Beyond Traceability: Leveraging Opportunities and Innovation in Chain of Custody Standards for the Mining Industry

Abstract

1. Introduction

1.1. Background

1.2. Problem Statement

1.3. Aim & Scope

2. Theoretical Aspects of Reference

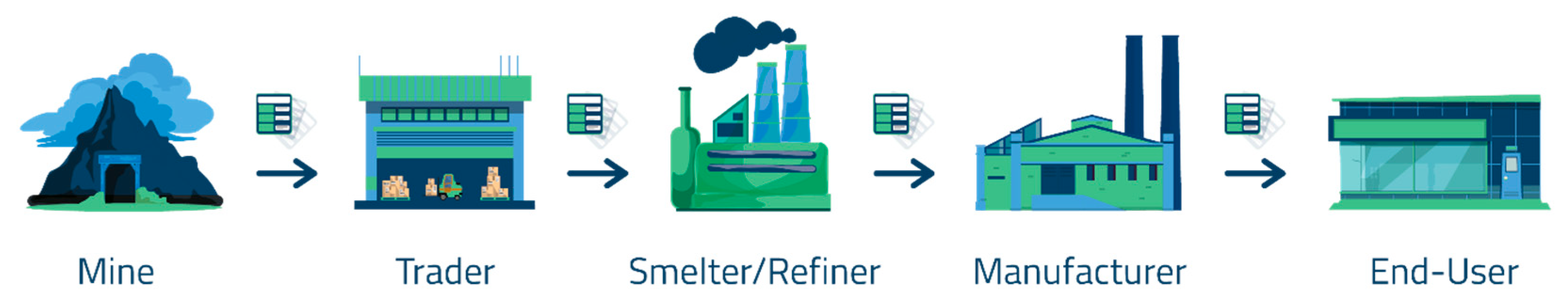

2.1. CoC System and Models

2.2. Status of Implementation of Chain of Custody Standards in the Mining Industry

3. Key Findings

4. Discussion

4.1. Strategic Opportunities

- (1)

- Inclusion of ESG aspects in sourcing and handling materials: using the same mode of information transfer, i.e., the CoC document for materials and suppliers, can also mandate the inclusion of information such as carbon footprint or due diligence practices when procuring minerals from the CAHRAs. Extend the scope of conducting due diligence of suppliers of non-CoC materials.

- (2)

- Information for stakeholders and increased transparency as part of communications: possibility of disclosing the verified information to interested parties and integrating this information in disclosures to build trust in their practices and claims.

- (3)

- Inclusiveness and consolidating supply chain actors in the scope: possibility of including ASMs in certification schemes by expanding the scope and recognising their efforts towards responsible practices. Detailed provisions for proactively seeking to integrate upstream actors by providing incentives or knowledge sharing to build their capabilities.

4.1.1. Inclusion of ESG Aspects in Sourcing and Handling Materials

4.1.2. Information for Stakeholders and Increased Transparency as Part of Communications

4.1.3. Inclusiveness and Consolidating Supply Chain Actors in the Scope

4.2. Transformative Innovation Areas

- (1)

- Chain of custody document: Provisions for technologies or systems to connect the nodes in the supply chain.

- (2)

- Concrete determination of origin and tracking solutions: Solutions for determining origin are still in their infancy, limited in scope and scalability. Currently, the documentation system is the only feasible option; however, innovative solutions must be promoted, and standards can play a key role in their development and adoption.

4.2.1. Chain of Custody Document

4.2.2. Concrete Determination of Origin and Tracking Solutions

4.2.3. Provisions and Practices for Improved CoC Implementation

5. Conclusions

Limitations of the Study

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CoC | Chain of Custody |

| ESG | Environmental, Social and Governance |

| QR | Quick Response |

| RFID | Radio Frequency Identification tags |

| CAHRA | Conflict-Affected and High-Risk Areas |

| iTSCi | International Tin Supply Chain Initiative |

| FSC | Forest Stewardship Initiative |

| NGO | Non-governmental Organisation |

| GRI | Global Reporting Initiative Standards |

| 3TG | Tin, Tungsten, Tantalum and Gold |

References

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Shankar, P. Why has DRC filed criminal charges against Apple over ‘conflict minerals’. Al Jazeera [Online]. 20 December 2024. Available online: https://www.aljazeera.com/news/2024/12/20/why-has-drc-filed-criminal-charges-against-apple-over-conflict-minerals (accessed on 26 May 2025).

- The Gecko Project. The Tin Racketword: Illegal mining ransacked these Indonesian islands. Tech titans turn a blind eye [Online]. 13 May 2025. Available online: https://thegeckoproject.org/articles/illegal-tin-mining/ (accessed on 15 September 2025).

- HRW. Aluminium: The car industry’s blind spot: Why Car Companies Should Address the Human Rights Impact of Aluminum Production. Available online: https://www.hrw.org/report/2021/07/22/aluminum-car-industrys-blind-spot/why-car-companies-should-address-human-rights (accessed on 22 June 2025).

- Carter, C.; Rogers, D.; Choi, T. Toward the Theory of the Supply Chain. J. Supply Chain. Manag. 2015, 51, 89–97. [Google Scholar] [CrossRef]

- Young, S.; Fernandes, S.; Wood, M. Jumping the Chain: How Downstream Manufacturers Engage with Deep Suppliers of Conflict Minerals. Resources 2019, 8, 26. [Google Scholar] [CrossRef]

- Barash-Harman, Y. Effect of trade and manufacturer traceability on the environmental performance of local companies in emerging economies. Regul. Gov. 2018, 14, 804–820. [Google Scholar] [CrossRef]

- GAO. Conflict Minerals: 2022 Company Reports on Mineral Sources Were Similar to Those Filed in Prior Years. Available online: https://www.gao.gov/assets/gao-23-106295.pdf (accessed on 28 December 2024).

- ISO/DIS 22095; Chain of Custody—General Terminology and Models. ISO: Geneva, Switzerland, 2019.

- Imbrogiano, J.-P.; Steiner, B.; Mori Junior, R.; Sturman, K. What enables metals ‘being’ ‘responsible’? An exploratory study on the enabling of organizational identity claims through a new sustainability standard. Resour. Policy 2023, 83, 103619. [Google Scholar] [CrossRef]

- van den Brink, S.; Kleijn, R.; Tukker, A.; Huisman, J. Approaches to responsible sourcing in mineral supply chains. Resources Conserv. Recycl. 2019, 145, 389–398. [Google Scholar] [CrossRef]

- Schöneich, S.; Saulich, C.; Müller, M. Traceability and foreign corporate accountability in mineral supply chains. Regul. Gov. 2023, 17, 954–969. [Google Scholar] [CrossRef]

- Farooki, M.; Graf, A.; Degreif, S. Advancing Responsible Sourcing in Mineral Value Chains: Environmental, Social, and Economic Sustainability; Springer Nature: Cham, Switzerland, 2024; ISBN 978-3-031-60455-3. [Google Scholar]

- ISEAL Alliance. Chain of Custody Models and Defintions. Available online: https://fefac.eu/wp-content/uploads/2021/07/21_INST_27_Annex-1.pdf (accessed on 22 June 2025).

- IPIECA. Chain of Custody Options for Sustainable Biofuels: Operations and Fuels 2010. Available online: https://www.ipieca.org/resources/chain-of-custody-options-for-sustainable-biofuels (accessed on 15 September 2025).

- Pechstein, J.; Bullerdiek, N.; Kaltschmitt, M. A “book and Claim”-Approach to account for sustainable aviation fuels in the EU-ETS—Development of a basic concept. Energy Policy 2020, 136, 111014. [Google Scholar] [CrossRef]

- Dehue, B.; Meyer, S.; Hamelinck, C. Towards a Harmonised Sustainable Biomass Certification Scheme; Ecofys: Utrechte, The Netherlands, 2007. [Google Scholar]

- ASI. Aluminium Stewardship Initiative Chain of Custody (CoC) Standard: Version 2.1. Available online: https://aluminium-stewardship.org/wp-content/uploads/2023/04/ASI-Chain-of-Custody-Standard-V2.1-April-2023.pdf (accessed on 2 June 2025).

- Alvarez, G. 23—Fair trade and beyond: Voluntary standards and sustainable supply chains. In Delivering Performance in Food Supply Chains: Woodhead Publishing Series in Food Science, Technology and Nutrition; Mena, C., Stevens, G., Eds.; Woodhead Publishing: Sawston Cambridge, UK, 2010; pp. 478–510. ISBN 978-1-84569-471-5. [Google Scholar]

- Bastian, J.; Zentes, J. Supply chain transparency as a key prerequisite for sustainable agri-food supply chain management. Int. Rev. Retail. Distrib. Consum. Res. 2013, 23, 553–570. [Google Scholar] [CrossRef]

- Liu, Y.; Eisingerich, A.; Auh, S.; Merlo, O.; Chun, H. Service Firm Performance Transparency: How, When, and Why Does It Pay Off? J. Serv. Res. 2015, 18, 451–467. [Google Scholar] [CrossRef]

- Global Witness. The ITSCI Laundromat: How a Due Diligence Scheme Appears to Launder Conflict Minerals. Available online: https://www.globalwitness.org/en/campaigns/natural-resource-governance/itsci-laundromat/ (accessed on 4 June 2025).

- Guan, Z.; Xu, Y.; Sheong, J. The impact of application of FSC Chain of Custody certification on global wood products trade. Eur. J. Wood Wood Prod. 2019, 77, 633–643. [Google Scholar] [CrossRef]

- Klarić, K.; Greger, K.; Klarić, K.; Greger, K.; Klarić, M.; Andric, T.; Hitka, M.; Kropivšek, J. An Exploratory Assessment of FSC Chain of Custody Certification Benefits in Croatian Wood Industry. Drv. Ind. 2016, 67, 241–248. [Google Scholar] [CrossRef]

- Bruzzese, S.; Brun, F.; Galati, A.; Borsellino, V.; Mirabella, C.; Brunori, A.; Blanc, S. Examining the adoption of PEFC chain of custody certification in the Italian forest-based industry: An empirical study on motivations and impacts. For. Policy Econ. 2025, 170, 103385. [Google Scholar] [CrossRef]

- Pappila, M.; Tynkkynen, M. The Role of MSC Marine Certification in Fisheries Governance in Finland. Sustainability 2022, 14, 7178. [Google Scholar] [CrossRef]

- Iue, M.; Makino, M.; Asari, M. Seafood Sustainability Supply Chain Trends and Challenges in Japan: Marine Stewardship Council Fisheries and Chain of Custody Certificates. Sustainability 2022, 14, 13523. [Google Scholar] [CrossRef]

- Erdmann, M.; Franken, G. Sustainability Standard Systems for Mineral Resources: A comparative Overview. Available online: https://www.bgr.bund.de/DE/Themen/Rohstoffe/Downloads/Downloads-MR/studie_sustainability_standard_systems_2022.html (accessed on 8 June 2025).

- Sturman, K.; Rogers, P.; Imbrogiano, J.; Mori Junior, R.; Ezeigbo, C. Monitoring impact of mineral sustainability standards to align with the Sustainable Development Goals. Available online: https://rue.bmz.de/resource/blob/79626/giz-impact-of-mineral-sustainability-standards-final.pdf (accessed on 12 July 2025).

- Potts, J.; Wenban-Smith, M.; Turley, L.; Lynch, M. State of Sustainability Initiatives Review: Standards and the Extractive Economy. Available online: https://www.iisd.org/system/files/publications/igf-ssi-review-extractive-economy.pdf (accessed on 4 June 2025).

- ASI. Tracking ASI Certified Material: 2023 Data Highlights and Reporting Insights. Available online: https://aluminium-stewardship.org/tracking-asi-certified-material-2023-data-highlights-and-reporting-insights#:~:text=During%202023%2C%20ASI%20Performance%20and,impact%20on%20the%20aggregated%20figures. (accessed on 21 July 2025).

- IWG. Breaking News: Celebrating our RJC Chain of Custody Certification! Available online: https://iwgplating.com/en/breaking-news-celebrating-our-rjc-chain-of-custody-certification-2/ (accessed on 25 July 2025).

- The Copper Mark. Annual Report. Available online: https://coppermark.org/wp-content/uploads/2024/07/CopperMark-AnnualReport-2023.pdf (accessed on 1 July 2025).

- ISO 9000:2015; Quality Management Systems—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2015.

- Bakhtiar, A.; Nugraha, A.; Suliantoro, H.; Pujotomo, D. The effect of quality management system (ISO 9001) on operational performance of various organizations in Indonesia. Cogent Bus. Manag. 2023, 10, 2203304. [Google Scholar] [CrossRef]

- Bastas, A.; Liyanage, K. ISO 9001 and Supply Chain Integration Principles Based Sustainable Development: A Delphi Study. Sustainability 2018, 10, 4569. [Google Scholar] [CrossRef]

- Rainforest Alliance. What Is Mass Balance Sourcing? Available online: https://www.rainforest-alliance.org/business/certification/what-is-mass-balance-sourcing/ (accessed on 2 July 2025).

- UN Global Compact; BSR. A Guide to Traceability: A Practical Approach to Advance Sustainability in Global Supply Chains. Available online: https://www.bsr.org/reports/BSR_UNGC_Guide_to_Traceability.pdf (accessed on 8 June 2025).

- RJC. Chain of Custody Guidance. Available online: https://www.responsiblejewellery.com/wp-content/uploads/RJC-2024-COC-Guidance-v1.1.pdf (accessed on 13 July 2025).

- EU Directive 2023/1542. Battery Regulation. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023R1542 (accessed on 27 December 2024).

- Lam, J.; Postle, R. Textile and apparel supply chain management in Hong Kong. Int. J. Cloth. Sci. Technol. 2006, 18, 265–277. [Google Scholar] [CrossRef]

- Bateman, A.; Bonanni, L. What Supply Chain Transparency Really Means. Harvard Business Review. 2019. Available online: https://hbr.org/2019/08/what-supply-chain-transparency-really-means (accessed on 15 September 2025).

- Islam, M.A.; McPhail, K. Regulating for corporate human rights abuses: The emergence of corporate reporting on the ILO’s human rights standards within the global garment manufacturing and retail industry. Critical Perspectives on Accounting 2011, 22, 790–810. [Google Scholar] [CrossRef]

- Okongwu, U.; Morimoto, R.; Lauras, M. The maturity of supply chain sustainability disclosure from a continuous improvement perspective. Int. J. Product. Perform. Manag. 2013, 62, 827–855. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Doorey, D. The Transparent Supply Chain: From Resistance to Implementation at Nike and Levi-Strauss. J. Bus. Ethics 2011, 103, 587–603. [Google Scholar] [CrossRef]

- Martinez, E.O.; Crowther, D. Is disclosure the right way to comply with stakeholders? Shell Case 2008, 17, 13–22. [Google Scholar]

- Cartier, L.; Ali, S.; Krzemnicki, M. Blockchain, Chain of Custody and Trace Elements: An Overview of Tracking and Traceability Opportunities in the Gem Industry. J. Gemmol. 2018, 36, 212–227. [Google Scholar] [CrossRef]

- Egels-Zandén, N.; Hulthén, K.; Wulff, G. Trade-offs in supply chain transparency: The case of Nudie Jeans Co. J. Clean. Prod. 2015, 107, 95–104. [Google Scholar] [CrossRef]

- Levin, E.; Cook, R.; Chishugi, A.; Jorns, A.; Mulumeoderhwa, P. Comparative Study of Certification and Traceability Systems. Available online: https://www.levinsources.com/assets/pages/report-promines-comparative-study-certification-traceability-systems-drc-congo.pdf (accessed on 30 June 2025).

- FSC. FSC Public Search—Certificate Data. Available online: https://connect.fsc.org/fsc-public-certificate-search (accessed on 15 September 2025).

- Vidal, N.; Kozak, R.; Cohen, D. Chain of custody certification: An assessment of the North American solid wood sector. For. Policy Econ. 2005, 7, 345–355. [Google Scholar] [CrossRef]

- Global Investor Commission on Mining 2030. Mining Landscape Report: The Role of Investors in Realising an Environmentally and Socially Responsible Mining Industry. A report by the Global Investor Commission on Mining 2030. Available online: https://mining2030.org/wp-content/uploads/2024/10/Mining2030-Report-v9.pdf (accessed on 4 June 2025).

- OECD. Costs and Value of Due Diligence in Mineral Supply Chains—OECD Position Paper. Available online: https://mneguidelines.oecd.org/costs-and-value-of-due-diligence-in-mineral-supply-chains.pdf (accessed on 16 July 2025).

- UNODC. Global Analysis on Crimes that Affect the Environment—Part 2b: Minerals Crime: Illegal Gold Mining. Available online: https://www.unodc.org/documents/data-and-analysis/Crimes%20on%20Environment/ECR25_P2b_Minerals_Crime.pdf (accessed on 22 June 2025).

- Eslava, N. Successful Implementation of Conflict Mineral Certification and Due Diligence Schemes and the European Union’s role: Lessons Learned for Responsible Mineral Supply. Available online: http://stradeproject.eu/fileadmin/user_upload/pdf/STRADE_Report_D4.19_Due_Diligence_Certification.pdf (accessed on 28 June 2025).

- RCS Global. Blockchain for Traceability in Minerals and Metals Supply Chains: Opportunities and Challenges. Available online: https://www.rcsglobal.com/wp-content/uploads/2018/09/ICMM-Blockchain-for-Traceability-in-Minerals-and-Metal-Supply-Chains.pdf (accessed on 10 July 2025).

- Calvão, F.; Archer, M. Digital extraction: Blockchain traceability in mineral supply chains. Political Geogr. 2021, 87, 102381. [Google Scholar] [CrossRef]

- Wolfson, R. Ford Motor Company Launches Blockchain Pilot On IBM Platform To Ensure Ethical Sourcing Of Cobalt. Available online: https://www.forbes.com/sites/rachelwolfson/2019/01/16/ford-motor-company-launches-blockchain-pilot-on-ibm-platform-to-ensure-ethical-sourcing-of-cobalt/ (accessed on 28 July 2025).

- Aartimona. Blockchain: The key to unlocking trust in mineral value chains. Available online: https://theintelligentminer.com/2024/10/30/blockchain-the-key-to-unlocking-trust-in-mineral-value-chains/ (accessed on 26 May 2025).

- IEA; OECD. The Role of Traceability in Critical Minerals Supply Chain. Available online: https://www.oecd.org/content/dam/oecd/en/publications/reports/2025/02/the-role-of-traceability-in-critical-mineral-supply-chains_4e5cc44a/edb0a451-en.pdf (accessed on 10 May 2025).

- GS1. GS1 Global Traceability Standard: GS1’s Framework for the Design of Interoperable Traceability Systems for Supply Chains. Available online: https://www.gs1.org/sites/default/files/docs/traceability/GS1_Global_Traceability_Standard_i2.pdf (accessed on 18 July 2025).

- FSC Trace. Transform Supply Chain Integrity and Traceability. Available online: https://fsc.org/sites/default/files/2024-12/FSCTrace_Fact%20sheet_v8.pdf (accessed on 29 August 2025).

- Ojo Publico. EL ORO DE LA DESTRUCCIÓN: UNA DÉCADA DE MINERÍA ILEGAL Y LAVADO. Available online: https://ojo-publico.com/especiales/latinoamerica/las-rutas-del-oro-sucio-amazonia/es/ (accessed on 28 May 2025).

- Siegel, D. Diamond Mining, Organized Crime, and Corruption. In Illegal Mining: Organized Crime, Corruption, and Ecocide in a Resource-Scarce World; Zabyelina, Y., van Uhm, D., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 185–203. ISBN 978-3-030-46327-4. [Google Scholar]

- Dietrich, V.; Melcher, F. Mineral Raw Material Supply Chain Transparency and Traceability: Does Provenance Matter in the Supply Chain? BHM Berg- Und Hüttenmännische Monatshefte 2022, 167, 594–597. [Google Scholar] [CrossRef]

- Melcher, F.; Dietrich, V.; Gäbler, H.-E. Analytical Proof of Origin for Raw Materials. Minerals 2021, 11, 461. [Google Scholar] [CrossRef]

- Schütte, P.; Melcher, F.; Gäbler, H.-E.; Sitnikova, M.; Hublitz, M.; Goldmann, S.; Schink, W.; Gawronski, T.; Ndikumana, A.; Nziza, L. The Analytical Fingerprint (AFP)—Method and Application; Bundesanstalt für Geowissenschaften und Rohstoffe: Hannover, Germany, 2018; Available online: https://www.whymap.org/EN/Themen/Min_rohstoffe/CTC/Downloads/AFP_Manual.pdf?__blob=publicationFile&v=7 (accessed on 15 September 2025).

- MaDiTraCe. CERA 4in1—Certification of Mineral Raw Materials for Sustainable Development in Mining. Available online: https://www.maditrace.eu/cera4in1 (accessed on 18 May 2025).

- FSC. World Forest ID. Available online: https://www.africa.fsc.org/en-cd/supply-chains/sample-testing#:~:text=That%20is%20why%20FSC%2C%20US,with%20the%20world’s%20leading%20laboratories (accessed on 30 August 2025).

- FSC. Requirements for Sourcing FSC Controlled Wood. Available online: https://connect.fsc.org/document-centre/documents/resource/373 (accessed on 14 June 2025).

| Identity Preserved | Segregation | Controlled Blending | Mass Balance | Book & Claim | |

|---|---|---|---|---|---|

| Strengths | Assurance of origin | Assurance of certified materials in the product | Assures a certain percentage of certified material is present in the product | Flexible, scalable and requires fewer stringent controls | Flexibility, scalability and can be adopted by actors with no access to certified materials. |

| Weaknesses | Costly and stringent controls | Comparatively less costly and less stringent controls compared to identity-preserved | Partial loss of traceability and a complex procedure to determine the percentage of material | Loss of traceability | No link between materials and administrative controls, so loss of traceability |

| Implications for the mining industry | More suitable for high-risk and high-value materials like 3TG | To ensure regulatory compliance, for instance, for battery materials to meet the requirements of the EU Battery Regulation | For bulk minerals, where a certain percentage of assurance regarding responsible sourcing is required | For bulk and low-risk minerals where segregation is not feasible | Suitable for ASMs which can sell credits for their certified materials when there is no demand, and also for larger organisations to support responsible sourcing |

| IRMA | ASI | RJC | Copper Mark | |

|---|---|---|---|---|

| Version | 1 | 2.1 | 2024 Version (2nd) | 1 |

| Year | 2024 | 2023 | 2024 | 2022 |

| Commodities coverage | All minerals | Bauxite, Alumina, Aluminium | Gold, PGMs (platinum, palladium and rhodium), Silver | Copper |

| Add on to | IRMA Standard for Responsible Mining | ASI Performance Standard | RJC Code of Practices | Copper Mark Responsible Production Criteria |

| Nature of certification | Voluntary | Voluntary | Voluntary | Voluntary |

| CoC model used | All models | Mass balance (credit method) | Segregation | Segregation and mass balance (credit method) |

| Governance | Multi-stakeholder governance | Not-for-profit multi-stakeholder governance | Multi-stakeholder governance | Multi-stakeholder governance |

| Management Criteria | Further Information |

|---|---|

| Roles and responsibilities |

|

| Records management |

|

| Metal Accounting system |

|

| Communications and training |

|

| Complaints procedure |

|

| Internal review |

|

| Corrective actions for non-conformity |

|

| Outsourcing |

|

| Sourcing Criteria | Further Information |

|---|---|

| CoC document |

|

| Secondary materials |

|

| Non-CoC materials |

|

| Handling and Sales Criteria | Further Information |

|---|---|

| CoC model |

|

| CoC document |

|

| Claims |

|

| Physical Layer | Digital Layer | ||

|---|---|---|---|

| Product | Run-of-mine, concentrate, components, or final products, recycled materials, etc. | Standard identifiers | Assign lot or batch ID, organisation ID, shipment or transport ID |

| Process | Production, transformation, input or output quantities, conversion factor, etc. | Event records | Record shipping, who, what, where, when and why details |

| Transaction | Transportation documents, sales invoices, etc. | Verification | Maintain transaction IDs and conducting a three-way match method |

| CoC document | Origin, percentage of certified or recycled materials, etc. | Control of claims | Evaluate whether certified outputs are less than certified inputs in the defined accounting period and reconciliation of data |

| Barriers to Faster Adoption and Effective Implementation of CoC | CoC Standard | Contribution | |

|---|---|---|---|

| Provisions | Practices | ||

| Lack of resources of SMEs | Stakeholder engagement and inclusive requirements | Cost and knowledge sharing through training of suppliers, as well as providing incentives | Responsible sourcing regardless of the size of the organisation |

| Loss of information integrity | In addition to documentation, provisions to operate on digital platforms | Support pilots for innovative digital solutions like blockchains and chemical technologies Spot-checks using chemical technological solutions | Reduced risk of illegal materials entering the supply chain and information credibility |

| Controls limited to CoC materials | Include due diligence requirements for non-CoC materials | Collect 2nd- or 3rd-party verified ESG data from non-certified suppliers | Reliable data for sustainability reports and extended responsible sourcing practices, and not complicit in supply chain risks |

| Complex standard requirements for internal controls | Tiered requirements, with different levels like core and advanced. With advanced requirements mandated for materials which are high-risk and under the scrutiny of regulations, and core requirements for upstream actors | SMEs could start with core compliance requirements, which could then be gradually transitioned to more advanced requirements | Fulfil regulatory requirements while increasing the uptake of standards across the supply chain |

| Limited access to ESG and traceability information | Standardised information templates considering business confidentiality Specify disclosures required by different stakeholder groups | Publicly reporting ESG and traceability information of suppliers, and making it accessible to relevant stakeholders in alignment with standard reporting formats like Global Reporting Initiative Standards (GRI) and contributing to publicly accessible databases | Increased trust among stakeholders and transparency about practices |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowaz, T.; Betin, S.O.; Förster, L.; Fernandez, P.; Baena, O.J.R. Beyond Traceability: Leveraging Opportunities and Innovation in Chain of Custody Standards for the Mining Industry. Mining 2025, 5, 61. https://doi.org/10.3390/mining5040061

Nowaz T, Betin SO, Förster L, Fernandez P, Baena OJR. Beyond Traceability: Leveraging Opportunities and Innovation in Chain of Custody Standards for the Mining Industry. Mining. 2025; 5(4):61. https://doi.org/10.3390/mining5040061

Chicago/Turabian StyleNowaz, Thania, Samuel Olmos Betin, Lukas Förster, Paulina Fernandez, and Oscar Jaime Restrepo Baena. 2025. "Beyond Traceability: Leveraging Opportunities and Innovation in Chain of Custody Standards for the Mining Industry" Mining 5, no. 4: 61. https://doi.org/10.3390/mining5040061

APA StyleNowaz, T., Betin, S. O., Förster, L., Fernandez, P., & Baena, O. J. R. (2025). Beyond Traceability: Leveraging Opportunities and Innovation in Chain of Custody Standards for the Mining Industry. Mining, 5(4), 61. https://doi.org/10.3390/mining5040061