Exploring Soil–Water Characteristic Curves in Transitional Oil Sands Tailings

Abstract

1. Introduction

- Gravimetric water content which is the ratio of mass of water (Mw) to mass of solids (Ms) as in Equation (1)

- Degree of saturation which refers to the percentage ratio of volume of water (Vw) to instantaneous volume of voids (Vv) as in Equation (2)

- Volumetric water content defined as the ratio of volume of water (Vw) to the initial total soil volume (V) shown in Equation (3)

- Instantaneous volumetric water content relating the volume of water in the soil to instantaneous volume of soil as shown in Equation (4)

2. Materials and Methods

2.1. Materials

2.2. Methodology

2.2.1. Samples Preparations

2.2.2. Particle Size Distribution (PSD)

2.2.3. Atterbergy Limits

2.2.4. Methylene Blue Index (MBI)

2.2.5. Bitumen Content

2.2.6. Specific Gravity

2.2.7. Soil Water Characteristics Curves (SWCC)

2.2.8. Shrinkage Curves

3. Results

3.1. Particle Size Distribution (PSD)

3.2. Atterberg Limits and Clay Properties

3.3. Shrinkage Curve

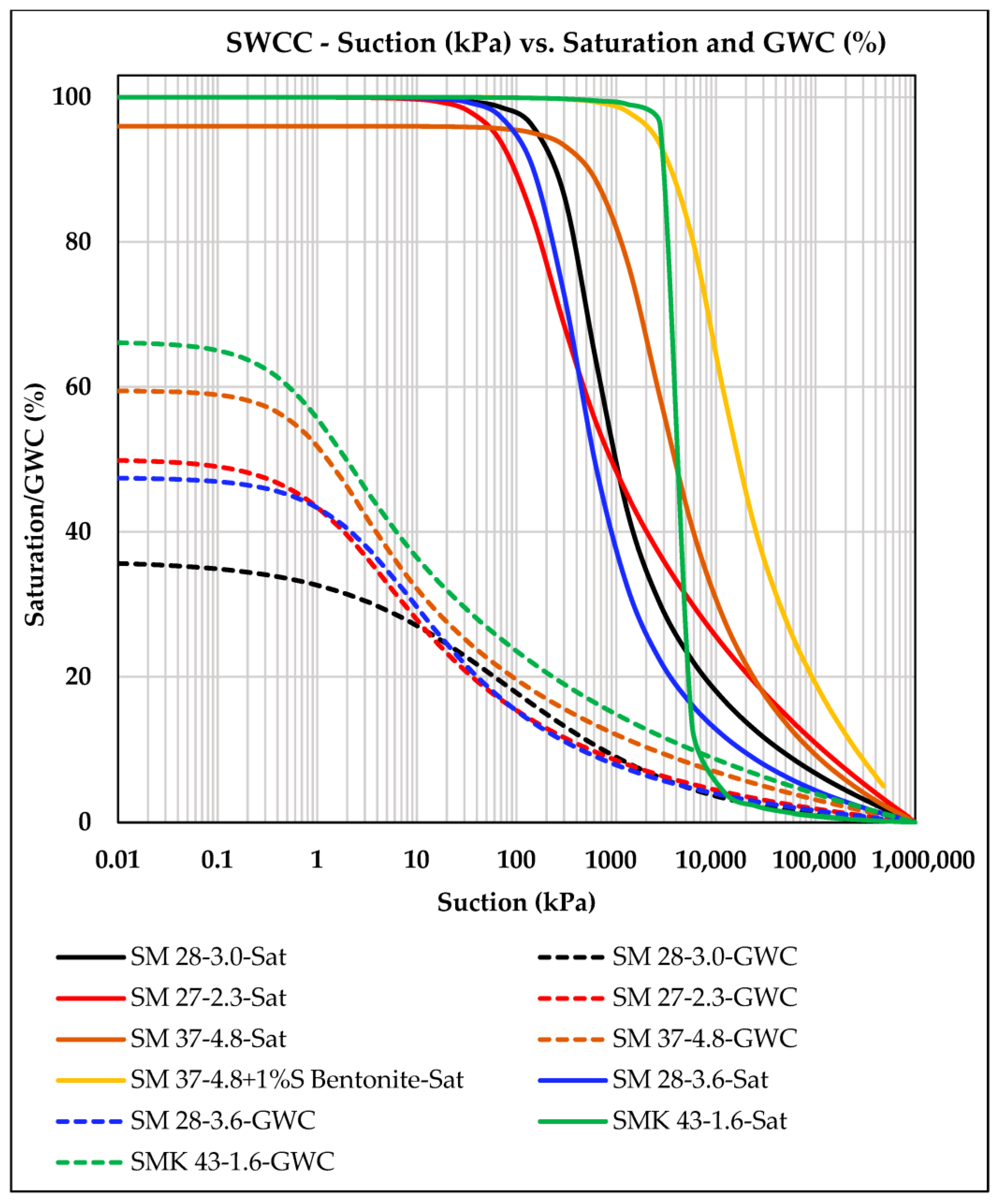

3.4. Soil Water Characteristics Curve

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Natural Resources Canada. Energy Fact Book 2022–2023; Natural Resources Canada: Ottawa, ON, Canada, 2023.

- Alberta Energy Regulator. State of Fluid Tailings Management for Mineable Oil Sands-2022; Alberta Energy Regulator: Calgary, AB, Canada, 2023.

- Beier Nicholas, A.; Kabwe Louis, K.; Don Scott, J.; Pham Nam, H.; Wilson, G.W. Modeling the Effect of Flocculation and Desiccation on Oil Sands Tailings. Geo-Chicago 2016, 2016, 321–330. [Google Scholar] [CrossRef]

- Chalaturnyk, R.J.; Don Scott, J.; Özüm, B. Management of oil sands tailings. Pet. Sci. Technol. 2002, 20, 1025–1046. [Google Scholar] [CrossRef]

- Fredlund, D.G.; Rahardjo, H.; Fredlund, M.D. Unsaturated Soil Mechanics in Engineering Practice; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar] [CrossRef]

- Zhang, F.; Fredlund, D.G.; Ward Wilson, G. Water Permeability Function for Soils that Undergo Volume Change as Suction Changes. Indian Geotech. J. 2016, 46, 210–227. [Google Scholar] [CrossRef]

- Fredlund, D.; Houston, S. Interpretation of soil-water characteristic curves when volume change occurs as soil suction is changed. Adv. Unsaturated Soils 2013, 1, 15. [Google Scholar]

- Fredlund, D.; Stone, J.; Stianson, J.; Sedgwick, A. Determination of water storage and permeability functions for oil sands tailings. In Proceedings of the Tailings and Mine Waste, Vancouver, BC, Canada, 1 November 2011. [Google Scholar]

- Watabe, Y.; Yamada, K.; Saitoh, K. Hydraulic conductivity and compressibility of mixtures of Nagoya clay with sand or bentonite. Géotechnique 2011, 61, 211–219. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Hasan, R.A. Compressional behaviour of various size/shape sand–clay mixtures with different pore fluids. Eng. Geol. 2013, 164, 36–49. [Google Scholar] [CrossRef]

- Carrera, A.; Coop, M.; Lancellotta, R. Influence of grading on the mechanical behaviour of Stava tailings. Géotechnique 2011, 61, 935–946. [Google Scholar] [CrossRef]

- Li, W.; Coop, M.R. Mechanical behaviour of Panzhihua iron tailings. Can. Geotech. 2019, 56, 420–435. [Google Scholar] [CrossRef]

- Croney, D.; Coleman, J. Soil Structure in Relation to Soil Suction (pF). J. Soil Sci. 1954, 5, 75–84. [Google Scholar] [CrossRef]

- Fredlund, D.; Zhang, F. Combination of shrinkage curve and soil-water characteristic curves for soils that undergo volume change as soil suction is increased. In Proceedings of the Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 2–6. [Google Scholar]

- Huang, S.; Barbour, S.L.; Fredlund, D.G. Development and verification of a coefficient of permeability function for a deformable unsaturated soil. Can. Geotech. J. 1998, 35, 411–425. [Google Scholar] [CrossRef]

- Fredlund, D.G. The 1999 RM Hardy Lecture: The implementation of unsaturated soil mechanics into geotechnical engineering. Can. Geotech. J. 2000, 37, 963–986. [Google Scholar] [CrossRef]

- Parent, S.-É.; Cabral, A.; Zornberg, J.G. Water retention curve and hydraulic conductivity function of highly compressible materials. Can. Geotech. J. 2007, 44, 1200–1214. [Google Scholar] [CrossRef]

- Mbonimpa, M.; Aubertin, M.; Maqsoud, A.; Bussière, B. Predictive Model for the Water Retention Curve of Deformable Clayey Soils. J. Geotech. Geoenvironmental Eng. 2006, 132, 1121–1132. [Google Scholar] [CrossRef]

- COSIA Deposit Characterization Committee. Measuring Undrained Shear Strength of Oil Sands Tailings Deposits; COSIA: Calgary, AB, Canada, 2014. [Google Scholar]

- OSTC/COSIA. Technical Guide for Fluid Fine Tailings Management; Oil Sands Tailings Consortium: Calgary, AB, Canada, 2012. [Google Scholar]

- Imperial Oil Resources Limited. Mine Plan Amendment and Tailings Management Plan Integrated Application; Alberta Energy Regulator: Calgary, AB, Canada, 2022.

- CNRL. Canadian Natural Jackpine Mine Fluid Tailings Management Report; Alberta Energy Regulator: Calgary, AB, Canada, 2020.

- Konert, M.; Vandenberghe, J. Comparison of laser grain size analysis with pipette and sieve analysis: A solution for the underestimation of the clay fraction. Sedimentology 1997, 44, 523–535. [Google Scholar] [CrossRef]

- D4318-17; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- Sethi, A. Methylene Blue Test for Clay Activity Determination in Fine Tails. MRRT Proced. 1995, 23. [Google Scholar]

- Kaminsky, H. Demystifying the methylene blue index. In Proceedings of the Oil Sands Tailings 2014, Lake Louise, AB, Canada, 8–10 December 2014. [Google Scholar]

- Wells, P.; Kaminsky, H. Slurry to soil clay behaviour model—Using methylene blue to cross the process/geotechnical engineering divide. In Proceedings of the Tailings and Mine Waste 2015, Vancouver, BC, Canada, 26–28 October 2015. [Google Scholar]

- Omotoso, O.; Morin, M. Methylene Blue Procedure: Dean Stark Solids; CanmetENERGY: Devon, UK, 2008.

- D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- UMS GmbH. Operation Manual-HYPROP; UMS GmbH: Frankfurt, Germany, 2015. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Gee, G.; Campbell, M.; Campbell, G.S.; Campbell, J. Rapid measurement of low soil water potentials using a water activity meter. Soil Sci. Soc. Am. J. 1992, 56, 1068–1070. [Google Scholar] [CrossRef]

- Decagon Devices. Operator’s Manual for Models WP4 and WP4-T; Hopkins Court: Pullman WA, USA, 1998. [Google Scholar]

- Fredlund, D.; Xing, A. Equations for the Soil–Water Characteristic Curve. Can. Geotech. 1994, 31, 521–532. [Google Scholar] [CrossRef]

- Fredlund, M.; Wilson, G.; Fredlund, D. Representation and estimation of the shrinkage curve. In Proceedings of the Unsaturated Soils: Proceedings of the Third International Conference, UNSAT2002, Recife, Brazil, 10–13 March 2002; p. 145. [Google Scholar]

- Song, Y.-S.; Hong, S. Effect of clay minerals on the suction stress of unsaturated soils. Eng. Geol. 2020, 269, 105571. [Google Scholar] [CrossRef]

| ID | Fines (−44 μm) | Clay (−2 μm) | SFR | D10 (μm) |

|---|---|---|---|---|

| SM 28-3.0 | 27.6% | 12% | 2.6 | 7.5 |

| SM 27-2.3 | 27.5% | 13% | 2.6 | 6.8 |

| SM 37-4.8 | 37.5% | 18% | 1.7 | 6.0 |

| SM 28-3.6 | 28.3% | 16% | 2.5 | 5.7 |

| SMK 43-1.6 | 43.0% | 38% | 1.3 | 0.2 |

| ID | Clay (−2 μm) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Activity | MBI |

|---|---|---|---|---|---|---|

| SM 28-3.0 | 12% | 23% | 10% | 13% | 1.1 | 3.0 |

| SM 27-2.3 | 13% | 22% | 9% | 13% | 1.0 | 2.3 |

| SM 37-4.8 | 18% | 29% | 10% | 19% | 1.0 | 4.8 |

| SM 28-3.6 | 16% | 21% | 12% | 9% | 0.6 | 3.6 |

| SMK 43-1.6 | 38% | 24% | 12% | 12% | 0.3 | 1.6 |

| ID | AEV (kPa) from w-SWCC | AEV (kPa) from s-SWCC | |

|---|---|---|---|

| SM 28-3.0 | 2.0 | 200 | 100 |

| SM 27-2.3 | 0.45 | 60 | 133 |

| SM 37-4.8 | 0.3 | 200 | 667 |

| SM 37-4.8 + 1%S Bentonite | - | 2000 | - |

| SM 28-3.6 | 1.5 | 90 | 60 |

| SMK 43-1.6 | 0.3 | 2700 | 9000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaheshi, P.; Wilson, G.W.; Kaminsky, H. Exploring Soil–Water Characteristic Curves in Transitional Oil Sands Tailings. Geotechnics 2024, 4, 1106-1123. https://doi.org/10.3390/geotechnics4040056

Kaheshi P, Wilson GW, Kaminsky H. Exploring Soil–Water Characteristic Curves in Transitional Oil Sands Tailings. Geotechnics. 2024; 4(4):1106-1123. https://doi.org/10.3390/geotechnics4040056

Chicago/Turabian StyleKaheshi, Peter, G. Ward Wilson, and Heather Kaminsky. 2024. "Exploring Soil–Water Characteristic Curves in Transitional Oil Sands Tailings" Geotechnics 4, no. 4: 1106-1123. https://doi.org/10.3390/geotechnics4040056

APA StyleKaheshi, P., Wilson, G. W., & Kaminsky, H. (2024). Exploring Soil–Water Characteristic Curves in Transitional Oil Sands Tailings. Geotechnics, 4(4), 1106-1123. https://doi.org/10.3390/geotechnics4040056