In Situ and Laboratory Testing of Boom Clay at Shallow Depths in Belgium

Abstract

1. Introduction

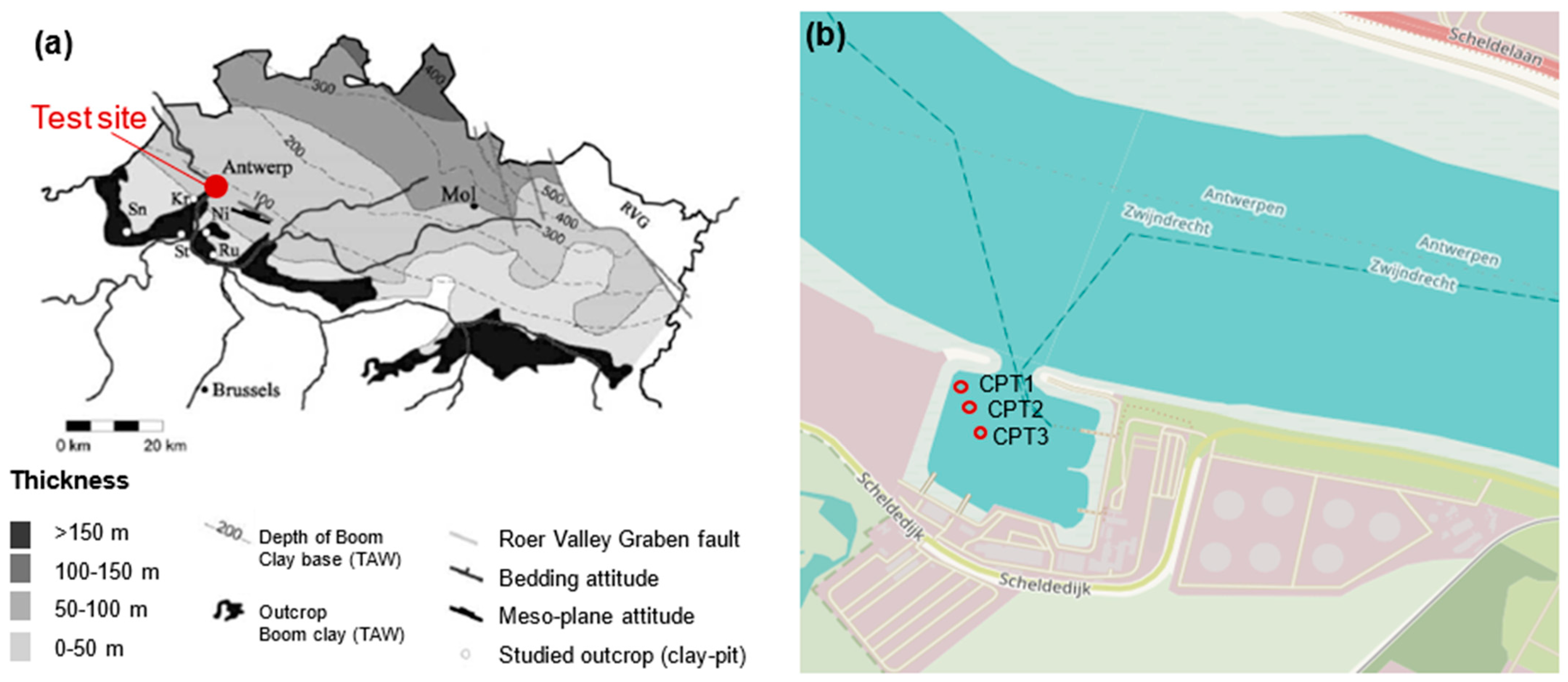

2. In Situ Testing and Sampling Material

3. Testing Program and Methods

4. Experimental Test Results

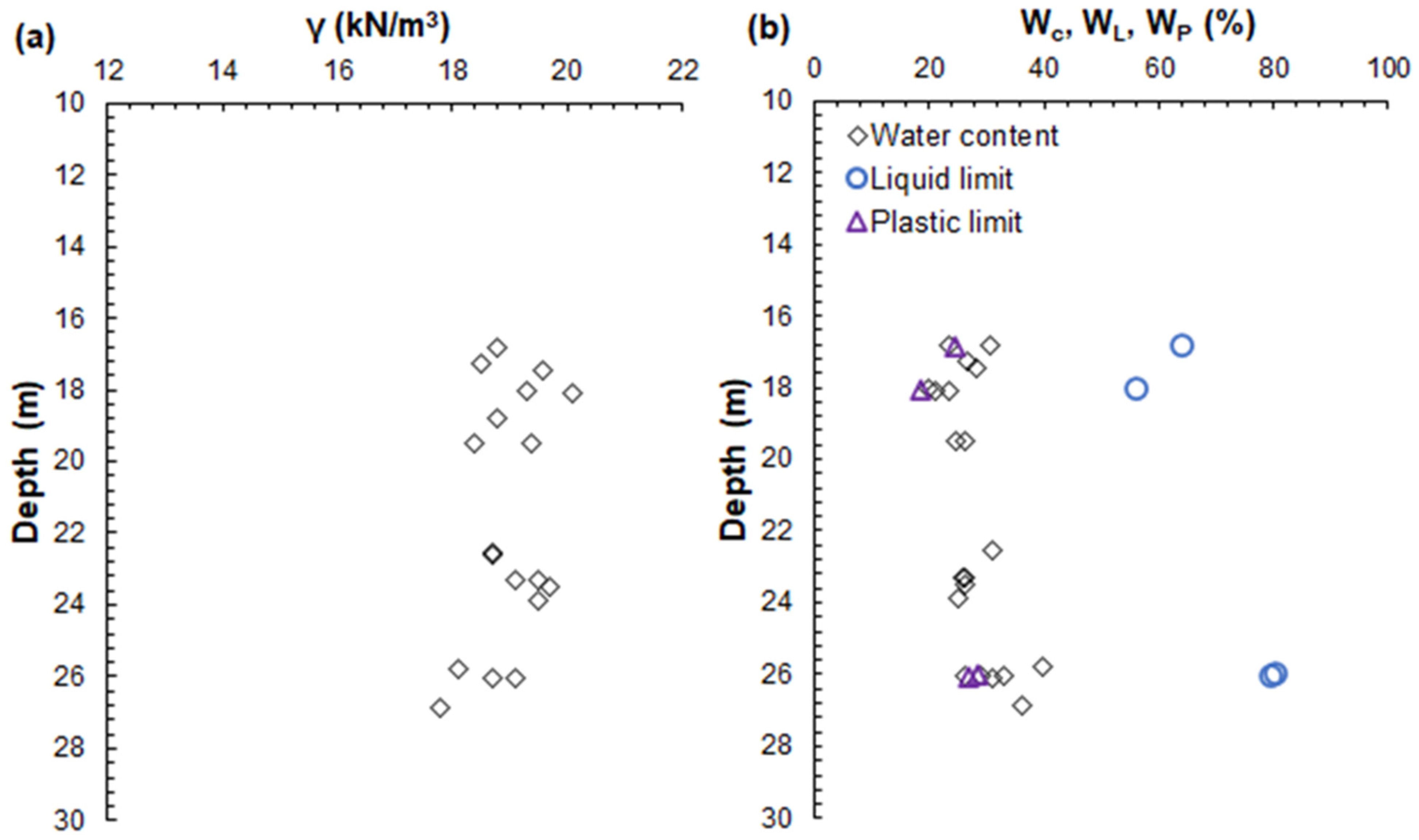

4.1. Index Classification Tests

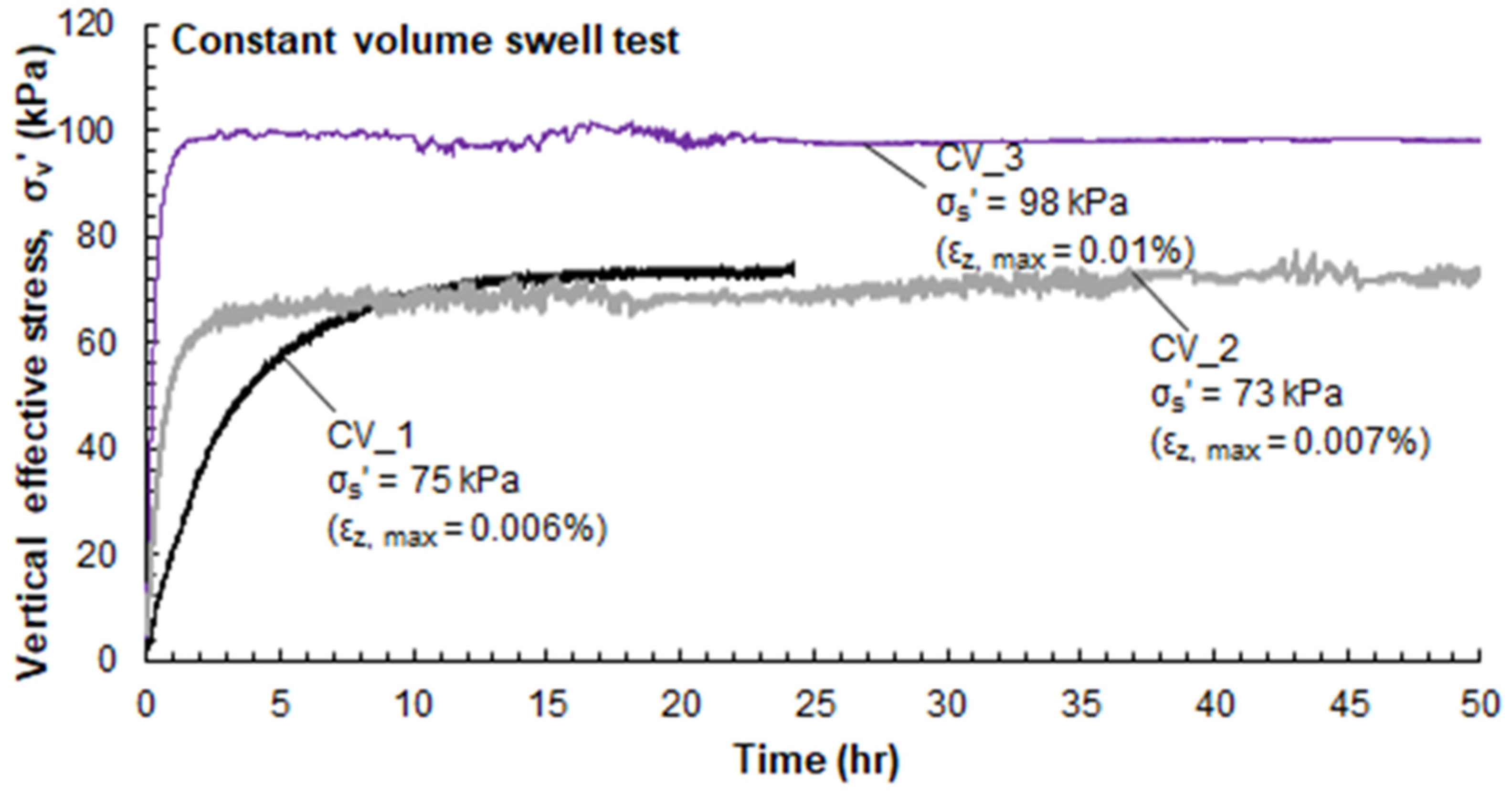

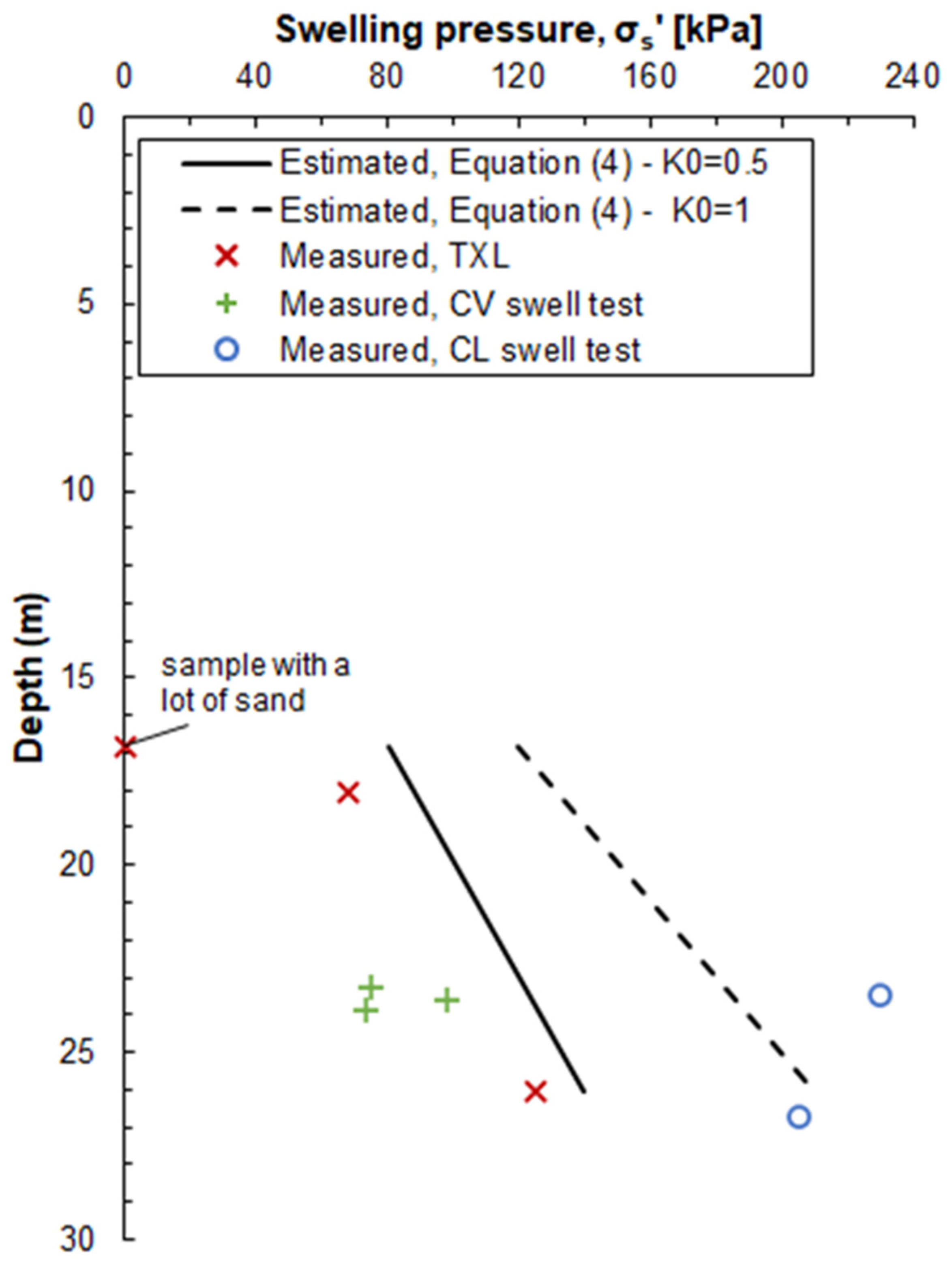

4.2. Swelling Tests

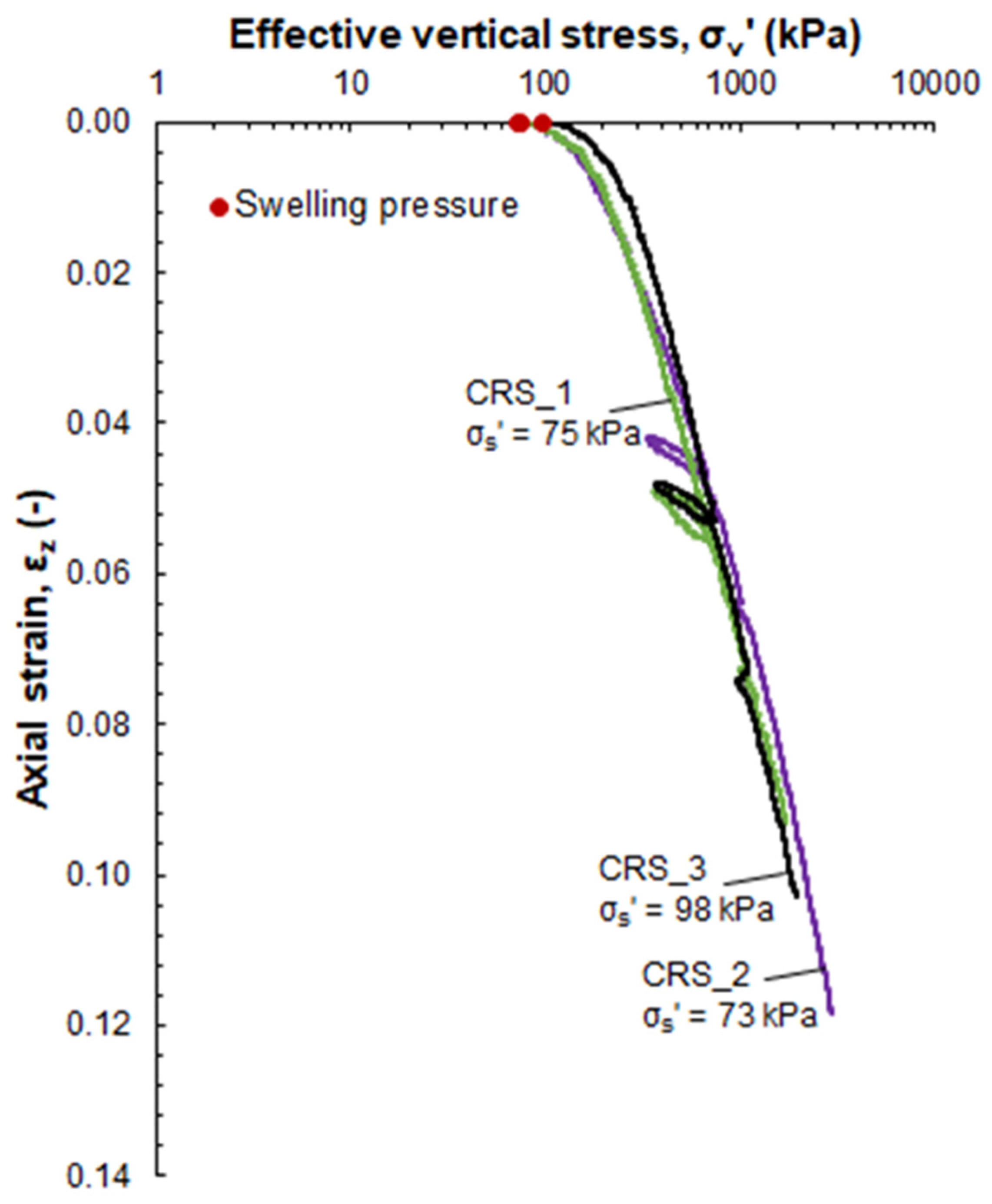

4.3. Compression Tests

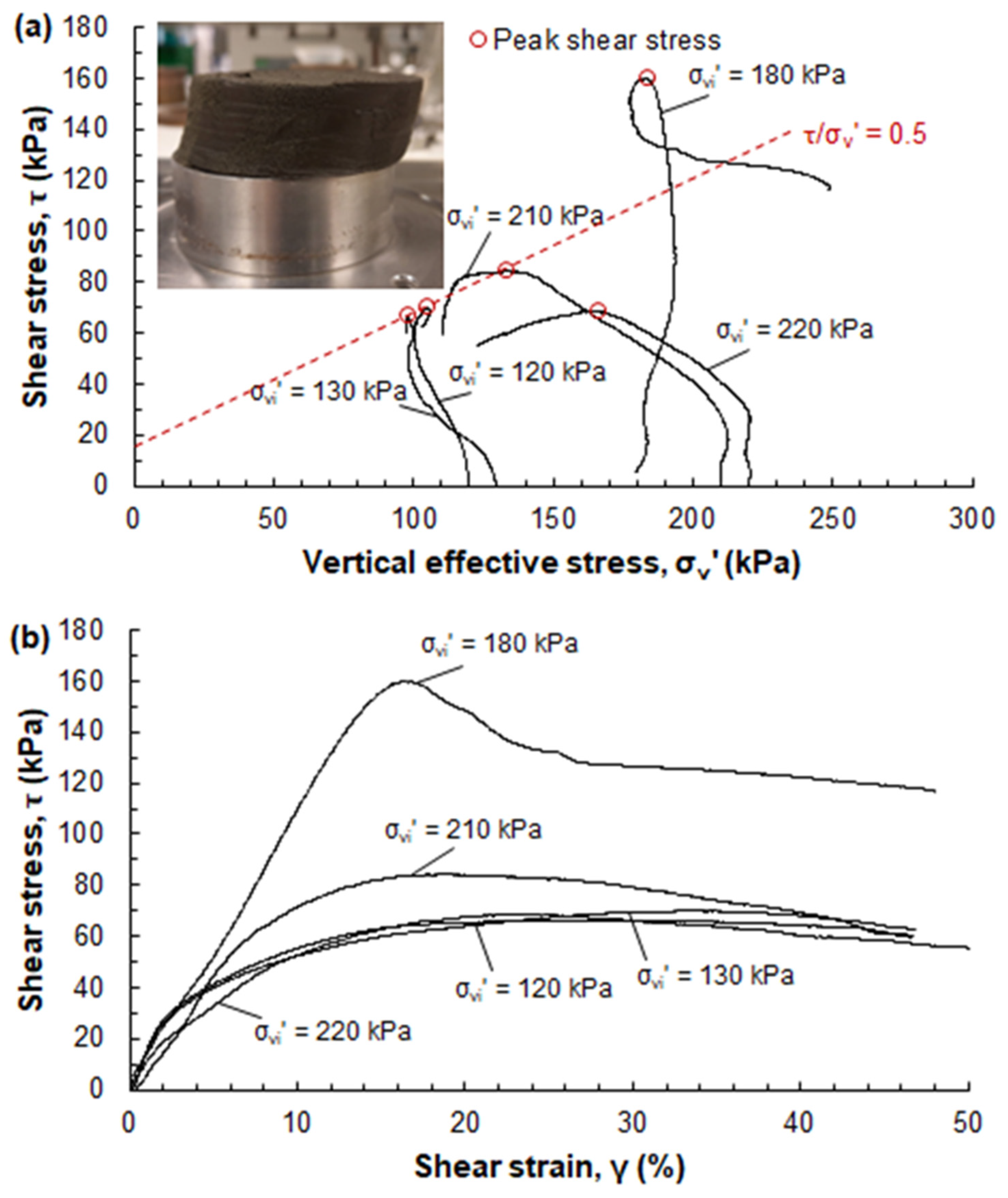

4.4. Shear Strength Tests

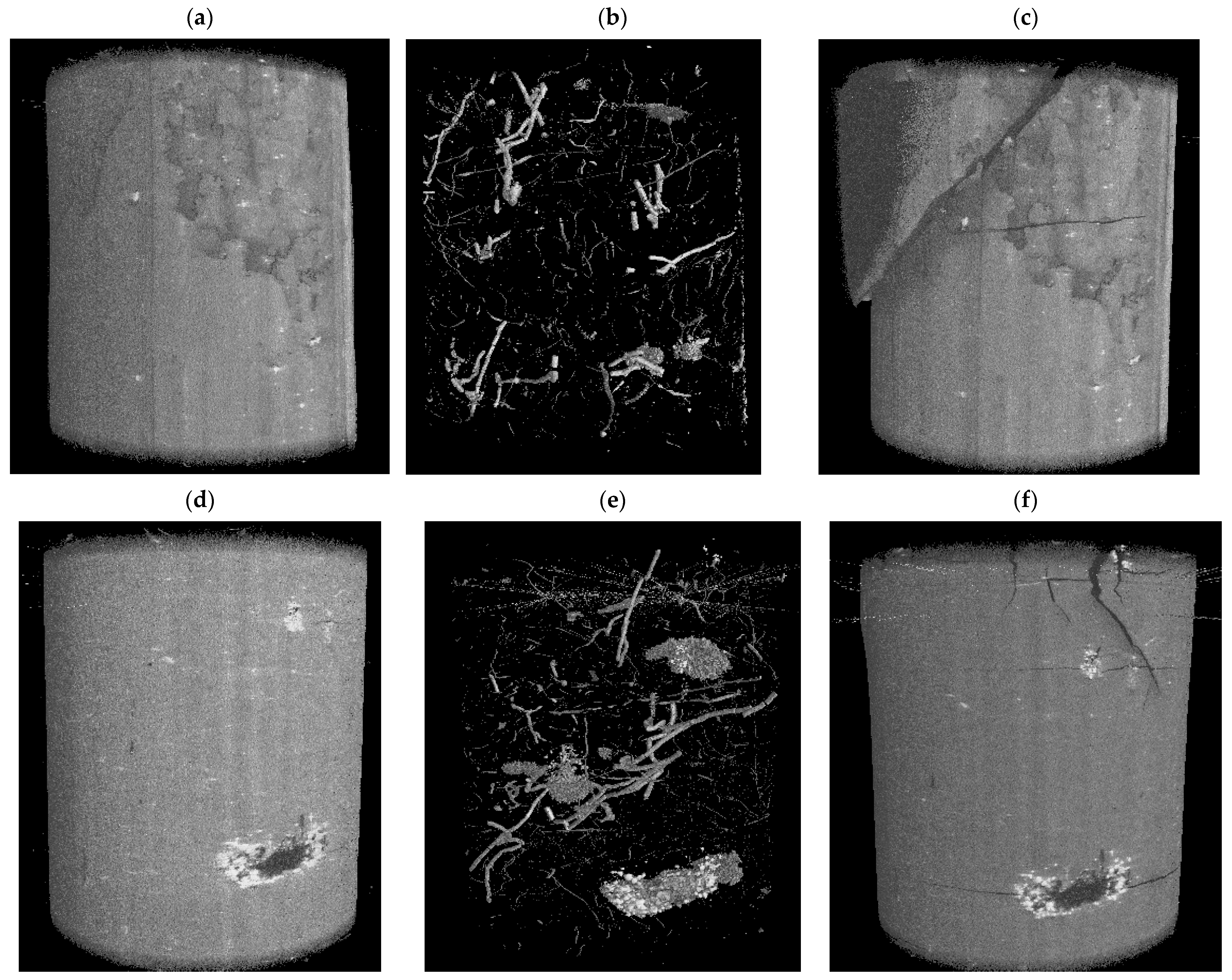

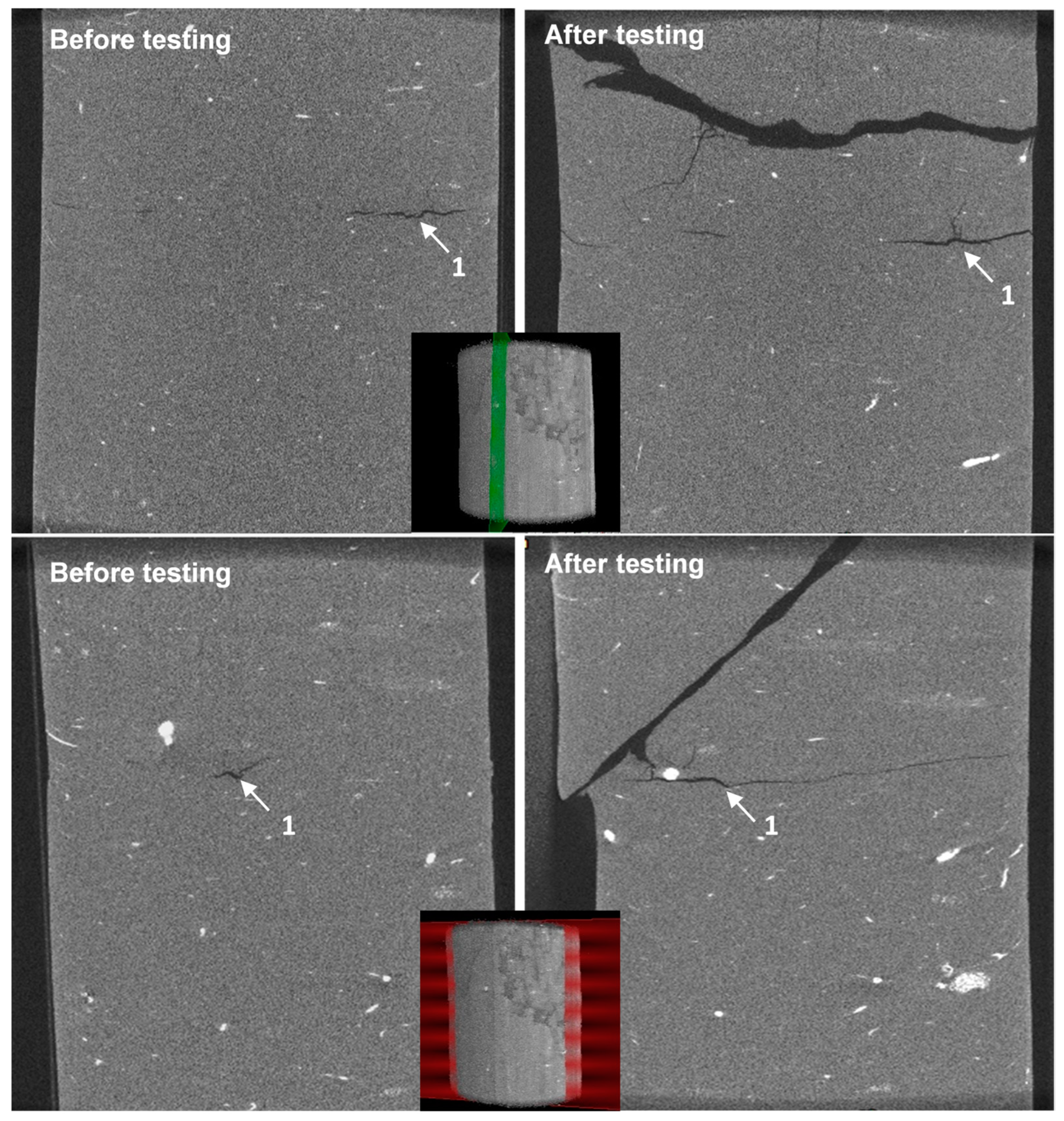

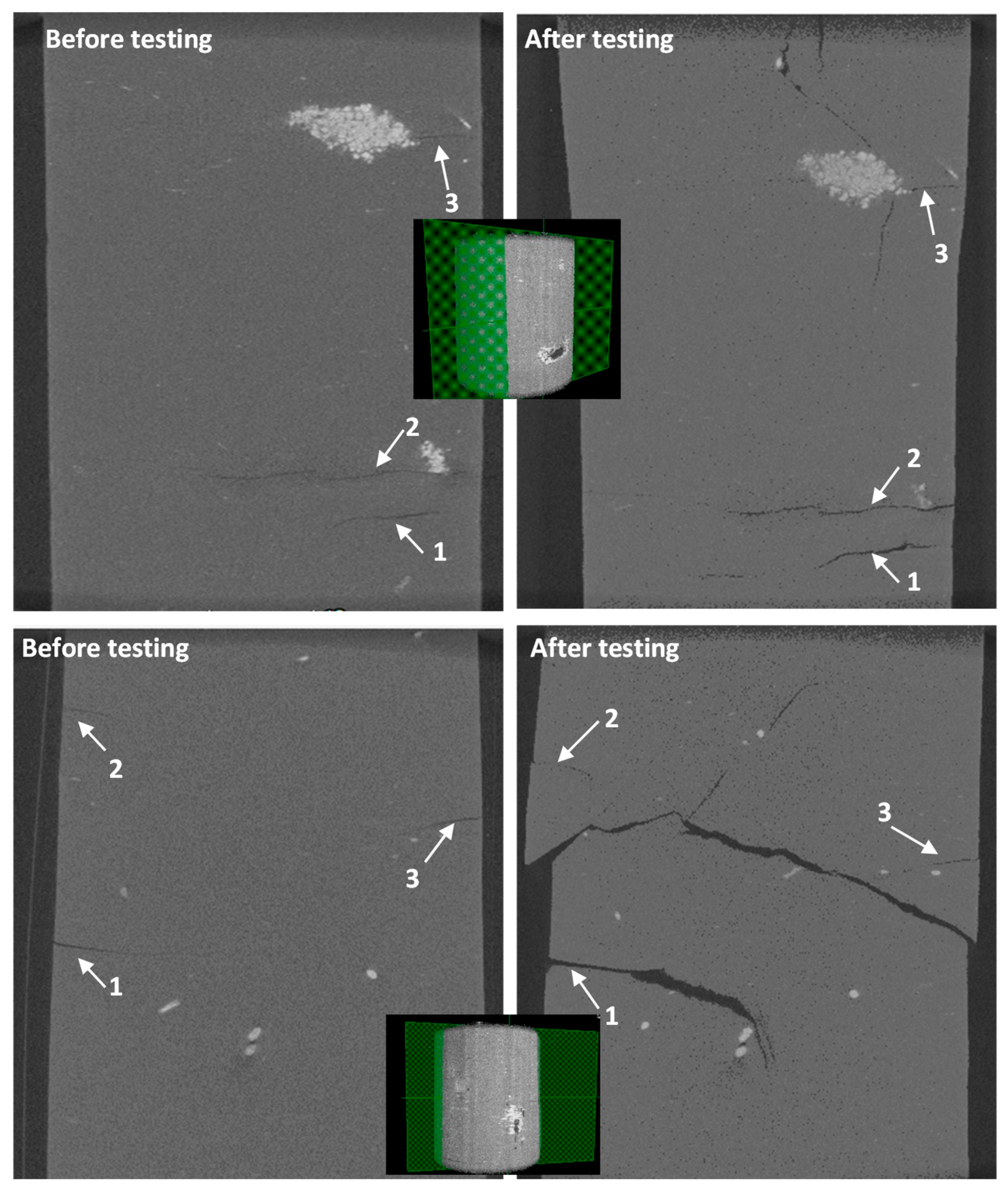

4.5. X-Ray Tomography

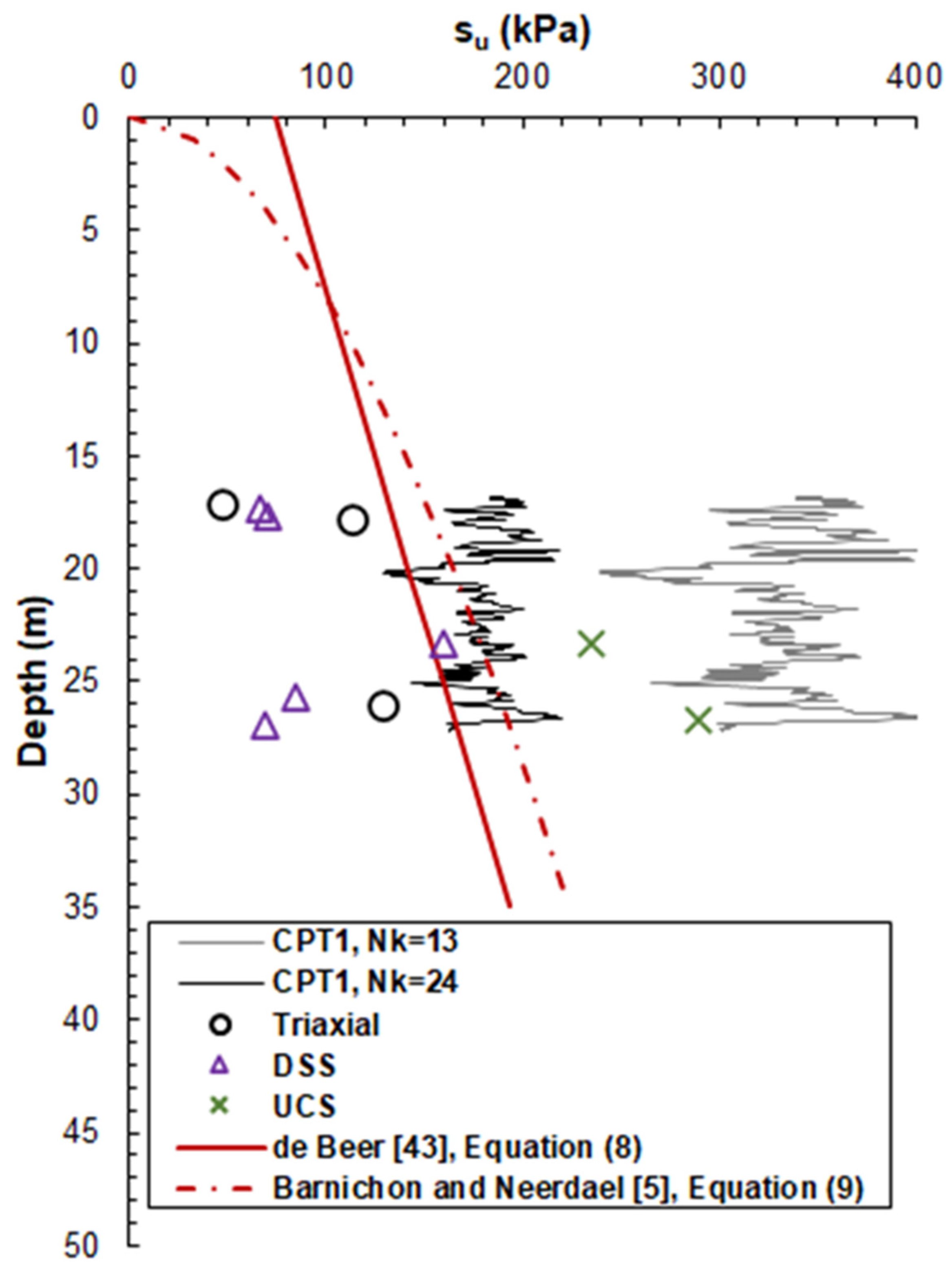

5. Undrained Shear Strength Profile

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bernier, F.; Volckaert, G.; Alonso, E.; Villar, M. Suction-controlled experiments on Boom clay. Eng. Geol. 1997, 47, 325–338. [Google Scholar]

- Mendoza, R.C. Determination of Lateral Stresses in Boom Clay Using a Lateral Stress Oedometer. Master’s Thesis, International Institute for Geo-Information Science and Earth Observation, Enschede, The Netherlands, 2004. [Google Scholar]

- ONDRAF/NIRAS. SAFIR 2—Safety Assessment and Feasibility Interim Report 2. Brussels, Belgium: Belgian Agency for Radioactive Waste and Enriched Fissile Materials, Dec. 2001a, NIROND 2001-06 E.

- Steen, B.; van de Vervoort, A. Mine Design in Clay, CORA Project TRUCK-I; Leuven, Belgium: Karholieke Universiteit Leuven. August 2008. Available online: https://www.covra.nl/app/uploads/2022/03/CORA-17-Mine-Design-in-Clay-TRUCK-I.pdf (accessed on 22 March 2025).

- Barnichon, J.D.; Neerdael, B.; Grupa, J.; Vervoort, A. Cora Project Truckii. Technical Report; Waste & Disposal Department SCK·CEN: Mol, Belgium, 2000; Available online: https://www.covra.nl/app/uploads/2019/08/CORA-18-Terughaalbare-opslag-op-diepte-van-500m-in-de-Boomse-kleiformatie-TRUCK-II.pdf (accessed on 20 December 2024).

- Vardon, P.; Buragohain, P.; Hicks, M.; Hart, J.; Fokker, P.A.; Graham, C. Technical Feasibility of a Dutch Radioactive Waste Repository in Boom Clay: Thermo-Hydro-Mechanical Behaviour; Delft University of Technology: Delft, The Netherlands, 2017; OPERA-PU-TUD321c. [Google Scholar]

- Horseman, S.T.; Winter, M.G.; Entwistle, D.C. Geotechnical Characterisation of Boom Clay in Relation to the Disposal of Radioactive Waste: Final Report; EUR 10987; Commission of the European Communities: Luxembourg, 1987. [Google Scholar]

- Baldi, G.; Hueckel, T.; Peano, A.; Pellegrini, R. Developments in Modelling of Thermo-Hydro-Geomechanical Behaviour of Boom Clay and Clay-Based Buffer Materials: Final Report; EUR 13365 EN; Commission of the European Communities: Luxembourg, 1991. [Google Scholar]

- Coll, C. Endommagement des roches Argileuses et Perméabilité Induite au Voisinage D’ouvrages Souterrains. Ph.D. Thesis, Université Grenoble I, Saint-Martin-d’Hères, France, 2005. [Google Scholar]

- Bernier, F.; Li, X.L.; Bastiaens, W. Twenty-five years’ geotechnical observation and testing in the Tertiary Boom clay formation. Géotechnique 2007, 57, 229–237. [Google Scholar]

- Cui, Y.J.; Le, T.T.; Tang, A.M.; Delage, P.; Li, X.L. Investigating the time dependent behaviour of Boom clay under thermo-mechanical loading. Géotechnique 2009, 59, 319–329. [Google Scholar]

- Yu, H.D.; Chen, W.Z.; Jia, S.P.; Cao, J.J.; Li, X.L. Experimental study on the hydro-mechanical behaviour of Boom clay. Int. J. Rock Mech. Min. Sci. 2012, 53, 59–165. [Google Scholar]

- Bésuelle, P.; Viggiani, G.; Desrues, J.; Coll, C.; Charrier, P. A laboratory experimental study of the hydromechanical behaviour of Boom clay. Rock Mech. Rock Eng. 2014, 47, 143–155. [Google Scholar]

- Wemaere, I.; Marivoet, J.; Labat, S. Hydraulic conductivity variability of the Boom Clay in north-east Belgium based on four core drilled boreholes. Phys. Chem. Earth 2008, 33, 24–36. [Google Scholar]

- Hass, H.R.; Klaff, J.; Seidel, H.W. Use of brine freezing for the construction of the traverse galleries. In Ground Freezing 2000—Frost Action in Soils; Thimus, J.F., Ed.; CRC Press: Louvain-la-Neuve, Belgium, 2000; pp. 289–294. [Google Scholar]

- Rijkers, R.; Hemmen, B.; Naaktgeboren, M.; Weigl, H. In situ frost heave loads in artificially frozen ground for tunneling. In Proceedings of the International Tunnel Association, Sydney, Australia, 2–6 March 2002. [Google Scholar]

- Milioritsas, M. Geotechnical Modelling of a Deep Tunnel Excavation in the Boom Clay Formation. Master’s Thesis, Department of Civil Engineering and Geosciences, Delft University of Technology, Delft, The Netherlands, 2014. [Google Scholar]

- Wiseall, A.; Graham, C.; Zihms, S.; Harrington, J.; Cuss, R.; Gregory, S.; Shaw, R. Properties and Behaviour of the Boom Clay Formation Within a Dutch Repository Concept; OPERA: Vlissingen, The Netherlands, 2015; OPERA-PU-BGS615. [Google Scholar]

- Deng, Y.F.; Tang, A.M.; Cui, Y.J.; Nguyen, X.P.; Li, X.L.; Wouters, L. Laboratory hydro-mechanical characterization of Boom clay at Essen and Mol. Phys. Chem. Earth 2011, 36, 1878–1890. [Google Scholar]

- Lunne, T.; Robertson, P.K.; Powell, J.J.M. The Cone Penetration Test in Geotechnical Practice; EF Spon/Blackie Academic, Routledge Publishing: New York, NY, USA, 1997; p. 64. [Google Scholar]

- Thompson, R.W.; Perko, H.A.; Rethamel, W.D. Comparison of constant volume swell pressure and oedometer load-back pressure. In Proceedings of the 4th International Conference on Unsaturated Soils, Carefree, AZ, USA, 2–6 April 2006. [Google Scholar]

- Okkels, N.; Hansen, P.B. Swell pressure and yield stresses in Danish, highly over-consolidated, Palaeogene clays of extreme plasticity. In Proceedings of the 17th Nordic Geotechnical Meeting, Challenges in Nordic Geotechnic, Reykjavik, Iceland, 25–28 May 2016. [Google Scholar]

- D4546; Standard Test Methods for One-Dimensional Swell or Collapse of Soils. ASTM: West Conshohocken, PA, USA, 2021.

- D4186; Standard Test Method for One-Dimensional Consolidation Properties of Saturated Cohesive Soils Using Controlled-Strain Loading. ASTM: West Conshohocken, PA, USA, 2006.

- ISO 17892-9; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 9: Consolidated Triaxial Compression Tests on Water Saturated Soils. ISO: Geneva, Switzerland, 2018.

- D6528; Standard Test Method for Consolidated Undrained Direct Simple Shear Testing of Fine Grain Soils. ASTM: West Conshohocken, PA, USA, 2017.

- D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM: West Conshohocken, PA, USA, 2016.

- Belanteur, N.; Tacherifet, S.; Pakzad, M. Etude des comportements mecanique, thermo-mecanique et hydro-mecanique des argiles gonflantes et non gonflantes fortement compactees. Rev. Fr. De Géotechnique 1997, 78, 31–50. [Google Scholar]

- Dehandschotter, B.; Vandycke, S.; Sintubin, M.; Vandenberghe, N.; Wouters, L. Brittle fractures and ductile shear bands in agrillaceous sediments: Inferences from Oligocen Boom Clay (Belgium). J. Struct. Geol. 2004, 27, 1095–1112. [Google Scholar]

- Skempton, A.W.; Sowa, V.A. The behaviour of saturated clays during sampling and testing. Géotechnique 1963, 13, 269–290. [Google Scholar]

- Bishop, A.W.; Kumapley, N.K.; El Ruwayih, A. The influence of pore water tension on the strength of a clay. Proc. R. Soc. Lond. 1974, 1286, 511–554. [Google Scholar]

- Doran, I.G.; Sivakumar, V.; Graham, J.; Johnson, A. Estimation of in-situ stresses using anisotropic elasticity and suction measurements. Géotechnique 2001, 50, 189–196. [Google Scholar]

- Horseman, S.T.; Winter, M.G.; Entwistle, D.C. Triaxial experiments on Boom clay. In The Engineering Geology of Weak Rock; CRC Press: Rotterdam, The Netherlands, 1993; pp. 36–43. [Google Scholar]

- Sultan, N. Etude Du Comportement Thermo-Mécanique De l’argile De Boom: Expériences Et Modélisation. Ph.D. Thesis, Ecole Nationale des Ponts et Chaussées, Paris, France, 1997. [Google Scholar]

- Berre, T. Triaxial testing at the Norwegian Geotechnical Institute. Geotech. Test. J. 1982, 5, 3–17. [Google Scholar]

- Henrion, P.N.; Monsecour, M.; Fonteyne, A.; Hermans, N.; Manfroy, P.; Neerdael, B.; de Bruyn, D. Characterisation of the Boom Clay, Semi-Annual Report 18; Contract WAS-334-83-7-B(RS); R&D Programme on Radioactive Disposal into Geological Formation (Study of a Clay Formation); SCK CEN: Mol, Belgium, 1984. [Google Scholar]

- Reiffsteck, P.; Szymkiewicz, F.; Fanelli, S. Comparison of the measurement of swelling pressure through different tests. In Proceedings of the XVII European Conference on Soil Mechanics and Geotechnical Engineering, Reykjavik, Iceland, 1–7 September 2019. [Google Scholar]

- Nagaraj, H.B.; Munnas, M.M.; Shridharan, A. Critical evaluation of determining swelling pressure by swell-load method and constant volume method. Geotech. Test. J. 2009, 32, 305–314. [Google Scholar]

- Graham, J.; Kwok, C.K.; Ambroise, R.W. Stress release, undrained storage, and reconsolidation in simulated underwater clay. Can. Geotech. J. 1987, 24, 279–288. [Google Scholar]

- Delage, P.; Le, T.T.; Tang, A.M.; Cui, Y.J.; Li, X.L. Suction effects in deep Boom clay block samples. Géotechnique 2007, 57, 239–244. [Google Scholar]

- Casagrande, A. The Determination of the Pre-Consolidation Load and Its Practical Significance. In Proceedings of the 1st International Conference on Soil Mechanics and Foundation Engineering, Cambridge, MA, USA, 22–26 June 1936. [Google Scholar]

- Sorensen, K.K.; Okkels, N. Correlation between compression index and index parameters for high plasticity Paleogene clays. In Proceedings of the XVI European Conference on Soil Mechanics and Geotechnical Engineering, Edinburgh, Scotland, 13–17 September 2015. [Google Scholar]

- de Beer, E. Shear strength characteristics of the ‘Boom clay’. Proc. Geotech. Conf. Oslo 1967, 1, 83–88. [Google Scholar]

- Schittekat, J.; Henriet, J.P.; Vandenberghe, N. Geology and geotechnique of the Scheldt Surge Barrier, characteristics of an overconsolidated clay. In Proceedings of the 8th International Harbour Congress, Antwerp, Belgium, 13–17 June 1983. [Google Scholar]

- Dyvik, R.; Berre, T.; Lacasse, S.; Raadim, B. Comparison of truly undrained and constant volume direct simple shear tests. Géotechnique 1987, 37, 3–10. [Google Scholar]

- Widodo, S.; Ibrahim, A.M.; Hong, S. Analysis of different equations of undrained shear strength estimations using Atterberg limits on Pontianak soft clay. Chall. Mod. Technol. 2012, 3, 46–50. [Google Scholar]

- Cui, Y.J.; Delage, P. Yielding and plastic behaviour of an unsaturated silt. Géotechnique 1996, 46, 291–311. [Google Scholar] [CrossRef]

- Uchaipichat, A. Effect of suction on unconfined compressive strength of clayey soils with different sand contents. ARPN J. Eng. Appl. Sci. 2014, 9, 881–884. [Google Scholar]

- Zhang, F.; Cui, Y.; Zeng, L.; Robinet, J.C.; Conil, L.; Talandier, J. Effect of degree of saturation on the unconfined compressive strength of natural stiff clays with consideration of air entry valve. Eng. Geol. 2018, 237, 140–148. [Google Scholar] [CrossRef]

- Nakata, Y.; Tashita, T.; Chibana, H.; Matsukata, K. Effect of drainage and saturation on undrained shear strength for compacted sandy soils. E3S Web Conf. 2019, 92, 07003. [Google Scholar] [CrossRef]

- Briaud, J.L. Geotechnical Engineering: Unsaturated and Saturated Soils; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- McManis, K.; Lourie, D.E. Issues and techniques for sampling overconsolidated clays. In Transportation Research Record 1479; National Academy Press: Washington, DC, USA, 1995. [Google Scholar]

| Test | Boring | Depth | Wc | γ | σvi′ | σvc′ | σhc′ | σs′ |

|---|---|---|---|---|---|---|---|---|

| (m) | (%) | (kN/m3) | (kPa) | (kPa) | (kPa) | (kPa) | ||

| ACU_1 | BH3 | 17.8 | 21.2 | 20.1 | 130 | 130 | 65 | 68.3 |

| ACU_2 | BH1 | 17.2 | 23.5 | 18.8 | 120 | 120 | 60 | 0 |

| ACU_3 | BH1 | 26.0 | 26.3 | 19.1 | 210 | 210 | 105 | 125 |

| DSS_1 | BH3 | 17.7 | 20 | 19.3 | 130 | 130 | - | - |

| DSS_2 | BH3 | 25.7 | 33.1 | 18.7 | 210 | 210 | - | - |

| DSS_3 | BH1 | 17.3 | 26.7 | 18.5 | 120 | 120 | - | - |

| DSS_4 | BH1 | 23.3 | 25.7 | 19.1 | 180 | 180 | - | - |

| DSS_5 | BH2 | 26.7 | 36.4 | 17.8 | 220 | 220 | - | - |

| CL_1 | BH1 | 23.5 | 26.1 | 19.7 | 180 | - | - | - |

| CL_2 | BH2 | 26.8 | 30.9 | 18.7 | 220 | - | - | 205 |

| CL_3 | BH2 | 23.5 | 26.4 | 19.4 | 190 | - | - | 230 |

| CV/CRS_1 | BH1 | 23.3 | 26.4 | 19.5 | 180 | - | - | 75 |

| CV/CRS_2 | BH2 | 23.9 | 25.1 | 15.7 | 190 | - | - | 73 |

| CV/CRS_3 | BH2 | 23.6 | 24.8 | 14.7 | 190 | - | - | 98 |

| UCS_1 | BH1 | 23.3 | 25.9 | 18.8 | 180 | - | - | - |

| UCS_2 | BH2 | 26.7 | 31.2 | 18.7 | 220 | - | - | - |

| Property | From the Literature * | Present Study |

|---|---|---|

| Water content, Wc (%) | 20–30 | 20–40 |

| Unit weight, γ (kN/m3) | - | 17.8–20.1 |

| Plastic limit, Wp (%) | 22–29 | 19–28 |

| Liquid limit, WL (%) | 55–80 | 56–80 |

| Test | Boring | Depth | Cc | Cs | Cα | σp′ |

|---|---|---|---|---|---|---|

| (m) | (-) | (-) | (-) | (kPa) | ||

| CRS_1 | BH1 | 23.3 | 0.110 | 0.023 | 0.0017 | 283 |

| CRS_2 | BH2 | 23.9 | 0.130 | 0.019 | 0.0015 | 440 |

| CRS_3 | BH2 | 23.6 | 0.130 | 0.018 | 0.0025 | 315 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konstadinou, M.; Alderlieste, E.A.; Zwanenburg, C.; Cengiz, C.; Peccin da Silva, A.; van Verseveld, C.J.W. In Situ and Laboratory Testing of Boom Clay at Shallow Depths in Belgium. Geotechnics 2025, 5, 23. https://doi.org/10.3390/geotechnics5020023

Konstadinou M, Alderlieste EA, Zwanenburg C, Cengiz C, Peccin da Silva A, van Verseveld CJW. In Situ and Laboratory Testing of Boom Clay at Shallow Depths in Belgium. Geotechnics. 2025; 5(2):23. https://doi.org/10.3390/geotechnics5020023

Chicago/Turabian StyleKonstadinou, Maria, Etienne A. Alderlieste, Cor Zwanenburg, Cihan Cengiz, Anderson Peccin da Silva, and Charlotte J. W. van Verseveld. 2025. "In Situ and Laboratory Testing of Boom Clay at Shallow Depths in Belgium" Geotechnics 5, no. 2: 23. https://doi.org/10.3390/geotechnics5020023

APA StyleKonstadinou, M., Alderlieste, E. A., Zwanenburg, C., Cengiz, C., Peccin da Silva, A., & van Verseveld, C. J. W. (2025). In Situ and Laboratory Testing of Boom Clay at Shallow Depths in Belgium. Geotechnics, 5(2), 23. https://doi.org/10.3390/geotechnics5020023