Envisioning Human–Machine Relationship Towards Mining of the Future: An Overview

Abstract

1. Introduction

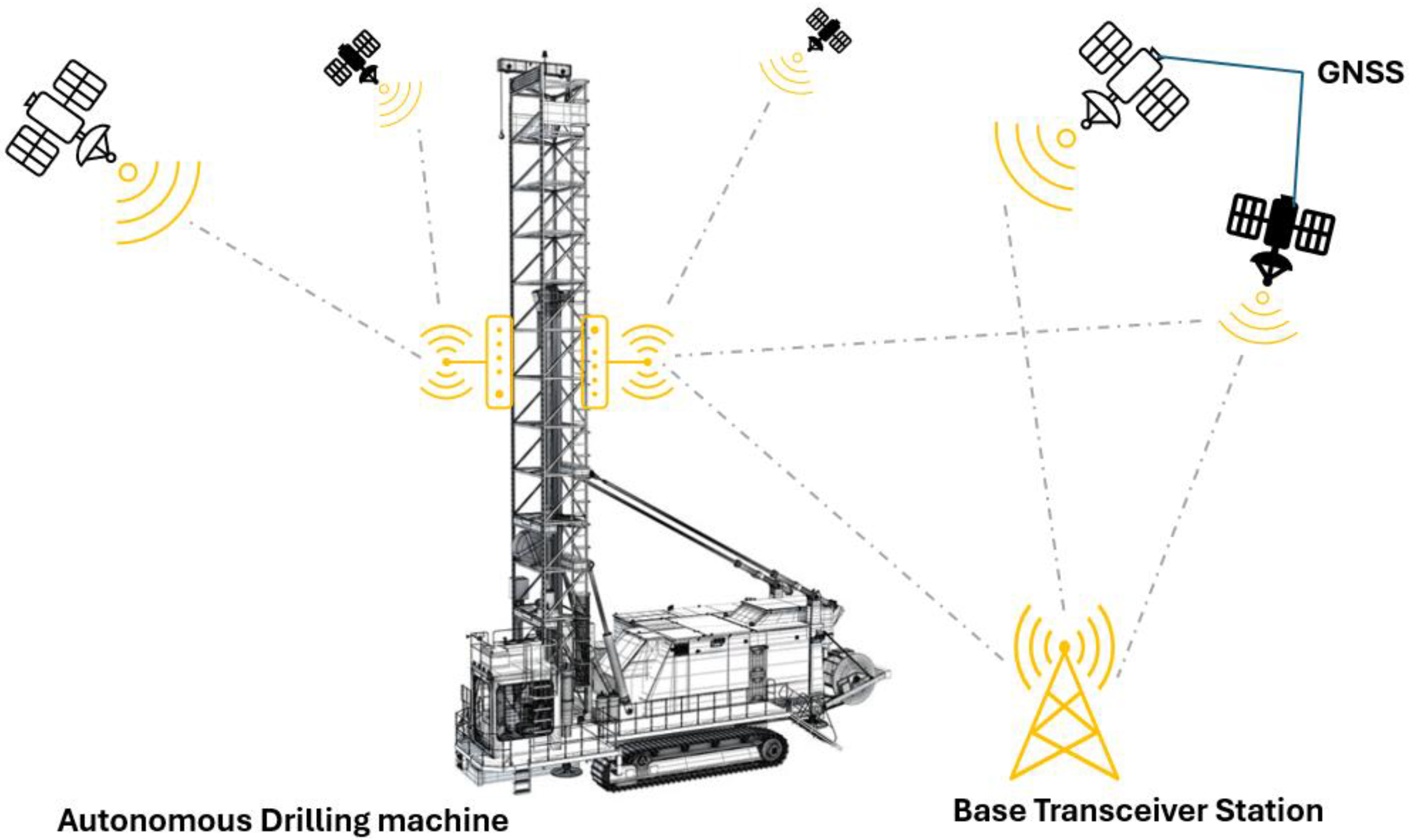

2. Trends of Automation and Implementation of Digital Systems in Mineral Industry

3. Application of Artificial Intelligence in Mining Operations

3.1. Mineral Prospecting and Exploration

3.2. Mineral Excavation

3.3. Mineral Processing

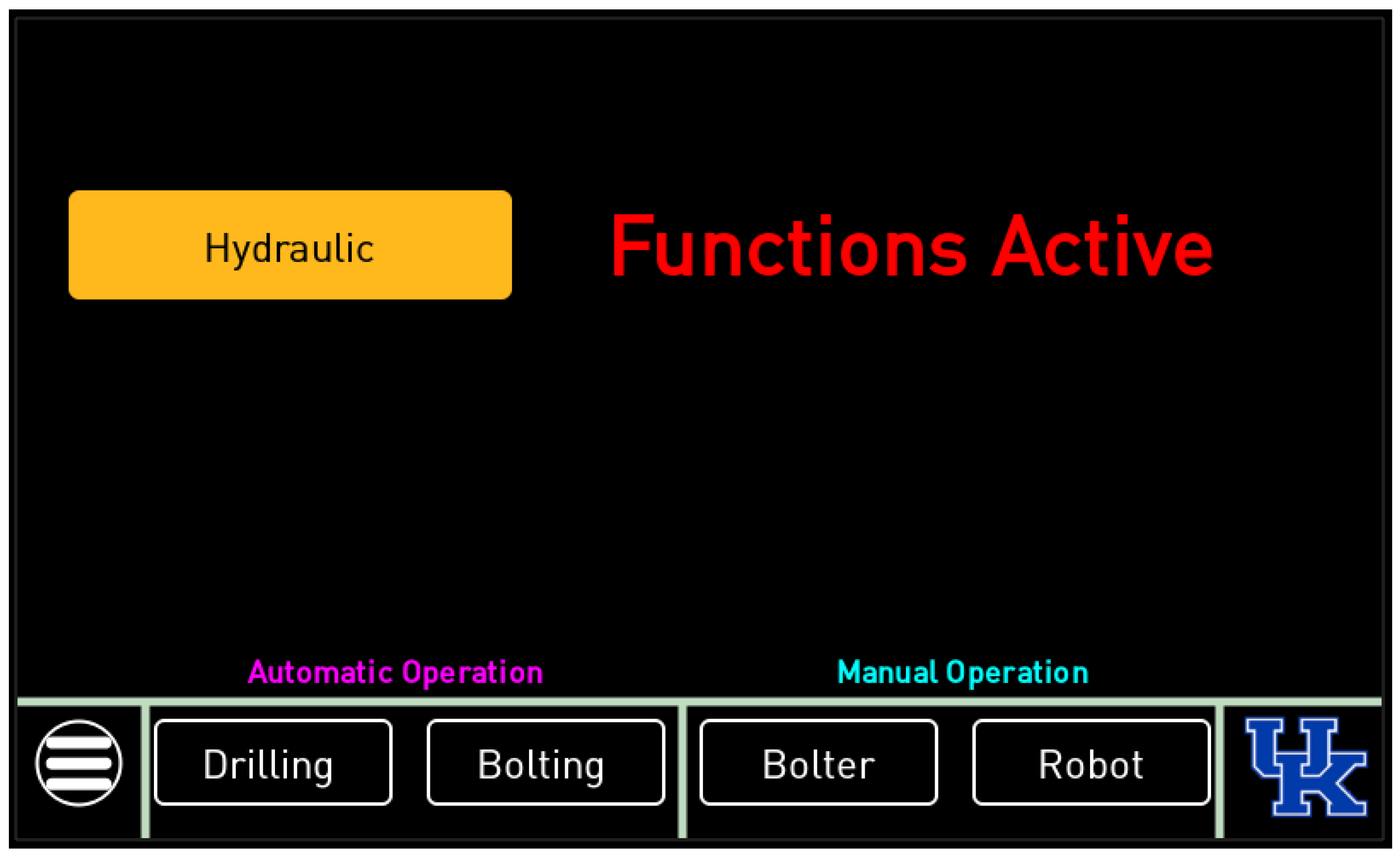

4. Enhancing Human–Machine Collaboration: A Scenario of Roof Bolting Machine Automation

4.1. Factors to Be Considered for an Effective HMI Design

4.2. Designing HMI for an Automated Roof Bolting Machine

5. Contributions and Limitations of Automation in Mineral Extraction Industry

5.1. Contributions of Automation to Mining Operations

5.1.1. Improved Health and Safety in Mining Operations

5.1.2. Reduction in Overall Mining Operating Costs

5.1.3. Increased Productivity

5.1.4. Real-Time Data Acquisition for Sound Decision Making

5.1.5. Remote Monitoring and Control of Equipment

5.2. Challenges and Limitations of Automation in the Mining Industry

5.2.1. Technological and Technical Challenges

5.2.2. Challenging Geology and Harsh Working Conditions

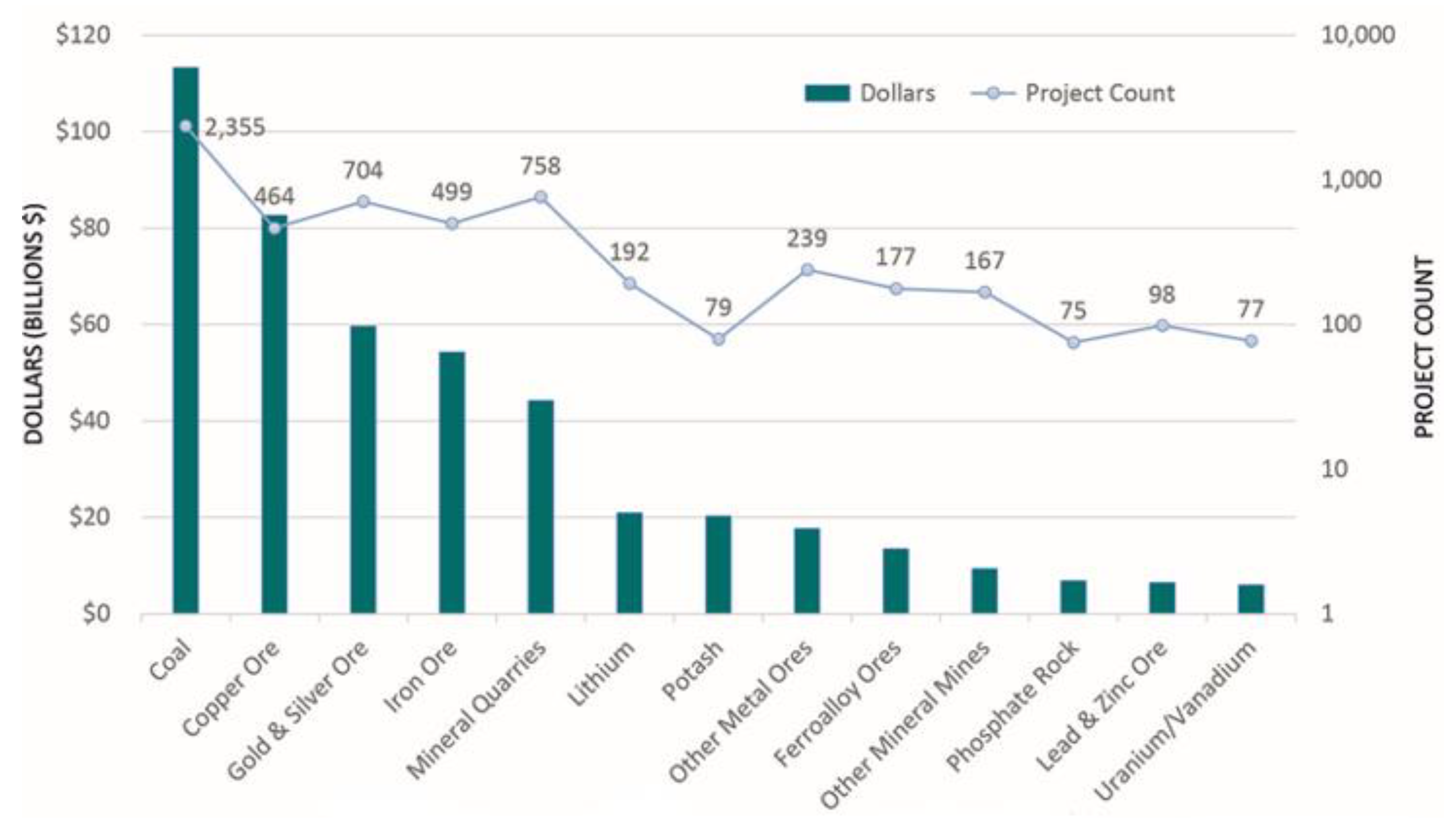

5.2.3. Economical and Cyclical Mining Commodity Price

5.2.4. Regulatory and Legal Issues

6. Conclusions

- (1)

- Human–machine interaction (HMI): developing effective HMIs is critical to fostering trust and ensuring seamless communication between operators and autonomous systems. Alarms and alert mechanisms must be intuitive, enabling swift and efficient responses during system failures or emergencies.

- (2)

- Human factors in automation: successful deployment of autonomous systems requires designs that account for human capabilities and limitations, including the ability to override and manage automated systems when necessary.

- (3)

- Training and trust: operators must be adequately trained to interact with and adapt to automated technologies, ensuring human oversight and operational efficiency.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schafrik, S.; Kolapo, P.; Agioutantis, Z. Development of an automated roof bolting machines for underground coal mines. In Proceedings of the 32nd SOMP Annual Meeting and Conference, Windhoek, Namibia, 12–14 September 2022; The Southern Africa Institute of Mining and Metallurgy: Johannesburg, South Africa, 2022. [Google Scholar]

- Ralston, J.; Reid, D.; Dunn, M.; Hainsworth, D. Logwall automation: Delivering enabling technology to achieve safer and more productive underground mining. Int. J. Min. Sci. Technol. 2015, 25, 865–876. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Significant applications of Cobots in the field of manufacturing. Cogn. Robot. 2022, 2, 222–233. [Google Scholar] [CrossRef]

- Paredes, D.; Fleming-Muñoz, D. Automation and robotics in mining: Jobs, income and inequality implications. Extr. Ind. Soc. 2021, 8, 189–193. [Google Scholar] [CrossRef]

- Lopes, L.; Miklovicz, T.; Bakker, E.; Milosevic, Z. The benefits and challenges of robotics in the mineral raw materials sector—An overview. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar] [CrossRef]

- Sam-Aggrey, H. Assessment of the Impacts of New Mining Technologies: Recommendations on the way Forward. WIT Trans. Ecol. Environ. 2020, 245, 177–187. [Google Scholar]

- Rowduru, S.; Kumar, N.; Kumar, A. A critical review on automation of steering mechanism of load haul dump machine. Proc. Inst. Mech. Eng. Part I J. Syst. Control. Eng. 2019, 234, 160–182. [Google Scholar] [CrossRef]

- Zimroz, R.; Hutter, M.; Mistry, M.; Stefaniak, P.; Walas, K.; Wodecki, J. Why Should Inspection Robots be used in Deep Underground Mines? In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection—MPES; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Larsson, J.; Broxvall, M.; Saffiotti, A. A Navigation System for Automated Loaders in Underground Mines. In Field and Service Robotics; Corke, P., Sukkariah, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 129–140. [Google Scholar]

- Larsson, J.; Broxvall, M.; Saffiotti, A. Laser Based Intersection Detection for Reactive Navigation in an Underground Mine. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Nice, France, 22–26 September 2008; pp. 2222–2227. [Google Scholar]

- Gu, Q.; Li, L.; Bai, G.; Li, K.; Meng, Y.; Ma, F. Longitudinal and Lateral Trajectory Planning for the Typical Duty Cycle of Autonomous Load Haul Dump. IEEE Access 2019, 7, 126679–126695. [Google Scholar] [CrossRef]

- Rocha, F.; Garcia, G.; Pereira, R.; Faria, H.; Silva, T.; Andrade, R.; Barbosa, E.; Almeida, A.; Cruz, E.; Andrade, W.; et al. ROSI: A Robotic System for Harsh Outdoor Industrial Inspection—System Design and Applications. J. Intell. Robot. Syst. 2021, 103, 1–22. [Google Scholar] [CrossRef]

- Szrek, J.; Wodecki, J.; Błazej, R.; Zimroz, R. An Inspection Robot for Belt Conveyor Maintenance in Underground Mine-Infrared Thermography for Overheated Idlers Detection. Appl. Sci. 2020, 10, 4984. [Google Scholar] [CrossRef]

- Gaber, T.; El Jazouli, Y.; Eldesouky, E.; Ali, A. Autonomous Haulage Systems in the Mining Industry: Cybersecurity, Communication and Safety Issues and Challenges. Electronics 2021, 10, 1357. [Google Scholar] [CrossRef]

- Chaowasakoo, P.; Leelasukseree, C.; Wongsurawat, W. Introducing GPS in fleet management of a mine: Impact on hauling cycle time and hauling capacity. Int. J. Technol. Intell. Plan. 2015, 10, 49–66. [Google Scholar] [CrossRef]

- Thrun, S.; Thayer, S.; Whittaker, W.; Baker, C.; Burgard, W.; Ferguson, D.; Hahnel, D.; Montemerlo, D.; Morris, A.; Omohundro, Z.; et al. Autonomous exploration and mapping of abandoned mines. IEEE Robot. Autom. Mag. 2004, 11, 79–91. [Google Scholar] [CrossRef]

- Nüchter, A. 3D Robotic Mapping: The Simultaneous Localization and Mapping Problem with Six Degrees of Freedom; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Lösch, R.; Grehl, S.; Donner, M.; Buhl, C.; Jung, B. Design of an Autonomous Robot for Mapping, Navigation, and Manipulation in Underground Mines. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Evans, S. IOT World Today. 2023. Available online: https://www.iotworldtoday.com/robotics/mining-robot-designed-to-automate-blasting-process#close-modal (accessed on 10 December 2024).

- Bonchis, A.; Duff, E.; Roberts, J.; Bosse, M. Robotic Explosive Charging in Mining and Construction Applications. IEEE Trans. Autom. Sci. Eng. 2014, 11, 245–250. [Google Scholar] [CrossRef]

- Peng, S.; Du, F.; Cheng, J.; Li, Y. Longwall mining automation horizon control: Coal seam gradient identification using piecewise linear fitting. Int. J. Min. Sci. Technol. 2019, 29, 151–159. [Google Scholar] [CrossRef]

- Billingsley, J.; Brett, P. Machine Vision and Mechatronics in Practice; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Liebherr. LIPOS—Liebherr Positioning System. 2023. Available online: https://www.liebherr.com/en/usa/products/construction-machines/deep-foundation/digital-solutions/lipos/lipos.html (accessed on 12 October 2023).

- Li, J.; Zhan, K. Intelligent Mining Technology for an Underground Metal Mine Based on Unmanned Equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Yang, X.; Wang, R.; Wang, H.; Yang, Y. A novel method for measuring pose of hydraulic supports relative to inspection robot using LiDAR. Measurement 2020, 154, 107452. [Google Scholar] [CrossRef]

- He, M.C.; Xu, M. Research and development of HEMS cooling system and heat-harm control in deep mine. Chin. J. Rock Mech. Eng. 2008, 27, 1353–1361. (In Chinese) [Google Scholar]

- Jeon, P.R.; Moon, J.H.; Ogunsola, N.O.; Lee, S.H.; Ling JL, J.; You, S.; Park, Y.K. Recent advances and future prospects of thermochemical biofuel conversion processes with machine learning. Chem. Eng. J. 2023, 471, 144503. [Google Scholar] [CrossRef]

- Ogunsola, N.O.; Oh, S.S.; Jeon, P.R.; Ling, J.L.J.; Park, H.J.; Park, H.S.; Lee, S.H. Progresses and Challenges of Machine Learning Approaches in Thermochemical Processes for Bioenergy: A Review. Korean J. Chem. Eng. 2024, 41, 1923–1953. [Google Scholar] [CrossRef]

- Lee, S.; Oh, H.J. Application of artificial neural network for mineral potential mapping. In Artificial Neural Networks—Application; Artificial Neural Networks-Applications: Shanghai, China, 2011; pp. 67–104. [Google Scholar]

- Zhang, N.; Zhou, K. Mineral prospectivity mapping with weights of evidence and fuzzy logic methods. J. Intell. Fuzzy Syst. 2015, 29, 2639–2651. [Google Scholar] [CrossRef]

- Kashani, S.; Abedi, M.; Norouzi, G. Fuzzy logic mineral potential mapping for copper exploration using multi-disciplinary geo-datasets, a case study in seridune deposit, Iran. Earth Sci. Inform. 2016, 9, 167–181. [Google Scholar] [CrossRef]

- Tabaei, M.; Esfahani, M.; Rasekh, P.; Esna-ashari, A. Mineral prospectivity mapping in GIS using fuzzy logic integration in Khondab area, western Markazi province, Iran. Q. J. Tethys 2017, 5, 367–379. [Google Scholar]

- Tessema, A. Mineral Systems Analysis and Artificial Neural Network Modeling of Chromite Prospectivity in the Western Limb of the Bushveld Complex, South Africa. Nat. Resour. Res. 2017, 26, 465–488. [Google Scholar] [CrossRef]

- Sun, T.; Chen, F.; Zhong, L.; Liu, W.; Wang, Y. GIS-based mineral prospectivity mapping using machine learning methods: A case study from Tongling ore district, eastern China. Ore Geol. Rev. 2019, 109, 26–49. [Google Scholar] [CrossRef]

- Yeomans, C.M.; Shail, R.K.; Grebby, S.; Nykänen, V.; Middleton, M.; Lusty, P.A. A machine learning approach to tungsten prospectivity modelling using knowledge-driven feature extraction and model confidence. Geosci. Front. 2020, 11, 2067–2081. [Google Scholar] [CrossRef]

- Farahbakhsh, E.; Maughan, J.; Müller, R.D. Prospectivity modelling of critical mineral deposits using a generative adversarial network with oversampling and positive-unlabelled bagging. Ore Geol. Rev. 2023, 162, 105665. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Y.; Xu, Y.; Shao, Y.; Chen, X.; Hao, J.; Wang, X. Machine learning model for deep exploration: Utilizing short wavelength infrared (SWIR) of hydrothermal alteration minerals in the Qianchen gold deposit, Jiaodong Peninsula, Eastern China. Ore Geol. Rev. 2024, 168, 106060. [Google Scholar] [CrossRef]

- Mining. Goldcorp Partners with IBM to Hunt for Exploration Targets at Red Lake. 2017. Available online: http://www.mining.com/goldcorp-partners-ibm-hunt-exploration-targets-red-lake/ (accessed on 1 November 2024).

- Wu, X.; Zhou, Y. Reserve estimation using neural network techniques. Comput. Geosci. 1993, 19, 567–575. [Google Scholar] [CrossRef]

- Al-Alawi, S.; Tawo, E. Application of Artificial Neural Networks in Mineral Resource Evaluation. J. King Saud Univ. Eng. Sci. 1998, 10, 127–138. [Google Scholar] [CrossRef]

- Jalloh, A.B.; Kyuro, S.; Jalloh, Y.; Barrie, A.K. Integrating artificial neural networks and geostatistics for optimum 3D geological block modeling in mineral reserve estimation: A case study. Int. J. Min. Sci. Technol. 2016, 26, 581–585. [Google Scholar] [CrossRef]

- Afeni, T.B.; Lawal, A.I.; Adeyemi, R.A. Re-examination of Itakpe iron ore deposit for reserve estimation using geostatistics and artificial neural network techniques. Arab. J. Geosci. 2020, 13, 657. [Google Scholar] [CrossRef]

- Kaplan, U.E.; Topal, E. A new ore grade estimation using combine machine learning algorithms. Minerals 2020, 10, 847. [Google Scholar] [CrossRef]

- Yasrebi, A.B.; Hezarkhani, A.; Afzal, P.; Karami, R.; Tehrani, M.E.; Borumandnia, A. Application of an ordinary kriging–artificial neural network for elemental distribution in Kahang porphyry deposit, Central Iran. Arab. J. Geosci. 2020, 13, 748. [Google Scholar] [CrossRef]

- Zhang, S.E.; Nwaila, G.T.; Tolmay, L.; Frimmel, H.E.; Bourdeau, J.E. Integration of machine learning algorithms with Gompertz Curves and Kriging to estimate resources in gold deposits. Nat. Resour. Res. 2021, 30, 39–56. [Google Scholar] [CrossRef]

- Atalay, F. Estimation of Fe Grade at an Ore Deposit Using Extreme Gradient Boosting Trees (XGBoost). In Mining, Metallurgy & Exploration; Springer Nature: Berlin/Heidelberg, Germany, 2024; pp. 1–10. [Google Scholar]

- Ajak, A.D.; Lilford, E.; Topal, E. Application of predictive data mining to create mine plan flexibility in the face of geological uncertainty. Resour. Policy 2018, 55, 62–79. [Google Scholar] [CrossRef]

- Nourali, H.; Osanloo, M. A regression-tree-based model for mining capital cost estimation. Int. J. Min. Reclam. Environ. 2020, 34, 88–100. [Google Scholar] [CrossRef]

- Zhang, H.; Nguyen, H.; Bui, X.N.; Nguyen-Thoi, T.; Bui, T.T.; Nguyen, N.; Vu, D.A.; Mahesh, V.; Moayedi, H. Developing a novel artificial intelligence model to estimate the capital cost of mining projects using deep neural network-based ant colony optimization algorithm. Resour. Policy 2020, 66, 101604. [Google Scholar] [CrossRef]

- Noriega, R.; Pourrahimian, Y. A systematic review of artificial intelligence and data-driven approaches in strategic open-pit mine planning. Resour. Policy 2022, 77, 102727. [Google Scholar] [CrossRef]

- Zheng, X.; Nguyen, H.; Bui, X.N. Exploring the relation between production factors, ore grades, and life of mine for forecasting mining capital cost through a novel cascade forward neural network-based salp swarm optimization model. Resour. Policy 2021, 71, 102300. [Google Scholar] [CrossRef]

- Nobahar, P.; Pourrahimian, Y.; Mollaei Koshki, F. Optimum fleet selection using machine learning algorithms-Case study: Zenouz Kaolin mine. Mining 2022, 2, 528–541. [Google Scholar] [CrossRef]

- Ogunsola, N.O.; Lawal, A.I.; Saliu, M.A. Variations of physico-mechanical, mineralogical, and geochemical properties of marble under the influence of weathering. Mining of mineral deposits. Min. Miner. Depos. 2019, 13, 95–102. [Google Scholar] [CrossRef]

- Lawal, A.I.; Oniyide, G.O.; Kwon, S.; Onifade, M.; Köken, E.; Ogunsola, N.O. Prediction of mechanical properties of coal from non-destructive properties: A comparative application of MARS, ANN, and GA. Nat. Resour. Res. 2021, 30, 4547–4563. [Google Scholar] [CrossRef]

- Ogunsola, N.O.; Lawal, A.I.; Kim, G.; Kim, H.; Cho, S. Prediction of Mode-I Fracture Toughness of the ISRM-Suggested Semi-Circular Bend Rock Specimen Using ANN and Optimized ANN Models. In Rock Mechanics and Rock Engineering; Springer Nature: Berlin/Heidelberg, Germany, 2024; pp. 1–26. [Google Scholar]

- Lawal, A.I.; Hosseini, S.; Kim, M.; Ogunsola, N.O.; Kwon, S. Prediction of factor of safety of slopes using stochastically modified ANN and classical methods: A rigorous statistical model selection approach. Nat. Hazards 2024, 120, 2035–2056. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mamou, A.; Maraveas, C.; Roussis, P.C.; Siorikis, V.G.; Skentou, A.D.; Asteris, P.G. Predicting the unconfined compressive strength of granite using only two non-destructive test indexes. Geomech. Eng. 2021, 25, 317–330. [Google Scholar]

- Skentou, A.D.; Bardhan, A.; Mamou, A.; Lemonis, M.E.; Kumar, G.; Samui, P.; Asteris, P.G. Closed-form equation for estimating unconfined compressive strength of granite from three non-destructive tests using soft computing models. Rock Mech. Eng. 2023, 56, 487–514. [Google Scholar] [CrossRef]

- Zhao, J.; Li, D.; Jiang, J.; Luo, P. Uniaxial Compressive Strength Prediction for Rock Material in Deep Mine Using Boosting-Based Machine Learning Methods and Optimization Algorithms. CMES-Comput. Model. Eng. Sci. 2024, 140, 275–304. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Mohammadi, M.; Ghafoor Salim, S.; Farid Hama Ali, H.; Hashim Ibrahim, H.; Nariman Abdulhamid, S.; Rashidi, S. Machine learning techniques to predict rock strength parameters. Rock Mech. Rock Eng. 2022, 55, 1721. [Google Scholar] [CrossRef]

- Frank, A.; Kolapo, P.; Ogunsola, N.; Munemo, P.; Akinola, A. Application of Improved Blasting Techniques in Open Pit Mining for Maximum Productivity: A Case of Oakyam Quarry Limited, Ogun State, Nigeria. Science 2022, 10, 12–23. [Google Scholar]

- Ogunsola, N.O.; Shin, C.; Kim, Y.K.; Lawal, A.I.; Cho, S. Development of an ANN-based closed-form equation for the prediction of airblast overpressure induced by construction rock excavation blasting in urban areas. Appl. Sci. 2022, 12, 12654. [Google Scholar] [CrossRef]

- Ogunsola, N.; Pureun, J.; Cho, S.; Kim, Y. An artificial neural network-based model for blast-induced ground vibration prediction in urban area. In Rock Dynamics: Prospect and Report; CRC Press: Boca Raton, FL, USA, 2023; pp. 229–234. [Google Scholar]

- Komadja, G.C.; Rana, A.; Glodji, L.A.; Anye, V.; Jadaun, G.; Onwualu, P.A.; Sawmliana, C. Assessing ground vibration caused by rock blasting in surface mines using machine-learning approaches: A comparison of CART, SVR, and MARS. Sustainability 2022, 14, 11060. [Google Scholar] [CrossRef]

- Abd Elwahab, A.; Topal, E.; Jang, H.D. Review of machine learning application in mine blasting. Arab. J. Geosci. 2023, 16, 133. [Google Scholar] [CrossRef]

- Dumakor-Dupey, N.K.; Arya, S.; Jha, A. Advances in blast-induced impact prediction. Minerals 2021, 11, 601. [Google Scholar] [CrossRef]

- Amiri, M.; Bakhshandeh Amnieh, H.; Hasanipanah, M.; Mohammad Khanli, L. A new combination of artificial neural network and K-nearest neighbors models to predict blast-induced ground vibration and air-overpressure. Eng. Comput. 2016, 32, 631–644. [Google Scholar] [CrossRef]

- Amoako, R.; Jha, A.; Zhong, S. Rock fragmentation prediction using an artificial neural network and support vector regression hybrid approach. Mining 2022, 2, 233–247. [Google Scholar] [CrossRef]

- Samadi, M.; Bakhtavar, E.; Hu, G.; Hewage, K.; Sadiq, R. Assessment of mine post-closure strategies by integrating evidential reasoning and fuzzy cognitive maps: Toward sustainable mining policy. Resour. Policy 2023, 83, 103719. [Google Scholar] [CrossRef]

- Maxwell, A.E.; Warner, T.A.; Strager MP CJ, F.; Sharp, A.L. Assessing machine-learning algorithms and image-and lidar-derived variables for GEOBIA classification of mining and mine reclamation. Int. J. Remote Sens. 2015, 36, 954–978. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Cheng, X.; Wang, L. A Comparison of Machine Learning Algorithms for Mapping of Complex Surface-Mined and Agricultural Landscapes Using ZiYuan-3 Stereo Satellite Imagery. Remote Sens. 2016, 8, 514. [Google Scholar] [CrossRef]

- Bui, X.N.; Nguyen, H.; Choi, Y.; Nguyen-Thoi, T.; Zhou, J.; Dou, J. Prediction of slope failure in open-pit mines using a novel hybrid artificial intelligence model based on decision tree and evolution algorithm. Sci. Rep. 2020, 10, 9939. [Google Scholar] [CrossRef]

- McCoy, J.T.; Auret, L. Machine learning applications in minerals processing: A review. Miner. Eng. 2019, 132, 95–109. [Google Scholar] [CrossRef]

- Zarie, M.; Jahedsaravani, A.; Massinaei, M. Flotation froth image classification using convolutional neural networks. Minerals Engineering 2020, 155, 106443. [Google Scholar] [CrossRef]

- Gomez-Flores, A.; Ilyas, S.; Heyes, G.W.; Kim, H. A critical review of artificial intelligence in mineral concentration. Miner. Eng. 2022, 189, 107884. [Google Scholar] [CrossRef]

- Bendaouia, A.; Qassimi, S.; Boussetta, A.; Benzakour, I.; Benhayoun, A.; Amar, O.; Hasidi, O. Hybrid features extraction for the online mineral grades determination in the flotation froth using Deep Learning. Eng. Appl. Artif. Intell. 2024, 129, 107680. [Google Scholar] [CrossRef]

- Hosseini, S.H.; Samanipour, M. Prediction of final concentrate grade using artificial neural networks from Gol-E-Gohar iron ore plant. Am. J. Min. Metall. 2015, 3, 58–62. [Google Scholar]

- Jahedsaravani, A.; Marhaban, M.H.; Massinaei, M. Application of statistical and intelligent techniques for modeling metallurgical performance of a batch flotation process. Chem. Eng. Commun. 2016, 203, 151–160. [Google Scholar] [CrossRef]

- Kolapo, P. The Methodology for Integrating Robotic Systems in Underground Mining Machines. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, 2023. [Google Scholar]

- Kolapo, P.; Onifade, M.; Akinseye, O.; Amwaama, M.; Khadija, O.; Abdulsalam, J.; Ismail, L.; Aladejare, E. An Overview of the Use of Rockbolts as Support Tools in Mining Operations. Geotech. Geol. Eng. 2021, 40, 1637–1661. [Google Scholar]

- Zhang, H.; Chan, S.-H.; Zhong, J.; Li, J.; Kolapo, P.; Koenig, S.; Agioutantis, Z.; Schafrik, S.; Nikolaidis, S. Multi-robot geometric task-and-motion planning for collaborative manipulation tasks. Auton. Robot. 2023, 47, 1537–1558. [Google Scholar] [CrossRef]

- Kolapo, P.; Schafrik, S.; Zhang, H.; Nikolaidiz, S.; Agioutantis, Z. A concept for integrating robotic systems in an underground roof support. J. Ind. Saf. 2024, 1, 100002. [Google Scholar]

- Gruhn, P. Human Machine Interface (HMI) Design: The Good, The Bad, and The Ugly (and What Makes Them so). In Proceedings of the 66th Annual Instrumentation Symposium for the Process Industries, College Station, TX, USA, 25–27 January 2011. [Google Scholar]

- Rockwell Automation. Rockwell Automation Process HMI Style Guide; Rockwell Automation: Milwaukee, WI, USA, 2019. [Google Scholar]

- Parker. IQAN-MD4 Display Modules; Parker Hannifin Corporation: Mayfield Heights, OH, USA, 2019. [Google Scholar]

- Global Mining Guidelines Group. System Safety for Autonomous Mining; Canadian Institute of Mining, Metallurgy and Petroleum: Montreal, QC, Canada, 2021. [Google Scholar]

- Heidi Vella. Exploring the Environmental Benefits of Autonomous Underground Mining Equipment. 2021. Available online: https://www.mining-technology.com/features/environmental-benefits-of-autonomous-underground-mining-equipment (accessed on 19 December 2024).

- Hazrathosseini, A.; Afrapoli, A. Maximizing Mining Operations: Unlocking the Crucial Role of Intelligent Fleet Management Systems in Surface Mining’s Value chain. Mining 2024, 4, 7–20. [Google Scholar] [CrossRef]

- Moore, P. International Mining. 2023. Available online: https://im-mining.com/2023/01/12/roll-out-of-autonomous-haulage-system-at-roy-hill-creates-worlds-largest-single-autonomous-mine (accessed on 30 August 2024).

- Motion Metrics. Weir Motion Metrics. 2019. Available online: https://www.motionmetrics.com/nulla-aliquet-auctor-leo-sit (accessed on 21 April 2023).

- World Economic Forum (WEF). Digital Transformation Initiative: Maximizing the Return on Digital Investments; (White Paper); World Economic Forum: Geneva, Switzerland, 2017; p. 36. [Google Scholar]

- Li, P.; Cai, M.-F. Challenges and new insights for exploitation of deep underground metal mineral resources. Trans. Nonferrous Met. Soc. China 2021, 31, 3478–3505. [Google Scholar] [CrossRef]

- He, M.C. Application of HEMS cooling technology in deep mine heat hazard control. Min. Sci. Technol. 2009, 19, 269–275. [Google Scholar] [CrossRef]

- Keenan, J.; Kemp, D.; Owen, J. Corporate responsibility and the social risk of new mining technologies. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 752–760. [Google Scholar] [CrossRef]

- Günther, F.; Mischo, H.; Lösch, R.; Grehl, S.; Güth, F. Increased safety in deep mining with IoT and autonomous robots. In Mining Goes Digital; Mueller, C., Assibey-Bonsu, W., Baafi, E., Dauber, C., Doran, C., Jerzy Jaszczuk, M., Nagovitsyn, O., Eds.; Taylor & Francis Group: London, UK, 2019; pp. 603–611. [Google Scholar]

- Govreau, J. Constraints Mount to Slow Mining Project Growth in 25 January 2024. Eng. Min. J. 2024, 225, 16–23.98. [Google Scholar]

- Marshall, J.; Bonchis, A.; Neobot, E.; Scheding, S. Robotics in Mining. In Springer Handbook of Robotic; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1549–1576. [Google Scholar]

| Autonomous Equipment | Area of Usage in Mining Operations | References |

|---|---|---|

| Selected Automated Mining Operations | Autonomous drilling | [23,24] |

| Explosive charging robots | [19,20] | |

| Loading, hauling and Dumping | [9,10,11,24] | |

| Conveyor belt inspection and monitoring robots | [12,13] | |

| LiDAR and Positioning | [16,17,18,25] | |

| Automated Longwall Mining | [21,22,26] | |

| GNSS Applications | [14,15] |

| Reference | Mineral Exploration and Prospecting | ML Model(s) | Model Performance(s) | |||

|---|---|---|---|---|---|---|

| Mineral Resource Mapping | Mine Cost Estimation | Mine Planning | Mine Reserve and Grade Estimation | |||

| Lee and Oh [29] | ✔ | ANN | Accuracy > 70% | |||

| Tessema [33] | ✔ | ANN *, fuzzy-WofE | MSE = 0.0937 SSE = 170.477 | |||

| Sun et al. [34] | ✔ | ANN, SVM, RF * | MSE = 0.039, Accuracy = 96.03%, Kappa = 92.06% | |||

| Afeni et al. [42] | ✔ | ANN | SE = 0.015, R2 = 0.819, MAE = 2.023 | |||

| Atalay [46] | ✔ | XGBoost | RMSE = 0.69, MAE = 0.65 | |||

| Jalloh et al. [41] | ✔ | ANN | R2 = 0.8807, MSE = 0.2087 | |||

| Nourali and Osanloo [48] | ✔ | RT | RMSE = 219.36, MAE = 178.5 | |||

| Zhang et al. [49] | ✔ | ANN, DNN, ACO-DNN * | R2 = 0.991, MAPE = 0.072, VAF = 99.052 | |||

| Zheng et al. [51] | ✔ | CFNN, SalpSO-CFNN * | R2 = 0.980, MAE = 179.567, RMSE = 248.401 | |||

| Ajak et al. [47] | ✔ | KNN, DT *, SVM, RF, LR, NB | Accuracy = 72%, Probability = 78.6% | |||

| Nobahar et al. [52] | ✔ | KNN, DT, LR, RF, GB * | Accuracy = 83% | |||

| Reference | Mineral Excavation | ML Model(s) | Model Performance(s) | |||

|---|---|---|---|---|---|---|

| Geomechanical Testing | Drilling and Blasting | Slope Stability | Mine Reclamation and Closure | |||

| Ogunsola et al. [55] | ✔ | ANN, ANN-GOA *, ANN-SSA, ANN-AOA | R = 0.98498, MSE = 0.0036, VAF = 97.02% | |||

| Lawal et al. [54] | ✔ | ANN *, MARS, GA, | RMSEUCS = 0.1248, RMSETS = 0.0332, RMSESS = 0.0639, RMSEYM = 2.91108 | |||

| Skentou et al. [58] | ✔ | ANN *, ANN-ICA, ANN-PSO | R = 0.9607 RMSE = 14.8272 | |||

| Lawal et al. [56] | ✔ | ANN, MVO-ANN *, SSA-ANN | RMSE = 0.35083 MAE = 0.263396 | |||

| Komadja et al. [64] | ✔ | CART, SVR, MARS * | RMSEBIGV = 0.227, R2BIGV = 0.951 | |||

| Amiri et al. [67] | ✔ | ANN, ANN-KNN * | R2BIGV = 0.88 R2AOP = 0.95 | |||

| Amoako et al. [68] | ✔ | ANN, SVR | MSEFRAG = 0.0031 | |||

| Ogunsola et al. [63] | ✔ | ANN | MAEBIGV = 0.1185, MSEBIGV = 0.0316 | |||

| Maxwell et al. [70] | ✔ | SVM *, RF, CART, KNN | Accuracy = 86.6% | |||

| Li et al. [71] | ✔ | ANN, SVM *, RF | Accuracy = 87.34% | |||

| Bui et al. [72] | ✔ | ANN, SVR, M5Rules-GA *, ANN-PSO, ANN-ICA | RMSE = 0.024, R2 = 0.983, VAF = 98.26 | |||

| Reference | Mineral Processing | ML Model(s) | Model Performance(s) |

|---|---|---|---|

| Hosseini et al. [77] | Final concentrate grade | ANN | R2 = 0.98 |

| Bendaouia et al. [76] | Floatation froth | ANN, RF *, GB, SVM, DT, LR | RMSE = 5.40, MAE = 4.58 |

| Zarie et al. [74] | Floatation froth | ANN, CNN * | Accuracy = 93.1% |

| Jahedsaravani et al. [78] | Batch floatation of copper sulfide | ANN *, ANFIS | RCu = 0.77, GCu = 0.84, Rm = 0.88, Rw = 0.87 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolapo, P.; Ogunsola, N.O.; Komolafe, K.; Omole, D.D. Envisioning Human–Machine Relationship Towards Mining of the Future: An Overview. Mining 2025, 5, 5. https://doi.org/10.3390/mining5010005

Kolapo P, Ogunsola NO, Komolafe K, Omole DD. Envisioning Human–Machine Relationship Towards Mining of the Future: An Overview. Mining. 2025; 5(1):5. https://doi.org/10.3390/mining5010005

Chicago/Turabian StyleKolapo, Peter, Nafiu Olanrewaju Ogunsola, Kayode Komolafe, and Dare Daniel Omole. 2025. "Envisioning Human–Machine Relationship Towards Mining of the Future: An Overview" Mining 5, no. 1: 5. https://doi.org/10.3390/mining5010005

APA StyleKolapo, P., Ogunsola, N. O., Komolafe, K., & Omole, D. D. (2025). Envisioning Human–Machine Relationship Towards Mining of the Future: An Overview. Mining, 5(1), 5. https://doi.org/10.3390/mining5010005