1. Introduction

The modern coal industry in Russia faces the need to ensure economic viability under conditions of global energy transition, tightening environmental requirements, and growing competition with alternative energy sources [

1,

2]. Under these conditions, high-performance mines play a key role in ensuring the competitiveness of underground coal mining [

3,

4].

The V.D. Yalevsky Mine of JSC “SUEK-Kuzbass” demonstrates the possibility of achieving record productivity indicators for a single longwall under favorable geological and mining conditions: up to 60,000 t/day and up to 1.63 million t/month [

5,

6]. However, intensive mining of thick coal seams at depths of 350–400 m using extended longwall panels (face length 400 m, panel length over 4 km) leads to the formation of an extensive network of underground roadways, which significantly increases the load on the mine transport system [

7,

8,

9].

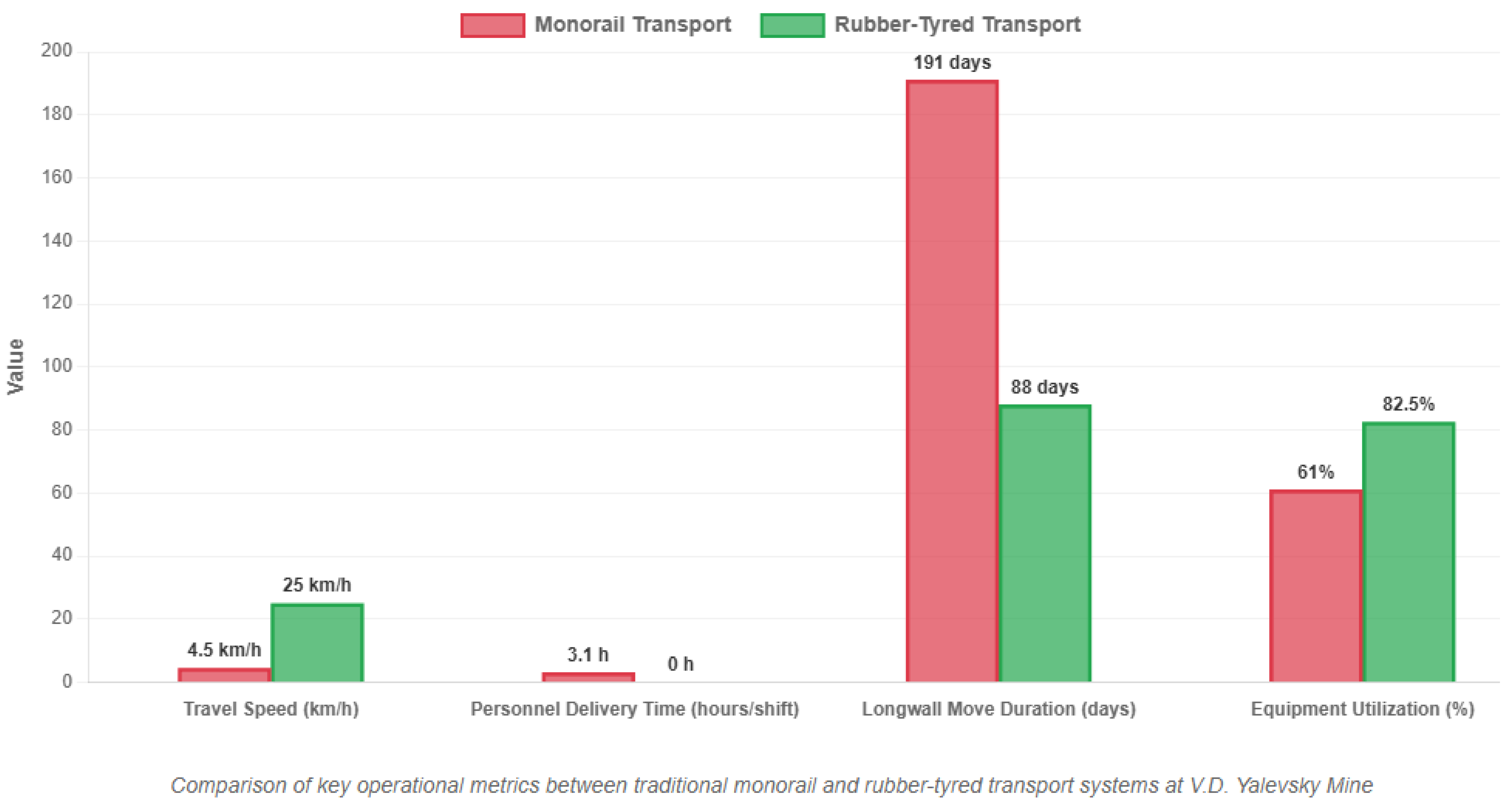

The scientific problem lies in the fact that widely used monorail transport systems demonstrate limited efficiency under intensive coal mining conditions. Low travel speeds (4.5 km/h) predetermine high time costs for personnel and equipment delivery, leading to operating time losses during main production cycles [

10,

11,

12]. Deformation processes in high-stress zones require special attention when designing transport routes [

13].

Global experience in applying rubber-tyred transport in coal mines of Australia, USA, and China demonstrates its high efficiency with the possibility of achieving speeds up to 25 km/h [

14]. However, an analysis of Russian publications reveals a lack of research on the comprehensive assessment of RTT transition in Russian mine conditions, as well as the absence of methodological approaches to the technical justification of such transition, considering the specifics of Russian conditions [

15,

16].

The scientific novelty of the work lies in developing a comprehensive approach to assessing the possibility and efficiency of transitioning to rubber-tyred transport in Russian coal mine conditions. For the first time, a methodology for the detailed development of technical measures for various RTT implementation stages is proposed, considering infrastructure limitations of existing underground roadways, and a methodology for the economic assessment of the RTT implementation effect is developed, considering acceleration of all mine technological processes [

17].

The research objective is the development of a concept for improving underground coal mining efficiency based on rubber-tyred transport implementation in high-performance mine conditions.

The research tasks include the following:

Conduct a comprehensive comparative analysis of various types of mine transport.

Analyze current mine transport efficiency at V.D. Yalevsky Mine.

Assess infrastructure limitations for RTT implementation in existing underground roadways.

Develop technical solutions for phased transition to rubber-tyred transport.

Perform economic justification of RTT implementation with calculations of the main efficiency indicators.

2. Materials and Methods

2.1. Study Site Characteristics

The research was conducted at the V.D. Yalevsky Mine of JSC “SUEK-Kuzbass”, one of Russia’s most productive coal mines with an annual production capacity of up to 10 million tons [

6]. The mine operates at depths of 350–400 m, developing seams 50 and 52 of the Gramoteinskaya suite with thicknesses of 3.7 m and 4.3 m, respectively. The mining system employs longwall retreat mining with complete roof caving, utilizing extended panels with 400 m face length and over 4 km panel length.

The mine’s maximum daily longwall output reaches 60,000 tons, with monthly production up to 1.63 million tons [

5,

6]. The geological conditions are characterized by floor rocks with low compressive strength (less than 2 MPa), susceptibility to heaving, and the presence of a false floor with even lower strength characteristics.

2.2. Data Collection Methods

Time study observations were conducted using the automated “Granch” system (Scientific and production company «Grach», Novosibirsk, Russia), which provides minute-level accuracy for recording operation execution times and equipment downtime [

18]. The system enables objective data collection on the working time structure of transport equipment throughout all shifts.

Equipment utilization coefficient (EUC) analysis was performed based on actual transport equipment operational data for 2023, with a detailed breakdown of the downtime structure by causes and time intervals [

16]. The analysis covered monorail systems, diesel–hydraulic locomotives, and contact-friction haulers to establish baseline utilization rates.

Underground infrastructure technical assessment employed modern diagnostic methods [

19,

20], including floor strength measurements, roadway geometric parameter evaluation, and analysis of deformation processes in high-stress zones. Measurements were taken at regular intervals along all main transport routes.

2.3. Comparative Analysis Methodology

International benchmarking involved systematic analysis of RTT application experience at coal mines in Australia, USA, and China, with adaptation of technical solutions to Russian conditions and industrial safety requirements [

14]. The benchmarking focused on travel speed indicators, productivity metrics, and safety performance parameters.

Multi-criteria transport comparison was conducted using the following evaluation framework:

Technical parameters (maximum gradient capability, minimum roadway width requirements, travel speeds);

Economic indicators (capital and operating costs per unit of transport work);

Operational flexibility and application versatility;

Industrial safety performance metrics.

The comparative evaluation employed weighted scoring based on V.D. Yalevsky Mine’s operational priorities: flexibility for route changes (0.35), personnel transport capability (0.30), equipment relocation efficiency (0.20), and infrastructure requirements (0.15). The assessment was based on operational data from 2020 to 2023 and analyzed by the mine’s technical team. The expert evaluation panel comprised 12 specialists from mine operations, transport engineering, safety, and academia. The Delphi method was used to achieve consensus, with three evaluation rounds conducted until the coefficient of concordance W > 0.75 was achieved.

2.4. Economic–Mathematical Modeling

The Net Present Value (NPV) calculation employed the discounted cash flow method with a 10-year calculation horizon. The discount rate was established based on the company’s weighted average cost of capital (WACC).

Modified Internal Rate of Return (MIRR) was calculated to address the limitations of classical IRR when evaluating projects with non-conventional cash flows, providing a more realistic assessment of reinvestment assumptions.

Payback period analysis was conducted to determine the time required to recover the initial investment of USD 31 million through cumulative positive cash flows generated by the project.

Sensitivity analysis examined the impact of key parameter variations on project economics, including coal price fluctuations (±30%), operating cost changes (±20%), and capital expenditure variations (±15%).

The economic model is based on the following input parameters: capital expenditure of USD 31 million, discount rate of 10% (based on the company’s WACC), 10-year calculation horizon, coal price of USD 85/ton (2023 average), and RTT operating costs of USD 3.33–5.56/t·km. The NPV calculation employed the standard discounted cash flow formula:

where CFt represents cash flows in year t, r is the discount rate, and C

0 is the initial investment.

2.5. Production Process Modeling

Baseline and potential productivity calculations were conducted based on normative reference information and mining equipment operation best practices [

21]. The modeling framework incorporated the following:

Current transport speed limitations and their impact on shift changeover times;

Equipment relocation time requirements for longwall moves;

Potential improvements from increased transport speeds.

Discrete event simulation was employed to model the complex interactions among transport operations, production cycles, and equipment availability, allowing for stochastic variation in operational parameters.

2.6. Infrastructure Constraint Assessment

Geomechanical condition evaluation included systematic measurement of the following:

Floor rock strength using portable testing equipment;

Roadway deformation patterns in critical zones;

Gradient profiles along main transport routes;

Turning radius limitations at key intersections.

Roadway geometry analysis involved detailed surveying of the following:

Cross-sectional areas at initial drivage and current conditions;

Height restrictions due to floor degradation;

Sag section identification at low-gradient zones (0–1°);

Assessment of five turns with angles less than 90° (ranging from 24° to 87°).

Ventilation system evaluation focused on air volume requirements for diesel equipment operation, with particular attention to blind headings and zones prone to spontaneous combustion [

6].

2.7. Technical Solution Development

Roadway surface technology assessment involved the development and testing of six surface treatment scenarios:

Concreted mesh lining;

Precast concrete slabs;

Composite decking systems (MDP Mobistek-80 and MDP Trassa “Type 1”);

Geogrid with crushed stone aggregate;

Sand–gravel mixture;

Grading without surface treatment.

The fleet composition optimization utilized mixed-integer programming to determine the optimal combination of 60 equipment units across different functional categories, considering capacity requirements, operational constraints, and compatibility factors.

An implementation phasing methodology was developed using stage-gate project management principles, with four distinct phases designed to minimize operational disruption while maximizing learning opportunities from initial deployment experience.

3. Results

3.1. Comparative Analysis of Various Types of Mine Transport Efficiency

The choice of optimal mine transport type is determined by a complex of factors, including mining technical and geological conditions, economic indicators, and the specifics of tasks to be solved. Since no universal transport solution exists, each type has its rational application area, requiring detailed analysis of limitations and opportunities to justify the feasibility of rubber-tyred transport implementation in high-performance mine conditions.

Modern mines use five main types of mine transport: rail, monorail, rubber-tyred, conveyor, and rope haulage. Each is characterized by specific technical parameters determining the application area (

Table 1). Rail transport is traditionally used for main haulage roads and personnel transportation over long distances, providing high productivity with gradient limitations up to 5% and minimum roadway width requirements of 3.5–4.5 m. Monorail transport demonstrates advantages in district roadways and face access, operating on gradients up to 35–45° with a minimum roadway width of 2.5–3.5 m, but is characterized by low travel speed and limited load capacity.

While conveyor transport offers excellent bulk material efficiency, the operational flexibility requirements of V.D. Yalevsky Mine, particularly for personnel transport and frequent longwall moves, made RTT the optimal choice for comprehensive transport modernization.

Economic analysis of various transport types reveals significant differences in capital and operating costs (

Table 2). Rubber-tyred transport is characterized by the lowest capital infrastructure costs (USD 22,000–56,000/km) compared to rail (USD 167,000–278,000/km) and conveyor (USD 222,000–444,000/km) transport. However, the cost of main RTT equipment is the highest: dump trucks cost USD 330,000–1,100,000, and specialized machines USD 220,000–660,000 versus USD 110,000–330,000 for electric locomotives.

While conveyor transport offers excellent bulk material efficiency, the operational flexibility requirements of V.D. Yalevsky Mine, particularly for personnel transport and frequent longwall moves, made RTT the optimal choice for comprehensive transport modernization.

Rubber-tyred transport operating costs are the highest among all types (USD 3.33–5.56/t·km), due to high fuel consumption (USD 1.50–2.50/t·km for diesel machines), intensive tire wear, and the need for frequent maintenance (15–20% of capital costs annually). Despite this, the RTT payback period is 3–5 years, which is comparable to other transport types.

Thus, rubber-tyred transport is most effective in high-performance mines with a developed network of wide roadways for solving tasks of personnel, equipment, and material delivery over medium distances, especially when frequent route changes and auxiliary operations are required (

Figure 1).

3.2. Analysis of Current Mine Transport Efficiency at V.D. Yalevsky Mine

Comprehensive analysis of mine transport operations at V.D. Yalevsky Mine revealed significant reserves for improving production process efficiency. The study was conducted using the automated “Granch” system, ensuring accuracy in time observations to one minute.

Transport equipment utilization coefficients (EUC) are characterized by low indicators: monorail systems, 52–60%; diesel–hydraulic locomotives, 65–70%; contact-surface haulers, 55–65%. These indicators are significantly lower than normative values (80–85%) for high-performance mines [

22], indicating the presence of systemic problems in transport process organization.

Personnel shift changeover time loss structure represents a critical factor in efficiency reduction. Analysis of development crew movement showed that total travel time to the workplace and back amounts to 3.0–3.2 h per shift. Meanwhile, losses due to delays and early departure reach 0.5–2.2 h per shift, totaling 4.3 h per day—practically half of the crew’s working time. For production crews, this indicator amounts to 1.1 h per day, which is also a significant reserve for productivity improvement.

The duration of moving longwall equipment amounts to 173–209 days, depending on the type and complexity of the powered roof support section dismantling. Critically important is the fact that transportation operations occupy 138–174 days (up to 80% of total duration), making the transport component the determining factor in longwall move efficiency. Modern energy-efficient support sections weighing up to 45 tons require special transportation conditions [

5], which additionally complicates logistics processes.

Utilization of transport capacity of existing equipment is inefficient: for diesel–hydraulic locomotives, this indicator does not exceed 49%, which is related to limitations on train composition and travel speed in confined conditions of underground roadways.

3.3. Infrastructure Limitations for Rubber-Tyred Transport Implementation

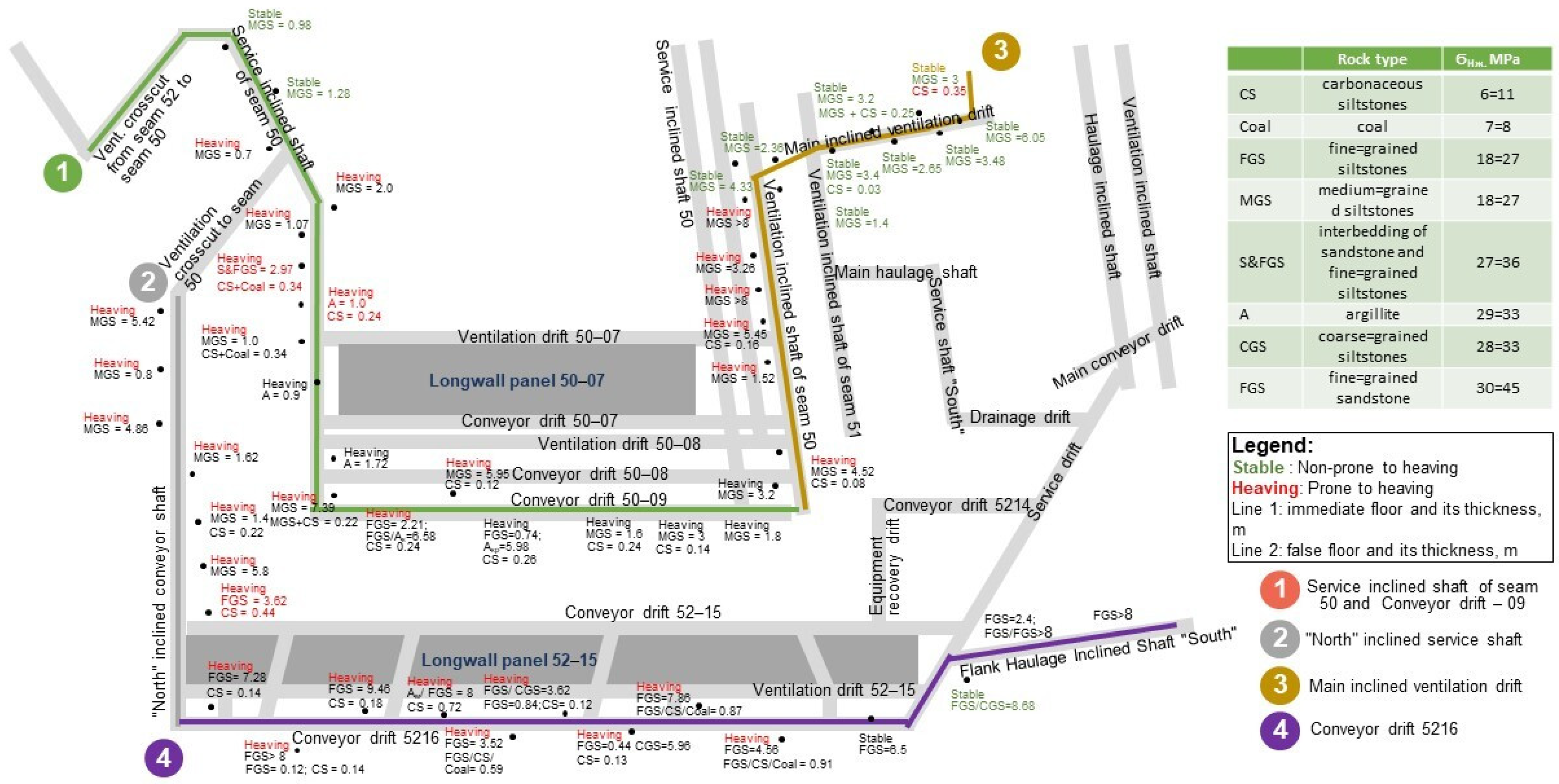

The detailed assessment of the underground infrastructure conditions at V.D. Yalevsky Mine revealed a complex of limitations requiring special technical solutions for successful RTT implementation.

Geomechanical conditions represent the main obstacle for effective rubber-tyred transport applications. The floor in all critical roadways is prone to floor heave and is characterized by low compressive strength (less than 2 MPa). In many areas, a false floor with even lower strength characteristics overlies the immediate floor (

Figure 2).

Sag sections form at gradients of 0–1° and are present on all main transport routes. Deformation processes in high-stress zones near extraction faces create additional risks for roadway stability [

4].

Geometric parameters of roadways create limitations for large equipment movement. Key routes revealed zones with inclination angles over 9° at mine entries, complicating wheeled transport passage from the surface. Five turns with angles less than 90° (from 24° to 87°) were found, requiring special maneuvers when transporting large equipment.

Roadway cross-sections during initial drivage comprise approximately 20 m2 (width ~5 m, height ~4 m). However, over time, floor degradation occurs, leading to reduced roadway height and creating risks for equipment movement exceeding 3.5 m in height.

Ventilation limitations are especially critical in blind headings where supplied air volumes amount to 640–700 m

3/min with a standard of 550 m

3/min for one diesel–hydraulic locomotive. RTT implementation will require revision of ventilation calculations considering diesel engine emissions and special requirements in zones prone to spontaneous combustion [

6].

3.4. Potential Effect from Rubber-Tyred Transport Implementation

Production process modeling shows significant potential for efficiency improvement when transitioning to rubber-tyred transport.

Primary effects:

- -

Five-fold increase in travel speed (from 4.5 to 25 km/h);

- -

Reduction of longwall move duration from 173–209 to 88 days;

- -

Complete elimination of shift changeover time losses.

Secondary effects:

- -

Operating time increase by 20% in development workings;

- -

Operating time increase by 4.5% in extraction operations;

- -

Additional coal production of 6.5 million tons.

Economic effects:

- -

NPV: USD 64.2 million;

- -

MIRR: 2.4%;

- -

Payback period: 4.5 years.

Shift changeover optimization provides the main effect through a five-fold increase in travel speed (from 4.5 to 25 km/h). The 25 km/h represents the maximum speed achieved on main haulage routes with gradients <5° and widths >6 m. Operational speeds vary by zone: 20–25 km/h on main routes, 10–15 km/h in district roadways, and 5–10 km/h in development headings, yielding a weighted average of 14 km/h across the mine network, still representing a 3.1-fold improvement over monorail transport. Calculations show the possibility of virtually complete elimination of personnel delivery time losses [

23], leading to increased operating time by 1.0 h (+20%) in development workings and 0.5 h (+4.5%) in extraction operations. The time-saving mechanism is straightforward: travel time reduces from 45–60 min (monorail) to 8–15 min (RTT) for typical 3.5–4.5 km distances, directly converting to additional productive hours per shift.

Acceleration of longwall moves is achieved through a radical reduction of transport operations from 173–209 to 88 days (effect of 85–121 days). The reduction structure includes an acceleration of longwall conveyor transportation by 2.2 times (from 22 to 10 days), reduction of shearer transportation from 17 to 12 days, acceleration of support section delivery by 44–80 days, and reduction of infrastructure installation time by 15 days [

24].

Additional coal production over the calculation period will amount to 6.5 million tons, including 4.5 million tons from reduced downtime during longwall moves (main effect), 1.2 million tons from increased development work productivity, and 0.8 million tons from extraction process optimization. After full RTT implementation, the projected average annual production volume will amount to 6.3 million tons.

3.5. Technical Solutions and Phasing of Rubber-Tyred Transport Implementation

Roadway surface technologies. Six scenarios for transport route arrangement were developed and tested with the determination of a priority solution—concreted mesh lining. This technology provides an optimal combination of strength, durability, and technological execution [

25]. Alternative solutions include concrete slabs, composite flooring (MDP Mobistek-80 and MDP Trassa “Type 1”), geogrid with aggregate, sand–gravel mixture, and a compromise option of grading without surface.

Floor bearing capacity analysis confirmed safety factors of 3.5–4.6, with maximum wheel loads generating 0.43 MPa contact pressure against a floor strength of 1.5–2.0 MPa. Field trials on a 500 m test section validated acceptable performance with <25 mm rutting after 1000 vehicle passes.

Optimal equipment fleet composition determined as 60 units of various purposes:

Fifty units for personnel and light cargo delivery (34 personnel carriers and 16 utility vehicles);

Eight units of specialized equipment for heavy loads and road grading;

Two haulers for the transportation of roof support sections with a load capacity up to 40 tons.

Industrial safety requirements include differentiated speed limits (up to 5, 10, and 20 km/h) depending on roadway width, a system for separating RTT and traditional transport routes, organization of underground workshops, and refueling stations [

26].

Ventilation analysis confirms a 29–65% safety margin above regulatory requirements for diesel operations. All equipment meets Tier 4 Final emission standards with continuous monitoring, maintaining DPM levels <0.16 mg/m3 (limit: 0.20 mg/m3) and CO < 20 ppm.

Four-stage project implementation scheme:

Stage 1: Implementation on the priority route of the northern wing of seam 50 with technological solution development.

Stage 2: Expansion to the second route of the northern wing with experience scaling.

Stage 3: Distribution to the southern wing of seam 50 with complete seam coverage.

Stage 4: Transition to seam 49 with achievement of 100% RTT utilization.

Modern mining technological structures require a comprehensive approach to transport system modernization [

7], which is considered in the developed phased implementation scheme. During project implementation, it is necessary to consider the features of mining coal seams prone to spontaneous combustion [

6], which affect ventilation requirements and diesel equipment operation safety.

Sensitivity analysis demonstrates project robustness: NPV remains positive (USD 18.5 M) even with a 30% coal price reduction, while a 25% CAPEX increase extends payback to 5.8 years, and 15% availability reduction yields an NPV of USD 41.3 M. The apparent discrepancy between high NPV (USD 64.2 M) and low MIRR (2.4%) reflects substantial reinvestment requirements for fleet replacement in years 5–7, typical for mining equipment lifecycle management.

Project economic indicators demonstrate high investment attractiveness with capital costs of USD 31 million: NPV amounts to USD 64.2 million, MIRR to 2.4%, and a payback period of 4.5 years. The synergistic effect from the simultaneous implementation of all modernization directions exceeds the sum of individual effects and forms the basis of project economic efficiency. Energy optimization of mining operations plays an important role in overall project efficiency [

27].

Organizational changes provide staffing optimization with a reduction of mine transport personnel by 56 people (~27%) and the creation of 48 new RTT operator positions, as well as 33 positions for workshop maintenance. The automation of longwall systems [

28] and the implementation of modern automated control systems [

29] create prerequisites for effective rubber-tyred transport utilization.

3.6. Risk Analysis of Rubber-Tyred Transport Implementation and Mitigation Measures

Rubber-tyred transport implementation in high-performance coal mine conditions is associated with a complex of technical, organizational, economic, and geomechanical risks requiring a systematic management approach.

Technical risks represent the most significant group of factors capable of affecting RTT functioning efficiency. Diesel equipment failures in underground conditions are characterized by a 15–20% probability and are due to operation specifics under conditions of increased humidity, dustiness, and limited space for maintenance [

26]. Roadway surface damage has the highest occurrence probability (25–30%) among technical risks, related to intensive loads from heavy equipment weighing up to 40 tons during roof support section transportation. Deformation processes in underground roadways under high stress–strain states of the rock mass exacerbate impacts on roadway surfaces, especially in zones influenced by extraction operations [

4].

Organizational risks occupy a special place in the project threat structure as they are associated with the human factor and organizational changes. Personnel resistance to changes is characterized by the highest probability among all identified risks (40–50%) and is due to the natural inertia of production processes, worker concerns regarding job cuts, and the need to master new competencies [

3]. Lack of qualified RTT operators (probability 30–40%) represents a critical factor since rubber-tyred equipment operation in underground conditions requires specific skills.

Economic risks have a direct impact on project financial efficiency and require special attention under coal market volatility conditions. Capital cost overrun by 15–25% is typical for large infrastructure projects in the mining industry [

17]. Coal price reduction by 20–30% represents a macroeconomic risk associated with global energy transition trends and geopolitical factors.

Geomechanical risks are specific to underground conditions and associated with heavy wheeled equipment interaction with the geological environment. Floor stability disruption in intensive traffic zones is due to low floor rock strength at V.D. Yalevsky Mine and the tendency to heave under water-saturated conditions. Analysis of roadway stability under adjacent coal seam mining conditions [

30] shows the need for special attention to geomechanical aspects when designing transport routes.

A comprehensive risk management system provides for the creation of a reserve equipment fleet at 10% of the main composition, a comprehensive personnel retraining program lasting 120 h, the implementation of a roadway surface condition monitoring system, and reinforcement of support in critical zones of heavy equipment movement. Phased project implementation with the possibility of strategy adjustment at each stage allows for minimizing aggregate risk and adapting technical solutions to actual operating conditions.

Risk assessment employed a probability–impact matrix approach, with probability estimates based on international RTT implementation experience.

During the first implementation phase on the northern wing of seam 50, the following mitigation measures were applied: a reserve equipment fleet of 6 units (10% of the main fleet) was established, 48 operators completed the 120 h training program, and a floor condition monitoring system was installed. Preliminary results demonstrate a 35% reduction in technical failures compared to predicted levels and an 87% successful personnel adaptation rate, validating the effectiveness of the proposed risk management approach.

4. Discussion

The obtained results demonstrate high potential for improving underground coal mining efficiency when transitioning to rubber-tyred transport. Key mechanisms for achieving the effect are associated with qualitative change in transport operation time characteristics [

31].

Impact of transport speed on productivity. A five-fold increase in travel speed (from 4.5 to 25 km/h) allows complete elimination of shift changeover time losses, leading to increased equipment operating time by 1.0 h (+20%) in development and 0.5 h (+4.5%) in extraction [

3].

Role of logistics optimization in reducing longwall moves. The most significant effect is achieved during longwall equipment relocations [

24]. Detailed analysis showed the possibility of reducing total duration from 173–209 to 88 days through radical acceleration of roof support section transportation by 44–80 days and a reduction of infrastructure completion time by 15 days.

Technological solutions for ensuring reliability. Conducted testing showed that the priority roadway surface scenario is concreted mesh lining, providing durability and high load capacity [

25].

Synergistic effect from comprehensive implementation is achieved using optimal fleet composition of 60 equipment units of various purposes [

31]: 50 utility vehicles for personnel and light cargo provide the main effect of reducing shift changeovers, 10 loading equipment units solve heavy cargo delivery and road grading tasks, and 2 specialized haulers for support sections provide the main effect of reducing longwall moves.

The obtained efficiency indicators correspond to international analogues [

14]. At Australian coal mines, RTT application allowed for an increase in labor productivity by 15–25%, which is comparable to our calculations of operating time growth by 20% in development and 4.5% in extraction. American mine experience shows the possibility of reducing longwall move time by 60–80% when using specialized wheeled transport [

32]. Our calculations of reduction by 85–121 days (50–60% from baseline level) are within the range of global experience.

Our projections align with reported outcomes from international RTT implementations in underground coal operations, where typical improvements include 15–40% reduction in equipment relocation times and 20–30% increase in development advance rates, adjusted for site-specific geological and operational conditions. The consistency of these improvements across different mining jurisdictions validates the transferability of RTT benefits to Russian mining conditions.

European experience in mining automation and digitalization [

33] confirms the prospects of implementing modern transport technologies to improve coal mining efficiency. An important aspect is methane emission control under intensive coal mining conditions [

34,

35], which must be considered when implementing diesel equipment.

Benchmarking against international RTT implementations shows comparable results: Anglo American’s Moranbah North achieved 18 km/h average speeds, Arch Coal’s Mountain Laurel reported a 40% reduction in move times, and Yankuang Group’s Zhaolou mine demonstrated a 25% increase in development rates. These outcomes validate our projections when adjusted for V.D. Yalevsky’s specific conditions of deeper operations and longer panels.

5. Conclusions

This study presents a comprehensive framework for modernizing underground coal mine transport systems through the transition from monorail to rubber-tyred transport, demonstrated through the case of V.D. Yalevsky Mine. The research contributes to the body of knowledge in mine transport optimization by integrating technical feasibility analysis, economic evaluation, and risk assessment within a unified decision-making framework. The key theoretical contribution lies in developing a systematic methodology for evaluating transport system transitions in high-performance longwall operations, considering the complex interactions among transport efficiency, production continuity, and infrastructure constraints. Unlike previous studies focusing on isolated transport performance metrics, our approach captures the synergistic effects of comprehensive transport modernization on the entire mining value chain. The practical implementation framework demonstrates that RTT adoption in deep coal mines is not merely an equipment substitution but requires fundamental reconsideration of mine logistics, infrastructure design, and operational philosophy. The positive NPV of USD 64.2 million and additional production of 6.5 million tons validate the economic viability, while the identified 20% improvement in development operating time and 50–60% reduction in longwall relocation duration confirm operational benefits comparable to international benchmarks. Critical success factors identified include: (1) adequate roadway dimensions (minimum 5 m width) and floor bearing capacity (>1.5 MPa); (2) phased implementation allowing operational learning and risk mitigation; (3) integrated planning of transport routes, ventilation systems, and emergency egress; and (4) comprehensive workforce training and change management programs. This research has several limitations that define boundaries for application and areas for future investigation. The analysis is based on specific geological and operational conditions of a single mine, and transferability to operations with different seam characteristics, depth, or production scales requires careful adaptation. The economic evaluation assumes stable regulatory environments and does not account for potential carbon pricing or emissions trading impacts that may affect diesel equipment operations. Future research directions should address the following: (1) development of real-time optimization algorithms for mixed fleet dispatching in constrained underground networks; (2) integration of battery–electric and hybrid propulsion systems to reduce ventilation requirements and emissions; (3) application of digital twin technologies for predictive maintenance and traffic flow optimization; and (4) comprehensive lifecycle assessment including environmental and social impacts of transport system transitions. The transition to rubber-tyred transport represents more than technological modernization—it exemplifies the mining industry’s capacity for systematic innovation in response to productivity imperatives and evolving sustainability requirements. As the global energy transition accelerates, such efficiency improvements become essential for maintaining the competitiveness of coal operations during the transitional period while meeting increasingly stringent environmental and safety standards.