Effect of Material Composition on Geotechnical Properties—Study on Synthetic Municipal Solid Waste

Abstract

1. Introduction

Background

- The impact of material size on the shear strength of the MSW;

- The effect of dynamic loading on the shear strength of MSW;

- The impact of each material composition on the shear strength of MSW;

- The significance of sample preparation and sample testing procedure in the laboratory.

2. Materials and Method

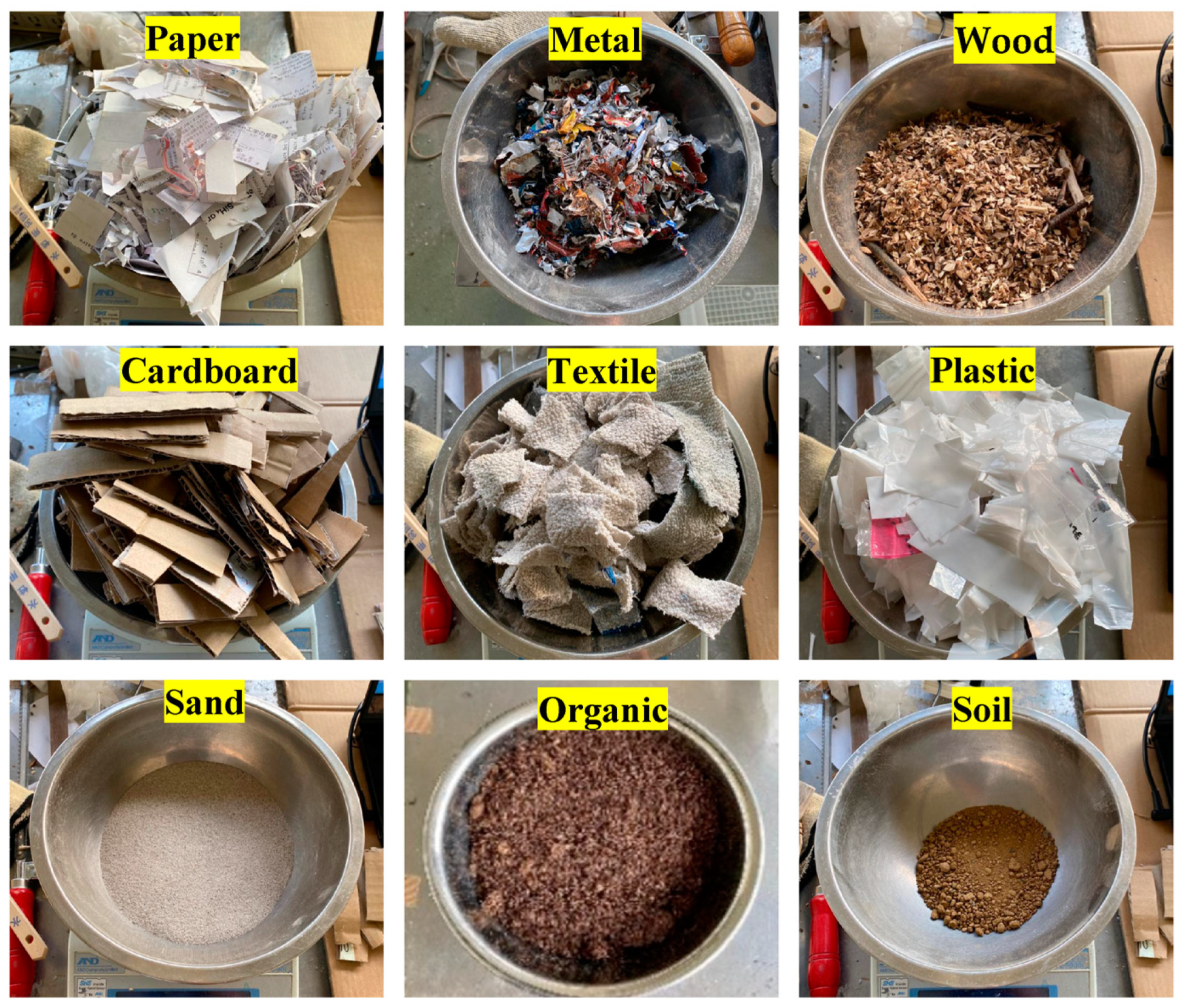

2.1. Synthetic Waste

Synthetic Municipal Solid Waste Composition Used for Testing

2.2. Methods

2.2.1. Modified Proctor Test

2.2.2. Direct Shear Test

3. Results

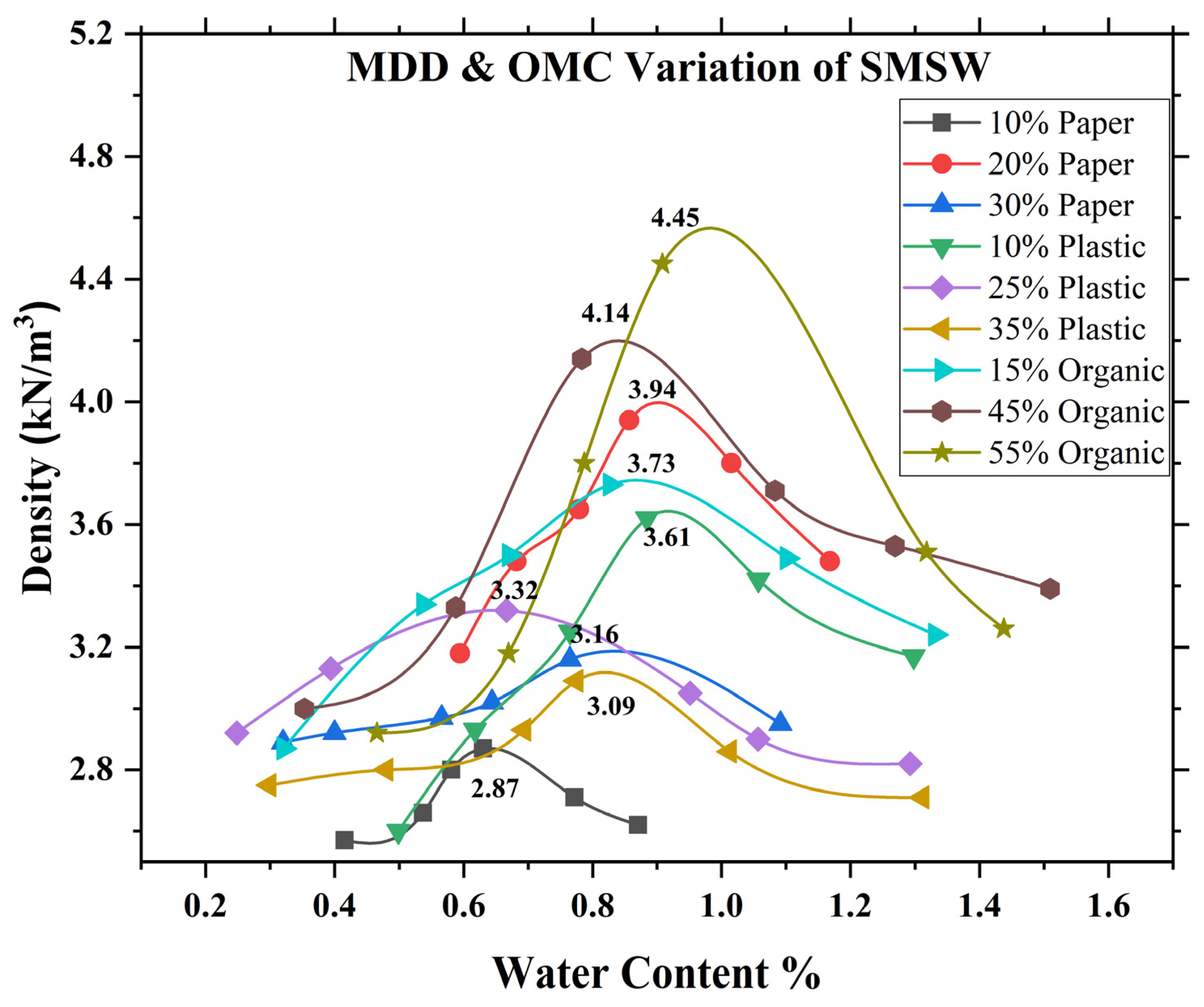

3.1. Proctor Test

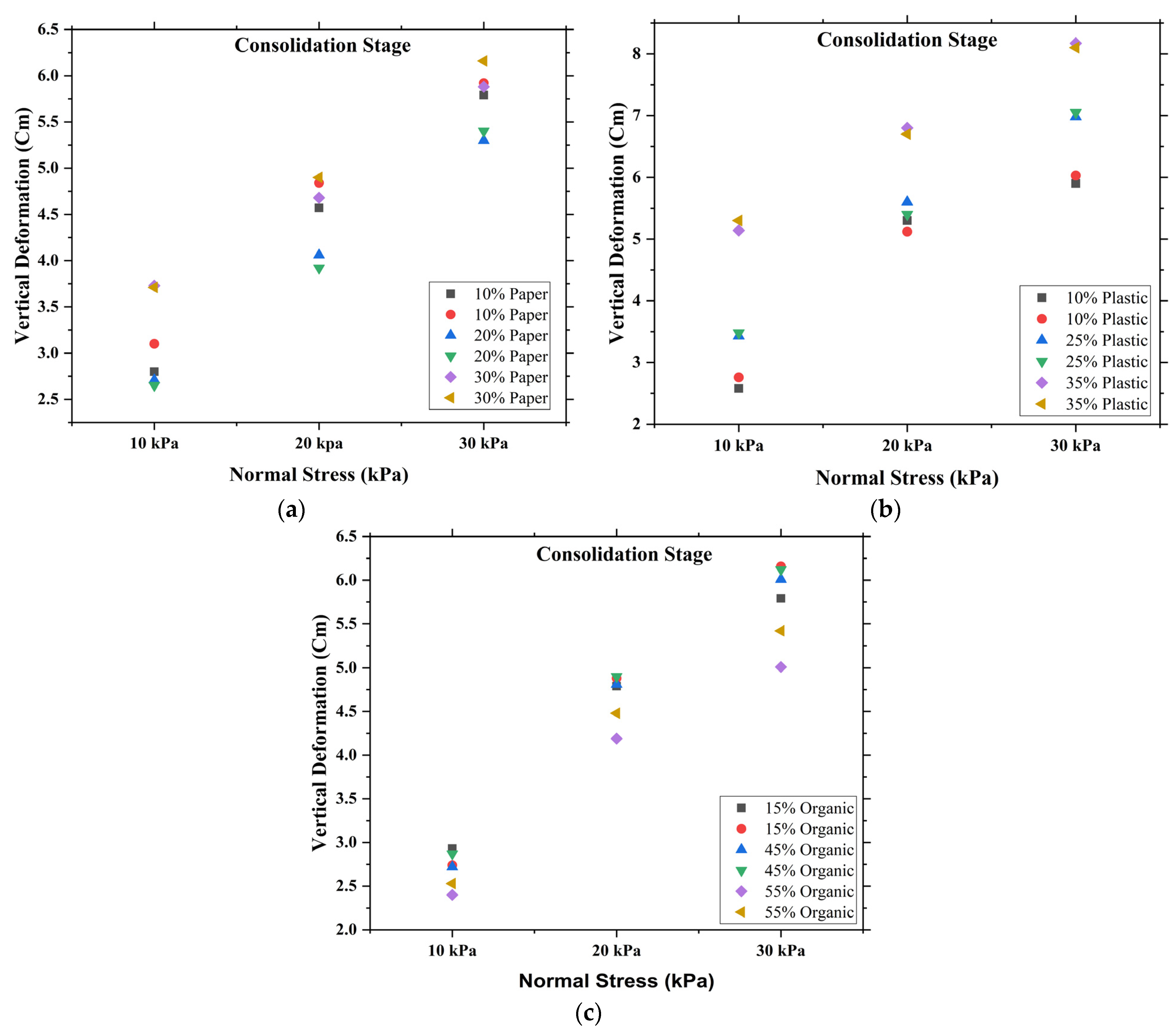

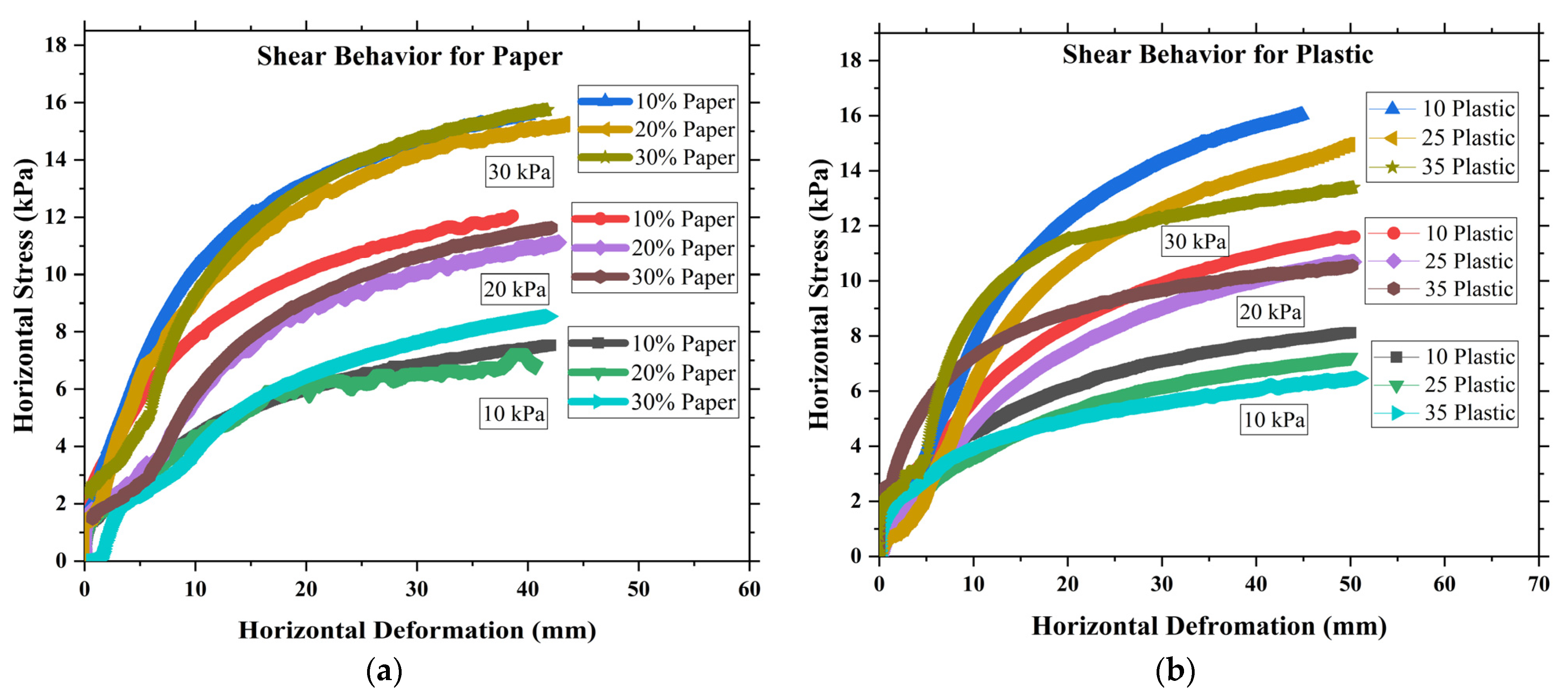

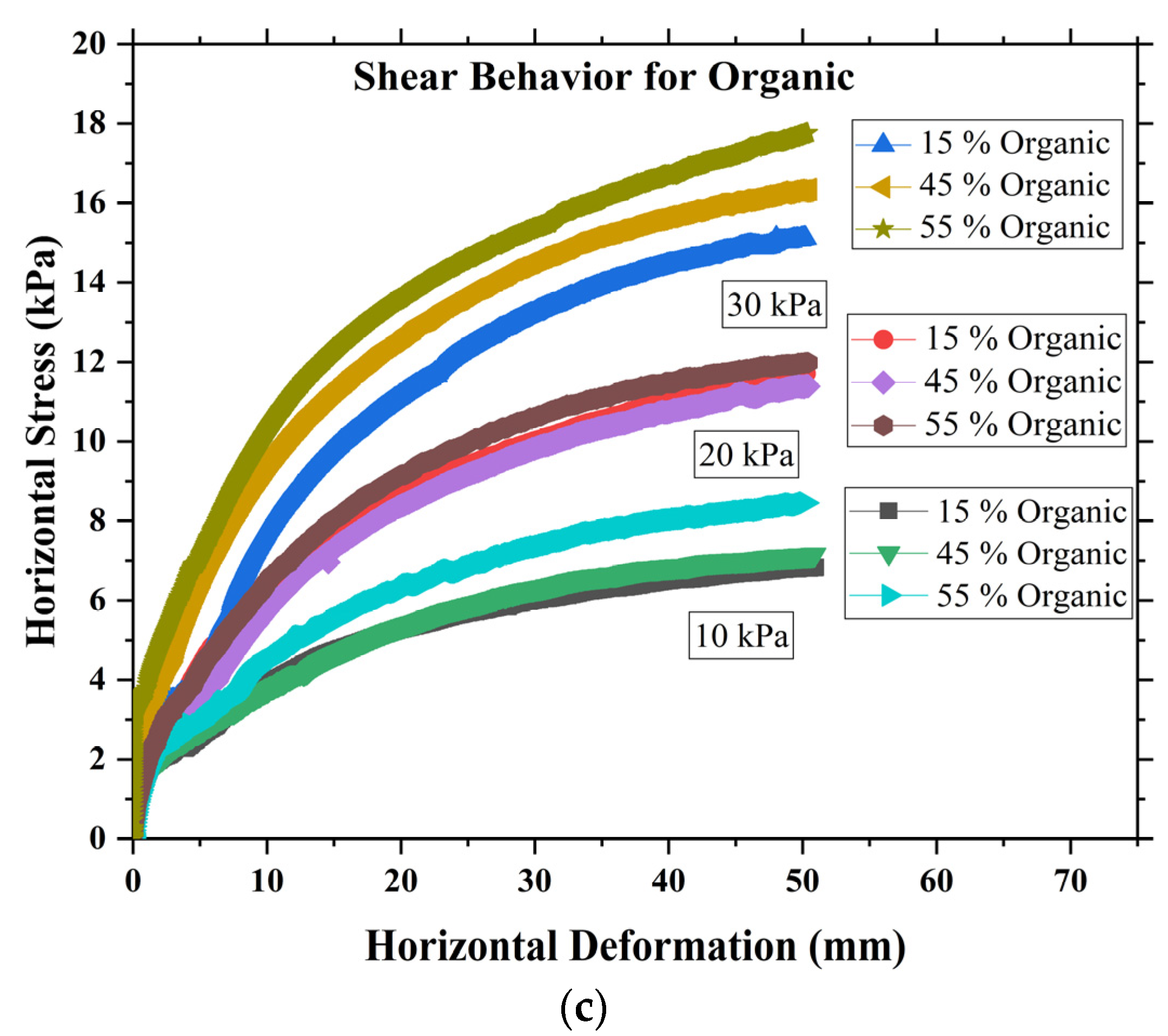

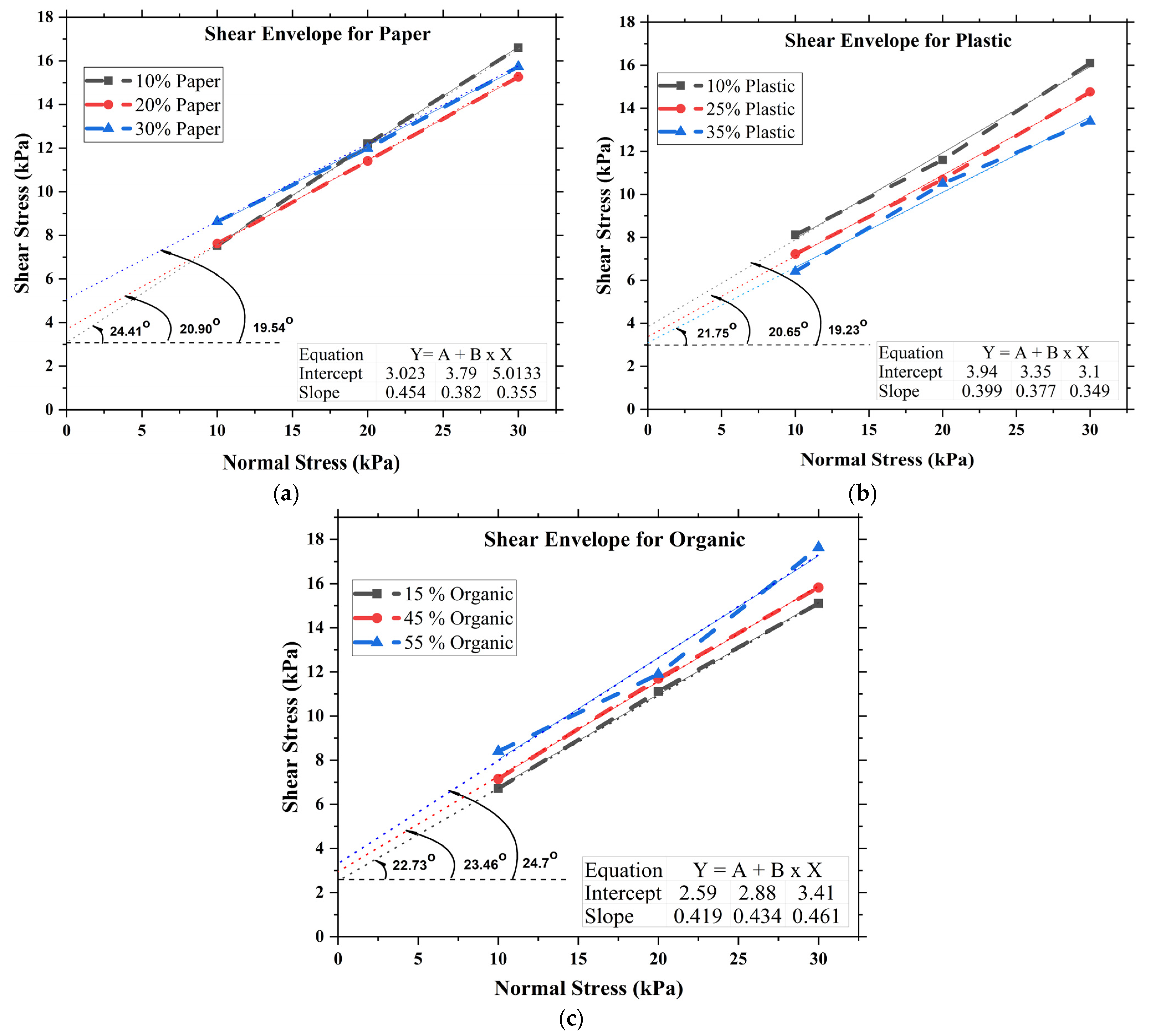

3.2. Direct Shear Test Result

4. Discussion

Measured SMSW Geotechnical Properties

5. Conclusions

- The shear strength parameters of SW-01, SW-02, and SW-03 are compared. It is observed as the proportion of paper increases, the cohesion increases, and the friction angle decreases. When samples SW-01 and SW-03 are compared, cohesion increases by 66.67%, and the friction angle decreases by 20%.

- The shear strength parameters of SW-04, SW-05, and SW-06 are compared, and the percentage of plastic increases in cohesion while the friction angle decreases. When comparing SW-04 and SW-06, the cohesion decreased by 25%, and the friction angle decreased by 11%.

- The samples SW-07, SW-08, and SW-09 are compared; with the increase in the organic content, the cohesion and friction angle increase. The samples SW-07 and SW-09 are compared, and the cohesion is increased by 36.41%, while the friction angle increased by 9%.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohammad, J.M.; Nader, S.; Mehran, K.F. Probabilistic Slope Stability Analysis in Kahrizak Landfill: Effect of Spatial Variation of MSW’s Geotechnical Properties. Bull. Eng. Geol. Environ. 2020, 79, 2679–2695. [Google Scholar]

- Vidit, S.; Uchimura, T. Influence of compositional analysis on unit weight of synthetic municipal solid waste. Int. J. Geomate 2022, 23, 134–141. [Google Scholar]

- Reddy, K.R.; Hettiarachchi, H.; Gangathulasi, J.; Bogner, J.E.; Lagier, T. Geotechnical Properties of Synthetic Municipal Solid Waste. Int. J. Geotech. Eng. 2009, 3, 429–438. [Google Scholar] [CrossRef]

- Hettiarachchi, H.; Thani, J. Variation of Shear Strength Properties with Organic Fraction in Unsaturated Synthetic Municipal Solid Waste. In Geo-Frontiers 2011: Advances in Geotechnical Engineering; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2011; pp. 1414–1423. [Google Scholar]

- Dixon, N.; Langer, U.; Gotteland, P. Classification and Mechanical Behavior Relationships for Municipal Solid Waste: Study Using Synthetic Wastes. J. Geotech. GeoEnviron. Eng. 2008, 134, 79–90. [Google Scholar] [CrossRef]

- Kinjal, H.G.; Manish, V.S.; Alpa, J.S. Performance Evaluation of Municipal Solid Waste as a Sustainable Backfill Material in RE Walls. In Geo-Congress 2019: Geoenvironmental Engineering and Sustainability; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 328–335. [Google Scholar]

- Mohsen, K.; Masoud, S.; Mohammad, H.A.; Hasan, A. Evaluation of the Shear Strength Behavior of Aged MSW using Large Scale in Situ Direct Shear Test, a case of Tabriz Landfill. Int. J. Civ. Eng. 2020, 18, 717–733. [Google Scholar]

- Landva, A.O.; Clarks, J.J. Geotechnics of Waste Fill—Theory and Practice; Landva, A., Knowles, G.D., Eds.; ASTM International: West Conshohocken, PA, USA, 1990; SPT No. 1070; pp. 86–103. [Google Scholar]

- Mazzucato, N.; Simonini, P.; Colombo, S. Analysis of block slide in MSW landfills. Int. Waste Manag. Landfill Symp. 1990, 3, 537–544. [Google Scholar]

- Jessberger, H.L.; Kockel, R. Determination and assessment of mechanical properties of waste. Waste Dispos. Landfill Green 1995, 93, 313–322. [Google Scholar]

- Kavazanjian, E., Jr.; Matasovic, N.; Bonaparte, R.; Schmertmann, G.R. Evaluation of MSW properties for seismic analysis. In Proceedings of the Specialty Conference on Geotechnical Practice in Waste Disposal. Part 1 (of 2); ASCE Geotechnical Special Publication: Reston, VA, USA, 2000; Volume 46, pp. 126–141. [Google Scholar]

- Eid, H.T.; Stark, T.D.; Douglas, W.D.; Sherry, P.E. Municipal solid waste slope failure- Waste and foundation properties. J. Geotech. Geoenviron. Eng. 2000, 126, 397–407. [Google Scholar] [CrossRef]

- Zekkos, D.; Bray, J.D.; Athanasopoulos, G.A.; Riemer, M.F.; Kavazanjian, E.; Founta, X.; Grizi, A. Compositional and loading rate effect on the shear strength of municipal solid waste. In Proceedings of the 4th International Conference on Earthquake Geotechnical Engineering, Thessaloniki, Greece, 25–28 June 2007. Paper No 1525. [Google Scholar]

- Zekkos, D.; Athanasopoulos, G.A.; Bray, J.D.; Grizi, A.; Theodoratos, A. Large-Scale Direct Shear Testing of Municipal Solid Waste. Waste Manag. 2010, 30, 1544–1555. [Google Scholar] [CrossRef]

- OJuri, O.O.; Adegoke, P.K. Geotechnical characteristics of synthetic municipal solid waste for effective landfill design. Int. J. Geomate 2015, 9, 1418–1427. [Google Scholar]

- Beaven, R.P.; Powrie, W. Hydrogeological and geotechnical properties of refuse using a large-scale compression cell. In Proceedings of the 5th International Landfill Symposium, Cagliari, Italy, 2–6 October 1995; pp. 745–760. [Google Scholar]

- Watts, K.S.; Charles, J.A. Settlement characteristics of landfill waste. Proc. Inst. Civ. Eng. Geotech. Eng. 1999, 137, 225–233. [Google Scholar] [CrossRef]

- Landva, A.O.; Valsangkar, A.O.; Pelkey, S.G. Lateral earth pressure at rest and compressibility of municipal solid waste. Can. Geotech. J. 2000, 37, 1157–1165. [Google Scholar] [CrossRef]

- Dixon, N.; Jones, D.R.V. Engineering properties of municipal solid waste. Geotext. Geomembr. 2005, 23, 205–233. [Google Scholar] [CrossRef]

- Jonathan, D.B.; Zekkos, D.; Kavazanjian, E.; George, A.; Athanasopoulos, M.; Michael, F. Shear Strength of Municipal solid waste. J. Geotech. Geoenviron. Eng. 2009, 135, 709–722. [Google Scholar]

- Hasan, F.P.; Yeliz, Y.A. Factors affecting the shear strength behavior of municipal solid waste. Waste Manag. 2017, 69, 215–224. [Google Scholar]

- Powrie, W.; Beaven, R.P. Hydraulic properties of household waste and implications for landfills. Proc. Inst. Civ. Engg-Geotech. Eng. 1999, 137, 235–247. [Google Scholar] [CrossRef]

- Kavazanjian, E., Jr. Mechanical properties of municipal solid waste. In Proceedings of the 8th International Waste Management and Landfill Symposium, Cagliari, Italy, 1–5 October 2001; pp. 415–424. [Google Scholar]

- Houston, W.N.; Houston, S.L.; Liu, J.W.; Elsayed, A.; Sanders, C.O. In situ testing methods for dynamic properties of MSW landfills. Earthquake design and performance of solid waste landfills. In Proceedings of the Geotechnical Engineering Division of the ASCE in Conjunction with the ASCE Convention, San Diego, CA, USA, 22–26 October 1995; ASCE Geotechnical Special Publication: Reston, VA, USA, 1995; Volume 54, pp. 73–82. [Google Scholar]

- Edincliler, A.; Benson, C.H.; Edil, T.B. Shear Strength of Municipal Solid Waste, Interim Report- Year 1, Environmental Geotechnics Report; Department of Civil and Environmental Engineering: London, UK, 1996; pp. 2–96. [Google Scholar]

- Mazzucato, N.; Simonini, P.; Colombo, S. Analysis of block slide in an MSW landfill. In Proceedings of the Sardinia—7th International Waste Management and Landfill Symposium, Cagliari, Italy, 4–8 October 1999; pp. 4–8. [Google Scholar]

- Kavazanjian, E.; Matasovic, N.; Bachus, R.C. Large diameter static and cyclic laboratory testing of municipal solid waste. In Proceedings of the Sardinia—7th International Waste Management and Landfill Symposium, Cagliari, Italy, 4–8 October 1999; Volume 3, pp. 437–444. [Google Scholar]

- Reddy, K.R.; Hettiarachchi, H.; Naveen, S.P.; Gangathulasi, J.; Jean, E.B. Geotechnical properties of fresh municipal solid waste at Orchard Hills landfills USA. Waste Manag. 2009, 29, 952–959. [Google Scholar] [CrossRef] [PubMed]

- Reddy, K.R.; Hiroshan, H.; Rajiv, G.; Janardhan, G. Effect of Degradation on Geotechnical Properties of Municipal Solid Waste from Orchard Hills Landfill, USA. Int. J. Geosynth. Ground Eng. 2015, 24, 24. [Google Scholar] [CrossRef]

- Fenf, S.J.; Cao, B.Y.; Bai, Z.B.; Yin, Z.Y. Constitutive Model for Municipal Solid Waste Considering the Effect of Biodegradation. Geotech. Lett. 2016, 6, 244–249. [Google Scholar]

| No. | Landfill | Failure Reason | Casualties |

|---|---|---|---|

| 1 | Mahad, India (2020) | Improper Design | 10 |

| 2 | Maputo, Mozambique (2018) | Overfilling | 17 |

| 3 | Meethotamulla, Sri Lanka (2017) | Rainfall | 32 |

| 4 | Ghazipur, India (2017) | Overfilling | 2 |

| 5 | Koshe, Ethiopia (2017) | Improper Design | 113 |

| 6 | Shenzhen, China (2015) | Human Negligence | 73 |

| 7 | Jardim Gramacho, Brazil (2012) | Improper Design | 2 |

| SMSW | Friction Angle | Cohesion |

|---|---|---|

| H.F. Pulat and Y.Y. Aksoy, 2017 (SMSW size—2 mm to 25 mm of fresh and aged SMSW) | 20–28 | 32–40 |

| H. Hettiarachchi et al., 2011 (SMSW size—10 mm) | 12–39 | 0–150 |

| K. Reddy et al., 2009 (SMSW size—1.5 mm, 35% smaller than 0.1 mm and 10% larger than 10 mm) | 27–29 | 16–19 |

| K. Reddy et al., 2008 (shredded fresh waste, SMSW size—40 mm) | 26–30 | 32–64 |

| N. Dixon et al., 2008 (SMSW size—120–500 mm) | 34 | 0 |

| Hossain, 2002 (shredded landfill waste, SMSW size—50 mm) | 24–32 | - |

| Caicedo et al., 2002 (unshredded fresh waste) | 23 | 78 |

| Landva and Clark, 1990 (shredded fresh waste) | 24 | 23 |

| Design Constraints | Shear Strength | Unit Weight | Permeability | Lateral Stiffness | Horizontal Stress |

|---|---|---|---|---|---|

| Liner Stability | ✓ | ✓ | ✓ | ✓ | ✓ |

| Subgrade Stability | ✓ | ✓ | ✓ | ✓ | |

| Cover System | ✓ | ✓ | |||

| Slope Stability | ✓ | ✓ | ✓ | ✓ | ✓ |

| Gas/Leachate Collection | ✓ | ✓ | ✓ | ✓ | ✓ |

| Subgrade Stability | ✓ | ✓ | ✓ | ||

| Drainage System | ✓ | ✓ | ✓ |

| Material | Replacement | Size |

|---|---|---|

| Paper | A4 Paper and Cardboard | 15–200 mm |

| Plastic | Waste Plastic Bags and PET Shredded Plastic | 10–100 mm |

| Metals | Shredded Aluminum Cans and Shredded Metal Sheets | <40 mm |

| Wood | Shredded Wood | <20 mm |

| Soil | Sand and Clay Mix | >4.75 μm |

| Organic | Garden waste, Food waste, and Peat Moss | 40–200 mm |

| Textile | Textile (cut) | 10–100 mm |

| Each Component % (by Weight) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Components | SW-01 | SW-02 | SW-03 | SW-04 | SW-05 | SW-06 | SW-07 | SW-08 | SW-09 |

| Paper | 21.20 | 10 | 30 | 22.42 | 18.69 | 16.20 | 25.68 | 16.61 | 13.6 |

| Metal | 5.10 | 5.81 | 4.52 | 5.39 | 4.50 | 3.90 | 6.18 | 4 | 3.27 |

| Garden Waste | 2 | 2.28 | 1.77 | 2.12 | 1.76 | 1.53 | 2.42 | 1.57 | 1.28 |

| Wood | 6 | 6.83 | 5.32 | 6.35 | 5.29 | 4.59 | 7.27 | 4.70 | 3.85 |

| Cardboard | 4.10 | 4.67 | 3.63 | 4.34 | 3.61 | 3.13 | 4.97 | 3.21 | 2.63 |

| Soil | 4 | 4.55 | 3.55 | 4.23 | 3.53 | 3.06 | 4.85 | 3.13 | 2.57 |

| Plastic | 15.10 | 17.19 | 13.39 | 10 | 25 | 35 | 18.29 | 11.83 | 9.69 |

| Textile | 3.65 | 4.15 | 3.24 | 3.86 | 3.22 | 2.79 | 4.42 | 2.86 | 2.34 |

| Organic | 30 | 34.15 | 26.60 | 31.73 | 26.44 | 22.93 | 15 | 45 | 55 |

| Sand | 9 | 10.24 | 7.98 | 9.52 | 7.93 | 6.88 | 10.90 | 7.05 | 5.77 |

| Sample | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| S. No. | SW-01 | SW-02 | SW-03 | SW-04 | SW-05 | SW-06 | SW-07 | SW-08 | SW-09 |

| MDD kN/m3 | 2.87 | 3.94 | 3.16 | 3.61 | 3.32 | 3.09 | 3.73 | 4.14 | 4.5 |

| OMC % | 62 | 85 | 76 | 88 | 77 | 67 | 82 | 78 | 85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, V.; Uchimura, T. Effect of Material Composition on Geotechnical Properties—Study on Synthetic Municipal Solid Waste. Geotechnics 2023, 3, 397-415. https://doi.org/10.3390/geotechnics3020023

Singh V, Uchimura T. Effect of Material Composition on Geotechnical Properties—Study on Synthetic Municipal Solid Waste. Geotechnics. 2023; 3(2):397-415. https://doi.org/10.3390/geotechnics3020023

Chicago/Turabian StyleSingh, Vidit, and Taro Uchimura. 2023. "Effect of Material Composition on Geotechnical Properties—Study on Synthetic Municipal Solid Waste" Geotechnics 3, no. 2: 397-415. https://doi.org/10.3390/geotechnics3020023

APA StyleSingh, V., & Uchimura, T. (2023). Effect of Material Composition on Geotechnical Properties—Study on Synthetic Municipal Solid Waste. Geotechnics, 3(2), 397-415. https://doi.org/10.3390/geotechnics3020023