A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction

Abstract

:1. Introduction

Types of Lightweight Aggregate

- Pumice: It forms from the supercooled liquid of lava, which contains mainly SiO2, erupted from volcanoes, and its low density is due to the occurrence of gas bubbles inside it.

- Palm oil shells: It is a waste by-product generated by oil industries while extracting oil from palm shells.

- Perlite: In Japan, a new lightweight aggregate has been developed using perlite, which is called Asano super sight.

- Lightweight aggregates from the treatment of natural aggregates: The clay or shale is heated in a kiln at a high temperature, which causes the material to expand to make it lightweight.

- Expanded clays and shales—This is capable of achieving sufficiently high strength for prestressed concrete.

- Sintered pulverized—It is developed from fuel ash aggregate and used in varied structural use, and its trade name is Lytag in the market.

2. Fresh Concrete Properties

3. Hardened Properties

3.1. Compressive Strength

3.2. Splitting Tensile Strength

3.3. Flexure Strength

3.4. Modulus of Elasticity

3.5. Ultrasonic Pulse Velocity

4. Durability Properties

4.1. Drying Shrinkage

4.2. Water Absorption

4.3. Water Permeability

4.4. Chloride Penetration

4.5. Carbonation

4.6. Fire Resistance

4.7. Freeze-Thaw Resistance

4.8. Summary of Durability Properties

5. Environmental Life Cycle Assessment

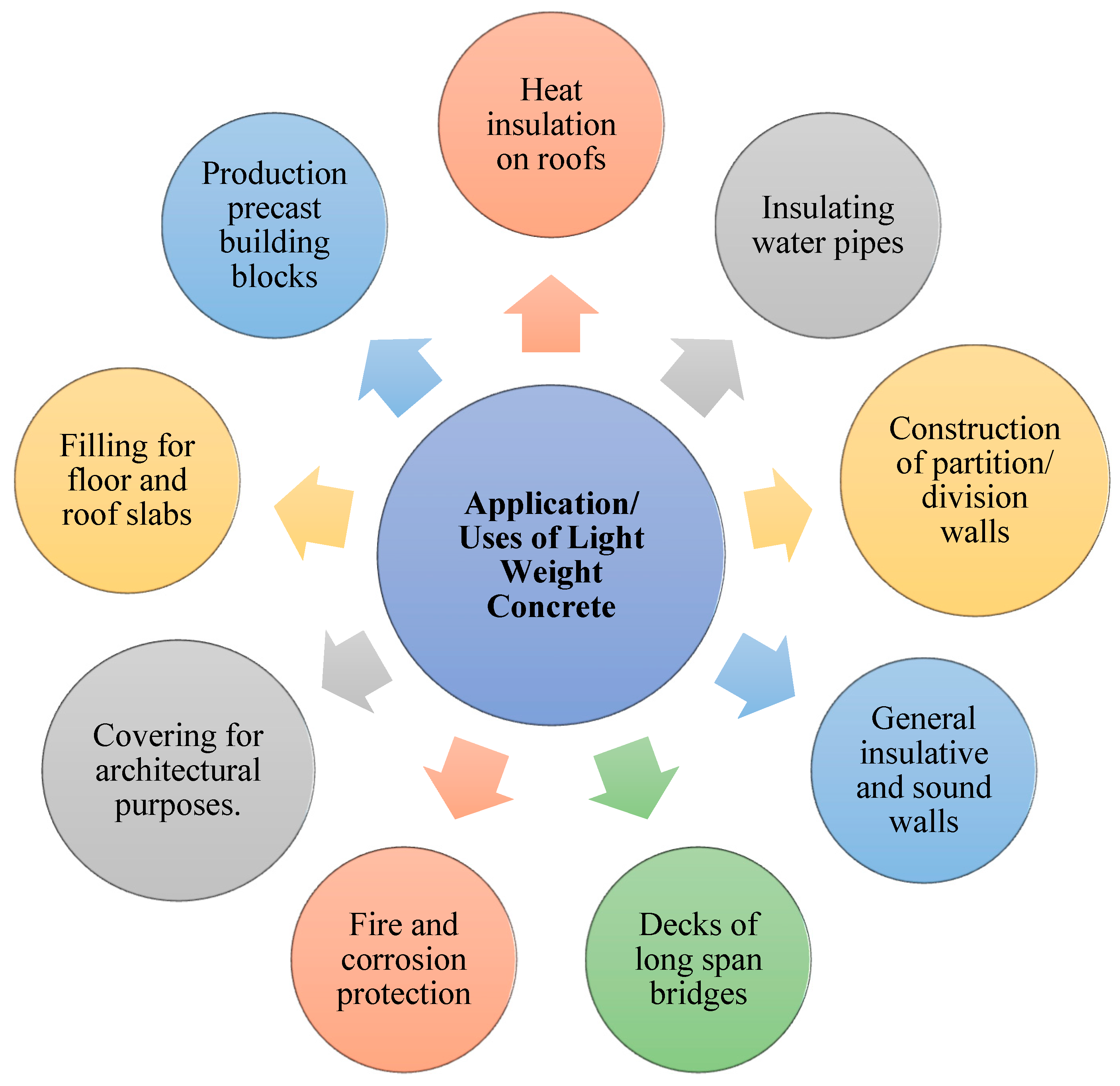

6. General Application of Lightweight Concrete

7. Concluding Remarks

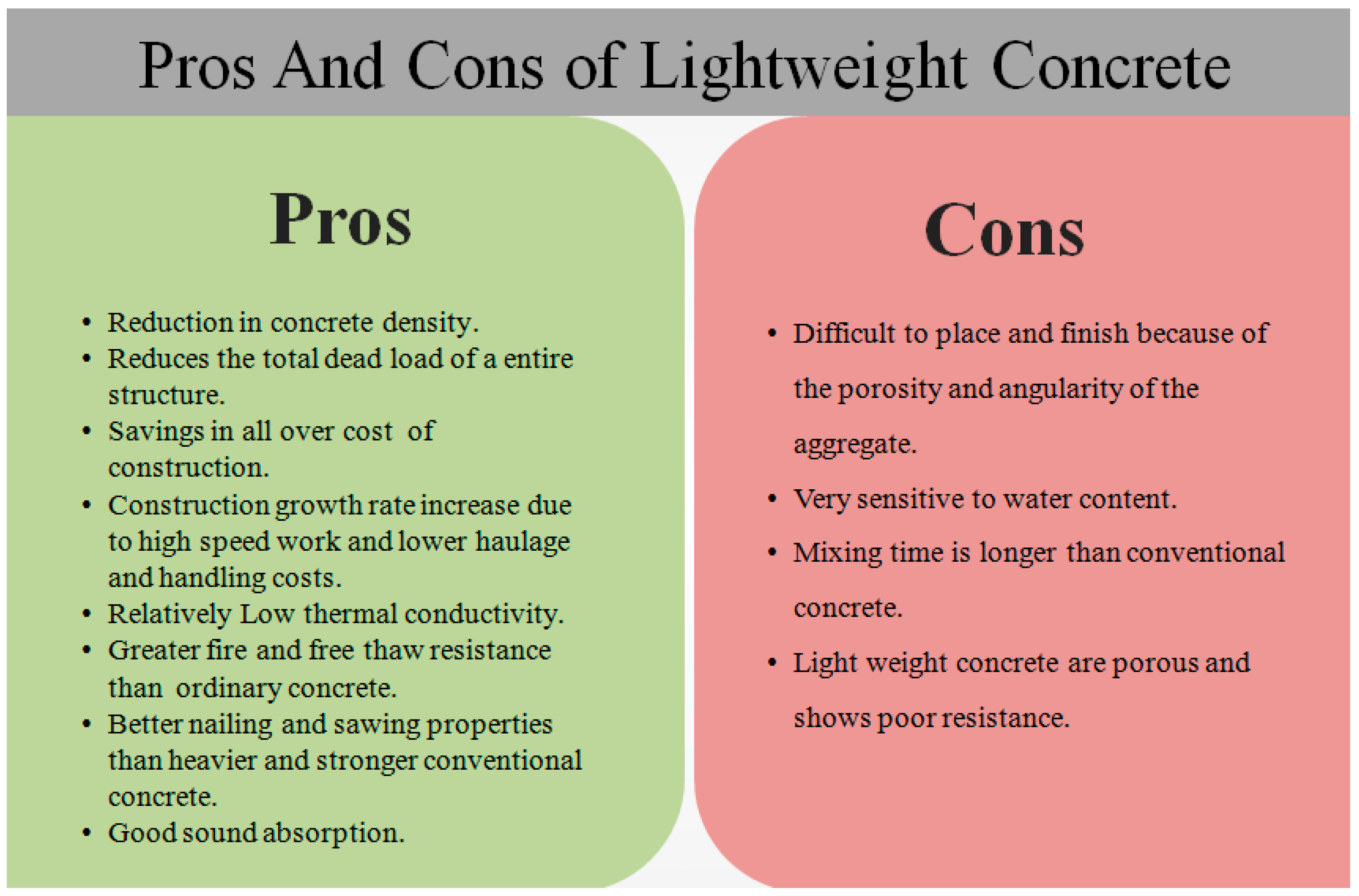

- Based on the various research article results subjected to varied aggregates in use of LWAC, it can be concluded that the utilization of different aggregate or waste demonstrates incredible results in terms of sustainable lightweight aggregate concrete production. The density of the normal concrete will be reduced with the use of the different lightweight aggregate. The addition of the lightweight aggregate in normal concrete significantly reduces the dead load of the structure.

- The fresh properties of the lightweight concrete showed that the inclusion of the different lightweight aggregate appears to be reduced, but it may also be seen that the fresh properties of the lightweight concrete can be improved by using the different admixtures and pre-treatment on the various lightweight aggregate.

- According to the study, it can also be concluded that the use of a different type of lightweight aggregate and waste material in LWAC decreases the mechanical properties of concrete. With the inclusion of supplementary cementitious material and modification/pre-treatment of lightweight aggregate, the mechanical properties can be improved.

- The incorporation of the different lightweight aggregate in the lightweight concrete generally decreased the concrete’s durability properties.

- The use of lightweight aggregate in structural concrete will help in productivity and in improving the initial and long-term performance of concrete and service life of the structure with environmental sustainability.

- Finally, the use of different waste materials in lightweight concrete production will lower the lightweight aggregate concrete cost.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mathew, B.J.; Sudhakar, M.; Natarajan, C. Strength, Economic and Sustainability Characteristics of Coal Ash—GGBS Based Geopolymer Concrete. Int. J. Comput. Eng. Res. 2013, 3, 207–212. [Google Scholar]

- Ferrari, G.; Miyamoto, M.; Ferrari, A. New sustainable technology for recycling returned concrete. Constr. Build. Mater. 2014, 67, 353–359. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Chouhan, D.S.; Agrawal, Y.; Gupta, T.; Sharma, R.K. Utilization of Granite Slurry Waste in Concrete: A Review. Indian J. Sci. Technol. 2017, 10, 1–9. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Bicer, A.; Kar, F. The effects of apricot resin addition to the light weight concrete with expanded polystyrene. J. Adhes. Sci. Technol. 2017, 31, 2335–2348. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Johari, M.A.M.; Tayeh, B.A.; Yusuf, M.O. Pozzolanic reactivity of ultrafine palm oil fuel ash waste on strength and durability performances of high strength concrete. J. Clean. Prod. 2017, 144, 511–522. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J. Clean. Prod. 2016, 112, 702–711. [Google Scholar] [CrossRef]

- Agrawal, Y.; Siddique, S.; Sharma, R.K.; Gupta, T. Valorization of granite production dust in development of rich and lean cement mortar. J. Mater. Cycles Waste Manag. 2021, 23, 686–698. [Google Scholar] [CrossRef]

- Ismail, H.B.; Mahmud, K.; Daniel; Anuar, N.H.; Azman, N.S.; Wahab, M.A.A.; Ibrahim, M.J.M.; Saripudin, S.S.; Nawi, N.M.; Jamal, M.H. Evaluation on the mechanical properties of concrete using clay Brick as Sand substituation. Int. J. Eng. Technol. 2018, 7, 406–407. [Google Scholar]

- Upadhyay, D.K.; Jamle, S. A Review on Stability Improvement with wall belt Supported dual Structural System using different Grades of Concrete. Int. J. Adv. Eng. Res. Sci. 2020, 7, 293–296. [Google Scholar] [CrossRef] [Green Version]

- Farahani, J.N.; Shafigh, P.; Bin Mahmud, H. Production of A Green Lightweight Aggregate Concrete by Incorporating High Volume Locally Available Waste Materials. Procedia Eng. 2017, 184, 778–783. [Google Scholar] [CrossRef]

- Jo, B.-W.; Park, S.-K.; Park, J.-B. Properties of concrete made with alkali-activated fly ash lightweight aggregate (AFLA). Cem. Concr. Compos. 2007, 29, 128–135. [Google Scholar] [CrossRef]

- Mo, K.H.; Ling, T.-C.; Alengaram, U.J.; Yap, S.P.; Yuen, C.W. Overview of supplementary cementitious materials usage in lightweight aggregate concrete. Constr. Build. Mater. 2017, 139, 403–418. [Google Scholar] [CrossRef]

- Rahman, A.; Barai, A.; Sarker, A.; Moniruzzaman, M. Light weight concrete from rice husk ash and glass powder. Bangladesh J. Sci. Ind. Res. 2018, 53, 225–232. [Google Scholar] [CrossRef] [Green Version]

- Oreshkin, D.; Semenov, V.; Rozovskaya, T. Properties of Light-weight Extruded Concrete with Hollow Glass Microspheres. Procedia Eng. 2016, 153, 638–643. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Chia, K.; Zhang, M. Development of lightweight aggregate concrete with high resistance to water and chloride-ion penetration. Cem. Concr. Compos. 2010, 32, 757–766. [Google Scholar] [CrossRef]

- Bogas, J.A.; De Brito, J.; Cabaço, J. Long-term behaviour of concrete produced with recycled lightweight expanded clay aggregate concrete. Constr. Build. Mater. 2014, 65, 470–479. [Google Scholar] [CrossRef]

- Libre, N.A.; Shekarchi, M.; Mahoutian, M.; Soroushian, P. Mechanical properties of hybrid fiber reinforced lightweight aggregate concrete made with natural pumice. Constr. Build. Mater. 2011, 25, 2458–2464. [Google Scholar] [CrossRef]

- Mo, K.H.; Anor, F.A.M.; Alengaram, U.J.; Jumaat, M.Z.; Rao, K.J. Properties of metakaolin-blended oil palm shell lightweight concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 852–868. [Google Scholar] [CrossRef]

- Parra, C.; Sánchez, E.M.; Miñano, I.; Benito, F.; Hidalgo, P. Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production. Sustainability 2019, 11, 1876. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Gao, J.; Chen, F.; Liu, C.; Chen, X. Utilization of waste clay bricks as coarse and fine aggregates for the preparation of lightweight aggregate concrete. J. Clean. Prod. 2018, 201, 706–715. [Google Scholar] [CrossRef]

- Gupta, T.; Patel, K.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Prediction of mechanical properties of rubberised concrete exposed to elevated temperature using ANN. Meas. J. Int. Meas. 2019, 147, 106870. [Google Scholar] [CrossRef]

- Bahsandy, A.A.; Eid, F.M.; Abdou, E.H. Lightweight Concrete Cast Using Recycled Aggregates. Int. J. Constr. Eng. Manag. 2017, 6, 35–45. [Google Scholar] [CrossRef]

- Gerritse, A. Design considerations for reinforced lightweight concrete. Int. J. Cem. Compos. Light. Concr. 1981, 3, 57–69. [Google Scholar] [CrossRef]

- Cavalline, T.L.; Castrodale, R.W.; Freeman, C.; Wall, J. Impact of Lightweight Aggregate on Concrete Thermal Properties. ACI Mater. J. 2017, 114, 945–956. [Google Scholar] [CrossRef]

- Lesovik, R.V.; Botsman, L.N.; Tarasenko, V.N.; Botsman, A.N. Enhancement of sound insulation of floors using light-weight concrete based on nanostructured granular aggregate. ARPN J. Eng. Appl. Sci. 2014, 9, 1789–1793. [Google Scholar]

- Yu, S.J.; Wang, Y.L.; Duan, B.J.; Zhou, J.W.; Yang, F.; Wang, X.G.; Liang, D.L. Fireproof Performance of Foam Concrete Insulation Board. Adv. Mater. Res. 2011, 250, 474–479. [Google Scholar] [CrossRef]

- Yun, T.S.; Jeong, Y.J.; Han, T.-S.; Youm, K.-S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

- Miller, N.M.; Tehrani, F.M. Mechanical properties of rubberized lightweight aggregate concrete. Constr. Build. Mater. 2017, 147, 264–271. [Google Scholar] [CrossRef]

- Topçu, I.B. Semi lightweight concretes produced by volcanic slags. Cem. Concr. Res. 1997, 27, 15–21. [Google Scholar] [CrossRef]

- Kunchala, A.; Tangudu, M. Study on Strength Properties of Lightweight Expanded Clay Aggregate Concrete. I-Manager’s J. Struct. Eng. 2019, 7. [Google Scholar] [CrossRef]

- Guneyisi, E.; Gesoğlu, M.; Ghanim, H.; Ipek, S.; Taha, I. Influence of the artificial lightweight aggregate on fresh properties and compressive strength of the self-compacting mortars. Constr. Build. Mater. 2016, 116, 151–158. [Google Scholar] [CrossRef]

- Yu, Q.L.; Glas, D.J.; Brouwers, H.J.H. Effects of Hydrophobic Expanded Silicate Aggregates on Properties of Structural Lightweight Aggregate Concrete. J. Mater. Civ. Eng. 2020, 32, 06020006. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B.; Shah, S.F.A. Investigate the influence of expanded clay aggregate and silica fume on the properties of lightweight concrete. Constr. Build. Mater. 2019, 220, 253–266. [Google Scholar] [CrossRef]

- Adem, H.; Athab, E.; Thamer, S.; Jasim, A. The Behavior of Lightweight Aggregate Concrete Made with Different Types of Crushed Bricks; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 584. [Google Scholar] [CrossRef] [Green Version]

- Kurt, M.; Gül, M.S.; Gül, R.; Aydin, A.C.; Kotan, T. The effect of pumice powder on the self-compactability of pumice aggregate lightweight concrete. Constr. Build. Mater. 2016, 103, 36–46. [Google Scholar] [CrossRef]

- He, K.-C.; Guo, R.-X.; Ma, Q.-M.; Yan, F.; Lin, Z.-W.; Sun, Y.-L. Experimental Research on High Temperature Resistance of Modified Lightweight Concrete after Exposure to Elevated Temperatures. Adv. Mater. Sci. Eng. 2016, 2016, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Polat, R.; Demirboğa, R.; Karakoç, M.B.; Türkmen, I. The influence of lightweight aggregate on the physico-mechanical properties of concrete exposed to freeze–thaw cycles. Cold Reg. Sci. Technol. 2010, 60, 51–56. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Du, Q.; Li, K. Experimental and analytical study on uniaxial compressive fatigue behavior of self-compacting rubber lightweight aggregate concrete. Constr. Build. Mater. 2020, 237. [Google Scholar] [CrossRef]

- Colangelo, F.; Farina, I. Lightweight concrete with polyolefins as aggregates. In Use of Recycled Plastics in Eco-Efficient Concrete; Woodhead Publishing: Cambridge, UK, 2019; pp. 167–187. [Google Scholar]

- Ahmad, H.H.; Tavio. Experimental study of cold—Bonded artificial lightweight aggregate concrete. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2018; Volume 1977, p. 030011. [Google Scholar]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Ben Fraj, A.; Kismi, M.; Mounanga, P. Valorization of coarse rigid polyurethane foam waste in lightweight aggregate concrete. Constr. Build. Mater. 2010, 24, 1069–1077. [Google Scholar] [CrossRef] [Green Version]

- Chia, K.S.; Zhang, M.-H. Water permeability and chloride penetrability of high-strength lightweight aggregate concrete. Cem. Concr. Res. 2002, 32, 639–645. [Google Scholar] [CrossRef]

- Zhang, B.; Poon, C.S. Use of Furnace Bottom Ash for producing lightweight aggregate concrete with thermal insulation properties. J. Clean. Prod. 2015, 99, 94–100. [Google Scholar] [CrossRef]

- Kockal, N.U.; Ozturan, T. Effects of lightweight fly ash aggregate properties on the behavior of lightweight concretes. J. Hazard. Mater. 2010, 179, 954–965. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Mannan, M.; Ganapathy, C. Concrete from an agricultural waste-oil palm shell (OPS). Build. Environ. 2004, 39, 441–448. [Google Scholar] [CrossRef]

- Senhadji, Y.; Escadeillas, G.; Benosman, A.; Mouli, M.; Khelafi, H.; Kaci, S.O. Effect of incorporating PVC waste as aggregate on the physical, mechanical, and chloride ion penetration behavior of concrete. J. Adhes. Sci. Technol. 2015, 29, 625–640. [Google Scholar] [CrossRef]

- Piyaphanuwat, R.; Asavapisit, S. Utilization Ceramic Wastes from Porcelain Ceramic Industry in Lightweight Aggregate Concrete. Int. J. Environ. Sci. Dev. 2017, 8, 342–346. [Google Scholar] [CrossRef] [Green Version]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Durability properties of sustainable concrete containing high volume palm oil waste materials. J. Clean. Prod. 2016, 137, 167–177. [Google Scholar] [CrossRef]

- Pal, D.R.; Behera, J.P.; Nayak, B.D. Relevance and Assessment of Fly Ash-Based Sintered Aggregate in the Design of Bricks, Blocks and Concrete. Lect. Notes Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Nomeli, M.A.; Jumaat, M.Z. Manufacturing of high-strength lightweight aggregate concrete using blended coarse lightweight aggregates. J. Build. Eng. 2017, 13, 53–62. [Google Scholar] [CrossRef]

- Shafigh, P.; Chai, L.J.; Bin Mahmud, H.; Nomeli, M.A. A comparison study of the fresh and hardened properties of normal weight and lightweight aggregate concretes. J. Build. Eng. 2018, 15, 252–260. [Google Scholar] [CrossRef]

- Ahmed, H.K.; Khalil, W.I.; Subhi, M.D. Mechanical properties of fiberous high performance lightweight aggregate Concrete. Eng. Technol. J. 2017, 35, 229–238. [Google Scholar]

- Adebakin, I.H.; Gunasekaran, K.; Annadurai, R. Mix design and rheological properties of self-compacting coconut shell aggregate concrete. ARPN J. Eng. Appl. Sci. 2018, 13, 1465–1475. [Google Scholar]

- Real, S.; Bogas, J.A.; Gomes, M.D.G.; Ferrer, B. Thermal conductivity of structural lightweight aggregate concrete. Mag. Concr. Res. 2016, 68, 798–808. [Google Scholar] [CrossRef]

- Ridtirud, C. Properties of Lightweight Aerated Geopolymer Synthesis from High-Calcium Fly Ash and Aluminium Powder. Int. J. GEOMATE 2019, 16. [Google Scholar] [CrossRef]

- Kılıç, A.; Atiş, C.D.; Yaşar, E.; Özcan, F. High-strength lightweight concrete made with scoria aggregate containing mineral admixtures. Cem. Concr. Res. 2003, 33, 1595–1599. [Google Scholar] [CrossRef]

- Saxena, R.; Siddique, S.; Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr. Build. Mater. 2018, 176, 415–421. [Google Scholar] [CrossRef]

- Demirdag, S.; Gunduz, L. Strength properties of volcanic slag aggregate lightweight concrete for high performance masonry units. Constr. Build. Mater. 2008, 22, 135–142. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef] [PubMed]

- Yasar, E.; Atis, C.D.; Kilic, A.; Gulsen, H. Strength properties of lightweight concrete made with basaltic pumice and fly ash. Mater. Lett. 2003, 57, 2267–2270. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Effect of aggressive environment on durability of concrete containing fibrous rubber shreds and silica fume. Struct. Concr. 2020. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr. Build. Mater. 2019, 217, 283–291. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Wee, T. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem. Concr. Res. 2005, 35, 1218–1223. [Google Scholar] [CrossRef]

- Demirboğa, R.; Gül, R. The effects of expanded perlite aggregate, silica fume and fly ash on the thermal conductivity of lightweight concrete. Cem. Concr. Res. 2003, 33, 723–727. [Google Scholar] [CrossRef]

- Topçu, I.B.; Uygunoğlu, T. Properties of autoclaved lightweight aggregate concrete. Build. Environ. 2007, 42, 4108–4116. [Google Scholar] [CrossRef]

- Akmal, A.Z.M.N.; Muthusamy, K.; Yahaya, F.M.; Hanafi, H.M.; Azzimah, Z.N. Utilization of fly ash as partial sand replacement in oil palm shell lightweight aggregate concrete. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 271, p. 012003. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Ghataora, G.; Dirar, S.; Khan, M.I.; Zafar, I. Experimental study to investigate the engineering and durability performance of concrete using synthetic aggregates. Constr. Build. Mater. 2018, 173, 350–358. [Google Scholar] [CrossRef] [Green Version]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Lachemi, M. Benefits of using blended waste coarse lightweight aggregates in structural lightweight aggregate concrete. J. Clean. Prod. 2016, 119, 108–117. [Google Scholar] [CrossRef]

- Numan, H.A.; Yaseen, M.H.; Al-Juboori, H.A.M.S. Comparison Mechanical Properties of Two Types of Light Weight Aggregate Concrete. Civ. Eng. J. 2019, 5, 1105–1118. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Elrahman, M.A.; Chung, S.-Y.; Stephan, D. Effect of different expanded aggregates on the properties of lightweight concrete. Mag. Concr. Res. 2019, 71, 95–107. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudžionis, Ž. Investigations on lightweight concrete prepared by combinations of rubber particles and expanded glass aggregate. In Proceedings of the 13th International Conference "Modern Building Materials, Structures and Techniques" (MBMST 2019); Vilnius Gediminas Technical University: Vilnius, Lithuania, 2019. [Google Scholar] [CrossRef]

- Wang, H.-Y.; Chen, B.-T.; Wu, Y.-W. A study of the fresh properties of controlled low-strength rubber lightweight aggregate concrete (CLSRLC). Constr. Build. Mater. 2013, 41, 526–531. [Google Scholar] [CrossRef]

- Ahmad, S.W.; Muthusamy, K.; Hashim, M.H.; Budiea, A.M.A.; Ariffin, N.F. Effect of Unground Palm Oil Fuel Ash as Partial Sand Replacement on Compressive Strength of Oil Palm Shell Lightweight Concrete; IOP Publishing: Bristol, UK, 2020; Volume 712, p. 2034. [Google Scholar] [CrossRef]

- Lv, J.; Du, Q.; Zhou, T.; He, Z.; Li, K. Fresh and Mechanical Properties of Self-Compacting Rubber Lightweight Aggregate Concrete and Corresponding Mortar. Adv. Mater. Sci. Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Güneyisi, E.; Gesoğlu, M.; Booya, E. Fresh properties of self-compacting cold bonded fly ash lightweight aggregate concrete with different mineral admixtures. Mater. Struct. 2012, 45, 1849–1859. [Google Scholar] [CrossRef]

- Ahmmad, R.; Jumaat, M.Z.; Alengaram, U.J.; Bahri, S.; Rehman, M.A.; bin Hashim, H. Performance evaluation of palm oil clinker as coarse aggregate in high strength lightweight concrete. J. Clean. Prod. 2016, 112, 566–574. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atiş, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part B Eng. 2013, 45, 721–726. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Du, Q.; Wu, H. Effects of rubber particles on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 2015, 91, 145–149. [Google Scholar] [CrossRef]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Wu, F.; Liu, C.; Sun, W.; Ma, Y.; Zhang, L. Effect of peach shell as lightweight aggregate on mechanics and creep properties of concrete. Eur. J. Environ. Civ. Eng. 2020. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, L.; Xu, J.; Li, Y. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr. Build. Mater. 2012, 27, 32–38. [Google Scholar] [CrossRef]

- Zhang, X.G.; Kuang, X.M.; Yang, J.H.; Wang, S.R. Experimental study on mechanical properties of lightweight concrete with shale aggregate replaced partially by nature sand. Electron. J. Struct. Eng. 2017, 17, 85–94. [Google Scholar]

- Muthusamy, K.; Zamri, N.A. Mechanical properties of oil palm shell lightweight aggregate concrete containing palm oil fuel ash as partial cement replacement. KSCE J. Civ. Eng. 2016. [Google Scholar] [CrossRef] [Green Version]

- Wu, F.; Liu, C.; Sun, W.; Zhang, L.; Ma, Y. Mechanical and Creep Properties of Concrete containing Apricot Shell Lightweight Aggregate. KSCE J. Civ. Eng. 2019, 23, 2948–2957. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater. 2011, 25, 1848–1853. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Nazreen, M.S.; Mohamed, R.N.; Ab Kadir, M.A.; Azillah, N.; Shukri, N.A.; Mansor, S.; Zamri, F. Characterization of lightweight concrete made of palm oil clinker aggregates. MATEC Web Conf. 2018, 250, 03002. [Google Scholar] [CrossRef]

- Santhosh Kumar, M.; Prasath Kumar, V.R.; Gunasekaran, K. Study on mechanical properties of high strength concrete using coconut shell as coarse aggregate. Int. J. Chem. Sci. 2016, 14, 247–256. [Google Scholar]

- Lo, T.Y.; Cui, H.; Memon, S.A.; Noguchi, T. Manufacturing of sintered lightweight aggregate using high-carbon fly ash and its effect on the mechanical properties and microstructure of concrete. J. Clean. Prod. 2016, 112, 753–762. [Google Scholar] [CrossRef] [Green Version]

- Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P. Structural Lightweight Concrete Containing Recycled Lightweight Concrete Aggregate. KSCE J. Civ. Eng. 2018, 22, 3077–3084. [Google Scholar] [CrossRef]

- Tajra, F.; Elrahman, M.A.; Lehmann, C.; Stephan, D. Properties of lightweight concrete made with core-shell structured lightweight aggregate. Constr. Build. Mater. 2019, 205, 39–51. [Google Scholar] [CrossRef]

- Hamada, H.M.; Yahaya, F.M.; Muthusamy, K.; Jokhio, G.A.; Humada, A.M. Fresh and hardened properties of palm oil clinker lightweight aggregate concrete incorporating Nano-palm oil fuel ash. Constr. Build. Mater. 2019, 214, 344–354. [Google Scholar] [CrossRef]

- Farahani, J.N.; Shafigh, P.; Alsubari, B.; Shahnazar, S.; Bin Mahmud, H. Engineering properties of lightweight aggregate concrete containing binary and ternary blended cement. J. Clean. Prod. 2017, 149, 976–988. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Andiç-Çakır, Ö.; Hızal, S. Influence of elevated temperatures on the mechanical properties and microstructure of self consolidating lightweight aggregate concrete. Constr. Build. Mater. 2012, 34, 575–583. [Google Scholar] [CrossRef]

- Gupta, T.; Siddique, S.; Sharma, R.K.; Chaudhary, S. Effect of elevated temperature and cooling regimes on mechanical and durability properties of concrete containing waste rubber fiber. Constr. Build. Mater. 2017, 137, 35–45. [Google Scholar] [CrossRef]

- Bogas, J.A.; De Brito, J.; Figueiredo, J.M. Mechanical characterization of concrete produced with recycled lightweight expanded clay aggregate concrete. J. Clean. Prod. 2015, 89, 187–195. [Google Scholar] [CrossRef]

- Shafigh, P.; Jumaat, M.Z.; Bin Mahmud, H.; Hamid, N.A.A. Lightweight concrete made from crushed oil palm shell: Tensile strength and effect of initial curing on compressive strength. Constr. Build. Mater. 2012, 27, 252–258. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z. Drying shrinkage behaviour of structural lightweight aggregate concrete containing blended oil palm bio-products. J. Clean. Prod. 2016, 127, 183–194. [Google Scholar] [CrossRef]

- Mannan, M.; Ganapathy, C. Engineering properties of concrete with oil palm shell as coarse aggregate. Constr. Build. Mater. 2002, 16, 29–34. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.S.; Zhang, M.-H. Water absorption, permeability, and resistance to chloride-ion penetration of lightweight aggregate concrete. Constr. Build. Mater. 2011, 25, 335–343. [Google Scholar] [CrossRef]

- Maghfouri, M.; Shafigh, P.; Ibrahim, Z.B.; Alimohammadi, V. Quality control of lightweight aggregate concrete based on initial and final water absorption tests. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 210, p. 12022. [Google Scholar] [CrossRef] [Green Version]

- Rossignolo, J.A.; Agnesini, M.V. Durability of polymer-modified lightweight aggregate concrete. Cem. Concr. Compos. 2004, 26, 375–380. [Google Scholar] [CrossRef]

- Hossain, K.; Ahmed, S.; Lachemi, M. Lightweight concrete incorporating pumice based blended cement and aggregate: Mechanical and durability characteristics. Constr. Build. Mater. 2011, 25, 1186–1195. [Google Scholar] [CrossRef]

- Ge, Y.; Kong, L.; Zhang, B.; Yuan, J. Effect of lightweight aggregate pre-wetting on microstructure and permeability of mixed aggregate concrete. J. Wuhan Univ. Technol. Sci. Ed. 2009, 24, 838–842. [Google Scholar] [CrossRef]

- Fazhou, W.; Shuguang, H.; Qingjun, D.; Yanzhou, P. Influence of mineral admixtures on the permeability of lightweight aggregate concrete. J. Wuhan Univ. Technol. Sci. Ed. 2005, 20, 115–118. [Google Scholar] [CrossRef]

- Gao, Y.; Cheng, L.; Gao, Z.; Guo, S. Effects of different mineral admixtures on carbonation resistance of lightweight aggregate concrete. Constr. Build. Mater. 2013, 43, 506–510. [Google Scholar] [CrossRef]

- Lo, T.; Tang, W.; Nadeem, A. Comparison of carbonation of lightweight concrete with normal weight concrete at similar strength levels. Constr. Build. Mater. 2008, 22, 1648–1655. [Google Scholar] [CrossRef]

- Haque, M.; Al-Khaiat, H.; Kayali, O. Strength and durability of lightweight concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

- CS (Chinese Standard) JGJ51-2002. Light-Weight Aggregate Concrete Technical Regulations, China Architecture and Building Press; Ministry of Construction of the People’s Republic of China: Beijing, China, 2002. [Google Scholar]

- Tanyildizi, H.; Coskun, A. Performance of lightweight concrete with silica fume after high temperature. Constr. Build. Mater. 2008, 22, 2124–2129. [Google Scholar] [CrossRef]

- Mao, J.; Ayuta, K. Freeze–Thaw Resistance of Lightweight Concrete and Aggregate at Different Freezing Rates. J. Mater. Civ. Eng. 2008, 20, 78–84. [Google Scholar] [CrossRef]

- Dong, W.; Shen, X.-D.; Xue, H.-J.; He, J.; Liu, Y. Research on the freeze-thaw cyclic test and damage model of Aeolian sand lightweight aggregate concrete. Constr. Build. Mater. 2016, 123, 792–799. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Napolano, L.; Menna, C.; Graziano, S.F.; Asprone, D.; D’Amore, M.; De Gennaro, R.; Dondi, M. Environmental life cycle assessment of lightweight concrete to support recycled materials selection for sustainable design. Constr. Build. Mater. 2016, 119, 370–384. [Google Scholar] [CrossRef]

- Ersan, Y.C.; Gulcimen, S.; Imis, T.N.; Saygin, O.; Uzal, N. Life cycle assessment of lightweight concrete containing recycled plastics and fly ash. Eur. J. Environ. Civ. Eng. 2020. [Google Scholar] [CrossRef]

| Authors | Material | Specific Gravity | Density (g/cm3) | Bulk Density (kg/m3) | Absorption (%) | Fineness Modulus |

|---|---|---|---|---|---|---|

| Choi et al. [43] | Polyethylene terephthalate (PET) bottles waste | – | 1.39 | 8.44 | 0.0 | 4.11 |

| Farj et al. [44] | Polyurethan foam waste | – | – | 21 | 13.9 | – |

| Chia and Zhang [45] | Expanded clay shale | – | 1.2 | 650 ± 25 | 7.3 | – |

| Zhang and Poon [46] | Expanded clay | – | – | 1192 | 9.41 | – |

| Kockal and Ozturan [47] | Fly ash pellets (Cold bonded) | 1.89 | – | 842 | 25.5 | – |

| Saikia and Brito [48] | PET-aggregate | – | 1.33 | 351 | 0.18 | – |

| Gunasekaran et al. [49] | Coconut shell | 1.05–1.20 | – | 650 | 24.00 | 6.26 |

| Mannan and Ganapathy. [50] | Oil palm shell | 1.17 | – | 590 | 23.32 | 6.24 |

| Senhadji et al. [51] | Polyvinylchloride (PVC) | – | 1.4 | 575 | 0.0 | 3.46 |

| Piyaphanuwat and Asavapisit [52] | Ceramic wastes (DWM) | 1.78 | – | 1016 | 41.27 | 2.44 |

| Islam et al. [53] | Oil palm shell | 1.25 | – | 684 | 18.70 | 5.94 |

| Bogas et al. [18] | Recycled lightweight concrete aggregates (RLCA) | – | 1.735 | 1000 | 15.7 | – |

| Pal et al. [54] | Fly ash sintered aggregate (Fly ash 2) | 1.77 | – | 835 | 12.0 | – |

| Aslam et al. [55] | Oil palm shell (OPS) | 1.19 | – | 610 | 20.5 | – |

| Aslam et al. [55] | Oil palm boiler clinker (OPBC) | 1.69 | – | 860 | 7.0 | |

| Shah et al. [56] | Oil palm boiler clinker (OPBC) | 1.9 | – | 1471 | 3.91 | 5.88 |

| Shafigh et al. [56] | Lightweight expanded clay aggregate (LECA) | 0.66 | – | 273 | 26.5 | 5.96 |

| Ahmed et al. [57] | Pumice (sand) | 2.3 | – | 964 | 3.75 | 2.56 |

| Ahmed et al. [57] | Pumice (Clay aggregate) | 2.53 | – | 571 | 6.0 | – |

| Adebakin et al. [58] | Coconut shell | 1.14 | – | 650 | 24.0 | 6.54 |

| Real et al. [59] | Leca | – | 1.076 | 624 | 15.8 | – |

| Real et al. [59] | Stalite | – | 1.483 | 760 | 3.6 | – |

| Real et al. [59] | Argex (2–4) | – | 0.669 | 377 | 21.4 | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.L.; Siddique, S. A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Constr. Mater. 2021, 1, 39-62. https://doi.org/10.3390/constrmater1010003

Agrawal Y, Gupta T, Sharma R, Panwar NL, Siddique S. A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Construction Materials. 2021; 1(1):39-62. https://doi.org/10.3390/constrmater1010003

Chicago/Turabian StyleAgrawal, Yash, Trilok Gupta, Ravi Sharma, Narayan Lal Panwar, and Salman Siddique. 2021. "A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction" Construction Materials 1, no. 1: 39-62. https://doi.org/10.3390/constrmater1010003

APA StyleAgrawal, Y., Gupta, T., Sharma, R., Panwar, N. L., & Siddique, S. (2021). A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Construction Materials, 1(1), 39-62. https://doi.org/10.3390/constrmater1010003