Probabilistic Seismic Risk Analysis of Buried Pipelines Due to Permanent Ground Deformation for Victoria, BC

Abstract

:1. Introduction

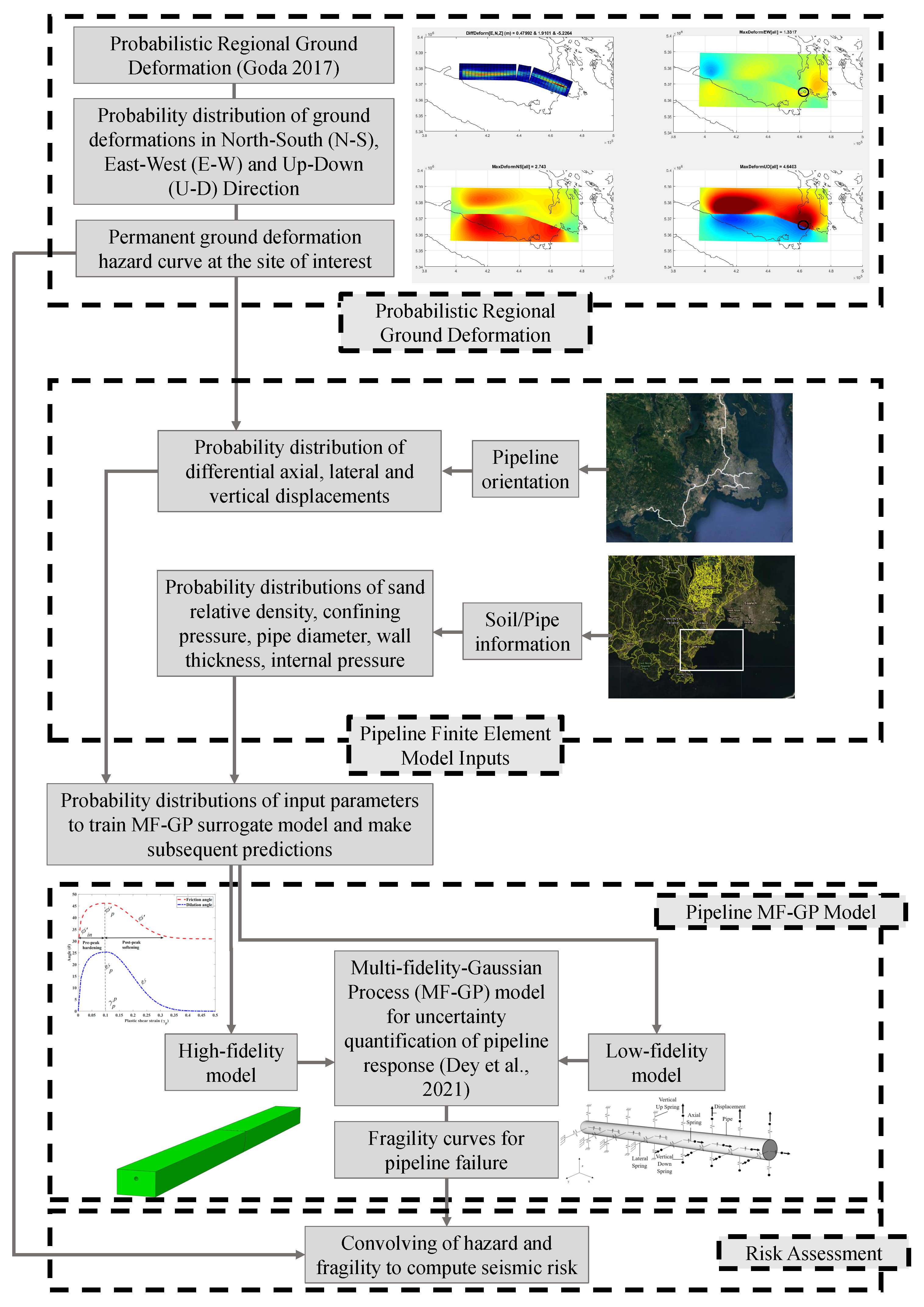

2. Integrated Risk Assessment Method for Buried Pipelines Due to Fault-Rupture-Induced Permanent Ground Deformations

3. Probabilistic Ground Deformation Hazard Assessment for Victoria, British Columbia

3.1. Leech River Valley Fault Zone (Lrvfz) Source Characterization and Rupture Occurrence

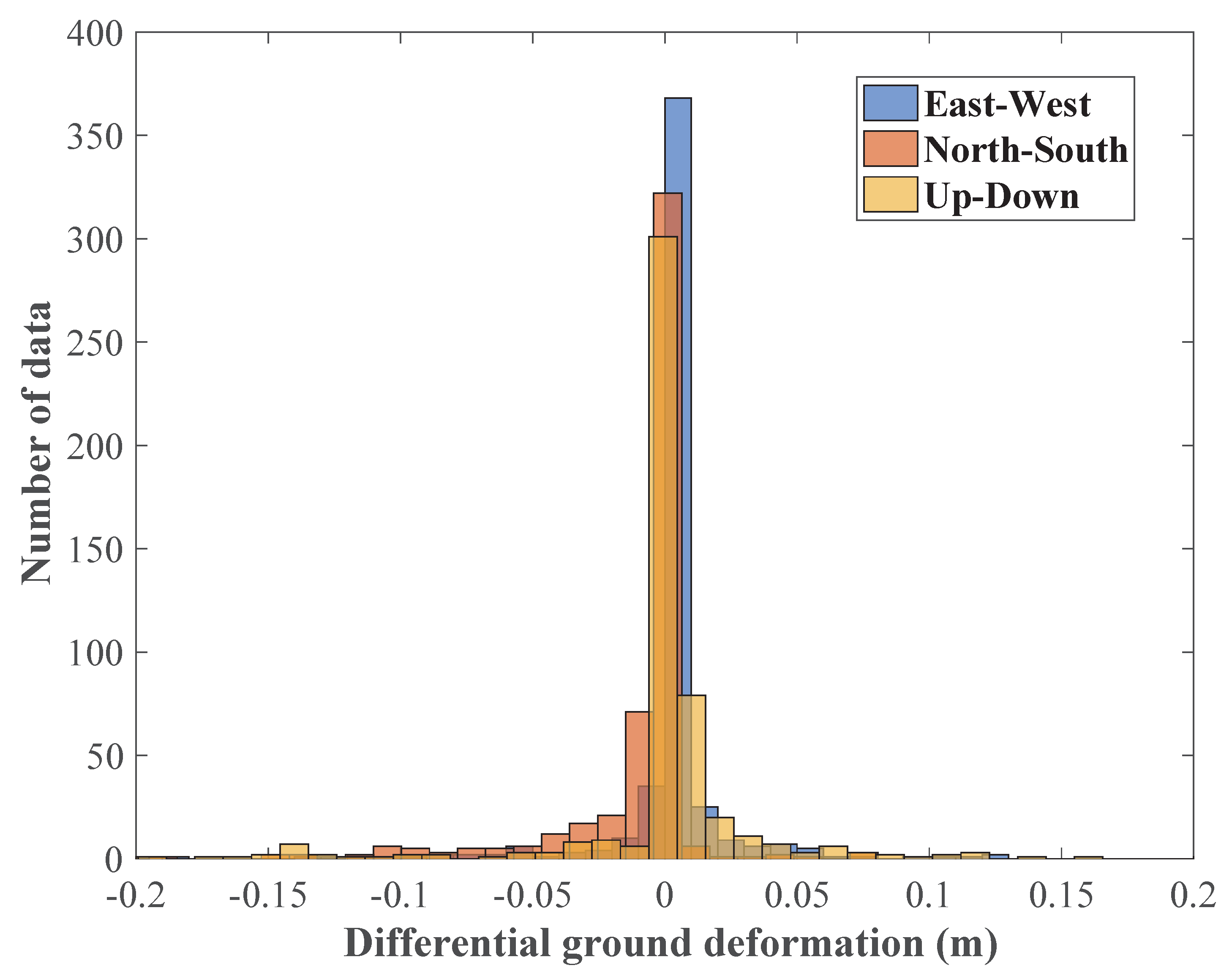

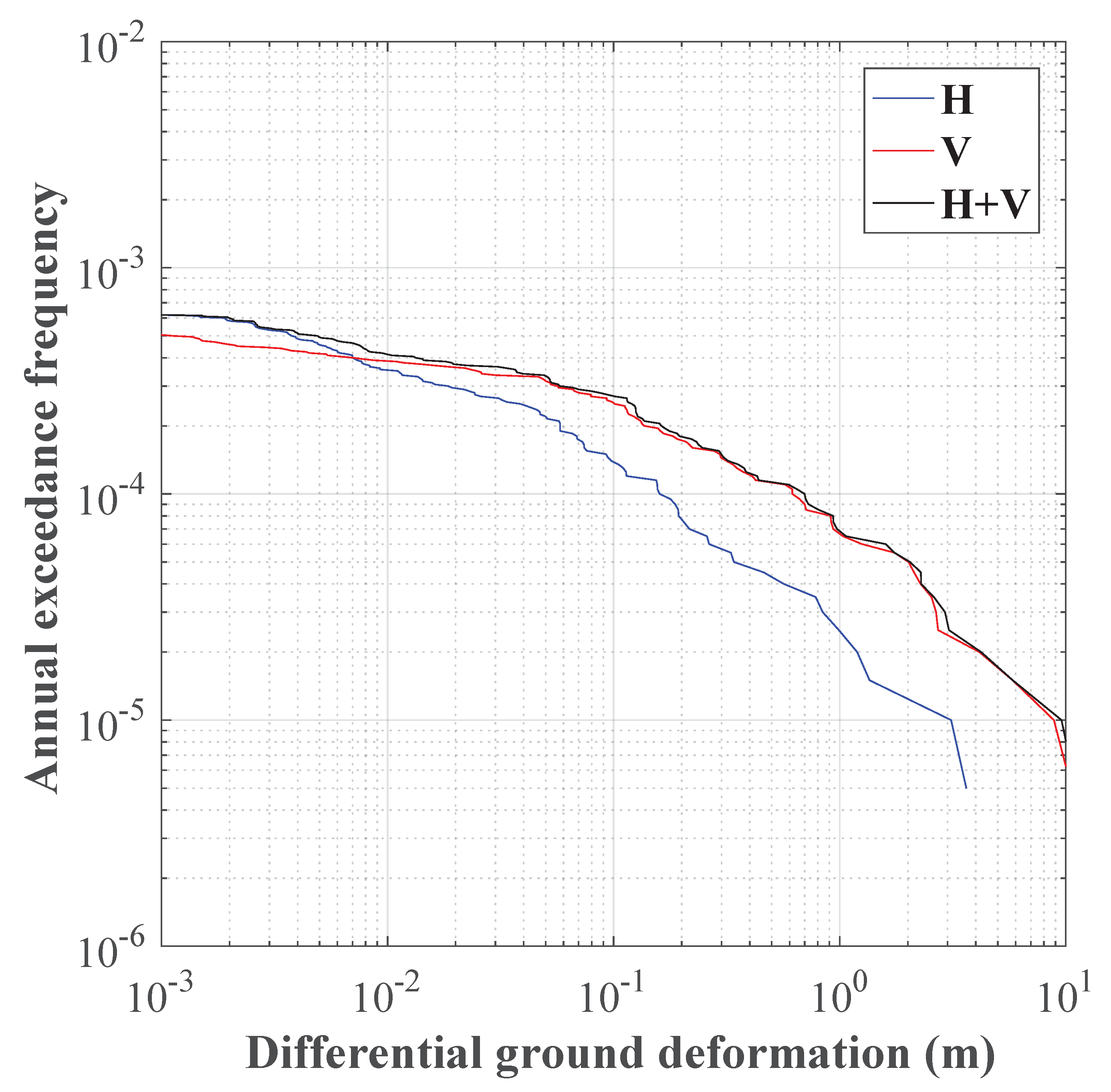

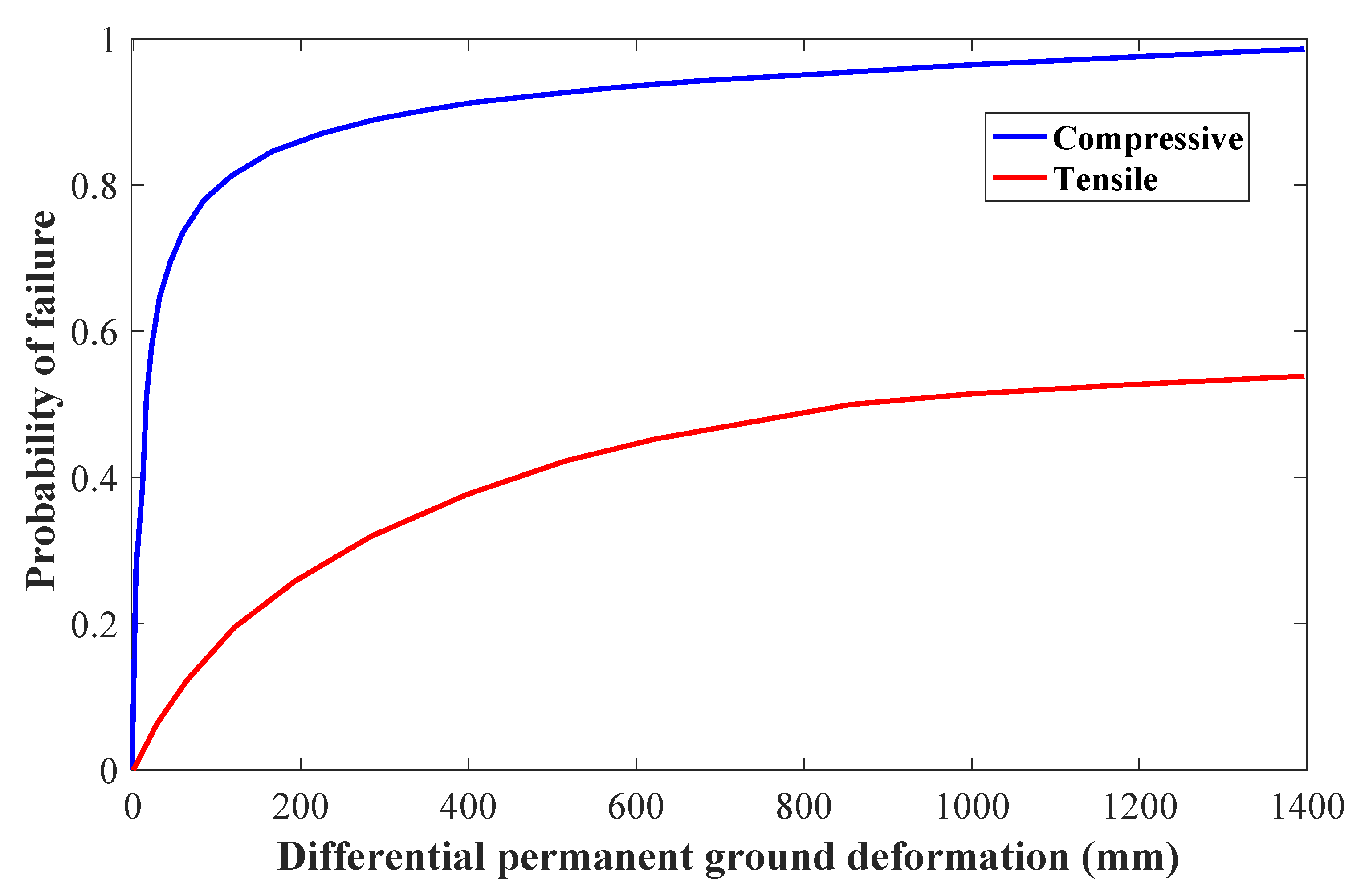

3.2. Probabilistic Ground Deformation Hazard Assessment

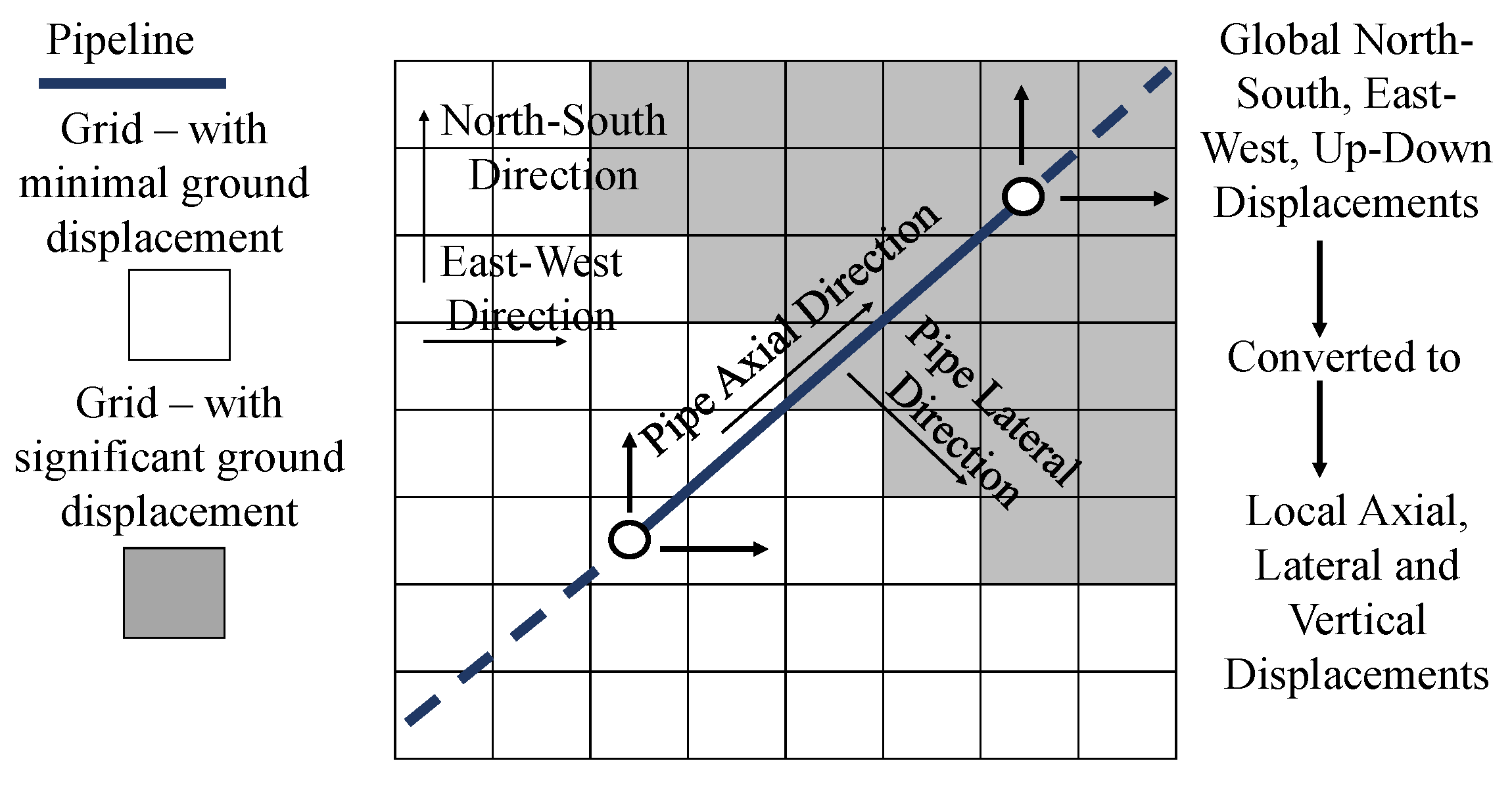

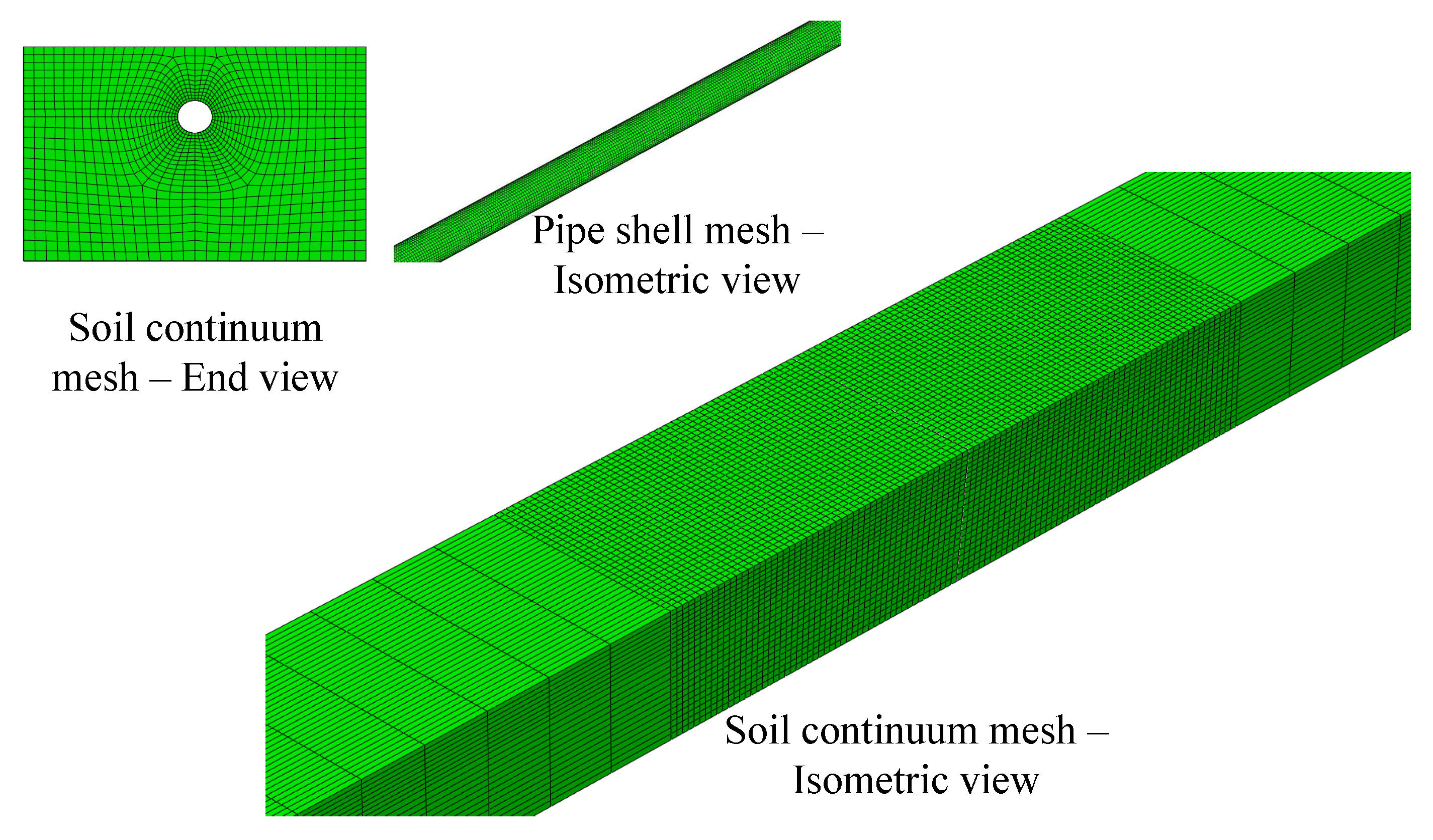

4. Finite Element Models of Buried Pipelines

4.1. Variation in Model Parameters

4.2. High-Fidelity Fe Model

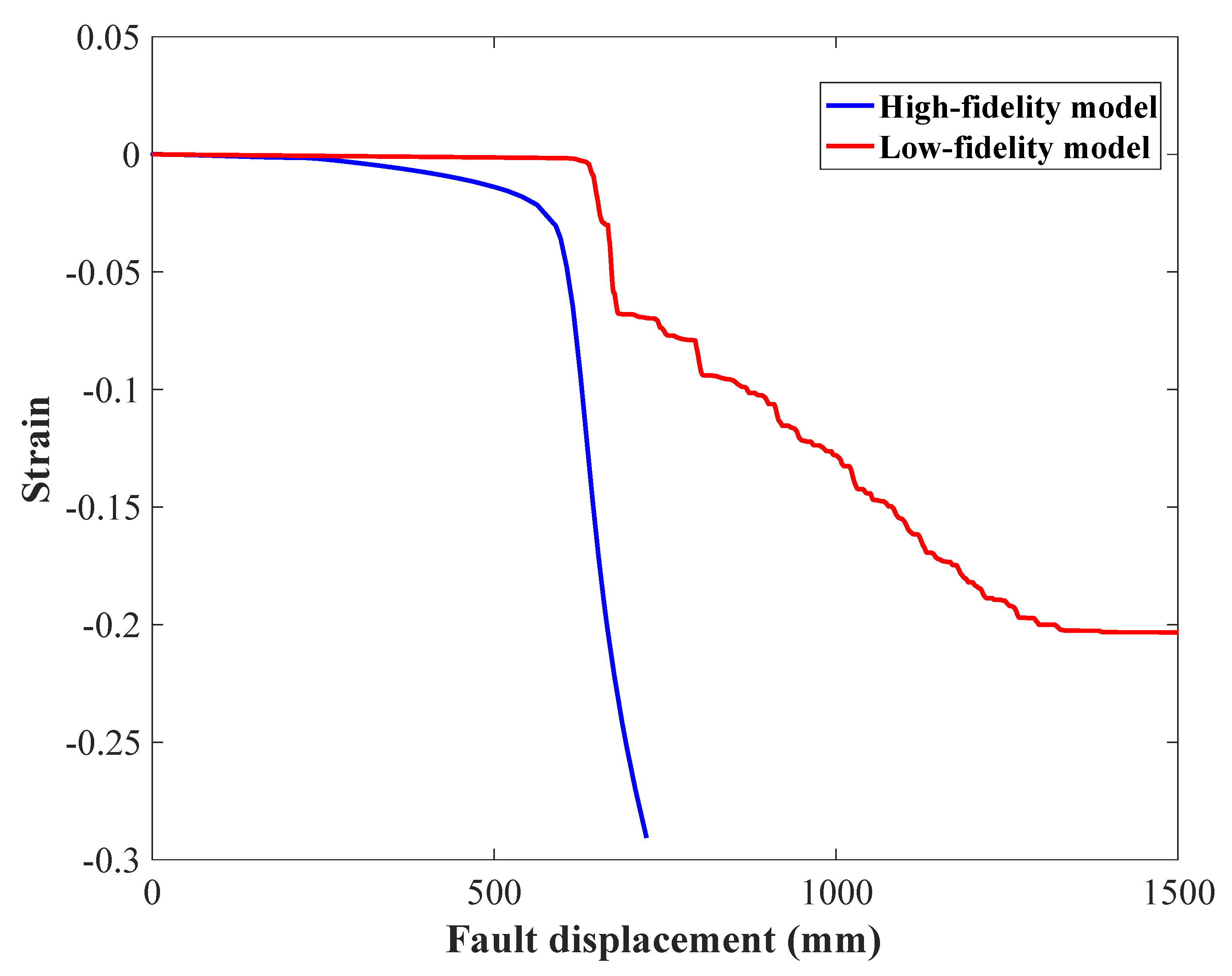

4.3. Low-Fidelity Fe Model

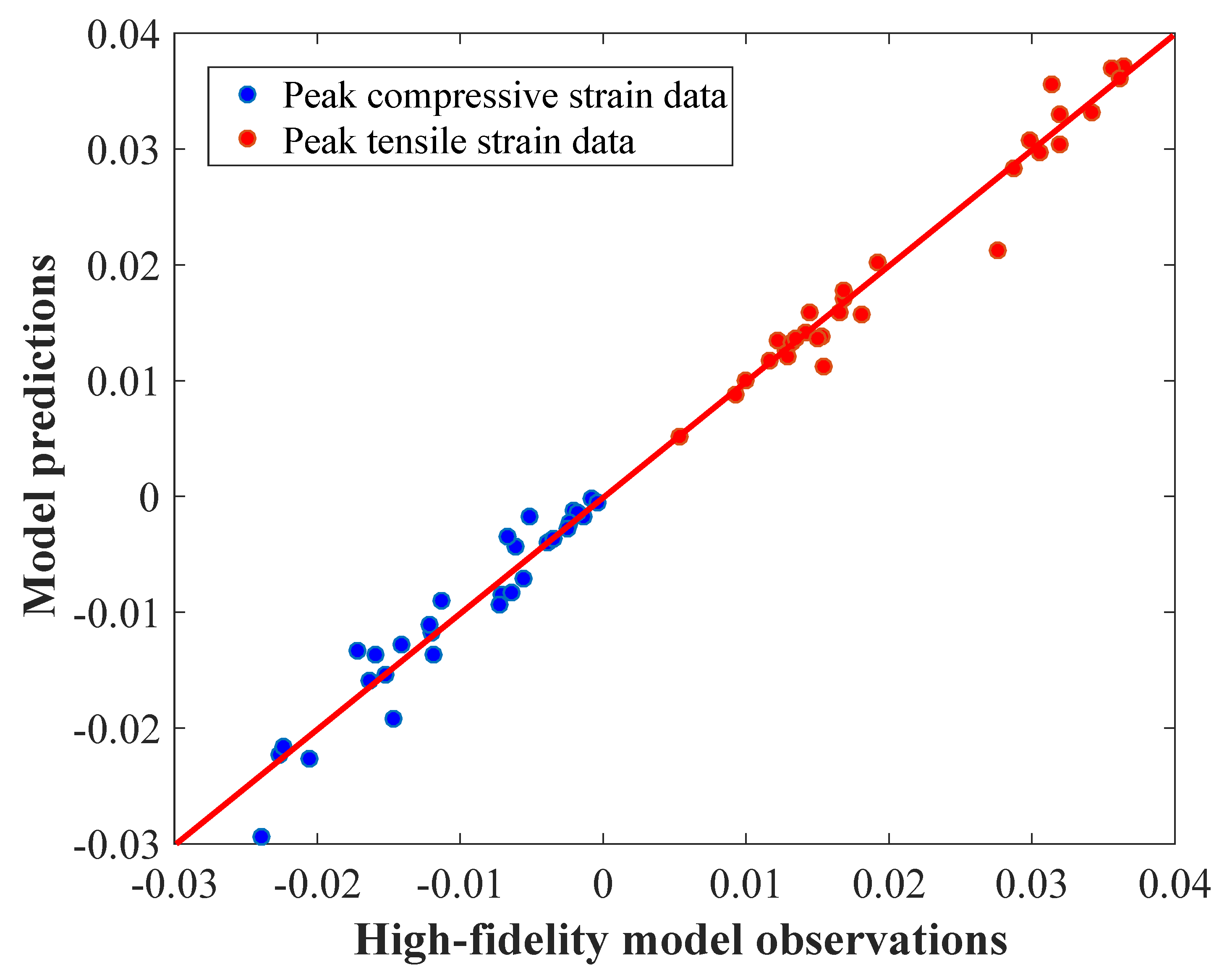

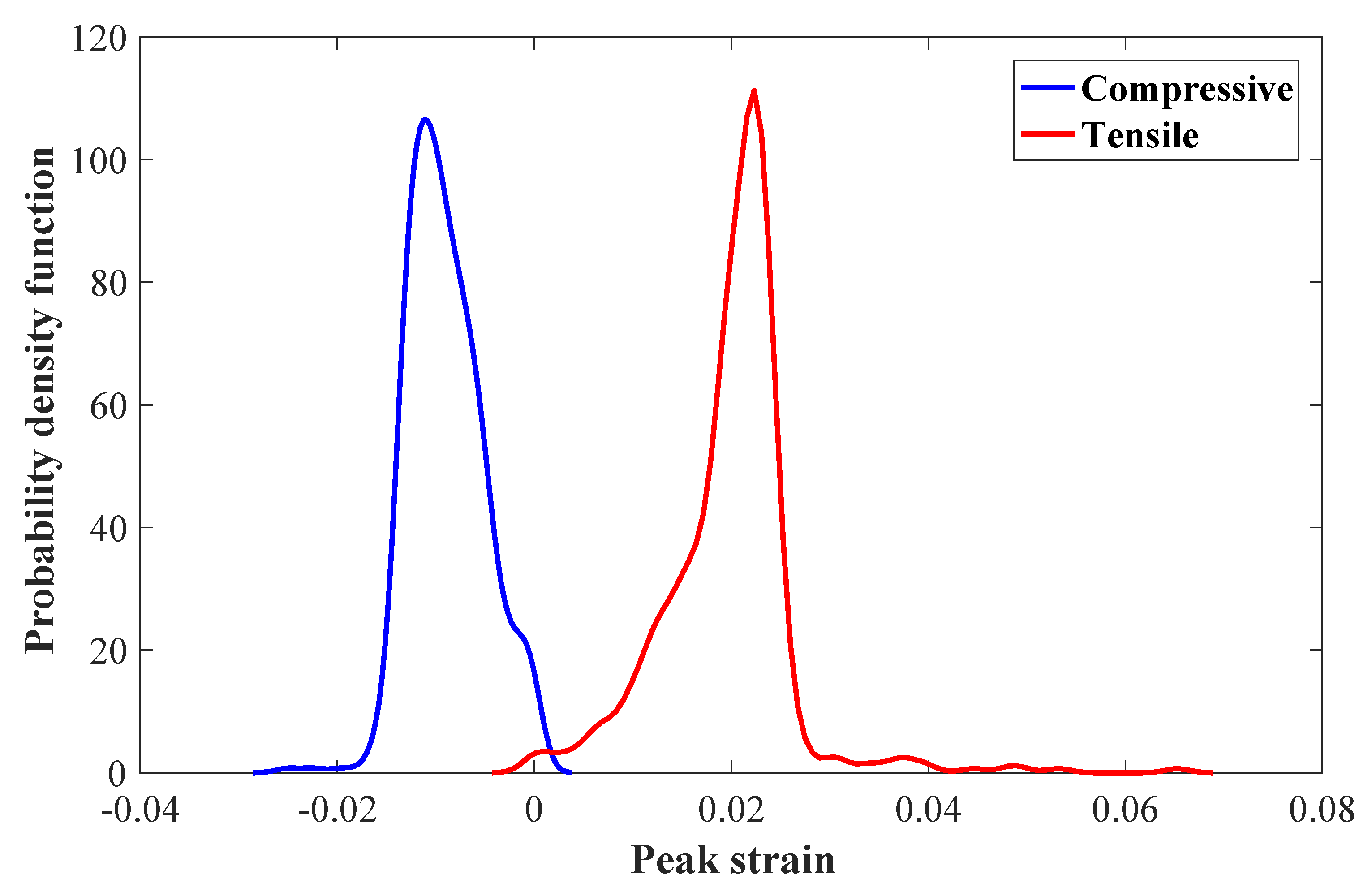

5. Uncertainty Quantification Using Multi-Fidelity Surrogate Modeling

6. Results and Discussion

6.1. Probabilistic Ground Deformation Hazard Estimation for Lrfz

6.2. Cross-Validation and Uncertainty Quantification of Pipeline Response

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. High-Fidelity Constitutive Equations

Appendix B. Low-Fidelity Model Soil Springs

Appendix C. Multi-Fidelity Gaussian Processes

References

- Cheng, Y.; Akkar, S. Probabilistic permanent fault displacement hazard via Monte Carlo simulation and its consideration for the probabilistic risk assessment of buried continuous steel pipelines. Earthq. Eng. Struct. Dyn. 2017, 46, 605–620. [Google Scholar] [CrossRef]

- Robert, D.J.; Soga, K.; O’Rourke, T.D. Pipelines subjected to fault movement in dry and unsaturated soils. Int. J. Geomech. 2016, 16, 1–16. [Google Scholar] [CrossRef]

- Eidinger, J.M.; O’Rourke, M.; Bachhuber, J. Performance of a pipeline at a fault crossing. In Proceedings of the 7th US National Conference of Earthquake Engineering, Earthquake Engineering Research Institute (EERI), Boston, MA, USA, 21–25 July 2002. [Google Scholar]

- De Risi, R.; De Luca, F.; Kwon, O.S.; Sextos, A. Scenario-based seismic risk assessment for buried transmission gas pipelines at regional scale. J. Pipeline Syst. Eng. Pract. 2018, 9, 04018018. [Google Scholar] [CrossRef]

- Lanzano, G.; de Magistris, F.S.; Fabbrocino, G.; Salzano, E. Seismic damage to pipelines in the framework of Na-Tech risk assessment. J. Loss Prev. Process Ind. 2015, 33, 159–172. [Google Scholar] [CrossRef]

- Hwang, H.; Chiu, Y.H.; Chen, W.Y.; Shih, B.J. Analysis of damage to steel gas pipelines caused by ground shaking effects during the Chi-Chi, Taiwan, earthquake. Earthq. Spectra 2004, 20, 1095–1110. [Google Scholar] [CrossRef]

- Melissianos, V.E.; Eeri, M. Performance Assessment of Buried Pipelines at Fault Crossings. Earthq. Spectra 2017, 33, 201–218. [Google Scholar] [CrossRef]

- Stepp, J.C.; Wong, I.; Whitney, J.W.; Quittmeyer, R.; Abrahamson, N.; Toro, G.; Young, S.; Coppersmith, K.; Savy, J.; Sullivan, T. Probabilistic seismic hazard analyses for ground motions and fault displacement at Yucca Mountain, Nevada. Earthq. Spectra 2001, 17, 113–151. [Google Scholar]

- Youngs, R.R.; Arabasz, W.J.; Anderson, R.E.; Ramelli, A.R.; Ake, J.P.; Slemmons, D.B.; McCalpin, J.P.; Doser, D.I.; Fridrich, C.J.; Swan, F.H., III; et al. A methodology for probabilistic fault displacement hazard analysis (PFDHA). Earthq. Spectra 2003, 19, 191–219. [Google Scholar] [CrossRef]

- Budnitz, R.; Apostolakis, G.; Boore, D.M. Recommendations for pRobabilistic Seismic Hazard Analysis: Guidance on Uncertainty and Use of Experts; Technical Report; US Nuclear Regulatory Commission (NRC): Washington, DC, USA, 1997. [Google Scholar]

- Petersen, M.D.; Dawson, T.E.; Chen, R.; Cao, T.; Wills, C.J.; Schwartz, D.P.; Frankel, A.D. Fault displacement hazard for strike-slip faults. Bull. Seismol. Soc. Am. 2011, 101, 805–825. [Google Scholar] [CrossRef]

- Goda, K. Probabilistic characterization of seismic ground deformation due to tectonic fault movements. Soil Dyn. Earthq. Eng. 2017, 100, 316–329. [Google Scholar] [CrossRef]

- Thingbaijam, K.K.S.; Martin Mai, P.; Goda, K. New empirical earthquake source-scaling laws. Bull. Seismol. Soc. Am. 2017, 107, 2225–2246. [Google Scholar] [CrossRef] [Green Version]

- Leonard, M. Earthquake fault scaling: Self-consistent relating of rupture length, width, average displacement, and moment release. Bull. Seismol. Soc. Am. 2010, 100, 1971–1988. [Google Scholar] [CrossRef]

- Blaser, L.; Krüger, F.; Ohrnberger, M.; Scherbaum, F. Scaling relations of earthquake source parameter estimates with special focus on subduction environment. Bull. Seismol. Soc. Am. 2010, 100, 2914–2926. [Google Scholar] [CrossRef]

- Wells, D.L.; Coppersmith, K.J. New empirical relationships among magnitude, rupture length, rupture width, rupture area, and surface displacement. Bull. Seismol. Soc. Am. 1994, 84, 974–1002. [Google Scholar]

- Somerville, P.; Irikura, K.; Graves, R.; Sawada, S.; Wald, D.; Abrahamson, N.; Iwasaki, Y.; Kagawa, T.; Smith, N.; Kowada, A. Characterizing crustal earthquake slip models for the prediction of strong ground motion. Seismol. Res. Lett. 1999, 70, 59–80. [Google Scholar] [CrossRef]

- Strasser, F.O.; Arango, M.; Bommer, J.J. Scaling of the source dimensions of interface and intraslab subduction-zone earthquakes with moment magnitude. Seismol. Res. Lett. 2010, 81, 941–950. [Google Scholar] [CrossRef]

- Goda, K.; Yasuda, T.; Mori, N.; Maruyama, T. New scaling relationships of earthquake source parameters for stochastic tsunami simulation. Coast. Eng. J. 2016, 58, 1650010-1. [Google Scholar] [CrossRef]

- Okada, Y. Surface deformation due to shear and tensile faults in a half-space. Bull. Seismol. Soc. Am. 1985, 75, 1135–1154. [Google Scholar] [CrossRef]

- Okada, Y. Internal deformation due to shear and tensile faults in a half-space. Bull. Seismol. Soc. Am. 1992, 82, 1018–1040. [Google Scholar] [CrossRef]

- Morell, K.D. Quaternary rupture of a crustal fault beneath Victoria, British Columbia, Canada. People 2017, 50, 100–500. [Google Scholar] [CrossRef]

- Li, G.; Liu, Y.; Regalla, C.; Morell, K.D. Seismicity relocation and fault structure near the Leech River fault zone, southern Vancouver Island. J. Geophys. Res. Solid Earth 2018, 123, 2841–2855. [Google Scholar] [CrossRef]

- Barrie, J.V.; Greene, H.G. The Devils Mountain fault zone: An active Cascadia upper plate zone of deformation, Pacific Northwest of North America. Sediment. Geol. 2018, 364, 228–241. [Google Scholar] [CrossRef]

- Halchuk, S.; Allen, T.; Adams, J.; Onur, T. Contribution of the Leech River Valley-Devil’s Mountain Fault System to Seismic Hazard in Victoria, BC. In Proceedings of the 12th Canadian Conference on Earthquake Engineering, Quebec City, QC, Canada, 17–20 June 2019; pp. 17–20. [Google Scholar]

- Kukovica, J.; Ghofrani, H.; Molnar, S.; Assatourians, K. Probabilistic seismic hazard analysis of Victoria, British Columbia: Considering an active fault zone in the Nearby Leech River Valley. Bull. Seismol. Soc. Am. 2019, 109, 2050–2062. [Google Scholar]

- Goda, K.; Sharipov, A. Fault-Source-Based Probabilistic Seismic Hazard and Risk Analysis for Victoria, British Columbia, Canada: A Case of the Leech River Valley Fault and Devil’s Mountain Fault System. Sustainability 2021, 13, 1440. [Google Scholar] [CrossRef]

- Melissianos, V.E.; Korakitis, G.P.; Gantes, C.J.; Bouckovalas, G.D. Numerical evaluation of the effectiveness of flexible joints in buried pipelines subjected to strike-slip fault rupture. Soil Dyn. Earthq. Eng. 2016, 90, 395–410. [Google Scholar] [CrossRef]

- Zhang, W.; Ayello, F.; Honegger, D.; Taciroglu, E.; Bozorgnia, Y. Comprehensive numerical analyses of the seismic performance of natural gas pipelines crossing earthquake faults. Earthq. Spectra 2022, 38, 1661–1682. [Google Scholar] [CrossRef]

- Esposito, S.; Iervolino, I.; D’Onofrio, A.; Santo, A.; Cavalieri, F.; Franchin, P. Simulation-Based Seismic Risk Assessment of Gas Distribution Networks. Comput.-Aided Civ. Infrastruct. Eng. 2015, 30, 508–523. [Google Scholar] [CrossRef]

- Dey, S.; Chakraborty, S.; Tesfamariam, S. Structural performance of buried pipeline undergoing strike-slip fault rupture in 3D using a non-linear sand model. Soil Dyn. Earthq. Eng. 2020, 135, 106180. [Google Scholar] [CrossRef]

- Dey, S.; Chakraborty, S.; Tesfamariam, S. Multi-fidelity approach for uncertainty quantification of buried pipeline response undergoing fault rupture displacements in sand. Comput. Geotech. 2021, 136, 104197. [Google Scholar] [CrossRef]

- Youngs, R.R.; Coppersmith, K.J. Implications of fault slip rates and earthquake recurrence models to probabilistic seismic hazard estimates. Bull. Seismol. Soc. Am. 1985, 75, 939–964. [Google Scholar] [CrossRef]

- Convertito, V.; Emolo, A.; Zollo, A. Seismic-hazard assessment for a characteristic earthquake scenario: An integrated probabilistic–deterministic method. Bull. Seismol. Soc. Am. 2006, 96, 377–391. [Google Scholar] [CrossRef]

- Morell, K.; Regalla, C.; Amos, C.; Bennett, S.; Leonard, L.; Graham, A.; Reedy, T.; Levson, V.; Telka, A. Holocene surface rupture history of an active forearc fault redefines seismic hazard in southwestern British Columbia, Canada. Geophys. Res. Lett. 2018, 45, 11–605. [Google Scholar] [CrossRef]

- Johnson, S.Y.; Dadisman, S.V.; Mosher, D.C.; Blakely, R.J.; Childs, J.R. Active Tectonics of the Devils Mountain Fault and Related Structures, Northern Puget Lowland and Eastern Strait of Juan de Fuca Region, Pacific Northwest; Technical Report; US Geological Survey: Denver, CO, USA, 2001. [Google Scholar]

- Halchuk, S.; Allen, T.I.; Adams, J.; Rogers, G.C. Fifth generation seismic hazard model input files as proposed to produce values for the 2015 National Building Code of Canada. Geol. Surv. Can. Open File 2014, 7576, 15. [Google Scholar]

- Goda, K.; Shoaeifar, P. Prospective Fault Displacement Hazard Assessment for Leech River Valley Fault Using Stochastic Source Modeling and Okada Fault Displacement Equations. Geohazards 2022, 3, 277–293. [Google Scholar] [CrossRef]

- Systèmes, D. ABAQUS Documentation; Dassault Systèmes: Providence, RI, USA, 2014. [Google Scholar]

- Banushi, G.; Squeglia, N.; Thiele, K. Innovative analysis of a buried operating pipeline subjected to strike-slip fault movement. Soil Dyn. Earthq. Eng. 2018, 107, 234–249. [Google Scholar] [CrossRef]

- Demirci, H.E.; Bhattacharya, S.; Karamitros, D.; Alexander, N. Experimental and numerical modelling of buried pipelines crossing reverse faults. Soil Dyn. Earthq. Eng. 2018, 114, 198–214. [Google Scholar] [CrossRef]

- Vazouras, P.; Karamanos, S.A.; Dakoulas, P. Mechanical behavior of buried steel pipes crossing active strike-slip faults. Soil Dyn. Earthq. Eng. 2012, 41, 164–180. [Google Scholar] [CrossRef]

- Vazouras, P.; Dakoulas, P.; Karamanos, S.A. Pipe-soil interaction and pipeline performance under strike-slip fault movements. Soil Dyn. Earthq. Eng. 2015, 72, 48–65. [Google Scholar] [CrossRef]

- Vazouras, P.; Karamanos, S.A.; Panos, D. Finite element analysis of buried steel pipelines under strike-slip fault displacements. Soil Dyn. Earthq. Eng. 2010, 30, 1361–1376. [Google Scholar] [CrossRef]

- Fadaee, M.; Farzaneganpour, F.; Anastasopoulos, I. Response of buried pipeline subjected to reverse faulting. Soil Dyn. Earthq. Eng. 2020, 132, 106090. [Google Scholar] [CrossRef]

- Jalali, H.H.; Rofooei, F.R.; Attari, N.K.A.; Masoud, S. Experimental and finite element study of the reverse faulting effects on buried continuous steel gas pipelines. Soil Dyn. Earthq. Eng. 2016, 86, 1–14. [Google Scholar] [CrossRef]

- Rofooei, F.R.; Attari, N.K.A.; Hojat Jalali, H. New Method of Modeling the Behavior of Buried Steel Distribution Pipes Subjected to Reverse Faulting. J. Pipeline Syst. Eng. Pract. 2018, 9, 04017029. [Google Scholar] [CrossRef]

- Sarvanis, G.C.; Karamanos, S.A. Analytical model for the strain analysis of continuous buried pipelines in geohazard areas. Eng. Struct. 2017, 152, 57–69. [Google Scholar] [CrossRef]

- Trifonov, O.V. Numerical Stress-Strain Analysis of Buried Steel Pipelines Crossing Active Strike-Slip Faults with an Emphasis on Fault Modeling Aspects. J. Pipeline Syst. Eng. Pract. 2015, 6, 04014008. [Google Scholar] [CrossRef]

- Tsatsis, A.; Loli, M.; Gazetas, G. Pipeline in dense sand subjected to tectonic deformation from normal or reverse faulting. Soil Dyn. Earthq. Eng. 2019, 127, 105780. [Google Scholar] [CrossRef]

- Bolton, M.D. The strength and dilatancy of sands. Géotechnique 1986, 36, 65–78. [Google Scholar] [CrossRef]

- Lee, K.L.; Seed, H.B. Drained strength characteristics of sands. J. Soil Mech. Found. Div. 1967, 93, 117–141. [Google Scholar] [CrossRef]

- Kolymbas, D.; Wu, W. Recent results of triaxial tests with granular materials. Powder Technol. 1990, 60, 99–119. [Google Scholar] [CrossRef]

- Lancelot, L.; Shahrour, I.; Al Mahmoud, M. Failure and dilatancy properties of sand at relatively low stresses. J. Eng. Mech. 2006, 132, 1396–1399. [Google Scholar] [CrossRef]

- Roy, K. Numerical Modelling of Pipe-Soil and aNchor-Soil Interactions in Dense Sand. Ph.D. Thesis, Memorial University of Newfoundland, St. John’s, NL, Canada, 2018. [Google Scholar]

- Hsu, S.T.; Liao, H.J. Uplift behaviour of cylindrical anchors in sand. Can. Geotech. J. 1998, 35, 70–80. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Antaki, G.; Hart, J.; Adams, T.M.; Chern, C.; Costantino, G.; Gailing, R.; Goodling, E.; Gupta, A.; Haupt, R.; Moser, A.; et al. American Lifelines Alliance—Guidelines for the Design of Buried Steel Pipe; American Society of Civil Engineers: Reston, VA, USA, 2005. [Google Scholar]

- Babu, S.L.; Srivastava, A. Reliability analysis of buried flexible pipe-soil systems. J. Pipeline Syst. Eng. Pract. 2010, 1, 33–41. [Google Scholar] [CrossRef]

- Chai, Y.; Zhao, T.; Chai, Y.; Zhao, T. Probability of upheaval buckling for subsea pipeline considering uncertainty factors. Ships Offshore Struct. 2018, 13, 630–636. [Google Scholar] [CrossRef]

- Imanzadeh, S.; Marache, A.; Denis, A. Influence of soil spatial variability on possible dysfunction and failure of buried pipe, case study in Pessac city, France. Environ. Earth Sci. 2017, 76, 1–17. [Google Scholar] [CrossRef]

- McCarron, W.O. Subsea flowline buckle capacity considering uncertainty in pipe-soil interaction. Comput. Geotech. 2015, 68, 17–27. [Google Scholar] [CrossRef]

- Nazari, A.; Rajeev, P.; Sanjayan, J.G. Offshore pipeline performance evaluation by different artificial neural networks approaches. Meas. J. Int. Meas. Confed. 2015, 76, 117–128. [Google Scholar] [CrossRef]

- Oswell, J.M.; Hart, J.; Zulfiqar, N. Effect of Geotechnical Parameter Variability on Soil-Pipeline Interaction. J. Pipeline Syst. Eng. Pract. 2019, 10, 04019028. [Google Scholar] [CrossRef]

- Tee, K.F.; Khan, L.R.; Chen, H.P. Probabilistic failure analysis of underground flexible pipes. Struct. Eng. Mech. 2013, 47, 167–183. [Google Scholar] [CrossRef]

- Tesfamariam, S.; Rajani, B.; Sadiq, R. Possibilistic approach for consideration of uncertainties to estimate structural capacity of ageing cast iron water mains. Can. J. Civ. Eng. 2006, 33, 1050–1064. [Google Scholar] [CrossRef]

- Westgate, Z.J.; Haneberg, W.; White, D.J. Modelling spatial variability in as-laid embedment for high pressure and high temperature (HPHT) pipeline design. Can. Geotech. J. 2016, 1865, 1853–1865. [Google Scholar] [CrossRef]

- Wijaya, H.; Rajeev, P.; Gad, E. Effect of seismic and soil parameter uncertainties on seismic damage of buried segmented pipeline. Transp. Geotech. 2019, 21, 100274. [Google Scholar] [CrossRef]

- Arregui-Mena, J.D.; Margetts, L.; Mummery, P.M. Practical Application of the Stochastic Finite Element Method. Arch. Comput. Methods Eng. 2016, 23, 171–190. [Google Scholar] [CrossRef]

- Rubinstein, R.Y.; Kroese, D. Simulation and the Monte Carlo Method; John Wiley & Sons: Hoboken, NJ, USA, 1981. [Google Scholar]

- Sudret, B. Global sensitivity analysis using polynomial chaos expansions. Reliab. Eng. Syst. Saf. 2008, 9, 964–979. [Google Scholar] [CrossRef]

- Xiu, D.; Karniaakis, G.E. The Wiener-Askey polynomial chaos for stochastic differential equations. Siam J. Sci. Comput. 2002, 24, 619–644. [Google Scholar] [CrossRef]

- Goswami, S.; Anitescu, C.; Chakraborty, S.; Rabczuk, T. Transfer learning enhanced physics informed neural network for phase-field modeling of fracture. Theor. Appl. Fract. Mech. 2020, 106, 102447. [Google Scholar] [CrossRef] [Green Version]

- Buhmann, M.D. Radial basis functions. Acta Numer. 2000, 9, 1–38. [Google Scholar] [CrossRef]

- Kaymaz, I. Application of kriging method to structural reliability problems. Struct. Saf. 2005, 27, 133–151. [Google Scholar] [CrossRef]

- Saha, A.; Chakraborty, S.; Chandra, S.; Ghosh, I. Kriging based saturation flow models for traffic conditions in Indian cities. Transp. Res. Part Policy Pract. 2018, 118, 38–51. [Google Scholar] [CrossRef]

- Perdikaris, P.; Venturi, D.; Royset, J.O.; Karniadakis, G.E. Multi-fiddelity modelling via. recursive co-krigging and Gaussian-Markov random fields. Proc. Proc. Math. Phys. Eng. Sci. R. Soc. 2015, 471, 18. [Google Scholar]

- Kennedy, M.C.; O’Hagan, A. Bayesian Calibration of Computer Models. J. R. Stat. Soc. Ser. Stat. Methodol. 2001, 63, 425–464. [Google Scholar] [CrossRef]

- Liu, B.; Liu, X.; Zhang, H. Strain-based design criteria of pipelines. J. Loss Prev. Process Ind. 2009, 22, 884–888. [Google Scholar] [CrossRef]

- Wijewickreme, D.; Honegger, D.; Mitchell, A.; Fitzell, T. Seismic vulnerability assessment and retrofit of a major natural gas pipeline system: A case history. Earthq. Spectra 2005, 21, 539–567. [Google Scholar] [CrossRef]

- Shome, N. Probabilistic Seismic Demand Analysis of Nonlinear Structures; Stanford University: Stanford, CA, USA, 1999. [Google Scholar]

- Ibarra, L.F. Global Collapse of Frame Structures under Seismic Excitations; Stanford University: Stanford, CA, USA, 2004. [Google Scholar]

- Haselton, C.B. Assessing Seismic Collapse Safety of Modern Reinforced Concrete Moment Frame Buildings. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 2006. [Google Scholar]

- Liel, A.B. Assessing the Collapse Risk of California’s Existing Reinforced Concrete Frame Structures: Metrics for Seismic Safety Decisions; Stanford University: Stanford, CA, USA, 2008. [Google Scholar]

- Baker, J.W. Efficient analytical fragility function fitting using dynamic structural analysis. Earthq. Spectra 2015, 31, 579–599. [Google Scholar] [CrossRef]

- Hardin, B.O.; Black, W.L. Sand stiffness under various triaxial stresses. J. Soil Mech. Found. Div. 1966, 92, 27–42. [Google Scholar] [CrossRef]

- Guo, P.; Stolle, D. Lateral pipe-soil interaction in sand with reference to scale effect. J. Geotech. Geoenviron. Eng. ASCE 2005, 131, 338–349. [Google Scholar] [CrossRef]

- Daiyan, N.; Kenny, S.; Phillips, R.; Popescu, R. Investigating pipeline-soil interaction under axial-lateral relative movements in sand. Can. Geotech. J. 2011, 48, 1683–1695. [Google Scholar] [CrossRef] [Green Version]

- Vermeer, P.A.; De Borst, R. Non-Associated Plasticity for Soils, Concrete and Rock. Heron 1984, 29, 1–64. [Google Scholar]

- Forrester, A.I.; Sóbester, A.; Keane, A.J. Multi-fidelity optimization via surrogate modelling. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 3251–3269. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, S.; Tesfamariam, S. Probabilistic Seismic Risk Analysis of Buried Pipelines Due to Permanent Ground Deformation for Victoria, BC. Geotechnics 2022, 2, 731-753. https://doi.org/10.3390/geotechnics2030035

Dey S, Tesfamariam S. Probabilistic Seismic Risk Analysis of Buried Pipelines Due to Permanent Ground Deformation for Victoria, BC. Geotechnics. 2022; 2(3):731-753. https://doi.org/10.3390/geotechnics2030035

Chicago/Turabian StyleDey, Sandip, and Solomon Tesfamariam. 2022. "Probabilistic Seismic Risk Analysis of Buried Pipelines Due to Permanent Ground Deformation for Victoria, BC" Geotechnics 2, no. 3: 731-753. https://doi.org/10.3390/geotechnics2030035

APA StyleDey, S., & Tesfamariam, S. (2022). Probabilistic Seismic Risk Analysis of Buried Pipelines Due to Permanent Ground Deformation for Victoria, BC. Geotechnics, 2(3), 731-753. https://doi.org/10.3390/geotechnics2030035