A Layered Electrode Solid–Oil Triboelectric Nanogenerator for Real-Time Monitoring of Oil Leakage and Emulsification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Electrode

2.3. Preparation of Modified Polymer

2.4. Preparation of Additional Electrode

2.5. Characterization

3. Results and Discussions

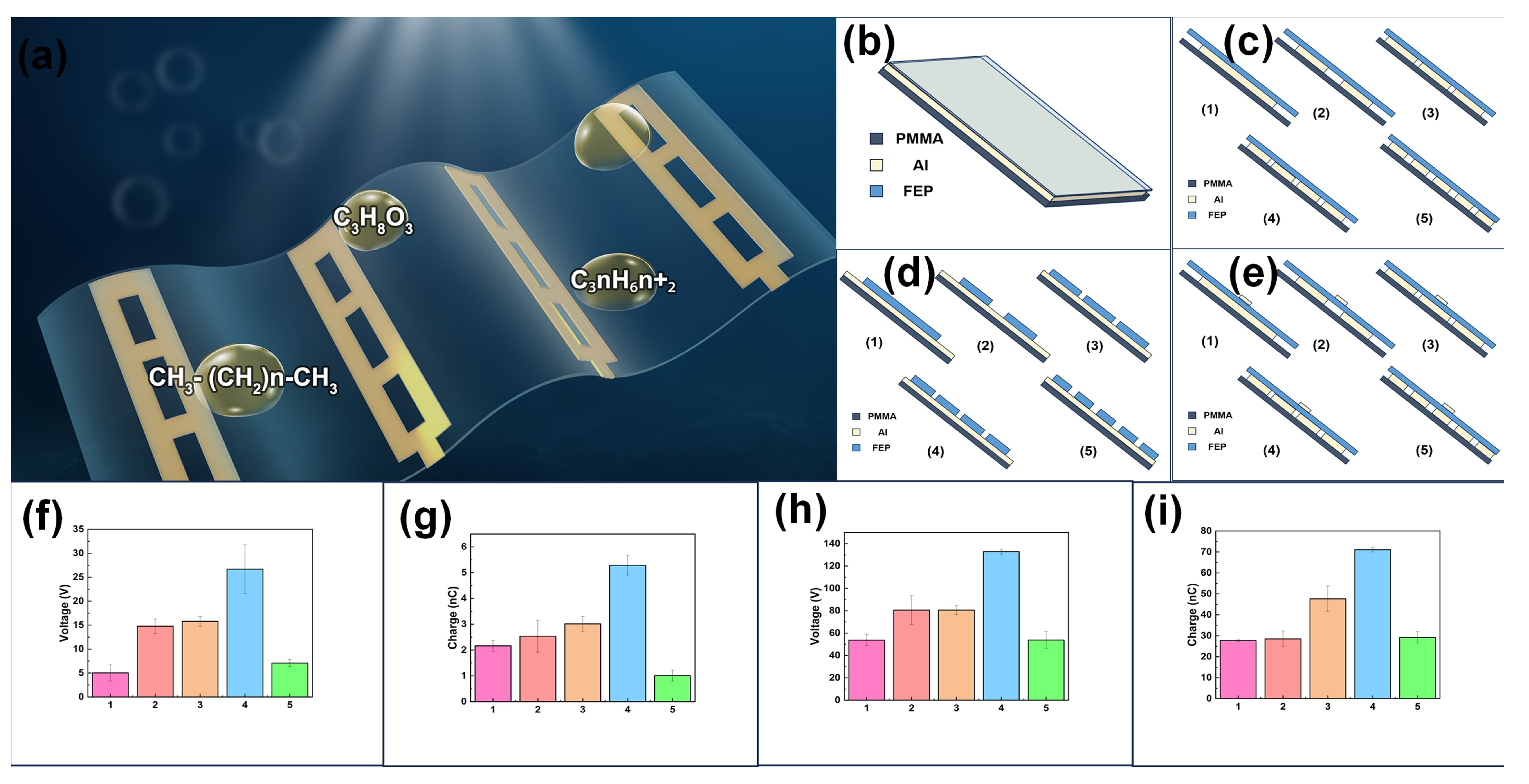

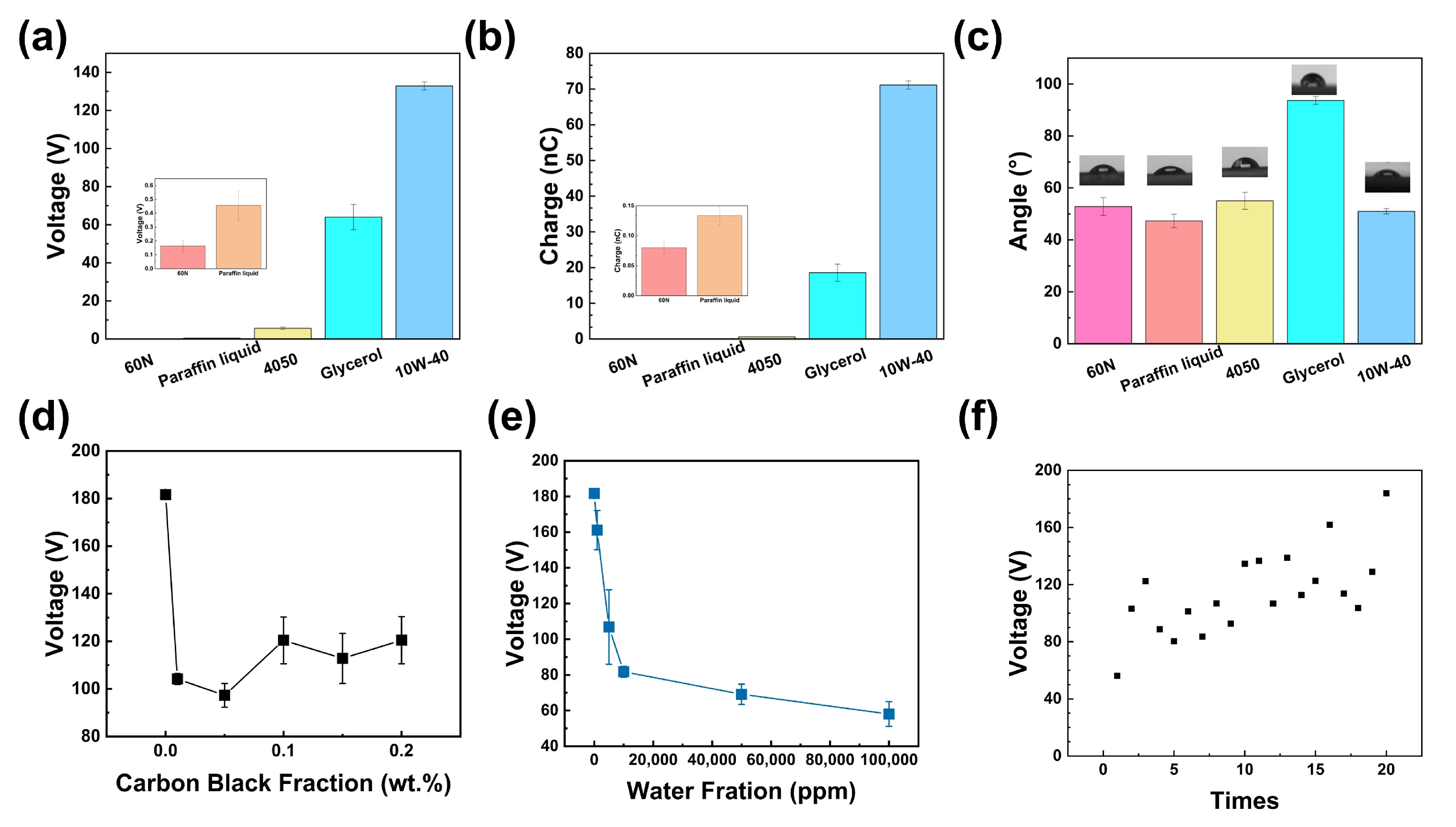

3.1. Modification and Performance of S-O-M-TENG

3.1.1. Modification of Solid–Oil TENGs

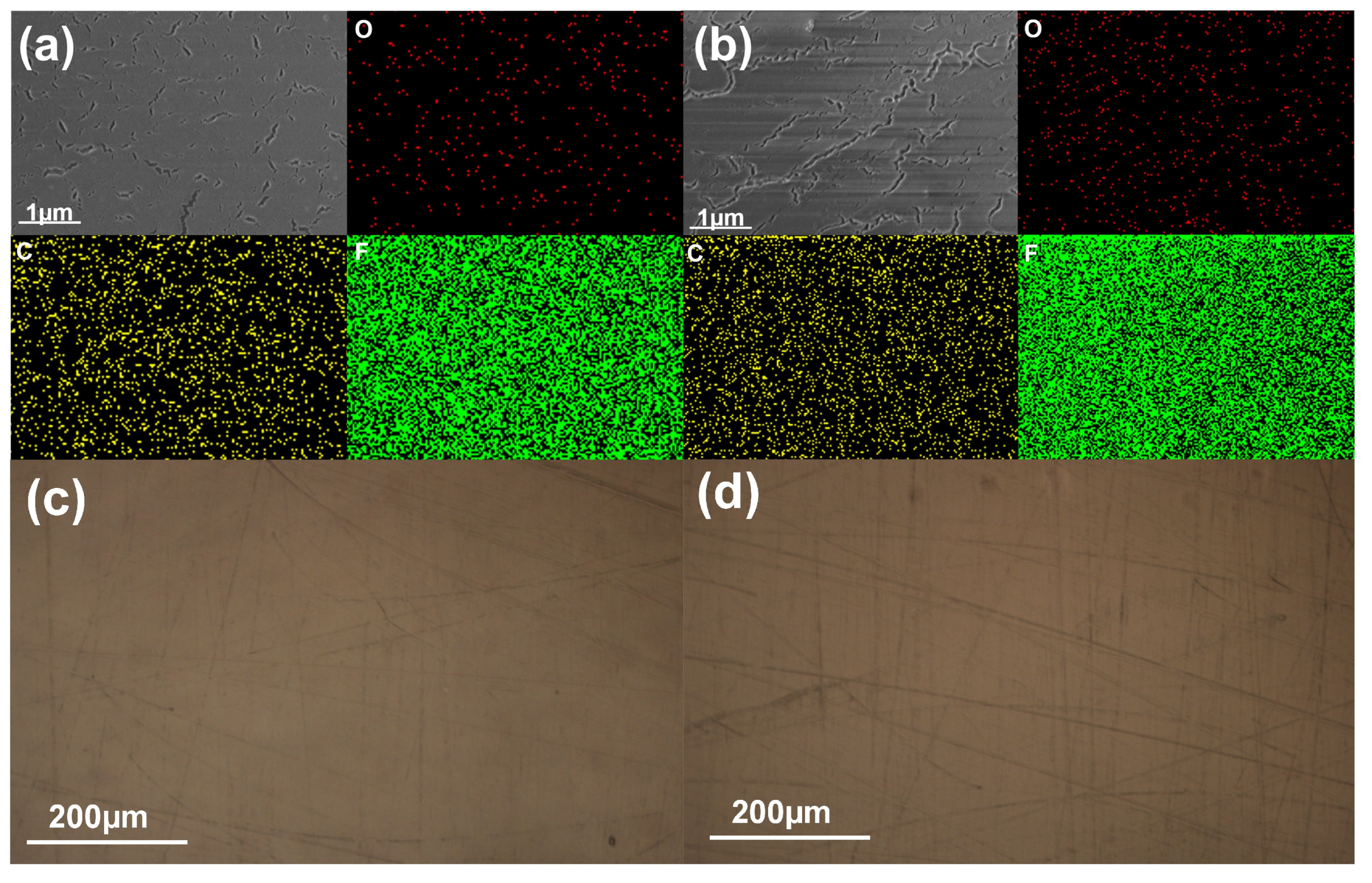

3.1.2. Material Characterization of S-O-M-TENG

3.1.3. Mechanism of S-O-M-TENG

3.1.4. Application of S-O-M-TENG

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| TENG | Triboelectric Nanogenerator |

| S-L-TENG | Solid–liquid Triboelectric Nanogenerators |

| S-O-M-TENG | Solid–oil Triboelectric Nanogenerators |

| FEP | Fluorinated ethylene propylene |

| PTFE | Polytetra-fluoroethylene |

| PMMA | Poly methyl methacrylate |

References

- Yang, S.; Cao, N.; Yu, B. Wear debris measurement in lubricating oil based on inductive method: A review. Meas. Control 2023, 56, 1422–1435. [Google Scholar] [CrossRef]

- Ren, C.; Zhang, X.; Jia, M.; Ma, C.; Li, J.; Shi, M.; Niu, Y. Antifoaming agent for lubricating oil: Preparation, mechanism and application. Molecules 2023, 28, 3152. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y.; Liang, X.; Tan, P.; Deng, S. Impacts of lubricating oil and its formulations on diesel engine particle characteristics. Combust. Flame 2021, 225, 48–56. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Maya-Yescas, R.; Béjar-Gómez, L. Reduction of lubricant life in lubrication systems for internal combustion engines due to high lubricant supply rates. Mater. Lett. 2022, 313, 131785. [Google Scholar] [CrossRef]

- Wang, K.; Sun, Y.; Zhang, H.; Ding, Z.; Song, W.; Li, J. Self-sensing smart thrust roller bearing based on triboelectric nanogenerator with highly sensitivity for monitoring trace contaminants in lubricating oil. Nano Energy 2024, 119, 109058. [Google Scholar] [CrossRef]

- Raţiu, S.; Josan, A.; Alexa, V.; Cioată, V.G.; Kiss, I. Impact of contaminants on engine oil: A review. J. Phys. Conf. Ser. IOP Publ. 2021, 1781, 012051. [Google Scholar] [CrossRef]

- Singh, A.; Verma, N.; Mamatha, T.; Kumar, A.; Singh, S.; Kumar, K. Properties, functions and applications of commonly used lubricant additives: A review. Mater. Today Proc. 2021, 44, 5018–5022. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Béjar-Gómez, L.; López-Velázquez, A.; Maya-Yescas, R.; Nápoles-Rivera, F. Maximizing lubricant life for internal combustion engines. Processes 2022, 10, 2070. [Google Scholar] [CrossRef]

- Stępień, Z. Premature degradation of lubricating oil during the service life of the positive-ignition engine. Tribol. Online 2021, 16, 31–37. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Zhang, S. The economic and environmental significance of sustainable lubricants. Lubricants 2021, 9, 21. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.H.; Inman, D.J. Feasibility of using impedance-based damage assessment for pipeline structures. Earthq. Eng. Struct. Dyn. 2001, 30, 1463–1474. [Google Scholar] [CrossRef]

- Martini, A.; Troncossi, M.; Rivola, A. Leak detection in water-filled small-diameter polyethylene pipes by means of acoustic emission measurements. Appl. Sci. 2016, 7, 2. [Google Scholar] [CrossRef]

- Tanimola, F.; Hill, D. Distributed fibre optic sensors for pipeline protection. J. Nat. Gas Sci. Eng. 2009, 1, 134–143. [Google Scholar] [CrossRef]

- Wang, Z.L. From contact electrification to triboelectric nanogenerators. Rep. Prog. Phys. 2021, 84, 096502. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Xu, P.; Liu, J.; Wang, H.; Si, J.; Deng, J.; Xu, M.; Wang, Z.L. Underwater triboelectric nanogenerator. Nano Energy 2023, 118, 109018. [Google Scholar] [CrossRef]

- Chung, S.H.; Chung, J.; Lee, S. Recent advances in lubricant-based triboelectric nanogenerators for enhancing mechanical lifespan and electrical output. Nanoenergy Adv. 2022, 2, 210–221. [Google Scholar] [CrossRef]

- Wang, H.; Xu, L.; Wang, Z. Advances of high-performance triboelectric nanogenerators for blue energy harvesting. Nanoenergy Adv. 2021, 1, 32–57. [Google Scholar] [CrossRef]

- Ding, Z.; Wang, X.; Huang, C.; Choi, K.; Choi, D. Advances in intelligent sports based on triboelectric nanogenerators. Nanoenergy Adv. 2024, 4, 258–283. [Google Scholar] [CrossRef]

- Dong, X.; Liu, Z.; Yang, P.; Chen, X. Harvesting wind energy based on triboelectric nanogenerators. Nanoenergy Adv. 2022, 2, 245–268. [Google Scholar] [CrossRef]

- Liu, L.; Hu, T.; Zhao, X.; Lee, C. Recent progress in blue energy harvesting based on triboelectric nanogenerators. Nanoenergy Adv. 2024, 4, 156–173. [Google Scholar] [CrossRef]

- Kaja, K.R.; Hajra, S.; Panda, S.; Belal, M.; Nam, S.; Pakawanit, P.; Panigrahi, B.K.; Khanbareh, H.; Bowen, C.; Yu, J.; et al. Waste Polyethylene-Coated Fabrics for Dual-Mode Interfaces Triboelectrification for Self-Powered Sensors. Results Eng. 2025, 107111. [Google Scholar] [CrossRef]

- Kaja, K.R.; Hajra, S.; Panda, S.; Belal, M.A.; Pharino, U.; Khanbareh, H.; Vittayakorn, N.; Vivekananthan, V.; Bowen, C.; Kim, H.J. Exploring liquid-solid interface based triboelectrification, structures, and applications. Nano Energy 2024, 131, 110319. [Google Scholar] [CrossRef]

- Kaja, K.R.; Hajra, S.; Panda, S.; Belal, M.A.; Pakawanit, P.; Vittayakorn, N.; Bowen, C.; Khanbareh, H.; Kim, H.J. Triboelectrification based on the waste waterproof textiles for multisource energy harvesting. Adv. Sustain. Syst. 2025, 9, 2400678. [Google Scholar] [CrossRef]

- Chen, P.; Zhang, Z.; Ye, C.; Jiang, Y.; Chen, L.; Xu, Z.; Xu, M.; Hong, Z.; Jiang, T.; Wang, Z.L. A Self-Sustainable, Ultrarobust and High-Power-Density Triboelectric Nanogenerator for In Situ Powering of Marine Internet of Things. Adv. Mater. 2025, 37, e11283. [Google Scholar] [CrossRef]

- Nie, J.; Ren, Z.; Xu, L.; Lin, S.; Zhan, F.; Chen, X.; Wang, Z.L. Probing contactelectrification-induced electron and ion transfers at a liquid-solid interface. Adv. Mater. 2020, 32, 1905696. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, D.; Zhang, F.; Liu, Y.; Chen, B.; Wang, Z.L.; Pan, J.; Larsson, R.; Shi, Y. Real-time and online lubricating oil condition monitoring enabled by triboelectric nanogenerator. ACS Nano 2021, 15, 11869–11879. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Zhang, C.; Song, Y.; Deng, X.; Leung, M.; Yang, Z.; Xu, R.X.; et al. A droplet-based electricity generator with high instantaneous power density. Nature 2020, 578, 392–396. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Lai, Y.; Gong, Z.; Zhang, H. A Layered Electrode Solid–Oil Triboelectric Nanogenerator for Real-Time Monitoring of Oil Leakage and Emulsification. Nanoenergy Adv. 2025, 5, 15. https://doi.org/10.3390/nanoenergyadv5040015

Li S, Lai Y, Gong Z, Zhang H. A Layered Electrode Solid–Oil Triboelectric Nanogenerator for Real-Time Monitoring of Oil Leakage and Emulsification. Nanoenergy Advances. 2025; 5(4):15. https://doi.org/10.3390/nanoenergyadv5040015

Chicago/Turabian StyleLi, Shuyao, Yuxuan Lai, Zujian Gong, and Huangxuan Zhang. 2025. "A Layered Electrode Solid–Oil Triboelectric Nanogenerator for Real-Time Monitoring of Oil Leakage and Emulsification" Nanoenergy Advances 5, no. 4: 15. https://doi.org/10.3390/nanoenergyadv5040015

APA StyleLi, S., Lai, Y., Gong, Z., & Zhang, H. (2025). A Layered Electrode Solid–Oil Triboelectric Nanogenerator for Real-Time Monitoring of Oil Leakage and Emulsification. Nanoenergy Advances, 5(4), 15. https://doi.org/10.3390/nanoenergyadv5040015