Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore

Abstract

1. Introduction

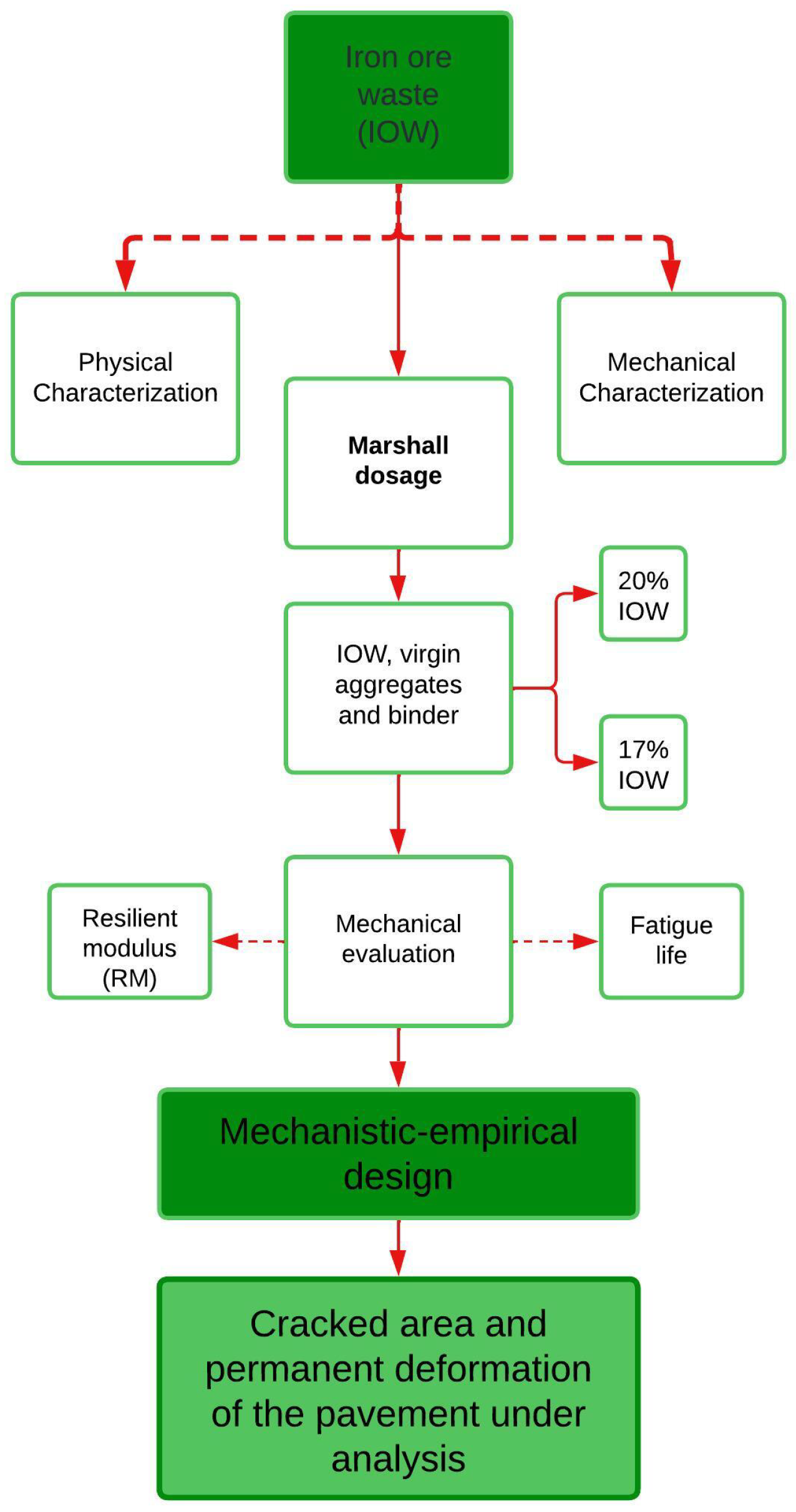

2. Materials and Methods

3. Materials

3.1. Characterization of Materials

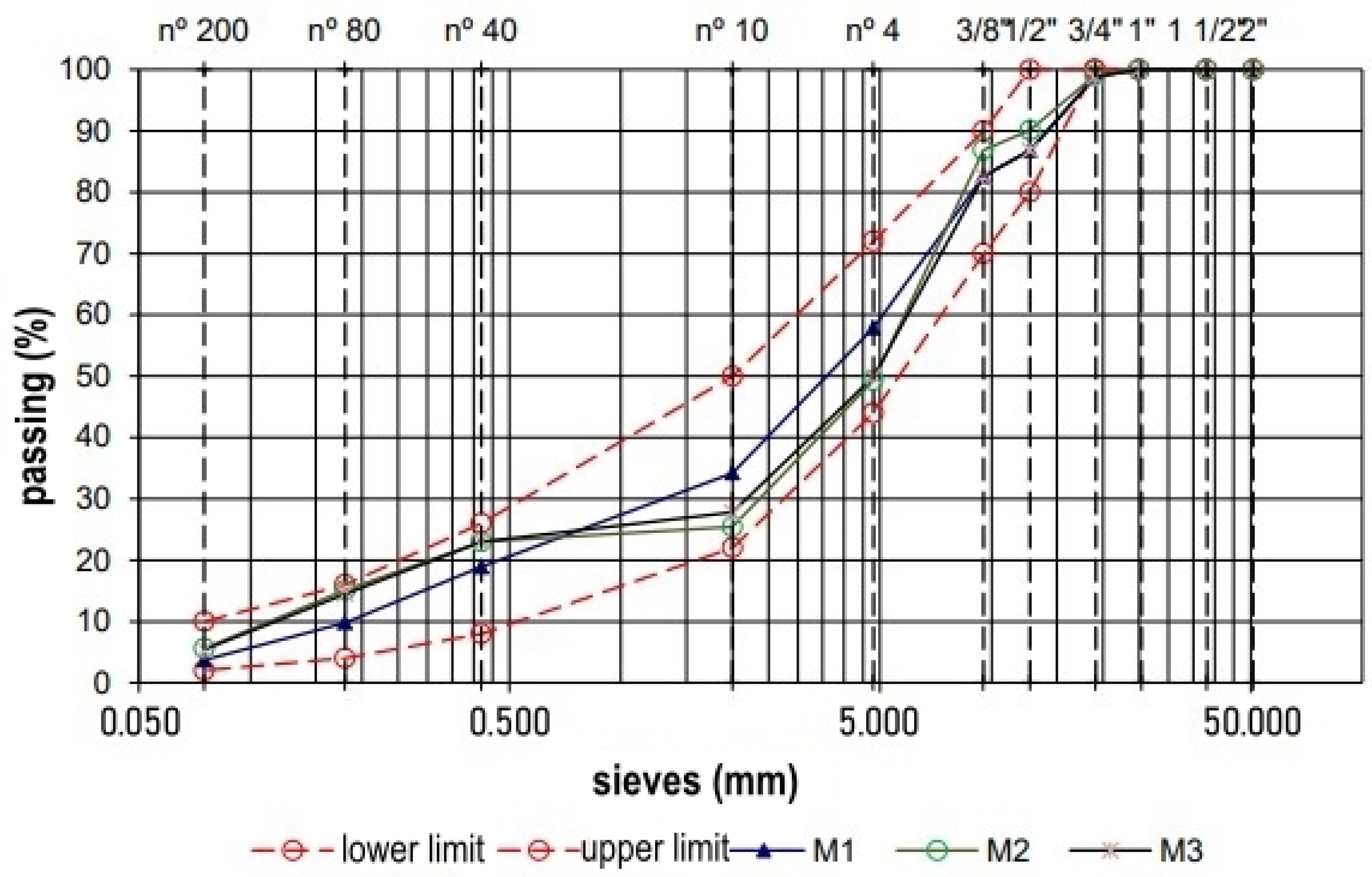

3.2. Dosage

3.3. Resilient Modulus and Fatigue Life Analysis

3.4. Mechanistic–Empirical Evaluation

4. Results and Discussions

4.1. Resilient Modulus

4.2. Fatigue Life Analysis

4.3. Mechanistic–Empirical Design

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Institute for Applied Economic Research (IPEA). Research Report: Diagnosis of Urban Solid Waste; Research Report; IPEA: Brasília, Brazil, 2012.

- Coelho, L.M.; Kox, R.P.; Guimarães, A.C.R.; Travincas, R.; Monteiro, S.N. Influence of Curing Time on the Mechanical Behavior of Cold Recycled Bituminous Mix in Flexible Pavement Base Layer. Appl. Sci. 2024, 14, 7612. [Google Scholar] [CrossRef]

- Guimarães, A.C.R.; Costa, K.Á.; Reis, M.M.; Santana, C.S.A.; Castro, C.D. Study of controlled leaching process of steel slag in soxhlet extractor aiming employment in pavements. Transp. Geotech. 2021, 27, 100485. [Google Scholar] [CrossRef]

- Gomes, M.B.B.; Guimarães, A.C.R.; Nascimento, F.A.C.d.; Santos, J.T.A.d. Ballast with siderurgic aggregates: Variation analysis of the shape parameters of particles submitted to triaxial tests through 3D scanner. Rev. Eng. 2023, 46. [Google Scholar] [CrossRef]

- Navarrete, C.; Guimarães, A.C.R.; Marques, M.E.S.; Castro, C.D.; Toulkeridis, T. Resistance to Fatigue in Asphalts Used in Military Airports of the Brazilian Amazon through the Use of Nickel-Holding Ash. Appl. Sci. 2022, 12, 9134. [Google Scholar] [CrossRef]

- de Souza Júnior, T.F.; Moreira, E.B.; Heineck, K.S. Mining tailings containment dams in Brazil. HOLOS 2018, 5, 2–39. [Google Scholar] [CrossRef]

- Costa, A.V.; Gumieri, A.G.; Brandão, P.R.G. Interlocking concrete blocks produced with sinter feed tailings. Ibracon Struct. Mater. J. 2014, 7, 228–259. [Google Scholar]

- Friber, M.A.; Guimarães, A.C.R.; Martins, C.A.; Soares, J.S. Study of the Mining Waste in the Production of Calcined Aggregate for Use in Pavement. Minerals 2023, 13, 1543. [Google Scholar] [CrossRef]

- Silveira, V.L.; Guimarães, A.C.R.; Coelho, L.M.; dos Santos, W.W.; da Silveira, P.H.P.M.; Monteiro, S.N. Recycling Iron Ore Waste through Low-Cost Paving Techniques. Sustainability 2024, 16, 5570. [Google Scholar] [CrossRef]

- Magnoni, M.; Toraldo, E.; Giustozzi, F.; Crispino, M. Recycling practices for airport pavement construction: Valorisation of on-site materials. Constr. Build. Mater. 2016, 112, 59–68. [Google Scholar] [CrossRef]

- Qasrawi, H.; Asi, I. Effect of bitumen grade on hot asphalt mixes properties prepared using recycled coarse concrete. Constr. Build. Mater. 2016, 121, 18–24. [Google Scholar] [CrossRef]

- Beale, J.M.; You, Z. The mechanical properties of asphalt mixtures with Recycled Concrete Aggregates. Constr. Build. Mater. 2010, 24, 230–235. [Google Scholar] [CrossRef]

- Leão, S.R.; Santiago, A.M.d.S. Tailings Dam Scenario: Knowing to Avoid New Catastrophes. Ambiente Soc. 2022, 25, e00661. [Google Scholar] [CrossRef]

- Bessa, S.; Duarte, M.; Lage, G.; Mendonça, I.; Galery, R.; Lago, R.; Texeira, A.P.; Lameiras, F.; Aguilar, M.T. Characterization and Analysis of Iron Ore Tailings Sediments and Their Possible Applications in Earthen Construction. Buildings 2024, 14, 362. [Google Scholar] [CrossRef]

- Assis, D.M.; Queiroga, F.O.C.S.; Mendes, J.C. Use of iron ore dam tailings in the manufacture of solid bricks. A Rev. Científ. FaSaR 2018, 3, 191–200. [Google Scholar]

- Carrasco, E.V.M.; Magalhaes, M.D.C.; Santos, W.J.D.; Alves, R.C.; Mantilla, J.N.R. Characterization of mortars with iron ore tailings using destructive and nondestructive tests. Constr. Build. Mater. 2017, 131, 31–38. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, F.; Li, W.; Liu, R.; Li, G.; Wei, J. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Morais, C.F.; Belo, B.R.; Bezerra, A.C.S.; Loura, R.M.; Porto, M.P.; Bessa, S.A.L. Thermal and mechanical analyses of colored mortars produced using Brazilian iron ore tailings. Constr. Build. Mater. 2021, 268, 121073. [Google Scholar] [CrossRef]

- Galvão, J.L.B.; Andrade, H.D.; Brigolini, G.J.; Peixoto, R.A.F.; Mendes, J.C. Reuse of iron ore tailings from tailings dams as pigment for sustainable paints. J. Clean. Prod. 2018, 200, 412–422. [Google Scholar] [CrossRef]

- Li, R.; Zhou, Y.; Li, C.; Li, S.; Huang, Z. Recycling of industrial waste iron tailings in porous bricks with low thermal conductivity. Constr. Build. Mater. 2019, 213, 43–50. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Fontes, M.P.F.; Ribeiro, J.C.L.; Vieira, C.M.F.; Pacheco, A.A.; Azevedo, A.R.G. Technical and environmental assessment of the incorporation of iron ore tailings in construction clay bricks. Constr. Build. Mater. 2019, 227, 116669. [Google Scholar] [CrossRef]

- Bessa, S.A.L.; Miranda, M.A.; Arruda, E.A.M.; Bezerra, A.C.S.; Sacht, H.M. Production and evaluation of microconcretes with iron ore waste for the manufacture of construction components. Mater. Rio De Jan. 2022, 27, 1–14. (In Portuguese) [Google Scholar] [CrossRef]

- Obenaus-Emler, R.; Falah, M.; Illikainen, M. Assessment of mine tailings as precursors for alkali-activated materials for on-site applications. Constr. Build. Mater. 2020, 246, 118470. [Google Scholar] [CrossRef]

- Defáveri, K.C.S.; Santos, L.F.; Carvalho, J.M.F.; Peixoto, R.A.F.; Silva, G.J.B. Iron ore tailing-based geopolymer containing glass wool residue: A study of mechanical and microstructural properties. Constr. Build. Mater. 2019, 220, 375–385. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W.; Ren, D. Development of fly ash and iron ore tailing based porous geopolymer for removal of Cu (II) from wastewater. Ceram. Int. 2016, 42, 13507–13518. [Google Scholar] [CrossRef]

- Kuranchie, F.A.; Shukla, S.K.; Habibi, D. Utilization of iron ore mine tailings for the production of geopolymer bricks. Int. J. Min. Reclam. Environ. 2016, 30, 92–114. [Google Scholar] [CrossRef]

- Strauch, J.C.M.; Souza, K.V.d.; Ajara, C.; Teixeira, M.d.P.; Cardoso, S.C. Large Mining Companies and the Community in Niquelândia (GO); CETEM/MCTI: Rio de Janeiro, Brazil, 2011.

- Brasil Mineral. Special Overview of Geological Mapping in Brazil—Anglo American 50 Years. Revista Brasil Mineral. no. 429. 2023. Available online: https://www.brasilmineral.com.br/revista/429/Revista%20Brasil%20Mineral%20-%20429.pdf (accessed on 8 February 2024).

- Apaza Apaza, F.R.; Rodrigues Guimarães, A.C.; Marcos Vivoni, A.; Schroder, R. Evaluation of the performance of iron ore waste as potential recycled aggregate for micro-surfacing type cold asphalt mixtures. Constr. Build. Mater. 2021, 266, 121020. [Google Scholar] [CrossRef]

- Loures, R.; Guimarães, A.; Silva, B.H.; Castro, C. Cold mix containing steel slag: A viable alternative for pavement construction. Transportes 2018, 26, 54–67. [Google Scholar] [CrossRef]

- Shamsi, M.; Zakerinejad, M. Production of sustainable hot mix asphalt from the iron ore overburden residues. Transp. Res. Part D Transp. Environ. 2023, 123, 103926. [Google Scholar] [CrossRef]

- de Moraes, T.M.R.P.; Neto, O.d.M.M.; Lucena, A.E.d.F.L.; Lucena, L.d.F.L.; Nascimento, M.S. Viability of Asphalt Mixtures with Iron Ore Tailings as a Partial Substitute for Fine Aggregate. Transp. Res. Rec. 2024, 2678, 770–794. [Google Scholar] [CrossRef]

- Sá, T.S.W.; Oda, S.; Balthar, V.K.C.B.L.; Toledo Filho, R.D. Use of iron ore tailings and sediments on pavement structure. Constr. Build. Mater. 2022, 342, 1. [Google Scholar] [CrossRef]

- Bonfim, V. Sustainable Pavement, 1st ed.; Exceção Editorial e Eventos: São Paulo, Brazil, 2021. [Google Scholar]

- de Medeiros Melo Neto, O.; Azam, A.; da Silva, J.; Diniz, M.I.L.; Youssef, A. Impact of sustainable additives on the thickness of the wearing course in flexible pavements: A comparison between design methodologies in Brazil. Innov. Infrastruct. Solut. 2024, 9, 336. [Google Scholar] [CrossRef]

- Coelho, L.M.; Guimarães, A.C.R.; Azevedo, A.R.G.d.; Monteiro, S.N. Sustainable Reclaimed Asphalt Emulsified Granular Mixture for Pavement Base Stabilization: Prediction of Mechanical Behavior Based on Repeated Load Triaxial Tests. Sustainability 2024, 16, 5335. [Google Scholar] [CrossRef]

- Coelho, L.M.; Guimarães, A.C.R.; Alves Moreira, C.R.C.L.; dos Santos, G.P.P.; Monteiro, S.N.; da Silveira, P.H.P.M. Feasibility of Using Ferronickel Slag as a Sustainable Alternative Aggregate in Hot Mix Asphalt. Sustainability 2024, 16, 8642. [Google Scholar] [CrossRef]

- Cardozo, L.G.E.; Resende, D.C.C.; Silva, N.A.B. Empirical and Empirical-Mechanistic Sizing: Impact on the Cracked Area and the Design Period of Flexible Pavements. Res. Soc. Dev. 2023, 12, e11612742543. [Google Scholar] [CrossRef]

- ME 083; Aggregates—Sieve Analysis. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1998.

- ME 035; Aggregates—Los Angeles Abrasion Test. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1998.

- ME 399; Aggregates—Impact Loss Test with Treton Apparatus. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1999.

- DNER ME 195; Aggregates—Determination of Absorption and Specific Gravity of Coarse Aggregates. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1997.

- ME 084; Fine Aggregates—Determination of Real Density. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1995.

- ME 079; Aggregates—Bituminous Binder Adhesion. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1994.

- DNER 057/1997; Sand Equivalent Test. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1997.

- DNIT—EM 095; Flexible Pavements—Petroleum Asphalt Cement—Material Specification. DNIT—National Department of Transport Infrastructure: Rio de Janeiro, Brazil, 2006.

- NBR 10004; Solid Waste—Classification. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2004.

- NBR 10006; Procedure for Obtaining Solubilized Extraction of Solid Wastes. ABNT—Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2004.

- DNER 043/1995; Hot Mix Asphalt. DNER—National Department of Highways: Rio de Janeiro, Brazil, 1995.

- DNIT 031/2006—ES; Flexible Pavements—Asphalt Concrete—Service Specification. DNIT—National Department of Transport Infrastructure: Brasília, Brazil, 2006.

- Bernucci, L.B.; Motta, L.M.G.; Ceratti, J.A.P.; Soares, J.B. Asphalt Pavement: Basic Training for Engineers; Abeda: Rio de Janeiro, Brazil, 2010. [Google Scholar]

- DNIT Standard 135/2018—ME; Asphalt Pavement—Asphalt Mixtures—Determination of Resilient Modulus—Test Method. DNIT—National Department of Infrastructure and Transport: Brasília, Brazil, 2018.

- DNIT Standard 183/2018—ME; Asphalt Pavement—Fatigue Test by Controlled-Stress Diametral Compression—Test Method. DNIT—National Department of Infrastructure and Transport: Brasília, Brazil, 2018.

- Franco, F. mechanistic–Empirical Design Method of Asphalt Pavements—SISPAV. Ph.D. Thesis, Federal University of Rio de Janeiro, Rio de Janeiro, Brazil, 2007. [Google Scholar]

- Fritzen, M.A.; Franco, F.A.C.P.; Motta, L.M.G.; Ubaldo, M.O.; Nascimento, L.A.H. Classification of Asphalt Mixtures Regarding Fatigue Performance. In Proceedings of the 9th Portuguese Road Congress (9 CRP), Lisbon, Portugal, 12–14 June 2019. [Google Scholar]

- Paulsen, G.; Stroup-Gardiner, M.; Epps, J. Recycling Waste Roofing Material in Asphalt Paving Mixtures. Transp. Res. Rec. 1987, 1115, 171–182. [Google Scholar]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of Asphalt Mixtures Incorporating Electric Arc Furnace Steel Slag and Copper Mine Tailings for Road Construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Shafabakhsh, G.H.; Sajed, Y. Investigation of Dynamic Behavior of Hot Mix Asphalt Containing Waste Materials; Case Study: Glass Cullet. Case Stud. Constr. Mater. 2014, 1, 96–103. [Google Scholar] [CrossRef]

- de Souza, T.D.; de Albuquerque e Silva, B.H.; Guimarães, A.C.R.; Mesquita, A.R. Mechanical Properties of Asphalt Concrete Dosed with Waste from Dry Magnetic Iron Ore Processing. Transportes 2020, 28, 175–187. [Google Scholar] [CrossRef]

- Medina, J.; Motta, L.M.G. Pavement Mechanics, 3rd ed.; Interciência: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- Guabiroba, J.V.d.O.C.; Rezende, L.R.d.; Barroso, L.X.; Silva, J.P.S. Study of fatigue and permanent deformation of asphalt mixtures produced in Goiás. Matéria 2023, 28, e13232. [Google Scholar] [CrossRef]

| Tests | Gravel 1 | Gravel 0 | Sand | Waste | DNIT Limit |

|---|---|---|---|---|---|

| Los Angeles Abrasion Loss | 27% | 46% | - | - | max 50% |

| Impact Loss in Treton Apparatus | 12% | - | - | - | - |

| Real Density | 2.798 | 2.703 | 2.620 | 2.830 | - |

| Apparent Density | 2.750 | 2.666 | - | - | - |

| Absorption | 0.6% | 0.8% | - | - | - |

| Sand Equivalent | - | - | 64% | 74% | min 55% |

| Adhesion to Asphalt Binder (CAP 50/70) | Not Satisfactory | - | - | - | - |

| Durability (Magnesium Sulfate—5 Cycles) | 5.92% | 2.67% | 9.69% | 5.56% | max 12% |

| Tests | Result | Limits |

|---|---|---|

| Penetration—100 g, 5 s, 25 C (0.1 mm) | 61 | 50 to 70 |

| Softening Point (C) | 47 | min 46 |

| Brookfield Viscosity (cP) | ||

| at 135 C, SP 21, 20 rpm | 465 | min 274 |

| at 150 C, SP 21, 50 rpm | 226 | min 112 |

| at 177 C, SP 21, 100 rpm | 81 | 57–285 |

| Thermal Susceptibility Index | −1.5 | −1.5 to +0.7 |

| Flash Point (C) | >265 | min 235 |

| Solubility in Trichloroethylene | 99.5% | min 99.5% |

| Specific Mass and Relative Density, 25 C | 1.055 | - |

| Ductility, at 25 C (cm) | >120 | min 60 |

| After RTFOT @ 163 C, 85min | ||

| Mass Variation | 0.02% | max 0.5% |

| Ductility, at 25 C (cm) | >120 | min 20 |

| Increase in Softening Point (C) | 0.05 | max 8 |

| Retained Penetration | 55% | min 55% |

| Material | Mass Percentage | ||

|---|---|---|---|

| M1 | M2 | M3 | |

| Gravel 1 | 20 | 15 | 20 |

| Gravel 0 | 40 | 65 | 55 |

| Sand | 40 | - | 8 |

| Waste | - | 20 | 17 |

| MIXES | % BINDER | Vv % | RBV % | STRENGTH (kgf) | RT (MPa) | VAM % |

|---|---|---|---|---|---|---|

| DNIT-ES 031/2006 | 4.5–9.0 | 3 to 5 | 75 to 82 | >500 | >0.65 | >15 |

| M1 | 5.9 | 3.1 | 81.4 | 1710 | 1.4 | 16.3 |

| M2 | 5.6 | 3.9 | 76.7 | 1361 | 1.5 | 16.7 |

| M3 | 5.5 | 3.1 | 80.7 | 1442 | 1.6 | 15.7 |

| Fatigue Class | Standard Repetition Number Interval (N) | Regression |

|---|---|---|

| 0 | — | |

| 1 | ||

| 2 | ||

| 3 | ||

| 4 |

| Layers | Type | RM (MPa) | Thickness (cm) |

|---|---|---|---|

| Base | Granular Material (Gneiss C5) | 381 | 15 |

| Sub-base | silty soil NS’ | 250 | 15 |

| Subgrade | clayey soil LG’ (1) | 189 | - |

| Mixture | Reliability Interval (95%) (MPa) | Standard Deviation (MPa) | Coefficient of Variation (%) | Average RM (MPa) |

|---|---|---|---|---|

| M1 | 5347 to 5883 | 140 | 2.5% | 5640 |

| M2 | 4927 to 5421 | 163 | 3.2% | 5137 |

| M3 | 5062 to 5773 | 127 | 2.4% | 5244 |

| Mixture | Nf = a1 ( | Nf = k1 ( | ||||

|---|---|---|---|---|---|---|

| a1 | b1 | k1 | k2 | |||

| M1 | 3573 | −2.676 | 0.9894 | −2.676 | 0.9894 | |

| M2 | 3514 | −2.909 | 0.9650 | −2.909 | 0.9650 | |

| M3 | 4370 | −2.802 | 0.9857 | −2.802 | 0.9851 | |

| Asphalt Concrete | M1 | M2 | M3 |

|---|---|---|---|

| Poisson’s Ratio | 0.30 | 0.3 | 0.3 |

| Modulus (MPa) | |||

| Constituent Model | Linear Resilient | Linear Resilient | Linear Resilient |

| Modulus (MPa) | 5640 | 5137 | 5244 |

| Characteristics | |||

| Type of Binder (CAP) | 50/70 | 50/70 | 50/70 |

| Specific Gravity (g/cm3) | 2.37 | 2.00 | 2.00 |

| Tensile Strength (MPa) | 2.08 | 1.16 | 1.09 |

| Asphalt Content (%) | 5.9 | 5.6 | 5.5 |

| Void Volume (%) | 3.1 | 3.9 | 3.1 |

| Standard or Specification | DNIT ES 31 | DNIT ES 31 | DNIT ES 31 |

| Fatigue Curve | |||

| Constituent Model | () | () | () |

| Regression Coefficient (k1) | 8.00 | 1.00 | 3.00 |

| Regression Coefficient (K2) | −2.676 | −2.909 | −2.802 |

| Fatigue Class | 1 | 0 | 1 |

| FFM | 0.83 | 0.82 | 0.85 |

| Medium Traffic (N 5 ) Layer Thickness | ||||||

|---|---|---|---|---|---|---|

| Mixture | % CA in 10 Years | PD in 10 Years (mm) | Surface (cm) | Base (cm) | Sub-Base (cm) | Total Thickness (cm) |

| M1 | 29.3 | 4.4 | 6.9 | 20 | 15 | 36.9 |

| M2 | 29.8 | 4.1 | 8.2 | 20 | 15 | 38.4 |

| M3 | 29.9 | 4.5 | 6.9 | 20 | 15 | 36.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guimarães, A.C.R.; Arêdes, M.L.A.d.; Castro, C.D.; Coelho, L.M.; Monteiro, S.N. Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore. Mining 2024, 4, 889-903. https://doi.org/10.3390/mining4040049

Guimarães ACR, Arêdes MLAd, Castro CD, Coelho LM, Monteiro SN. Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore. Mining. 2024; 4(4):889-903. https://doi.org/10.3390/mining4040049

Chicago/Turabian StyleGuimarães, Antônio Carlos Rodrigues, Marcio Leandro Alves de Arêdes, Carmen Dias Castro, Lisley Madeira Coelho, and Sergio Neves Monteiro. 2024. "Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore" Mining 4, no. 4: 889-903. https://doi.org/10.3390/mining4040049

APA StyleGuimarães, A. C. R., Arêdes, M. L. A. d., Castro, C. D., Coelho, L. M., & Monteiro, S. N. (2024). Evaluation of the Mechanical Behavior of Asphaltic Mixtures Utilizing Waste of the Processing of Iron Ore. Mining, 4(4), 889-903. https://doi.org/10.3390/mining4040049