Image-Based Quantification of Soil Disturbance in Vane Shear Tests on Reconstituted Kaolinitic Clayey Soil

Abstract

1. Introduction

2. Background

2.1. Vane Shear Test (VST)

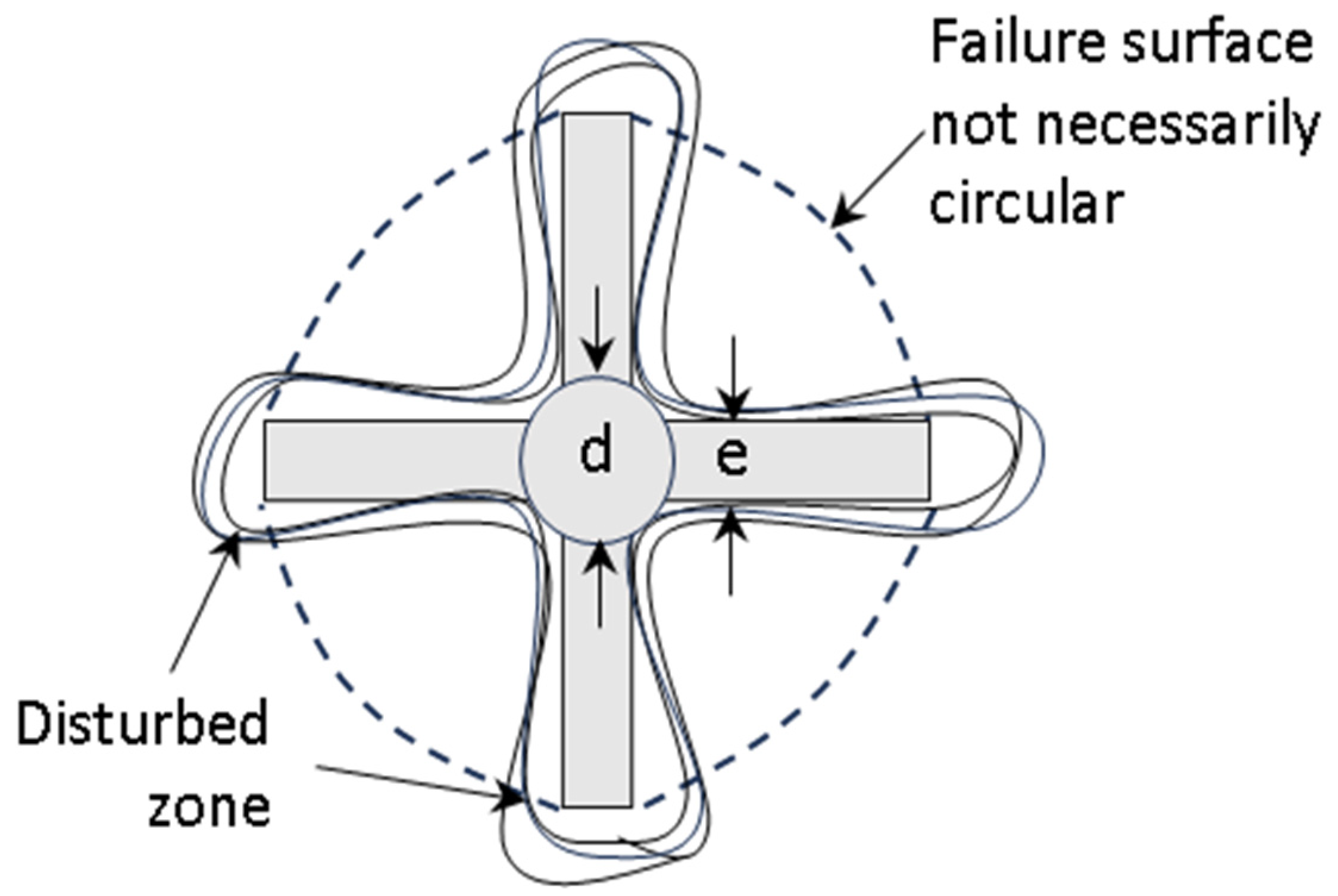

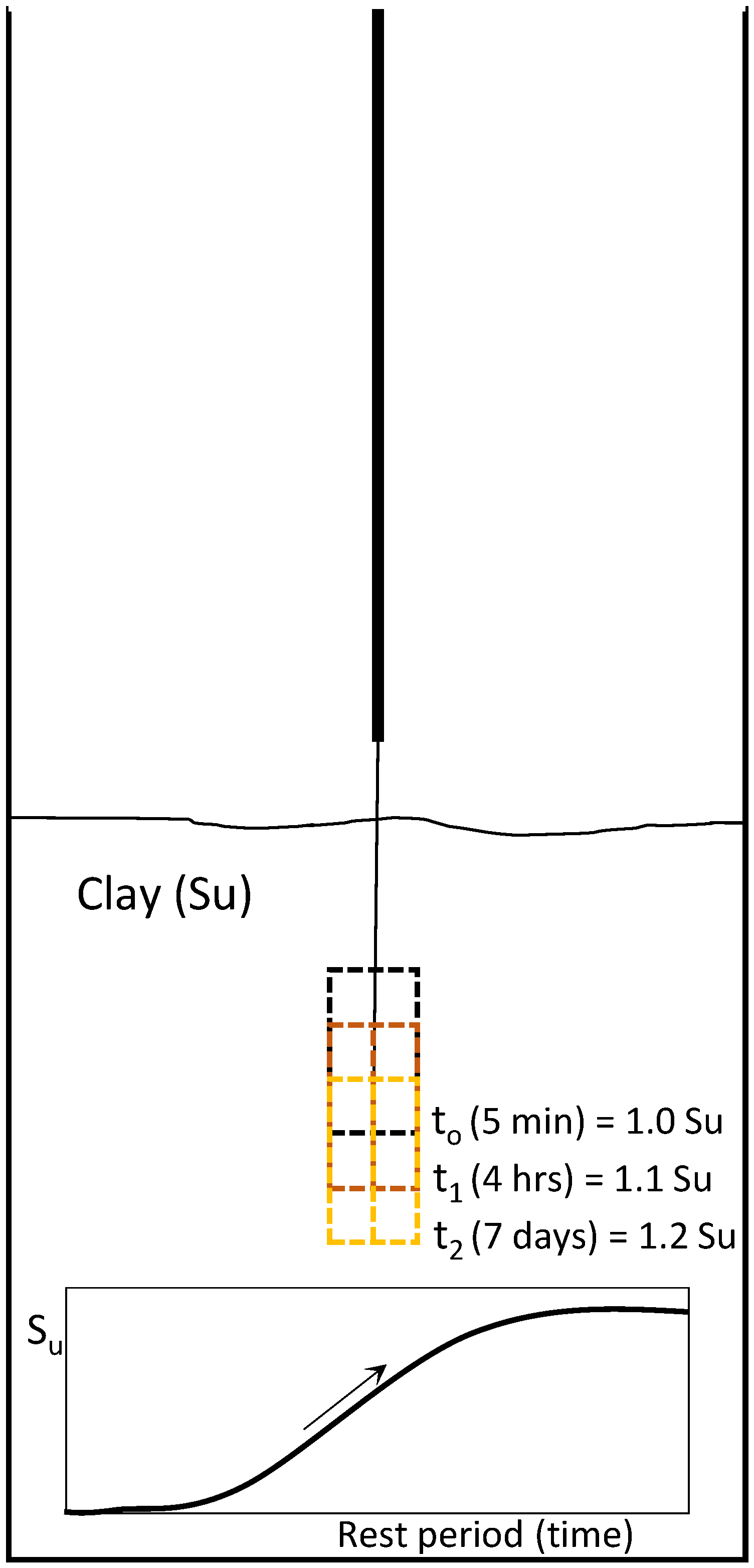

2.2. Soil Disturbance Due to Vane Shear Tests

3. Materials and Methods

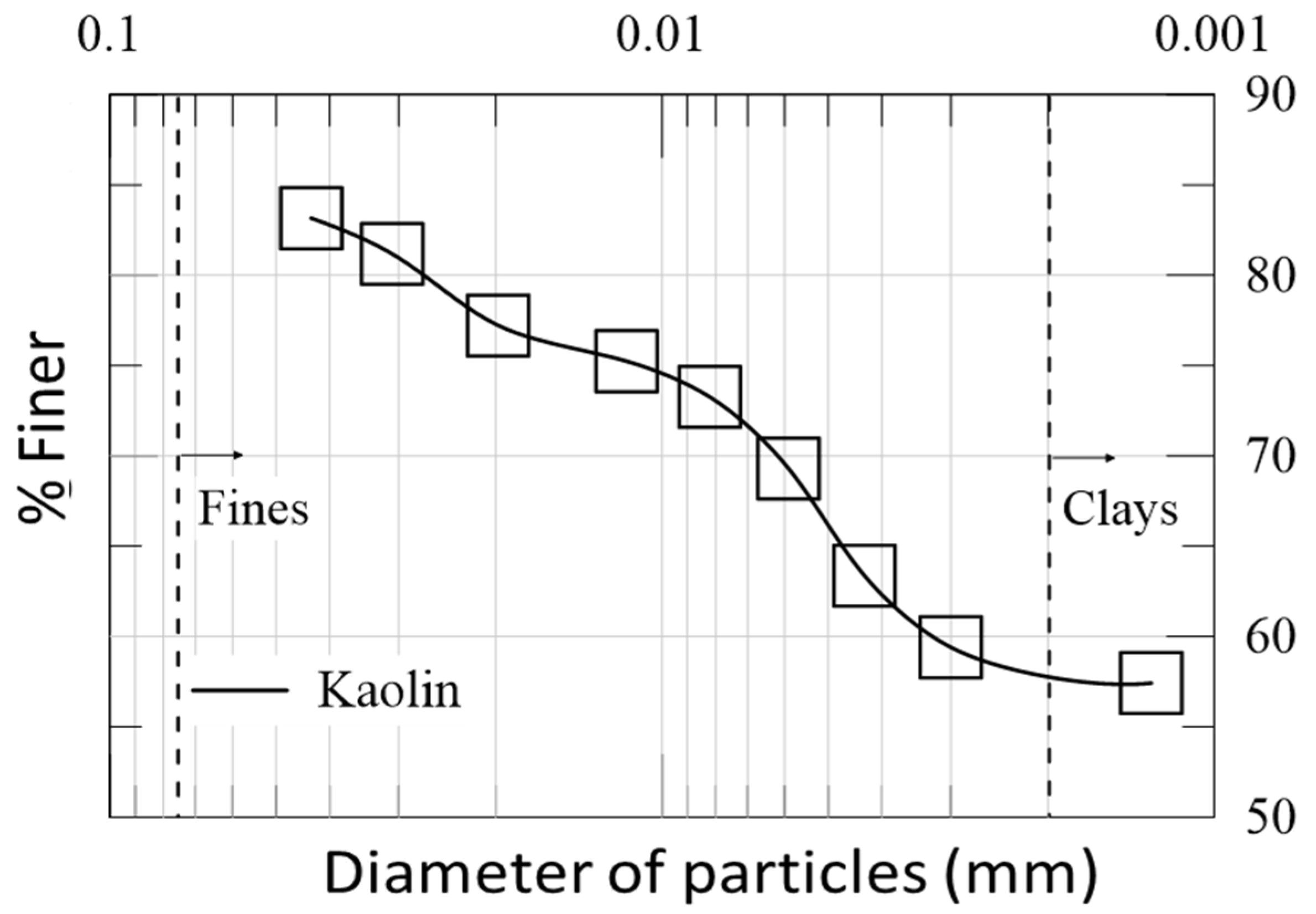

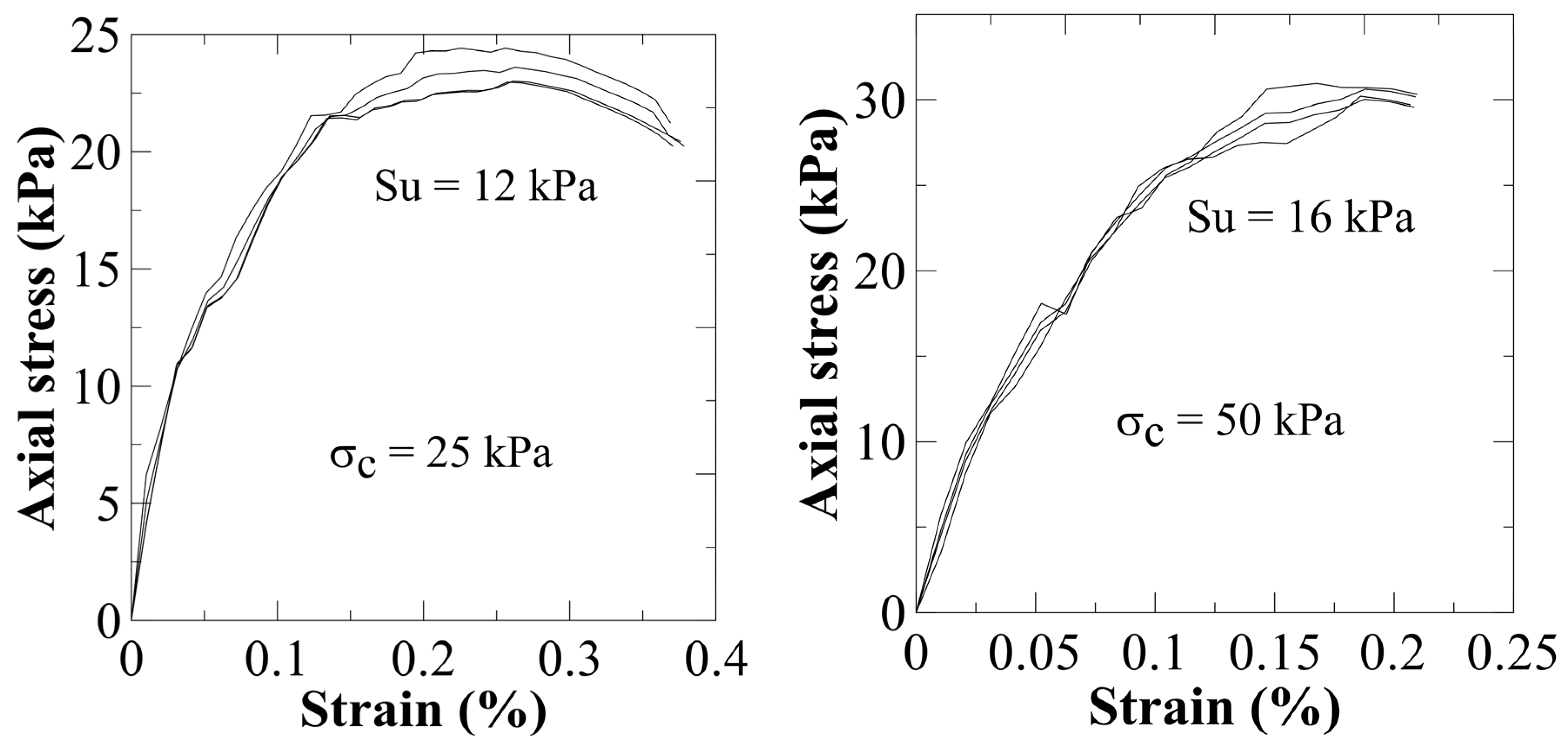

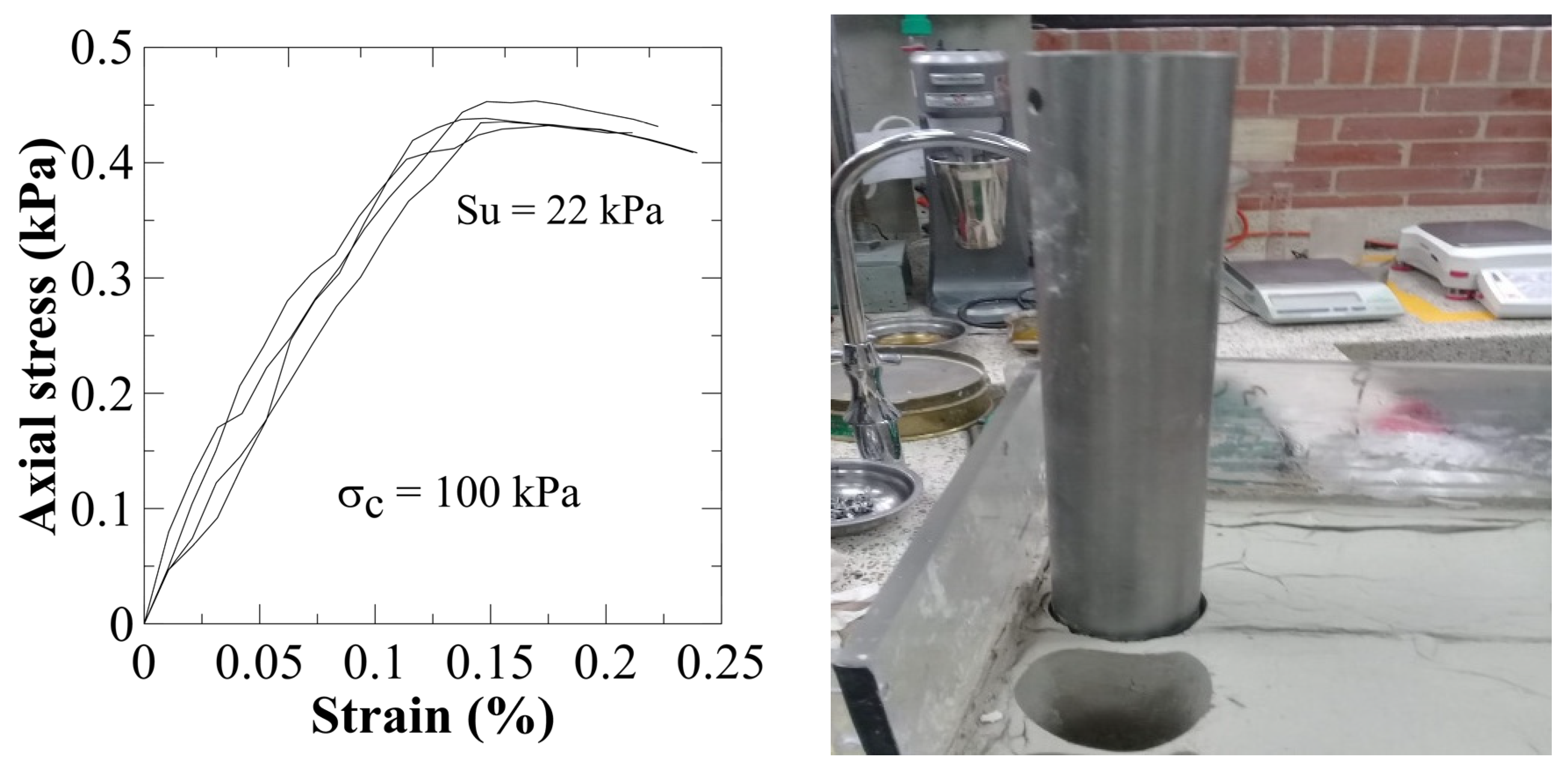

3.1. Tested Soil Descriptions

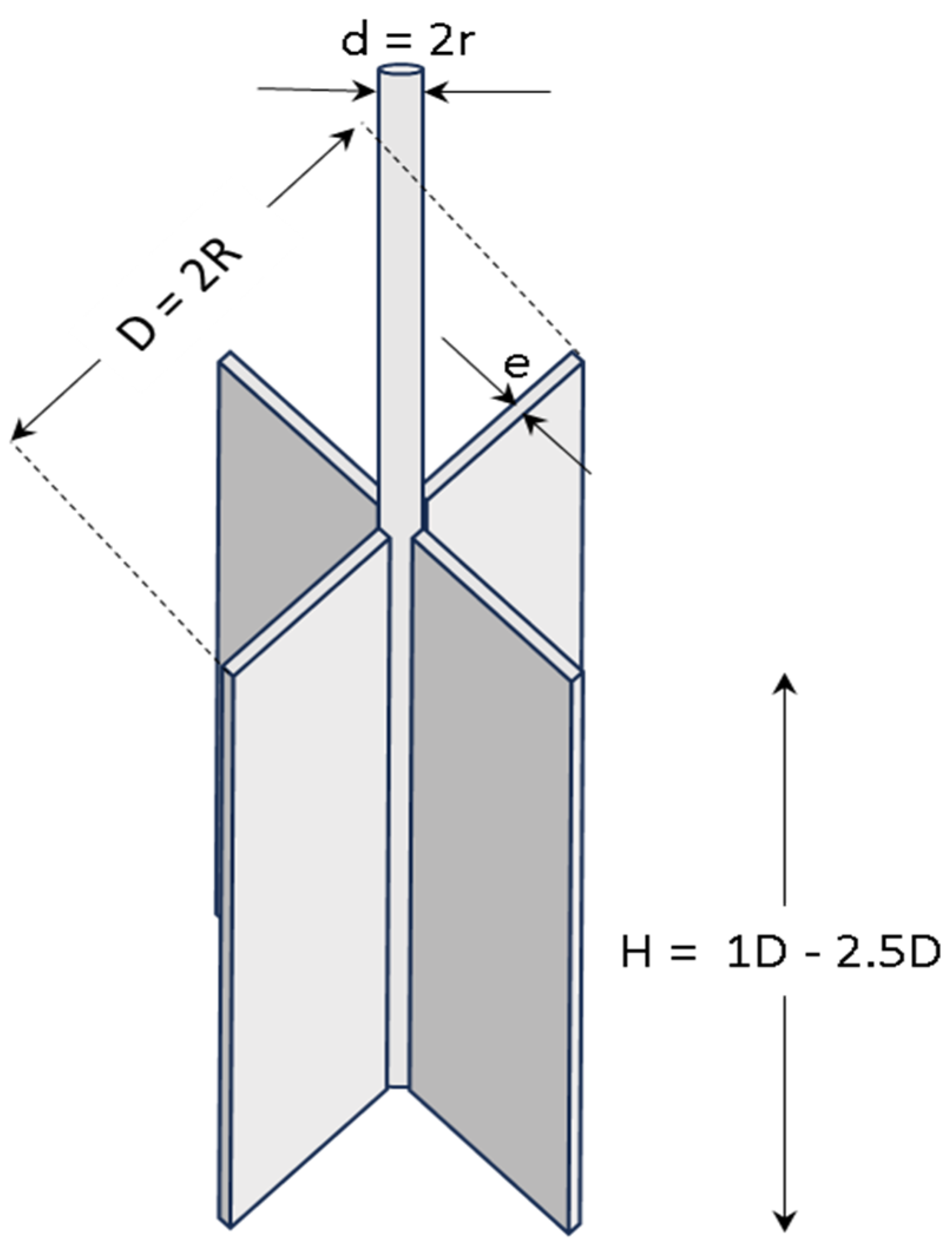

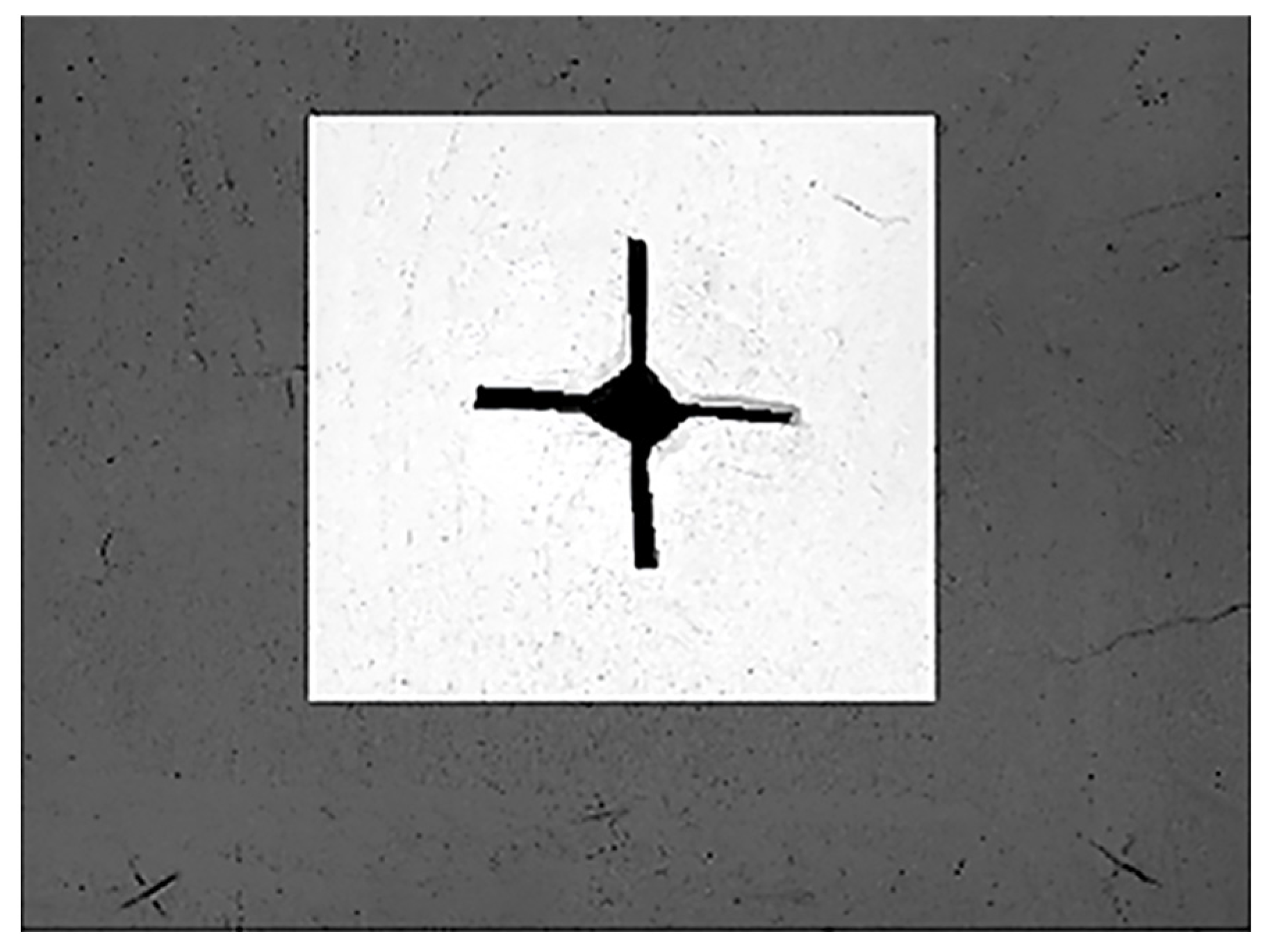

3.2. Shear Vane Configuration Used in This Research

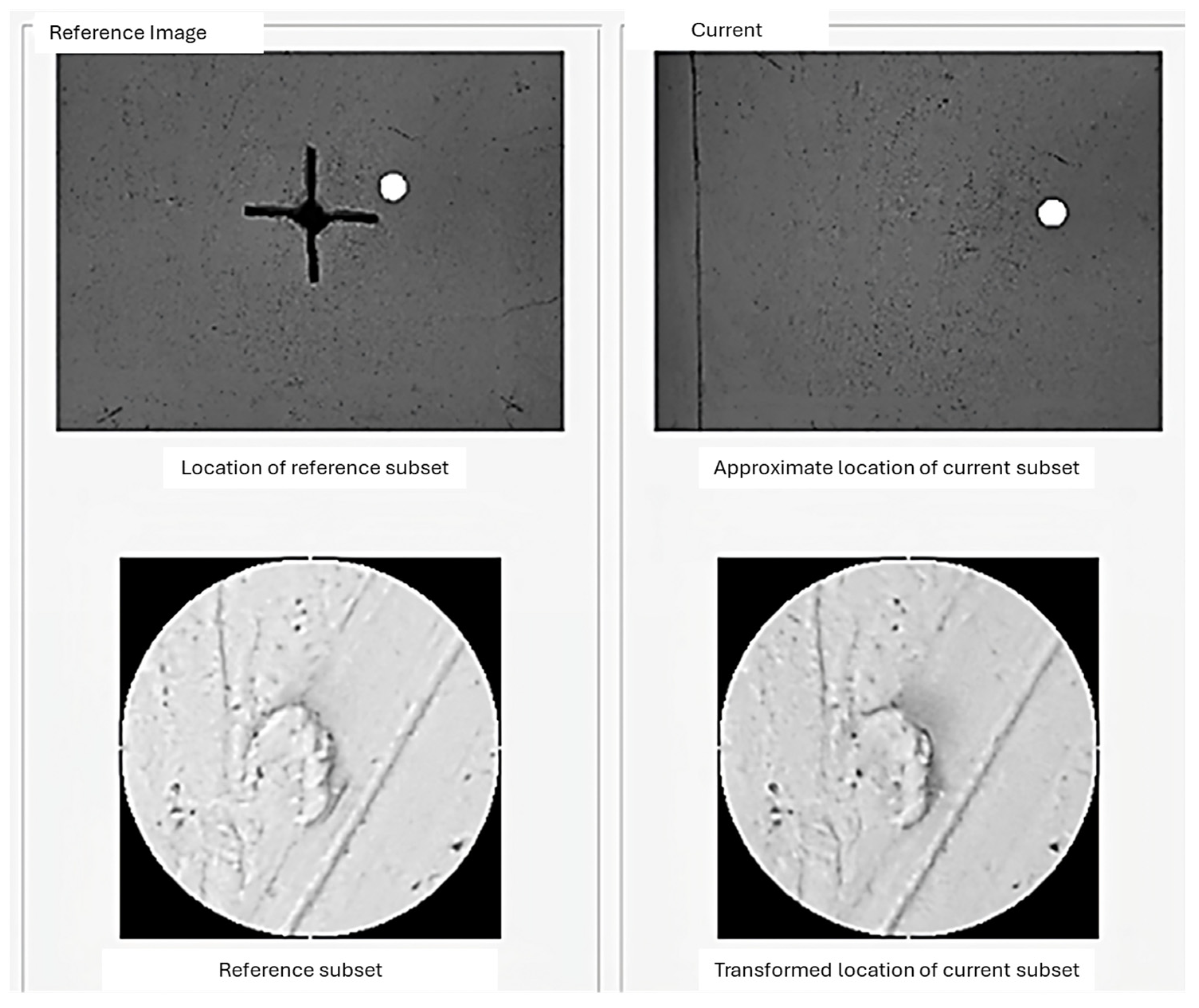

3.3. Digital Image Correlation (DIC)

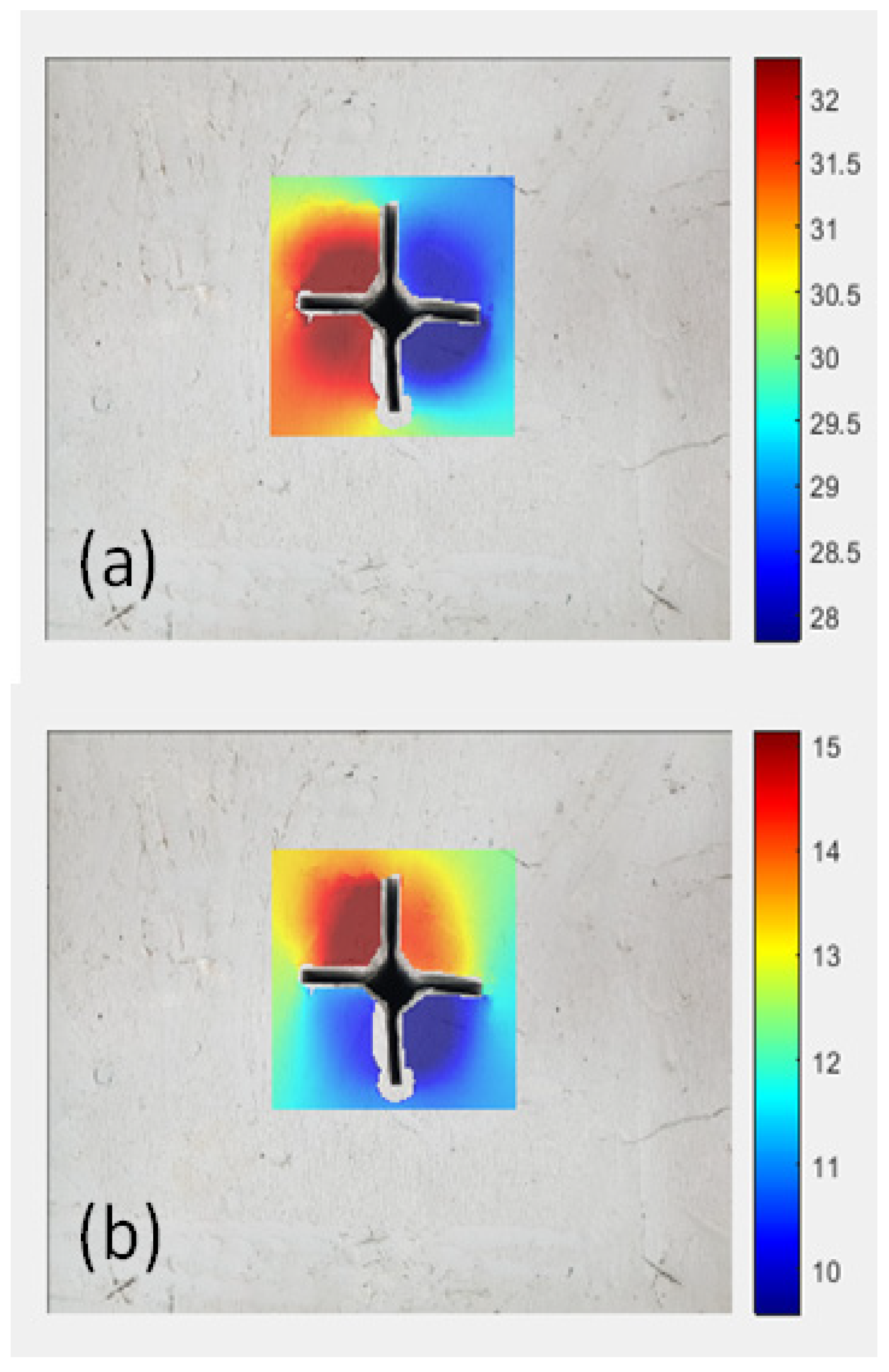

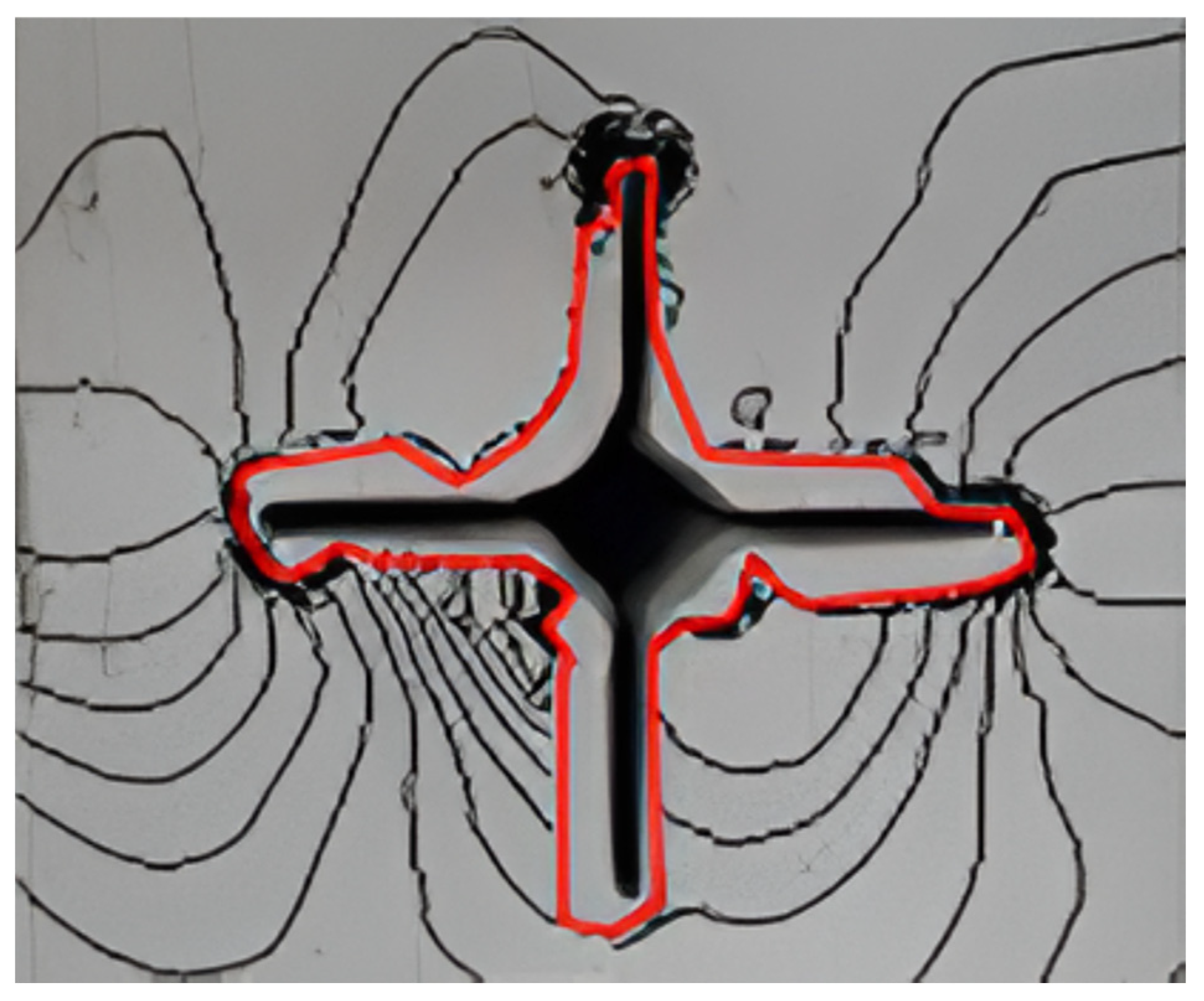

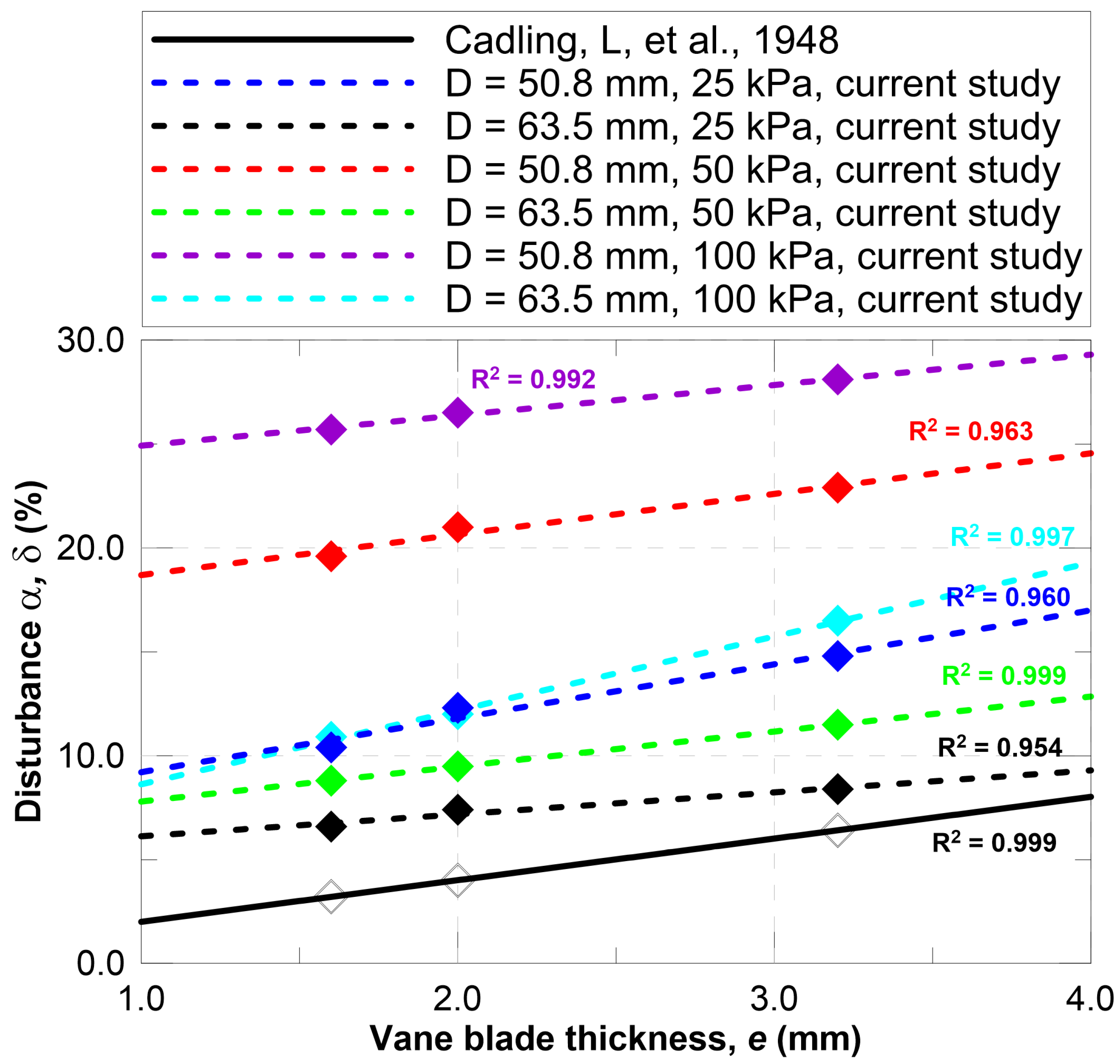

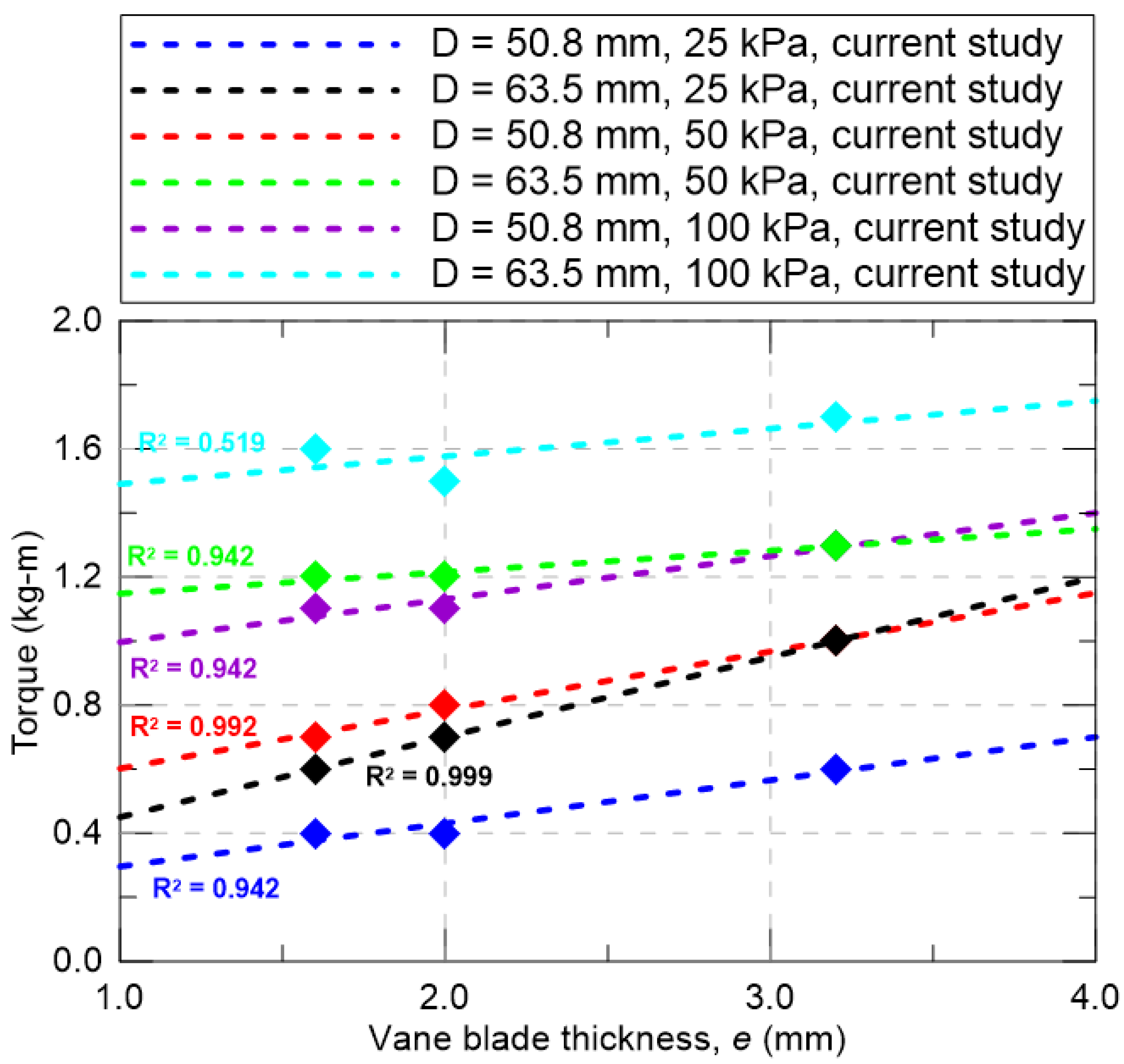

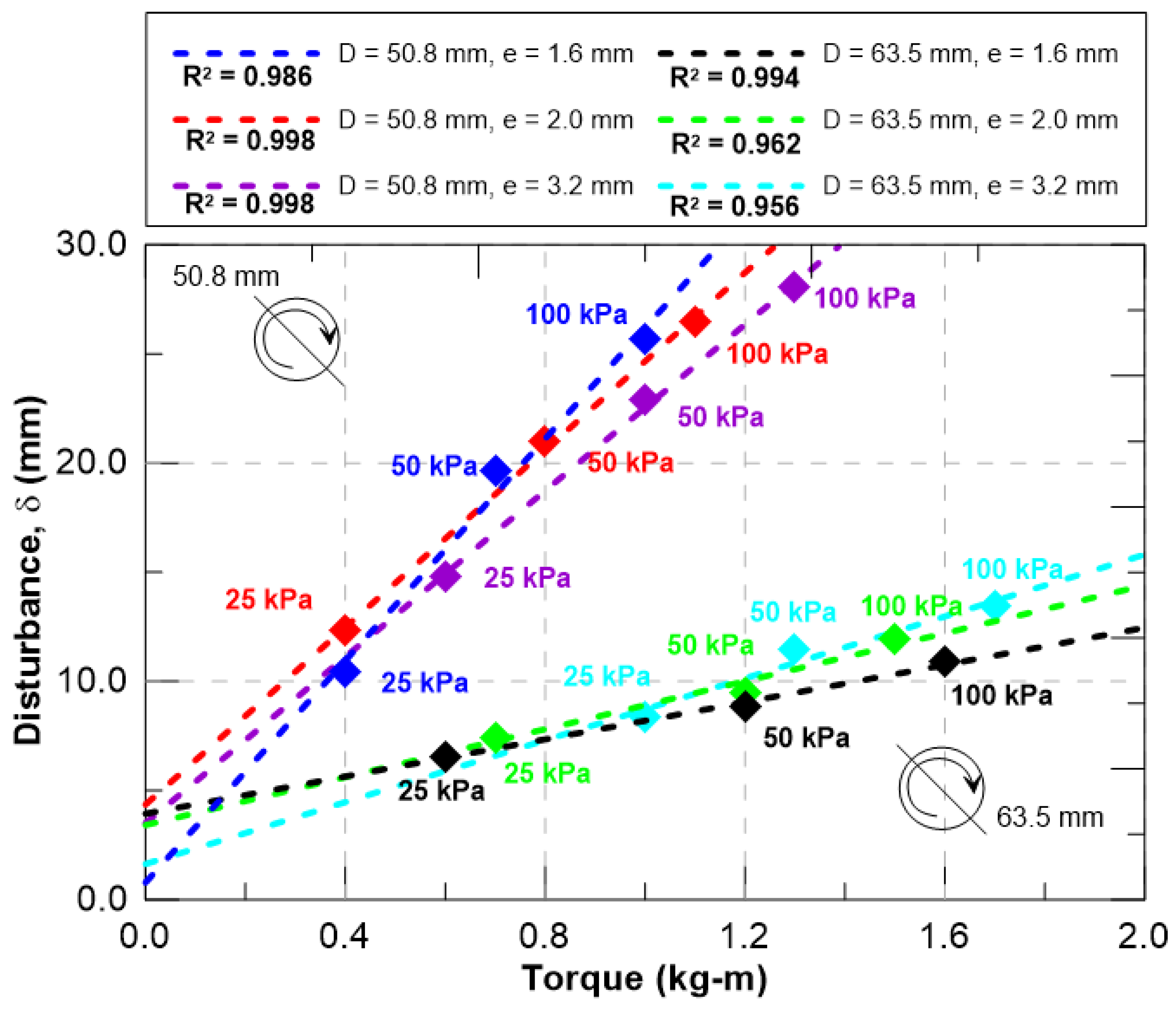

4. Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Suárez, J. Deslizamientos Análisis Geotécnico; Universidad Industrial de Santander—UIS: Santander, Colombia, 2009; Volume 1. (In Spanish) [Google Scholar]

- D4648; Standard Test Methods for Laboratory Miniature Vane Shear Test for Saturated Fine-Grained Clayey Soil. ASTM International: West Conshohocken, PA, USA, 2024.

- Chandler, R.J. The In-Situ Measurement of the Undrained Shear Strength. In Vane Shear Strength Testing in Soils: Field and Laboratory; ASTM: West Conshohocken, PA, USA, 1988; pp. 13–44. [Google Scholar]

- Carreño, J. Evaluación de la Anisotropía de Materiales Arcillosos Reconstituidos en Laboratorio Mediante Parámetros Obtenidos del Ensayo de Consolidación Edométrica. Master’s Thesis, Universidad Militar Nueva Granada, Bogotá, Colombia, 2019. (In Spanish). [Google Scholar]

- López, E.; Lopez, G.; Dorado, R.; Diaz, F. Aplicación de correlación digital de imágenes para el análisis de problemas de contacto. An. Ing. Mecánica 2012, 11–19. (In Spanish). Available online: https://www.xixcnim.uji.es/CDActas/Documentos/ComunicacionesOrales/11-09.pdf?utm (accessed on 2 April 2025).

- Young, A.; McClelland, B.; Quiros, G. In-Situ Vane Shear Testing at Sea. In Vane Shear Strength Testing in Soils: Field and Laboratory; ASTM: West Conshohocken, PA, USA, 1988; pp. 46–67. [Google Scholar]

- Cadling, L.; Ondenstad, S. The Vane Borer. In Proceedings of the Royal Swedish Geotechnical Institute; Royal Swedish Geotechnical Institute: Stockholm, Sweden, 1948; pp. 1–87. [Google Scholar]

- Geise, J.M.; Hoope, J.T.; May, R.E. Design and offshore experience with an in-situ vane. In ASTM STP 104 Vane Shear Strength in Soils: Field and Laboratory Studies; Richards, A.F., Ed.; ASTM: West Conshohocken, PA, USA, 1988; pp. 318–338. [Google Scholar]

- Coutinho, R.Q.; Oliveira, A.T.J.; Oliveira, J.T. Palheta: Experiência, Tradição e Inovação; SEFE IV/BIC: São Paulo, Brazil, 2000; Volume 3, pp. 53–80. (In Portuguese) [Google Scholar]

- D2573; Standard Test Method for Field Vane Shear Test in Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2018.

- INV E-170; Ensayo de Corte Sobre Suelos Cohesivos. Instituto Nacional De Vias “INVIAS”: Bogotá, Colombia, 2007. (In Spanish)

- Skempton, A.W. The post-glacial clays of the Thames estuary at Tilbury and Shellhaven. In Proceedings of the 3rd ICSMFE, Zurich, Switzerland, 16–17 May 1953; pp. 302–308. [Google Scholar]

- Aas, G. A study of the effect of vane shape and rate of strain on the measured values of in-situ shear strength of clays. In Proceedings of the 6th ICSMFE, Montreal, QC, Canada, 8–15 September 1965; pp. 141–145. [Google Scholar]

- La Rochelle, P.; Roy, M.; Travenas, F. Field measurements of cohesion in Champlain clay. In Proceedings of the 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, Russia, 6–11 June 1973; pp. 229–236. [Google Scholar]

- Matsui, T.; Abe, N. Shear mechanism of vane test in soft clays. Soils Found. 1981, 21, 69–80. [Google Scholar] [CrossRef][Green Version]

- Roy, M.; Leblanc, A. Factors Affecting the Measurements and Interpretation of the Vane Strength in Soft Sensitive Clays. In Vane Shear Strength Testing in Soils: Field and Laboratory; ASTM International: West Conshohocken, PA, USA, 1988; pp. 117–128. [Google Scholar][Green Version]

- Pérez-Foguet, A.; Ledesma, A.; Huerta, A. Analysis of the vane test considering size and time effects. Int. J. Numer. Anal. Meth. Geomech. 1999, 23, 383–412. [Google Scholar] [CrossRef]

- Cerato, A.; Lutenegger, A. Disturbance Effects of Field Vane Tests in a Varved Clay; University of Massachusetts: Amherst, MA, USA, 2004. [Google Scholar]

- Torstensson, B.A. Time-Dependent Effects in the Field Vane Test. In Proceedings of the International Symposium on Soft Clay, Bangkok, Thailand, 5–7 July 1977; pp. 387–397. [Google Scholar]

- Morgenstern, N.R.; Tchalenko, J.S. Microscopic Structures in Kaolin Subjected to Direct Shear. Géotechnique 1967, 17, 309–328. [Google Scholar] [CrossRef]

- Blight, G.E. A Note on Field Vane Testing of Silty Soils. Can. Geotech. J. 1968, 5, 142–149. [Google Scholar] [CrossRef]

- Bjerrum, L. Problems of Soil Mechanics and Construction on Soft Clays. In Proceedings of the 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, Russia, 6–11 June 1973; pp. 111–159. [Google Scholar]

- Weisel, C.E. Some Factors Influencing In Situ Vane Test Results. In Proceedings of the 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, Russia, 6–11 June 1973. [Google Scholar]

- Silvestri, V.; Aubertin, M. Anisotropy and In-Situ Vane Tests. In Vane Shear Strength Testing in Soils: Field and Laboratory; ASTM: West Conshohocken, PA, USA, 1988; pp. 88–103. [Google Scholar]

- Resendiz Hernandez, J.; Palacios Pineda, L.M. Análisis de deformaciones unitarias en juntas soldadas utilizando correlación digital de imágenes. Rev. Ing. Mecánica 2017, 1, 10–19. (In Spanish) [Google Scholar]

- Saltos, K.G. Caracterización de Deformaciones Mecánicas Usando Correlación Digital de Imágenes; Universidad San Francisco De Quito Usfq: Quito, Ecuador, 2015. (In Spanish) [Google Scholar]

- Blaber, J.; Adair, B.; Antoniou, A. Ncorr: Open-source 2D digital image correlation MATLAB software. Exp. Mech. 2015, 55, 1105–1122. [Google Scholar] [CrossRef]

- Blaber, J.; Antoniou, A. Ncorr; Georgia Institute of Technology: Atlanta, GA, USA, 2018. [Google Scholar]

- Stanier, S.A.; Blaber, J.; Take, W.A.; White, D.J. Improved image-based deformation measurement for geotechnical applications. Can. Geotech. J. 2016, 53, 727–739. [Google Scholar] [CrossRef]

- Ruge, J.C.; Palacios, X.; Molina-Gómez, F.; Rojas Suárez, J.P. Mineralogical, Microstructural and Porosimetry Analysis in Three Different Clayey Soils. J. Phys. Conf. Ser. 2019, 1388, 012014. [Google Scholar] [CrossRef]

- Kimura, T.; Saitoh, K. Effect of disturbance due to insertion on vane shear strength of normally consolidated cohesive soils. Soils Found. 1983, 23, 113–124. [Google Scholar] [CrossRef] [PubMed][Green Version]

| Parameter | ASTM (2018) | AASHTO (2000) | BS (1990) | NGF (1989) | SGF (1995) | CEN (1997) | NBR (1989) | INVIAS (2013) |

|---|---|---|---|---|---|---|---|---|

| Vane geometry | Rectangular/tapered | Rectangular/tapered | Rectangular | Rectangular | Rectangular | Rectangular | Rectangular | Rectangular/tapered |

| H/D ratio | 1–2.5 | 2 | 2 | 2 | 2 | 2 | 2 | 1–2.5 |

| Vane diameter, D (mm) | 35–100 | 38.1/50.8/63.5/92.1 | 50/75 | 55/65 | 40–100 | 40–100 | 50/65 | 35–100 |

| Blade thickness, e (mm) | 1.52/3.18 | 1.59/2.0/3.18 | Not specified | 2.0 | 0.8–3.0 | 0.0–3.0 | 2 +/− 0.2 | <3.0 |

| Vane shaft diameter, d = 2r (mm) | 12.5–16.5 | 11/20/12.7 | 13.0 | 12.0 | <14.0 | <16.0 | 13 +/− 1 | 12.5–16.5 |

| Accuracy torque reading | +/− 1.0 kPa (computed shear strength) | +/− 1.2 kPa (computed shear strength) | 1% range (0–100 N-m) | +/− 0.5% (scale end) | +/− 0.5% (applied torque) | +/− 0.5% (applied torque) | 2% (maximum torque in calibration) | +/− 1.0 kPa (computed shear strength) |

| Torque imposition | Preferably geared drive/acceptable by hand | Preferably geared drive/acceptable by hand | Geared drive/engine | Preferably geared drive | Not specified | Not specified/slowly and continuously | Geared drive | Preferably geared drive/acceptable by hand |

| Vane area ratio | <12% | Not specified | <12% | <12% | Not specified | Not specified | <12% | <12% |

| Insertion depth | 5× diameter of the hole | 5× diameter of the hole | 3× diameter of the hole | 0.5 m | 5× diameter of the hole | 5× diameter of the hole/0.5 m | >4× diameter of the hole/0.5 m | 5× diameter of the hole |

| Rotational rate | 0.1 °/s | 0.1 °/s | 6–12 °/min | 12 °/min | Not specified | 6–12 °/min | 6 +/− 0.6 °/min | <0.1 °/s |

| Time to failure (min) | 2.0–5.0 | 2.0–5.0 | 5.0 | 1.0–3.0 | 2.0–4.0 | Not specified | Not specified | 2.0–5.0 |

| Revolutions to remoulded strength | 5–10 | 10 | 6 | 25 | 20 | >10 | 10 | 5–10 |

| Time to remoulding process (min) | <1.0 | <1.0 | 5.0 | <5.0 | 2.0–5.0 | Not specified | <5.0 | <1.0 |

| Test intervals (m) | 0.5–0.75 | Not specified | 0.5 | 0.5–1.0 | >5.0 | >0.5 | Not specified | 0.5–0.75 |

| D (mm) | H (mm) | e (mm) | d (mm) | VA (%) | Recommendation of VA < 12% |

|---|---|---|---|---|---|

| 63.5 | 127 | 1.6 | 12.7 | 9.13 | OK |

| 63.5 | 127 | 2.0 | 12.7 | 10.42 | OK |

| 63.5 | 127 | 3.2 | 12.7 | 14.27 | Not OK |

| 50.8 | 102 | 1.6 | 12.7 | 12.27 | Not OK |

| 50.8 | 102 | 2.0 | 12.7 | 13.77 | Not OK |

| 50.8 | 102 | 3.2 | 12.7 | 18.28 | Not OK |

| D (mm) | e (mm) | α (%) a | DA (mm2) b | δ (%) c |

|---|---|---|---|---|

| σc = 25 kPa | ||||

| 63.5 | 1.6 | 3.21 | 208.20 | 6.6 |

| 63.5 | 2.0 | 4.01 | 235.92 | 7.4 |

| 63.5 | 3.2 | 6.42 | 265.08 | 8.4 |

| 50.8 | 1.6 | 4.01 | 211.48 | 10.4 |

| 50.8 | 2.0 | 5.01 | 249.52 | 12.3 |

| 50.8 | 3.2 | 8.02 | 299.64 | 14.8 |

| σc = 50 kPa | ||||

| 63.5 | 1.6 | 3.21 | 280.20 | 8.8 |

| 63.5 | 2.0 | 4.01 | 300.92 | 9.5 |

| 63.5 | 3.2 | 6.42 | 363.08 | 11.5 |

| 50.8 | 1.6 | 4.01 | 397.48 | 19.6 |

| 50.8 | 2.0 | 5.01 | 425.52 | 21.0 |

| 50.8 | 3.2 | 8.02 | 463.64 | 22.9 |

| σc = 100 kPa | ||||

| 63.5 | 1.6 | 3.21 | 344.20 | 10.9 |

| 63.5 | 2.0 | 4.01 | 378.92 | 12.0 |

| 63.5 | 3.2 | 6.42 | 524.08 | 16.5 |

| 50.8 | 1.6 | 4.01 | 520.48 | 25.7 |

| 50.8 | 2.0 | 5.01 | 536.52 | 26.5 |

| 50.8 | 3.2 | 8.02 | 568.64 | 28.1 |

| D = 50.8 mm | σc = 25 kPa | σc = 50 kPa | σc = 100 kPa | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Blade Thickness (mm) | Tmax (kN-m) | Su (VST) (kN/m2) | Su (UC) (kN/m2) | Tmax (kN-m) | Su (VST) (kN/m2) | Su (UC) (kN/m2) | Tmax (kN-m) | Su (VST) (kN/m2) | Su (UC) (kN/m2) |

| 1.6 | 0.004 | 8.32 | 12.0 | 0.007 | 14.57 | 16.0 | 0.012 | 24.97 | 22.0 |

| 2.0 | 0.004 | 8.32 | 0.008 | 16.65 | 0.013 | 27.06 | |||

| 3.2 | 0.006 | 12.49 | 0.01 | 20.81 | 0.014 | 29.14 | |||

| D = 63.5 mm | 25 kPa | 50 kPa | 100 kPa | ||||||

| 1.6 | 0.006 | 6.39 | 12.0 | 0.012 | 12.79 | 16.0 | 0.016 | 17.05 | 22.0 |

| 2.0 | 0.007 | 7.46 | 0.012 | 12.79 | 0.015 | 15.98 | |||

| 3.2 | 0.01 | 10.66 | 0.013 | 13.85 | 0.017 | 18.11 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruge, J.C.; Caballero-Rojas, D.; Molina-Gómez, F.; Pinto da Cunha, R.; Meléndez-Suarez, D. Image-Based Quantification of Soil Disturbance in Vane Shear Tests on Reconstituted Kaolinitic Clayey Soil. Geotechnics 2025, 5, 66. https://doi.org/10.3390/geotechnics5030066

Ruge JC, Caballero-Rojas D, Molina-Gómez F, Pinto da Cunha R, Meléndez-Suarez D. Image-Based Quantification of Soil Disturbance in Vane Shear Tests on Reconstituted Kaolinitic Clayey Soil. Geotechnics. 2025; 5(3):66. https://doi.org/10.3390/geotechnics5030066

Chicago/Turabian StyleRuge, Juan Carlos, Diego Caballero-Rojas, Fausto Molina-Gómez, Renato Pinto da Cunha, and Diego Meléndez-Suarez. 2025. "Image-Based Quantification of Soil Disturbance in Vane Shear Tests on Reconstituted Kaolinitic Clayey Soil" Geotechnics 5, no. 3: 66. https://doi.org/10.3390/geotechnics5030066

APA StyleRuge, J. C., Caballero-Rojas, D., Molina-Gómez, F., Pinto da Cunha, R., & Meléndez-Suarez, D. (2025). Image-Based Quantification of Soil Disturbance in Vane Shear Tests on Reconstituted Kaolinitic Clayey Soil. Geotechnics, 5(3), 66. https://doi.org/10.3390/geotechnics5030066