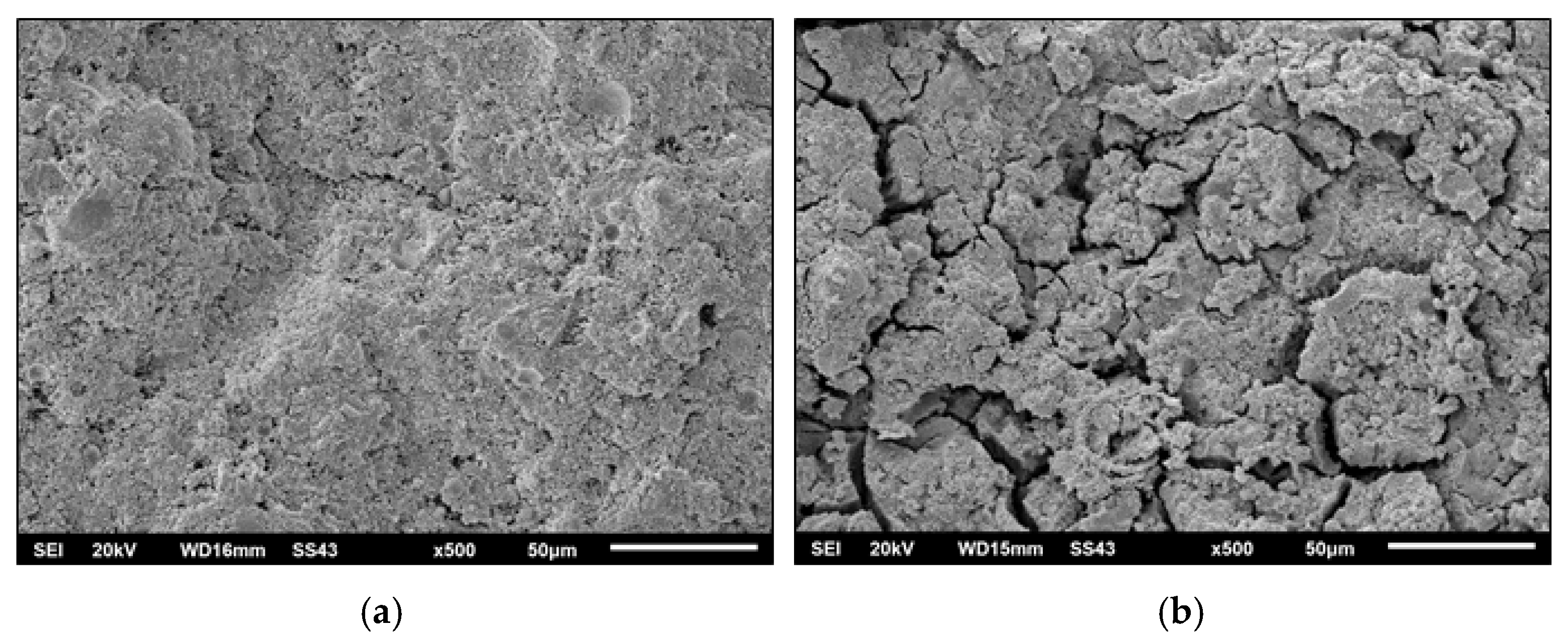

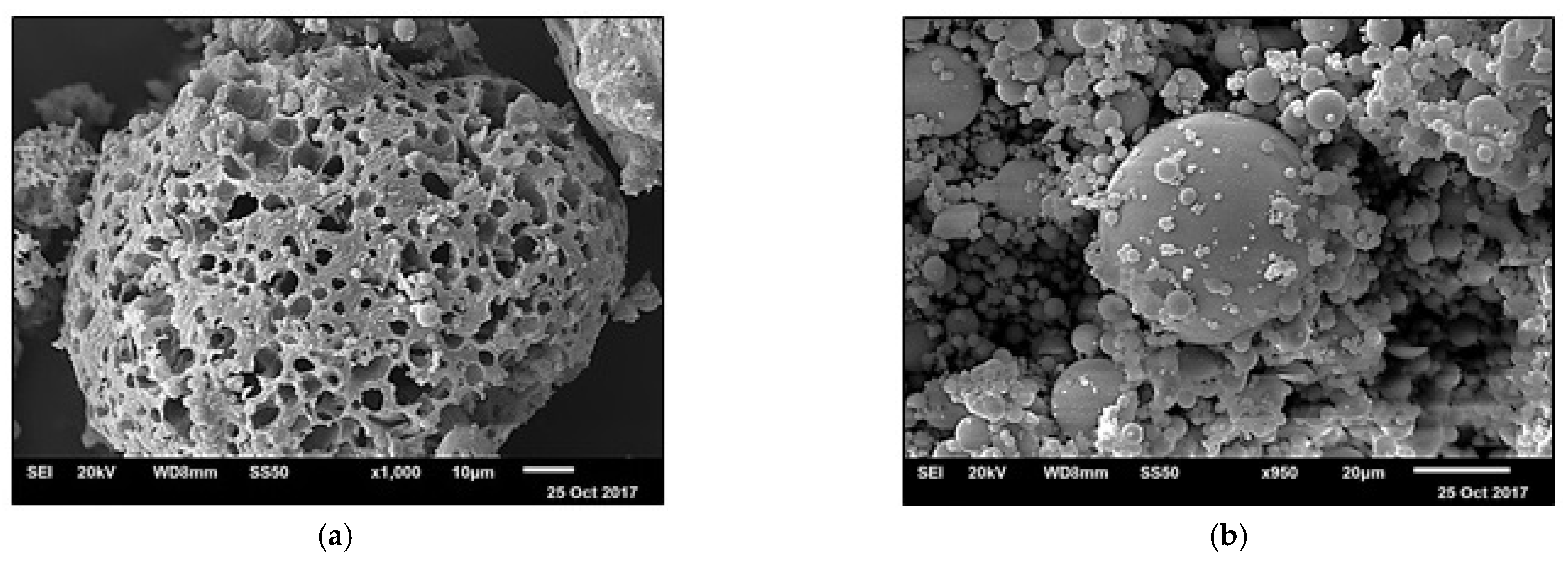

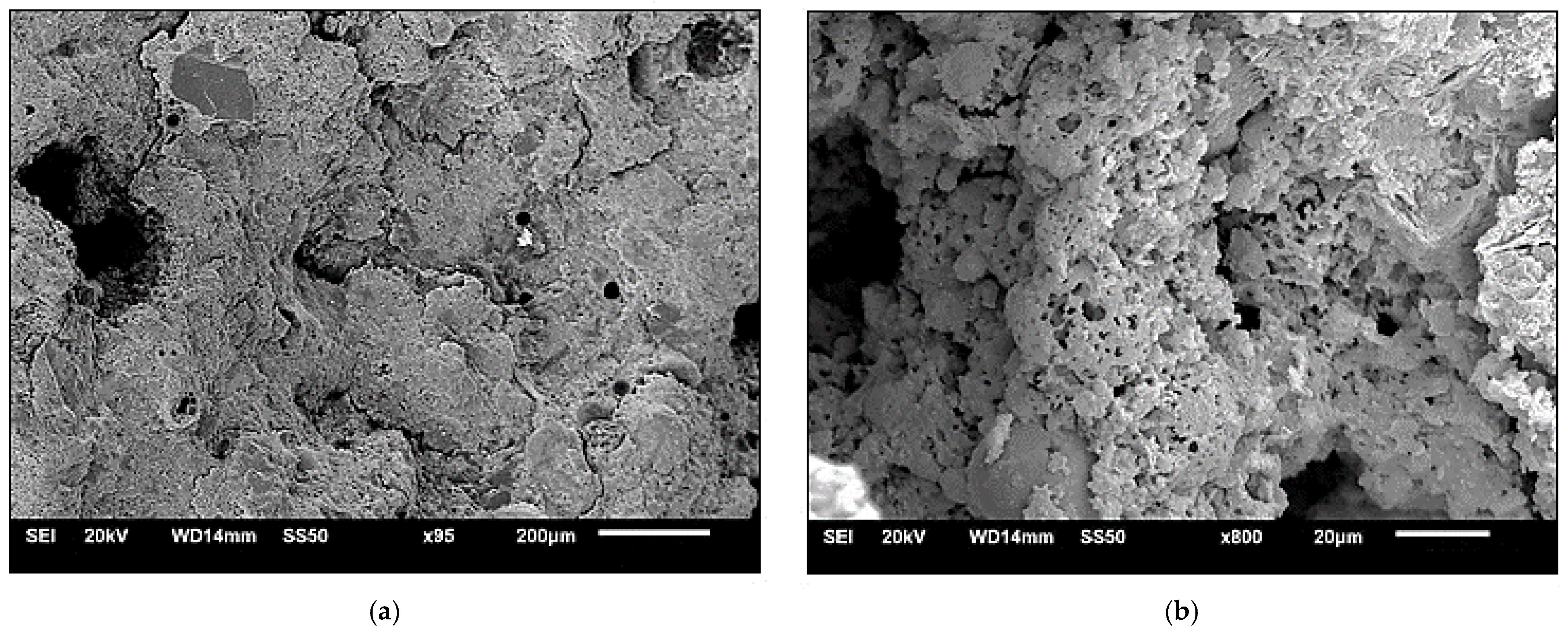

3.1. Raw Materials

3.2. Mix Designs

3.3. Specimen Preparation

3.4. Testing

3.4.1. Uniaxial Compression

3.4.2. Three-Point Bending

3.4.3. Porosity and Bulk Density

3.4.4. Capillary Absorption (Sorptivity)

4. Results

4.1. Porosity and Bulk Density

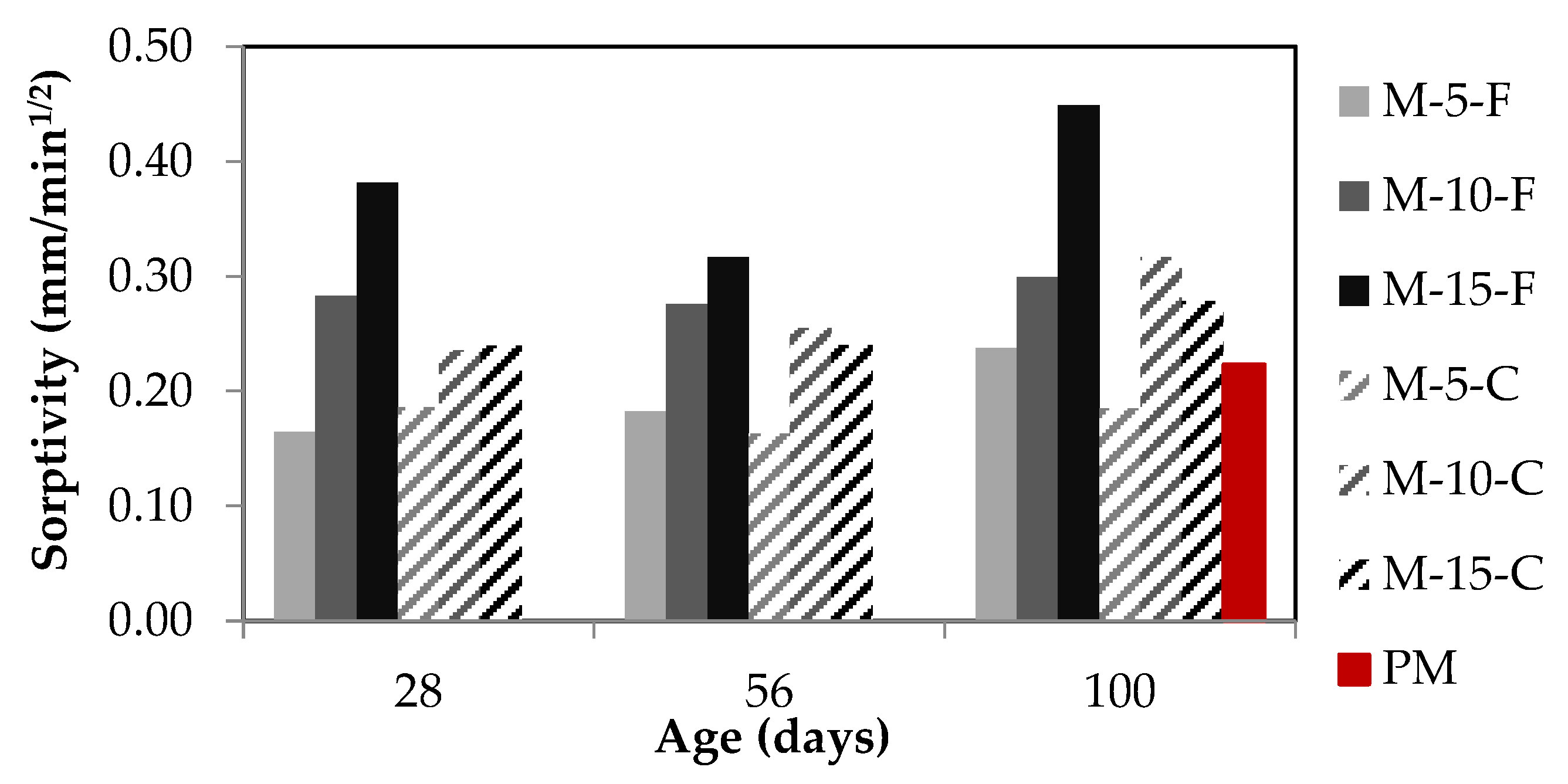

4.2. Capillary Absorption (Sorptivity)

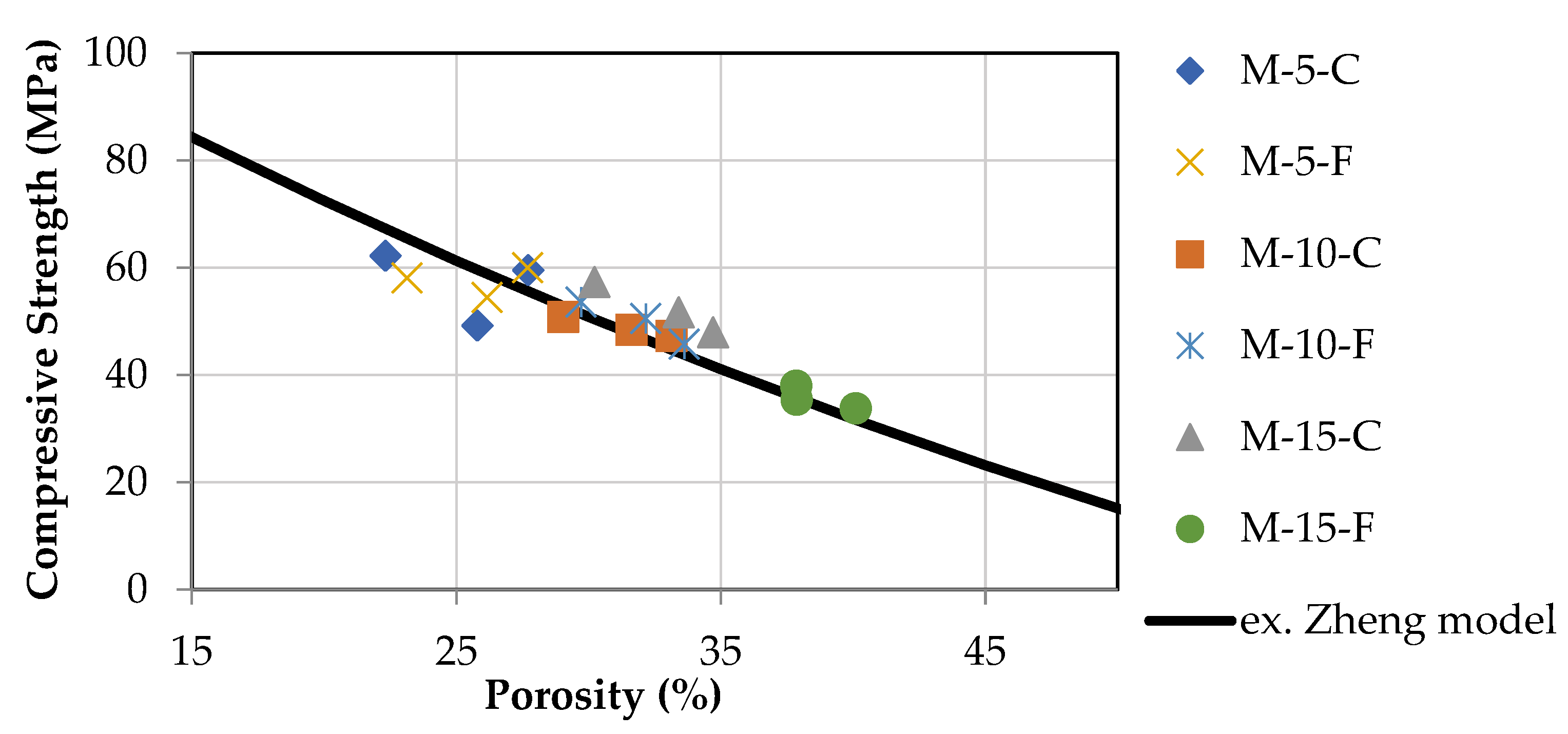

4.3. Three-Point Bending and Uniaxial Compression

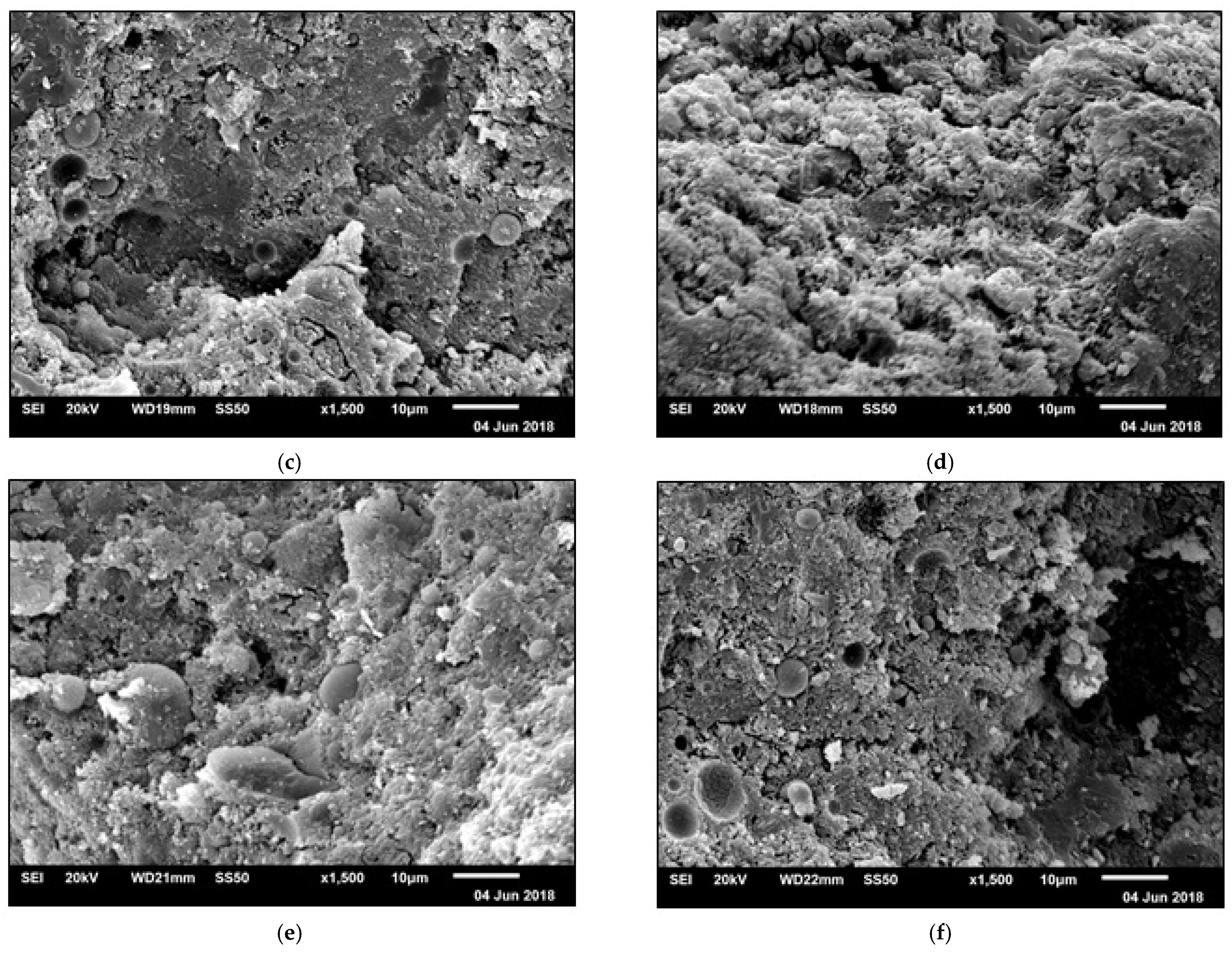

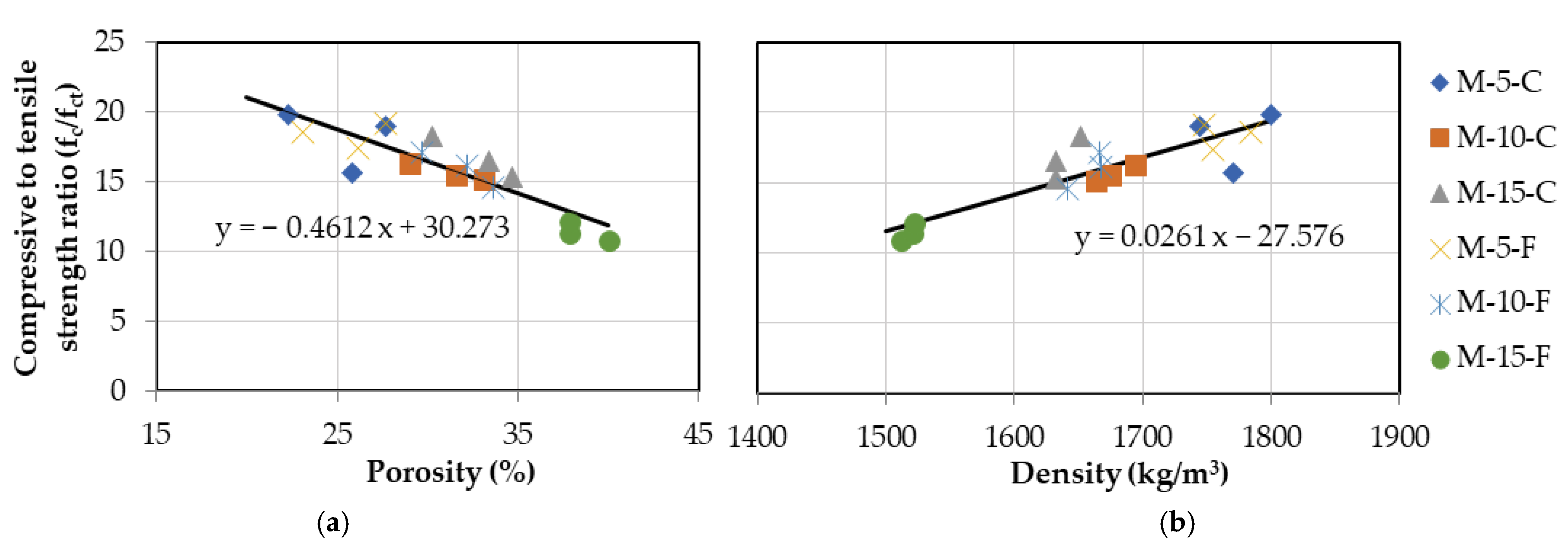

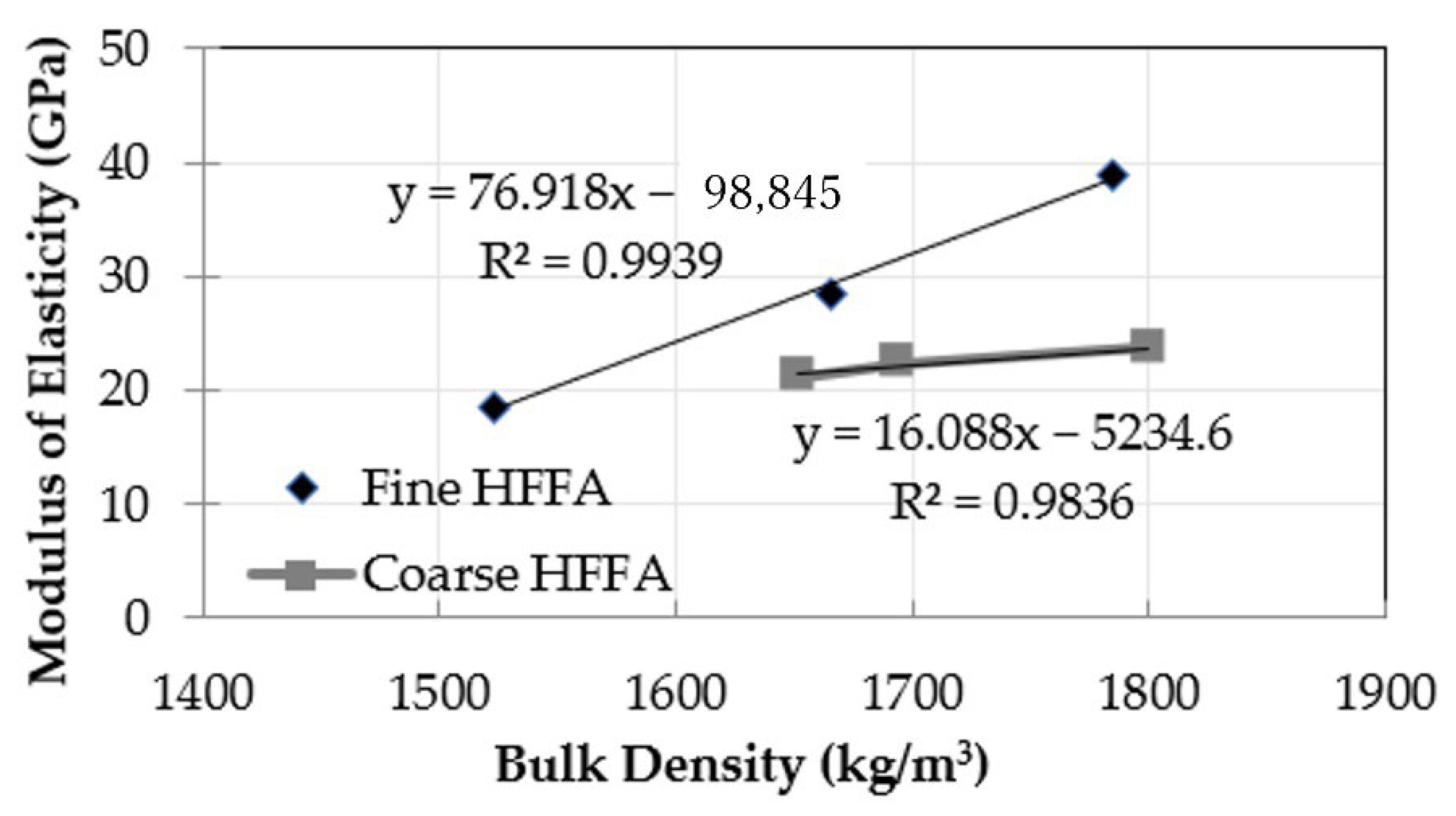

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rubenstein, M. Emissions from the Cement Industry. 2012. Available online: https://news.climate.columbia.edu/2012/05/09/emissions-from-the-cement-industry/ (accessed on 8 November 2022).

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly Ash Application as Supplementary Cementitious Material: A Review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef] [PubMed]

- Onyelowe, K.C.; Kontoni, D.-P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings 2022, 12, 948. [Google Scholar] [CrossRef]

- ACI Committee 232. Use of Fly Ash in Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Kagadgar, S.A.; Saha, S.; Rajasekaran, C. Mechanical and Durability Properties of Fly Ash Based Concrete Exposed to Marine Environment. Sel. Sci. Pap.-J. Civ. Eng. 2017, 12, 7–18. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.D.; Fahim, A. Performance of high-volume fly ash concrete in marine environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Badar, S.; Kupwade-Patil, K.; Bernal, S.A.; Provis, J.; Allouche, E.N. Corrosion of steel bars induced by accelerated carbonation in low and high calcium fly ash geopolymer concretes. Constr. Build. Mater. 2014, 61, 79–89. [Google Scholar] [CrossRef]

- Dave, N.; Misra, A.K.; Srivastava, A.; Kaushik, S.K. Setting time and standard consistency of quaternary binders: The influence of cementitious material addition and mixing. Int. J. Sustain. Built Environ. 2017, 6, 30–36. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The Effect of Fly Ash Properties on Concrete Strength. J. South Afr. Inst. Civ. Eng. 2003, 45, 19–24. [Google Scholar]

- Chousidis, N.; Rakanta, E.; Ioannou, I.; Batis, G. Mechanical properties and durability performance of reinforced concrete containing fly ash. Constr. Build. Mater. 2015, 101, 810–817. [Google Scholar] [CrossRef]

- Chousidis, N.; Ioannou, I.; Rakanta, E.; Koutsodontis, C.; Batis, G. Effect of fly ash chemical composition on the reinforcement corrosion, thermal diffusion and strength of blended cement concretes. Constr. Build. Mater. 2016, 126, 86–97. [Google Scholar] [CrossRef]

- American Coal Ash Association. Fly Ash Facts for Highway Engineers. J. Chem. Inf. Model. 2013, 53, 1689–1699. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Fournier, B.; Folliard, K.J. Alkali-Aggregate Reactivity (AAR) Facts Book; United States Federal Highway Administration; Office of Pavement Technology: Washington, DC, USA, 2013. [Google Scholar]

- Concrete Society. The Use of GGBS and PFA in Concrete; Technical Report No. 40; Slough (UK); The Concrete Society Press: Wexham, UK, 1991. [Google Scholar]

- Barrow, R.S.; Hadchiti, K.M.; Carrasquillo, P.M.; Carrasquillo, R.L. Temperature Rise and Durability of Concrete Containing Fly Ash. In Third International Conference on the Use of Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete; Malhotra, V.M., Ed.; ACI SP-114; American Concrete Institute: Detroit, MI, USA, 1989; Volume 2, pp. 331–347. [Google Scholar]

- Anon, A. Investigation of the Pozzolanic Nature of Coal Ashes. Eng. News 1914, 71, 1334–1335. [Google Scholar]

- Davis, R.E.; Carlson, R.W.; Kelly, J.W.; Davis, H.E. Properties of Cements and Concretes Containing Fly Ash. J. Am. Concr. Institude 1937, 33, 577–611. [Google Scholar]

- Halstead, W.J. Use of Fly Ash in Concrete; Transportation Research Board, National Research Council: Washington, DC, USA, 1986; Volume 127. [Google Scholar]

- Timms, A.G.; Grieb, W.E. Use of Fly Ash in Concrete; American Society for Testing and Materials: Washington, DC, USA, 1956; pp. 1139–1160. [Google Scholar]

- Brink, R.H.; Halstead, W.J. Studies Relating to the Testing of Fly Ash for Use in Concrete; American Society for Testing and Materials: Washington, DC, USA, 1956; Volume 56, pp. 1161–1214. [Google Scholar]

- Malhotra, V.M. Superplasticized Fly Ash Concrete for Structural Applications. Concr. Int. 1986, 8, 28–31. [Google Scholar]

- Bilodeau, A.; Malhotra, V.M. High-Volume Fly Ash System: Concrete Solution for Sustainable Development. ACI Mater. J. 2000, 97, 41–48. [Google Scholar]

- Mehta, P.K. High-Performance, High-Volume Fly Ash Concrete for Sustainable Development. In Proceedings of the International Workshop on Sustainable Development and Concrete Technology, Beijing, China, 20–21 May 2004; pp. 3–14. [Google Scholar]

- Malhotra, V.M.; Mehta, P.K. High-Performance, High-Volume Fly Ash Concrete. Concr. Int. 2002, 24, 30–34. [Google Scholar]

- National Research Council of the National Academies. Managing Coal Combustion Residues in Mines; Committee on Mine Placement of Coal Combustion Wastes; National Academies Press: Washington, DC, USA, 2006. [Google Scholar]

- U.S. Environmental Protection Agency, Office of Solid Waste. Human and Ecological Risk Assessment of Coal Combustion Wastes. 2007. Available online: https://grist.org/wp-content/uploads/2011/02/epa-coal-combustion-waste-risk-assessment.pdf (accessed on 5 May 2022).

- Vitolo, S.; Seggiani, M.; Filippi, S.; Brocchini, C. Recovery of vanadium from heavy oil and Orimulsion fly ashes. Hydrometallurgy 2000, 57, 141–149. [Google Scholar] [CrossRef]

- Al-Degs, Y.S.; Ghrir, A.; Khoury, H.; Walker, G.M.; Sunjuk, M.; Al-Ghouti, M.A. Characterization and utilization of fly ash of heavy fuel oil generated in power stations. Fuel Process. Technol. 2014, 123, 41–46. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Baig, M.G.; Al-Malack, M.H.; Al-Amoudi, O.S.B. Study of heavy fuel oil fly ash for use in concrete blocks and asphalt concrete mixes. Adv. Concr. Constr. 2016, 4, 123–143. [Google Scholar] [CrossRef]

- Camilleri, J.; Anastasi, M.; Torpiano, A. The microstructure and physical properties of heavy oil fuel ash replaced Portland cement for use in flowable fill concrete and the production of concrete masonry units. Constr. Build. Mater. 2013, 38, 970–979. [Google Scholar] [CrossRef]

- Desjardins, J. Europe’s Electricity Production by Country and Fuel Type. Available online: http://www.visualcapitalist.com/europes-electricity-production-by-country-and-fuel-type (accessed on 10 May 2022).

- Al-Malack, M.; Bukhari, A.; Al-Amoudi, O.; Al-Muhanna, H.; Zaidi, T. Characteristics of Fly ash Produced at Power and Water Desalination Plants Firing Fuel Oil. Int. J. Environ. Res. 2013, 7, 455–466. [Google Scholar] [CrossRef]

- Hassan, M.I.H.; Kadir, A.A.; Mohd Kamil, N.A.F.; Hashar, N.N.H.; Sarani, N.A.; Ibrahim, B.; Salleh, K.M.; Abdullah, M.M.A.B. Mechanical properties and toxicity characteristics of petroleum sludge incorporated with palm oil fuel ash and quarry dust in solidification/stabilization matrices. Arch. Metall. Mater. 2022, 67, 1259–1266. [Google Scholar]

- Chen, Q.; Tyrer, M.; Hills, C.; Yang, X.; Carey, P. Immobilisation of heavy metal in cement-based solidification/stabilisation: A review. Waste Manag. 2009, 29, 390–403. [Google Scholar] [CrossRef] [PubMed]

- Daous, M. Utilization of Cement Kiln Dust and Fly Ash in Cement Blends in Saudi Arabia. J. King Abdulaziz Univ. Eng. Sci. 2004, 15, 33–45. [Google Scholar] [CrossRef]

- Rybowicz, P.; Mochnaczewski, M.; Kozieł, M.; Uruski, L.; Łagosz, A.; Michalik, M.; Chmielarz, L.; Adamski, A. Key Parameters of Fly Ashes Generated from the Industrial Energy Sector Decisive for Their Pro-ecological Applications. Energy Fuels 2020, 34, 6229–6238. [Google Scholar] [CrossRef]

- Basha, S.I.; Aziz, A.; Maslehuddin, M.; Ahmad, S.; Hakeem, A.S.; Rahman, M.M. Characterization, Processing, and Application of Heavy Fuel Oil Ash, an Industrial Waste Material—A Review. Chem. Rec. 2020, 20, 1568–1595. [Google Scholar] [CrossRef]

- Al-Slaty, F.; Al-Dabsheh, I.; Odeh, T. Characteristics of Residual Oil Fly Ash and Their Utility for Construction Purposes. Kuwait J. Sci. 2019, 46, 83–89. [Google Scholar]

- Alshaaer, M.; Fahmy, T.; Shqair, M.; Al-Kafawein, J. Production of Heavy Fuel Oil Fly Ash (HFO)-Based Geopolymers for Passive Cooling Systems. Int. J. Appl. Eng. Res. 2018, 13, 134–140. [Google Scholar]

- Evagorou, K.; Dimitriou, A.; Tsamatsoulis, D. Technical Mathematical Relations of Concrete Compressive Strength to Cement. In Proceedings of the 15th Concrete Conference, Alexandroupoli, Greece, 25–27 October 2006; pp. 25–27. [Google Scholar]

- Georgiou, A.V.; Pantazopoulou, S.J. Effect of fiber length and surface characteristics on the mechanical properties of cementitious composites. Constr. Build. Mater. 2016, 125, 1216–1228. [Google Scholar] [CrossRef]

- Fischer, G.; Wang, S.; Li, V.C. Design of Engineered Cementitious Composites (ECC) for Processing and Workability Re-quirements. In Brittle Matrix Composites 7; Woodhead Publishing: Sawston, UK, 2003. [Google Scholar]

- Fuller, W.B.; Thompson, S.E. The Laws of Proportioning Concrete. Trans. Am. Soc. Civ. Eng. 1907, 59, 67–143. [Google Scholar] [CrossRef]

- Hanehara, S.; Oyamada, T. Reproduction of Delayed Ettringite Formation (DEF) in concrete And Relationship between DEF and Alkali Silica Reaction; Korea Concrete Institute: Seoul, Korea, 2010; pp. 1024–1029. [Google Scholar]

- Ingham, J.P. Concrete. In Geomaterials Under the Microscope; Ingham, J.P., Ed.; Academic Press: Boston, MA, USA, 2013; pp. 75–120. [Google Scholar]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete. Pearson Education; Prentice-Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese., W.C. Design and Control of Concrete Mixtures; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- FIB Model Code. Model Code 2010; Federation Internationale du Beton (fib). 2010. Available online: https://www.fib-international.org/publications/fib-bulletins/model-code-2010-first-complete-draft-vol-2-book-144-detail.html (accessed on 8 July 2022).

- Hall, C.; Hoff, W.D. Water Transport in Brick, Stone and Concrete; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Nath, P.; Sarker, P. Effect of Fly Ash on the Durability Properties of High Strength Concrete. Procedia Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Thiebaut, Y.; Multon, S.; Sellier, A.; Lacarrière, L.; Boutillon, L.; Belili, D.; Linger, L.; Cussigh, F.; Hadji, S. Effects of stress on concrete expansion due to delayed ettringite formation. Constr. Build. Mater. 2018, 183, 626–641. [Google Scholar] [CrossRef]

- Diamond, S. Delayed ettringite formation—Processes and problems. Cem. Concr. Compos. 1996, 18, 205–215. [Google Scholar] [CrossRef]

- Mehta, P. Mechanism of expansion associated with ettringite formation. Cem. Concr. Res. 1973, 3, 1–6. [Google Scholar] [CrossRef]

- Sicakova, A.; Draganovska, M.; Kovac, M. Water Absorption Coefficient as a Performance Characteristic of Building Mixes Containing Fine Particles of Selected Recycled Materials. Procedia Eng. 2017, 180, 1256–1265. [Google Scholar] [CrossRef]

- Fetter, C.W. Applied Hydrogeology, 3rd ed.; Macmillan College Publishing: New York, NY, USA, 1994. [Google Scholar]

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- Kosior-Kazberuk, M.; Lelusz, M. Strength development of concrete with fly ash addition. J. Civ. Eng. Manag. 2007, 13, 115–122. [Google Scholar] [CrossRef]

- Upadhyay, R.; Srivastava, V.; Herbert, A.; Mehta, P.K. Effect of Fly Ash on Flexural Strength of Portland Pozzolona Cement Concrete. J. Acad. Ind. Res. 2014, 3, 218–220. [Google Scholar]

- Chen, X.; Wu, S.; Zhou, J. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Rossler, M.; Odler, I. Investigations on the Relationship between Porosity, Structure and Strength of Hydrated Portland-Cement Pastes I. Effect of Porosity. Cem. Concr. Res. 1985, 15, 320–330. [Google Scholar]

| Sieve (mm) | <0.063 | 0.063–0.1 | 0.1–0.2 | 0.2–0.315 |

|---|---|---|---|---|

| Material retained (%) | 1 | 7.5 | 86 | 5.5 |

| Elements (%) | Class F | HFFA |

|---|---|---|

| LOI | 2.31 | 67.35 |

| SiO2 | 55.1 | 11.8 |

| Al2O3 | 24.7 | 5.53 |

| Fe2O3 | 6.65 | 22 |

| CaO | 4.35 | 1.66 |

| MgO | 1.49 | 0.39 |

| Na2O | 2.57 | 1.91 |

| K2O | 2.02 | 0.39 |

| SO3 | 1.23 | 46.5 |

| Sb2O3 | - | 0.26 |

| TiO2 | 0.96 | 0.2 |

| BaO | 0.37 | 0.21 |

| P2O5 | 0.27 | 0.35 |

| SrO | 0.13 | 340 ppm |

| Co3O4 | - | 0.21 |

| V2O5 | 290 ppm | 4.39 |

| MnO | 280 ppm | 0.19 |

| ZnO | 210 ppm | 0.14 |

| NiO | 120 ppm | 3.63 |

| Name | Cement | Class F FA | HFFA (d < 300 μm) | HFFA (300 μm < d < 1 mm) | Sand | Water | SP | T (°C) | Demolding Time (Days) |

|---|---|---|---|---|---|---|---|---|---|

| PM | 3.16 | 3.80 | 2.53 | 1.74 | 0.038 | --- | 1 | ||

| M-5-F | 3.16 | 3.45 | 0.350 | 2.53 | 1.84 | 0.042 | 40 | 1 | |

| M-10-F | 3.16 | 3.10 | 0.696 | 2.53 | 2.24 | 0.068 | 48 | 2 | |

| M-15-F | 3.16 | 2.75 | 1.040 | 2.53 | 2.70 | 0.080 | 60 | 2 | |

| M-5-C | 3.16 | 3.45 | 0.350 | 2.53 | 1.94 | 0.038 | 38 | 1 | |

| M-10-C | 3.16 | 3.10 | 0.696 | 2.53 | 2.24 | 0.058 | 49 | 2 | |

| M-15-C | 3.16 | 2.75 | 1 | 2.53 | 2.25 | 0.065 | 51 | 2 |

| Method | Property | PM | Minimum | Maximum |

|---|---|---|---|---|

| Slump flow (mm) | Filling ability | 705 | 650 | 800 |

| T50 cm slump flow (sec) | Filling ability | 2 | 2 | 5 |

| L-box | Passing ability | 0.8 | 0.8 | 1.0 |

| U-box (mm) | Passing ability | 3 | 0 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgiou, A.; Chousidis, N.; Ioannou, I. Self-Compacting Cementitious Composites with Heavy Fuel Fly Ash Replacement. Constr. Mater. 2022, 2, 276-296. https://doi.org/10.3390/constrmater2040018

Georgiou A, Chousidis N, Ioannou I. Self-Compacting Cementitious Composites with Heavy Fuel Fly Ash Replacement. Construction Materials. 2022; 2(4):276-296. https://doi.org/10.3390/constrmater2040018

Chicago/Turabian StyleGeorgiou, Antroula, Nicolaos Chousidis, and Ioannis Ioannou. 2022. "Self-Compacting Cementitious Composites with Heavy Fuel Fly Ash Replacement" Construction Materials 2, no. 4: 276-296. https://doi.org/10.3390/constrmater2040018

APA StyleGeorgiou, A., Chousidis, N., & Ioannou, I. (2022). Self-Compacting Cementitious Composites with Heavy Fuel Fly Ash Replacement. Construction Materials, 2(4), 276-296. https://doi.org/10.3390/constrmater2040018