An Extended Evaluation of the CERCHAR Abrasivity Test for a Practical Excavatability Assessment

Abstract

1. Introduction

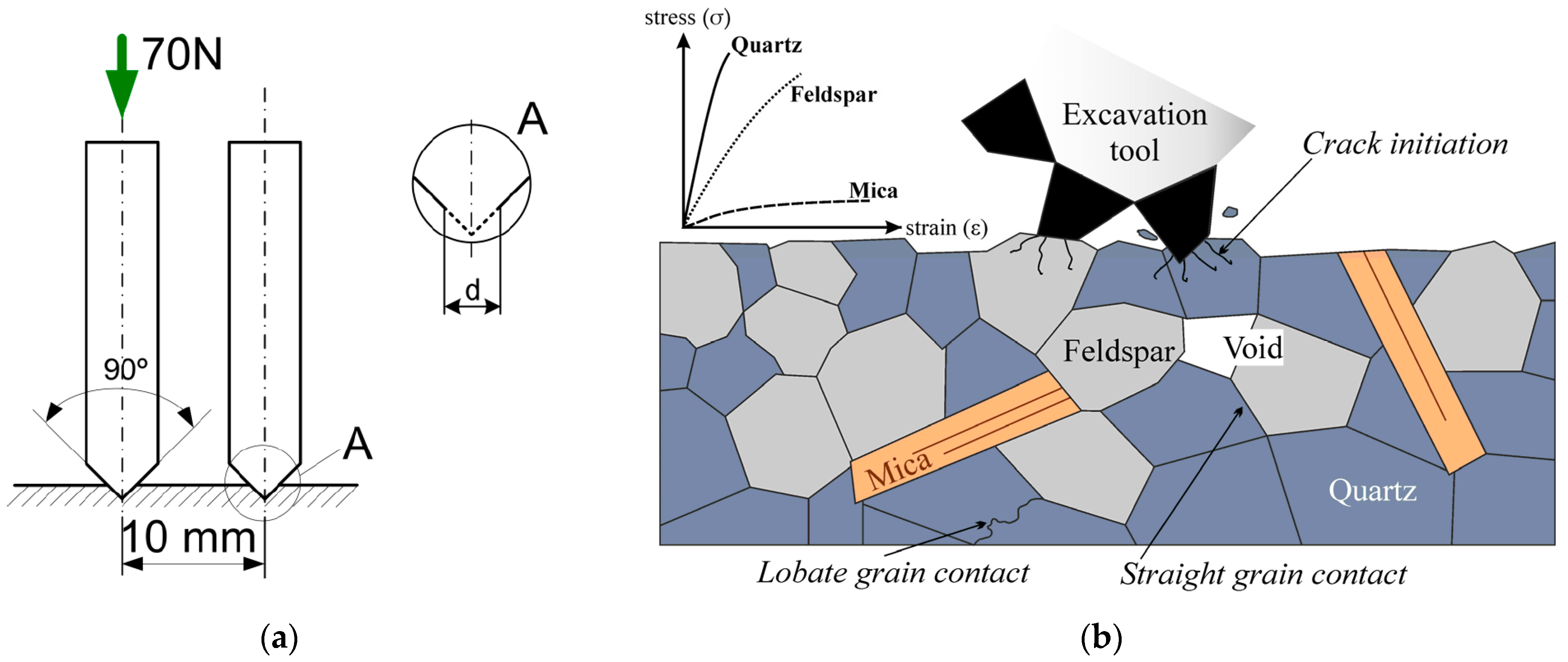

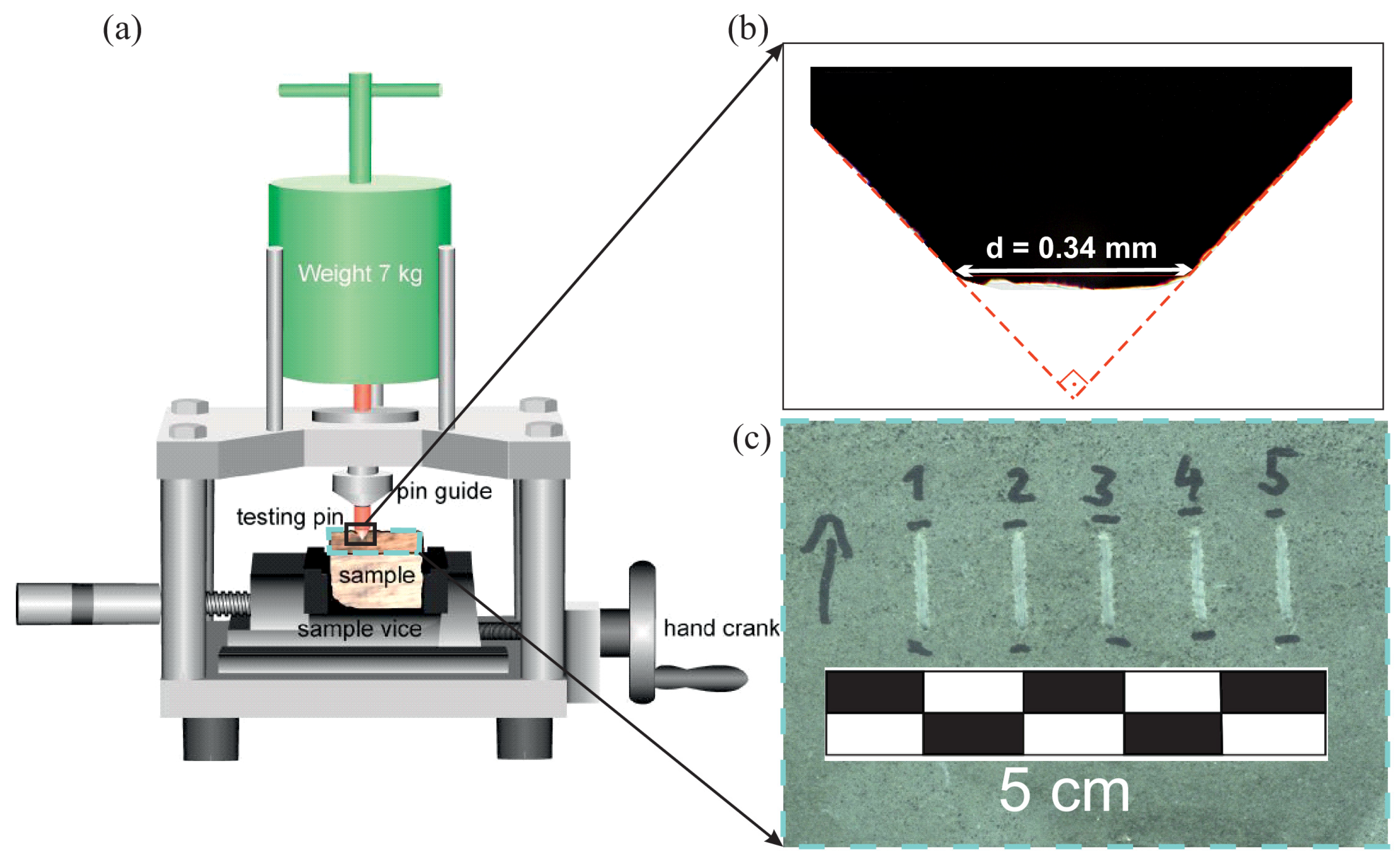

2. Materials and Methods

- CAI = CERCHAR abrasivity index (−)

- d = Wear of the steel pin (mm)

- where

- CAR = CERCHAR abrasivity ratio (−)

- Vm = Volume of the rock material removed from the specimen (mm3)

- Vs = Volumetric wear of the abraded steel pin tip (mm3)

3. Results

3.1. Concept Layout

- Px = Pin penetration depth into the rock surface (mm)

- Sw = Scratch width at the top of the groove (mm)

- CAI = CERCHAR abrasivity index (−)

- where

- Vm = Volume of the rock material removed from specimen (mm3)

- Px = Pin penetration depth into the rock surface (mm)

- Sw = Scratch width at the top of the groove (mm)

3.2. The Excavatability Classification Scheme

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thuro, K. Drillability prediction: Geological influences in hard rock drill and blast tunneling. Geol. Rundsch. 1997, 86, 426–438. [Google Scholar] [CrossRef]

- Plinninger, R.; Kasling, H.; Thuro, K.; Spaun, G. Testing conditions and geomechanical properties influencing the CERCHAR abrasiveness index (CAI) value. Int. J. Rock Mech. Min. Sci. 2003, 40, 259–263. [Google Scholar] [CrossRef]

- Plinninger, R.J. Abrasiveness assessment for hard rock drilling. Geomech. Tunn. 2008, 1, 38–46. [Google Scholar] [CrossRef]

- Schumacher, L. Design parameters and operating conditions for hard-rock tunnelling machines. Felsbau 2004, 22, 21–28. [Google Scholar]

- Cardu, M.; Catanzaro, E.; Farinetti, A.; Martinelli, D.; Todaro, C. Performance analysis of tunnel boring machines for rock excavation. Appl. Sci. 2021, 11, 2794. [Google Scholar] [CrossRef]

- Mucha, K. Application of rock abrasiveness and rock abrasivity test methods—A review. Sustainability 2023, 15, 11243. [Google Scholar] [CrossRef]

- Hamzaban, M.-T.; Rostami, J.; Dahl, F.; Macias, F.J.; Jakobsen, P.D. Wear of cutting tools in hard rock excavation process: A critical review of rock abrasiveness testing methods. Rock Mech. Rock Eng. 2023, 56, 1843–1882. [Google Scholar] [CrossRef]

- Centre d’Études et Recherches des Charbonnages de France. The CERCHAR Abrasiveness Index; CERCHAR Report No 86-538; Centre d’Études et Recherches des Charbonnages de France: Paris, France, 1986; 12p.

- Zhang, S.-R.; She, L.; Wang, C.; Wang, Y.-J.; Cao, R.-L.; Li, Y.-L.; Cao, K.-L. Investigation on the relationship among the Cerchar abrasivity index, drilling parameters and physical and mechanical properties of the rock. Tunn. Undergr. Space Technol. 2021, 112, 103907. [Google Scholar] [CrossRef]

- Gao, K.; Wang, X.; Wei, H.; Wang, S.; Xu, W.; Li, X.; Sun, L. Abrasivity database of different genetic rocks based on CERCHAR Abrasivity Test. Sci. Data 2024, 11, 630. [Google Scholar] [CrossRef]

- AFNOR. Détermination du Pouvoir Abrasive D’une Roche—Partie 1: Essai de Rayure avec une Pointe (NF P94-430-1); Association Française de Normalisation: Paris, France, 2000; 7p. [Google Scholar]

- Zhang, G.; Konietzky, H. CERCHAR Abrasion Ratio (CAR) as a new indicator for assessing rock abrasivity, rock–stylus interaction and cutting efficiency. Rock Mech. Rock Eng. 2020, 53, 3363–3371. [Google Scholar] [CrossRef]

- Hamzaban, M.-T.; Memarian, H.; Rostami, J. Continuous monitoring of pin tip wear and penetration into rock surface using a new Cerchar Abrasivity testing device. Rock Mech. Rock Eng. 2014, 47, 689–701. [Google Scholar] [CrossRef]

- Hamzaban, M.-T.; Memarian, H.; Rostami, J.; Ghasemi-Monfared, H. Study of rock–pin interaction in Cerchar abrasivity test. Int. J. Rock Mech. Min. Sci. 2014, 72, 100–108. [Google Scholar] [CrossRef]

- Kaspar, M.; Frühwirt, T.; Latal, C.; Blümel, M. Towards a rapid and practical determination of the pin-rock interaction parameters of the CERCHAR abrasivity test. In Engineering Geology and Geotechnics: Building for the Future, Proceedings of the 4th European Regional Conference of IAEG, Dubrovnik, Croatia, 8–12 October 2024; University of Zagreb, Faculty of Civil Engineering: Zagreb, Croatia, 2024; pp. 71–80. [Google Scholar]

- Heiniö, M. Rock Excavation Handbook; Sandvik Tamrock Corporation: Tampere, Finland, 1999; 183p. [Google Scholar]

- Arthur, C.D. The determination of rock material properties to predict the performance of machine excavation in tunnels. Q. J. Eng. Geol. 1996, 29, 67–81. [Google Scholar] [CrossRef]

- Piazzetta, G.R.; Lagoeiro, L.E.; Figueira, I.F.R.; Rabelo, M.A.G.; Pintaude, G. Identification of abrasion regimes based on mechanisms of wear on the steel stylus used in the Cerchar abrasiveness test. Wear 2018, 410–411, 181–189. [Google Scholar] [CrossRef]

- Verhoef, P.N.W. Wear of Rock Cutting Tools—Implications for the Site Investigation of Rock Dredging Projects, 1st ed.; Routledge: London, UK, 1997; 340p. [Google Scholar] [CrossRef]

- Maidl, B.; Schmid, L.; Ritz, W.; Herrenknecht, M. Hardrock Tunnel Boring Machines; Ernst & Sohn: Berlin, Germany, 2008; 343p. [Google Scholar] [CrossRef]

- Oggeri, C.; Oreste, P. The wear of Tunnel Boring Machine excavation tools in rock. Am. J. Appl. Sci. 2012, 9, 1606–1617. [Google Scholar] [CrossRef]

- ASTM D 7625-22; Standard Test Method for Laboratory Determination of Abrasiveness of Rock Using the CERCHAR Abrasiveness Index Method (D 7625). ASTM International: West Conshohocken, PA, USA, 2022.

- Alber, M.; Yarali, O.; Dahl, F.; Bruland, A.; Kasling, H.; Michalakopoulos, T.N.; Cardu, M.; Hagan, P.; Aydin, H.; Ozarslan, A. ISRM suggested method for determining the abrasivity of rock by the CERCHAR Abrasivity Test. Rock Mech. Rock Eng. 2014, 47, 261–266. [Google Scholar] [CrossRef]

- Käsling, H.; Plinninger, R.J. Determining the abrasivity of rock using the CERCHAR test—Recommendation No. 23 of the Commission on Rock Testing of the German Geotechnical Society. Bautechnik 2016, 93, 409–415. [Google Scholar] [CrossRef]

- ÖBV. Merkblatt Abrasivitätsbestimmung von Grobkörnigem Lockergestein; Österreichische Bautechnikvereinigung: Vienna, Austria, 2013; 27p. [Google Scholar]

- West, G. Rock abrasiveness testing for tunnelling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1989, 26, 151–160. [Google Scholar] [CrossRef]

- Plinninger, R.J.; Restner, U. Abrasivity Testing, Quo Vadis?—A commented overview of abrasivity testing methods. Geomech. Tunn. 2008, 1, 61–70. [Google Scholar] [CrossRef]

- Valantin, A. Test CERCHAR pour la mesure de la dureté et de l’abrasivité des roches. In Development and Exploratory Techniques in Coal Mines; Commission of the European Communities: Luxembourg, Luxembourg, 1974; pp. 186–193. [Google Scholar]

- Rostami, J.; Ozdemir, L.; Bruland, A.; Dahl, F. Review of issues related to Cerchar abrasivity testing and their implications on geotechnical investigations and cutter cost estimates. In Proceedings of the Rapid Excavation and Tunneling Conference, Seattle, WA, USA, 27–29 June 2005; Society for Mining Metallurgy & Exploration: Englewood, CO, USA, 2005. 13p. [Google Scholar]

- Suana, M.; Peters, T. The Cerchar Abrasivity Index and its relation to rock mineralogy and petrography. Rock Mech. 1982, 15, 1–8. [Google Scholar] [CrossRef]

- Al-Ameen, S.I.; Waller, M.D. The influence of rock strength and abrasive mineral content on the CERCHAR Abrasive Index. Eng. Geol. 1994, 36, 293–301. [Google Scholar] [CrossRef]

- Ersoy, A.; Waller, M.D. Textural characterization of rocks. Eng. Geol. 1995, 39, 123–136. [Google Scholar] [CrossRef]

- Thuro, K.; Käsling, H. Classification of the abrasiveness of soil and rock. Geomech. Tunn. 2009, 2, 179–188. [Google Scholar] [CrossRef]

- Moradizadeh, M.; Cheshomi, A.; Ghafoori, M.; TrighAzali, S. Correlation of equivalent quartz content, Slake durability index and Is50 with Cerchar abrasiveness index for different types of rock. Int. J. Rock Mech. Min. Sci. 2016, 86, 4247. [Google Scholar] [CrossRef]

- Askaripour, M.; Saeidi, A.; Mercier-Langevin, P.; Rouleau, A.A. Review of relationship between texture characteristic and mechanical properties of rock. Geotechnics 2022, 2, 262–296. [Google Scholar] [CrossRef]

- Kaspar, M.; Latal, C.; Pittino, G.; Blümel, M. Hardness, strength and abrasivity of rocks: Correlations and predictions. Geomech. Tunn. 2023, 16, 184–192. [Google Scholar] [CrossRef]

- Plinninger, R.J.; Spaun, G.; Thuro, K. Prediction and classification of tool wear in drill and blast tunnelling. In Engineering Geology for Developing Countries; International Association for Engineering Geology and the Environment: Durban, South Africa, 2002; pp. 2226–2236. ISBN 0-620-28559-1. [Google Scholar]

- Kanji, M.A. Critical issues in soft rocks. J. Rock Mech. Geot. Eng. 2014, 6, 186–195. [Google Scholar] [CrossRef]

- Kaspar, M.; Latal, C.; Blümel, M.; Pittino, G. Is soft rock also non-abrasive rock? An evaluation from lab testing campaigns. IOP Conf. Ser. Earth Environ. Sci. 2023, 1124, 012019. [Google Scholar] [CrossRef]

- Rao Karanam, U.M.; Misra, B. Principles of Rock Drilling; A.A. Balkema: Rotterdam, The Netherlands, 1998; 265p. [Google Scholar]

- Piazzetta, G.R.; Figueira, I.F.R.; Gonçalves, M.A. Cerchar Abrasiveness Test—The portability between rock abrasiveness laboratory test and real excavation projects. In International Symposium on Field Measurements in Geomechanics; ISSMGE: Rio de Janeiro, Brazil, 2018; 16p. [Google Scholar]

- Rostami, J. Hard rock TBM cutterhead modeling for design and performance prediction. Geomech. Tunn. 2008, 1, 18–28. [Google Scholar] [CrossRef]

- Singh, S.P. A simple criterion for the machinability of hard rocks. Int. J. Mining Geol. Eng. 1989, 7, 257–266. [Google Scholar] [CrossRef]

- Lislerud, A. Principles of Mechanical Excavation; Posiva Report No. 97-12; Possiva Oy: Helsinki, Finland, 1997; 186p. [Google Scholar]

- Alber, M. Stress dependency of the Cerchar abrasivity index (CAI) and its effects on wear of selected rock cutting tools. Tunn. Undergr. Space Technol. 2008, 23, 351–359. [Google Scholar] [CrossRef]

| Rock Type | Specimen No. | CAI (−) | Vm (mm3) | CAR (−) |

|---|---|---|---|---|

| Limestone (marly) | 1 | 0.8 | 1.24 | 4.27 |

| Limestone (marly) | 2 | 1.9 | 0.37 | 2.61 |

| Limestone (marly) | 3 | 2.5 | 0.06 | 1.46 |

| Limestone (marly) | 4 | 0.8 | 1.20 | 4.25 |

| Limestone (marly) | 5 | 1.5 | 0.24 | 2.73 |

| Limestone | 6 | 2.3 | 0.10 | 1.80 |

| Marble w. dolomite | 7 | 0.7 | 3.37 | 4.88 |

| Marble w. dolomite | 8 | 1.3 | 0.14 | 2.70 |

| Limestone | 9 | 1.2 | 0.16 | 2.85 |

| Limestone | 10 | 1.2 | 0.25 | 3.05 |

| Limestone | 11 | 1.1 | 0.25 | 3.15 |

| Dolomitic marble | 12 | 1.4 | 0.40 | 3.04 |

| Dolomitic marble | 13 | 0.9 | 2.43 | 4.41 |

| Dolomite (w. palygorskite) | 14 | 2.2 | 0.22 | 2.20 |

| Limestone (marly) | 15 | 0.8 | 1.34 | 4.30 |

| Limestone (marly) | 16 | 1.1 | 1.86 | 4.03 |

| Dolomite breccia | 17 | 1.2 | 1.02 | 3.65 |

| Anhydrite w. dolomite | 18 | 1.3 | 0.20 | 2.84 |

| Anhydrite w. dolomite | 19 | 1.5 | 0.24 | 2.73 |

| Gypsum | 20 | 1.4 | 0.93 | 3.41 |

| Gypsum | 21 | 1.7 | 0.76 | 3.07 |

| Sandstone | 22 | 2.2 | 2.22 | 3.20 |

| Sandstone | 23 | 1.7 | 1.35 | 3.32 |

| Sandstone | 24 | 1.7 | 2.41 | 3.57 |

| Sandstone | 25 | 1.4 | 2.90 | 3.91 |

| Sandstone | 26 | 3.2 | 0.60 | 2.14 |

| Sandstone | 27 | 2.0 | 0.35 | 2.52 |

| Sandstone (coarse-grained) | 28 | 2.4 | 0.82 | 2.66 |

| Sandstone | 29 | 1.0 | 1.73 | 4.12 |

| Clay-/siltstone | 30 | 0.3 | 1.04 | 5.47 |

| Clay-/siltstone | 31 | 0.6 | 1.36 | 4.68 |

| Clay-/siltstone | 32 | 1.0 | 3.57 | 4.44 |

| Clay-/siltstone | 33 | 0.4 | 3.66 | 5.64 |

| Clay-/siltstone | 34 | 0.9 | 2.05 | 4.33 |

| Clay-/siltstone | 35 | 0.6 | 2.21 | 4.89 |

| Mica schist | 36 | 2.6 | 0.13 | 1.74 |

| Mica schist | 37 | 4.4 | 0.14 | 1.10 |

| Mica schist | 38 | 2.9 | 0.49 | 2.19 |

| Mica schist | 39 | 3.3 | 0.23 | 1.68 |

| Mica schist | 40 | 1.5 | 0.65 | 3.17 |

| Quartzitic phyllite | 41 | 3.8 | 0.21 | 1.47 |

| Serizitic phyllite/mica schist | 42 | 2.7 | 0.96 | 2.57 |

| Mica schist | 43 | 3.2 | 0.76 | 2.25 |

| Mica schist (folded) | 44 | 3.3 | 0.79 | 2.23 |

| Mica schist | 45 | 3.9 | 0.17 | 1.35 |

| Mica schist | 46 | 3.5 | 0.12 | 1.34 |

| Granite | 47 | 3.9 | 0.12 | 1.20 |

| Gneiss | 48 | 4.6 | 0.17 | 1.11 |

| Gneiss (coarse-grained) | 49 | 3.8 | 0.16 | 1.34 |

| Granite | 50 | 3.9 | 0.20 | 1.41 |

| Gneiss (coarse-grained) | 51 | 3.8 | 0.16 | 1.34 |

| Gneiss (coarse-grained) | 52 | 3.7 | 0.18 | 1.44 |

| Gneiss (coarse-grained) | 53 | 3.6 | 0.08 | 1.14 |

| Granite | 54 | 2.4 | 1.68 | 2.97 |

| Granite | 55 | 3.4 | 0.23 | 1.65 |

| Gneiss, quarzitic, banded | 56 | 4.1 | 0.23 | 1.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaspar, M.; Latal, C. An Extended Evaluation of the CERCHAR Abrasivity Test for a Practical Excavatability Assessment. Geotechnics 2024, 4, 1246-1258. https://doi.org/10.3390/geotechnics4040063

Kaspar M, Latal C. An Extended Evaluation of the CERCHAR Abrasivity Test for a Practical Excavatability Assessment. Geotechnics. 2024; 4(4):1246-1258. https://doi.org/10.3390/geotechnics4040063

Chicago/Turabian StyleKaspar, Markus, and Christine Latal. 2024. "An Extended Evaluation of the CERCHAR Abrasivity Test for a Practical Excavatability Assessment" Geotechnics 4, no. 4: 1246-1258. https://doi.org/10.3390/geotechnics4040063

APA StyleKaspar, M., & Latal, C. (2024). An Extended Evaluation of the CERCHAR Abrasivity Test for a Practical Excavatability Assessment. Geotechnics, 4(4), 1246-1258. https://doi.org/10.3390/geotechnics4040063