Multi-Level Characterization of Lignite Mine Waste by the Integration of Wide Wavelength Range Infrared Spectroscopy

Abstract

1. Introduction

2. Geological and Analytical Background Information

2.1. Geological Setting

2.2. Infrared Spectroscopy

3. Methods

3.1. Location and Sampling

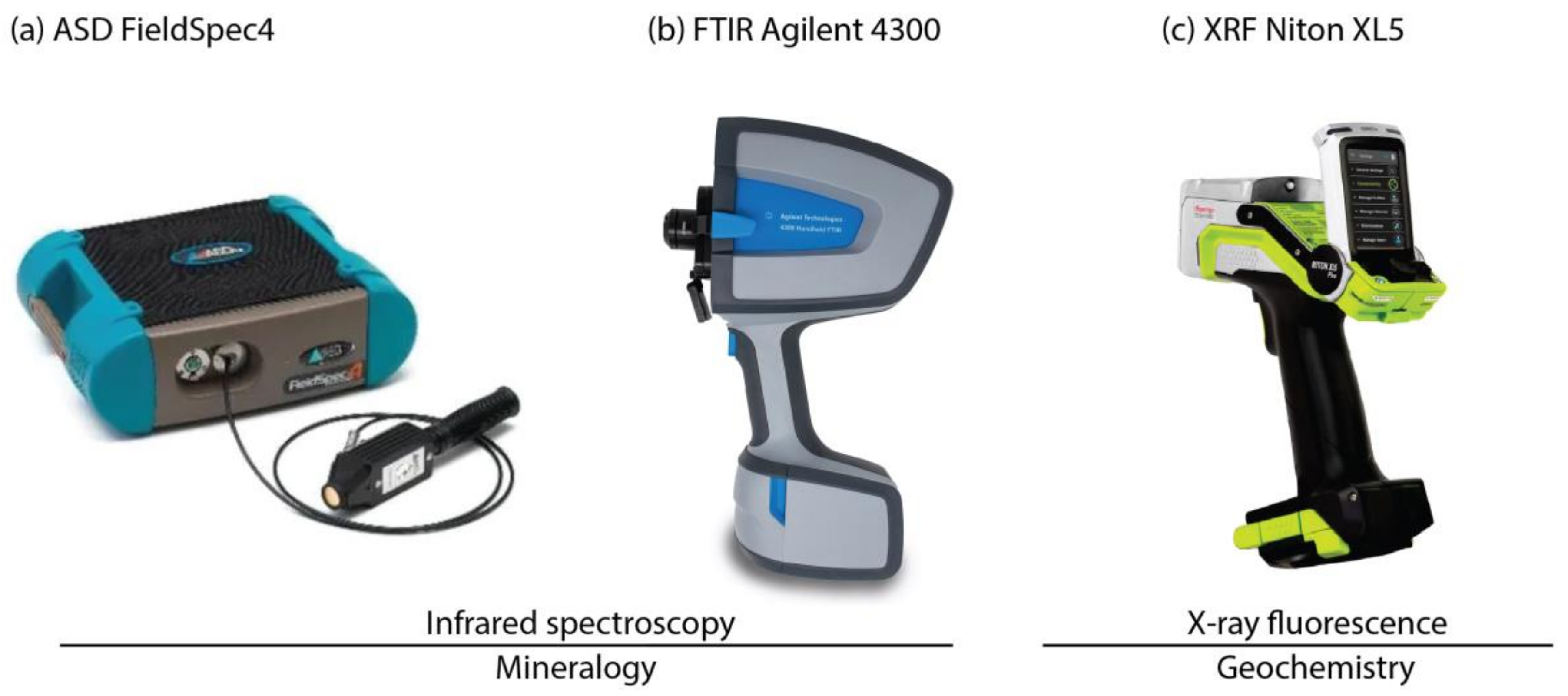

3.2. Instrumentation

3.2.1. Wide Range Infrared Spectroscopy Techniques

3.2.2. X-ray Fluorescence

3.2.3. Inductively Coupled Plasma Analysis

3.2.4. X-ray Diffraction

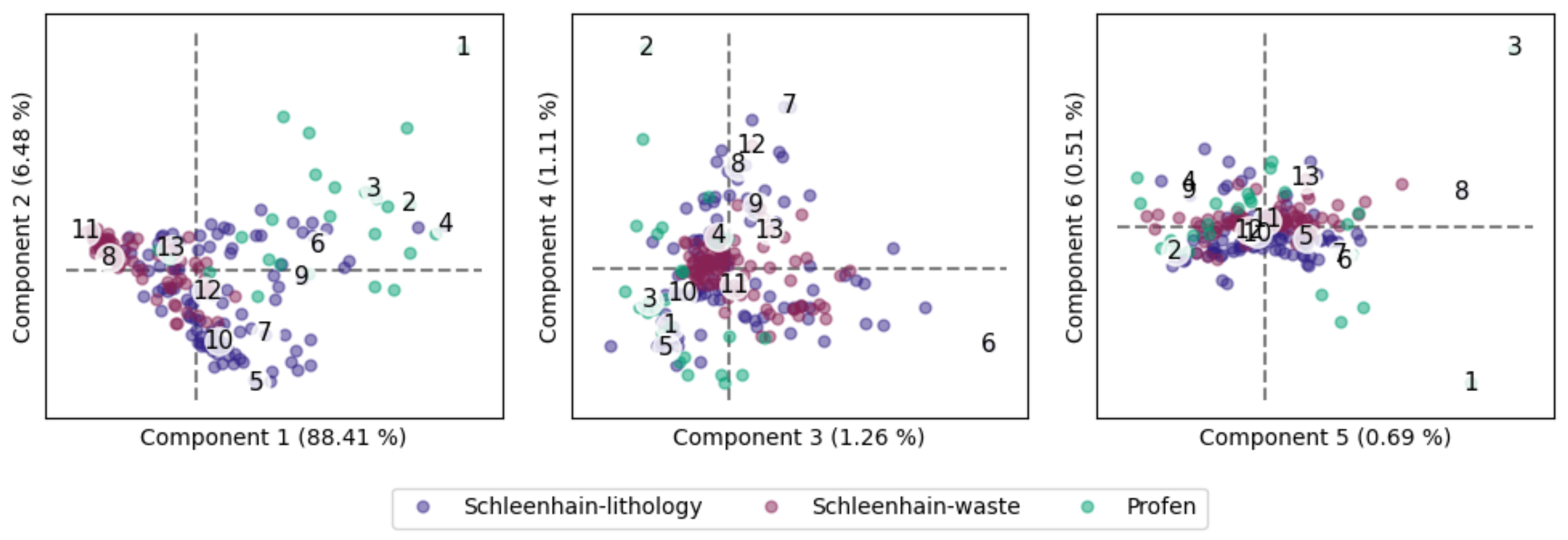

3.3. Exploratory Analysis

3.3.1. Principal Component Analysis (PCA)

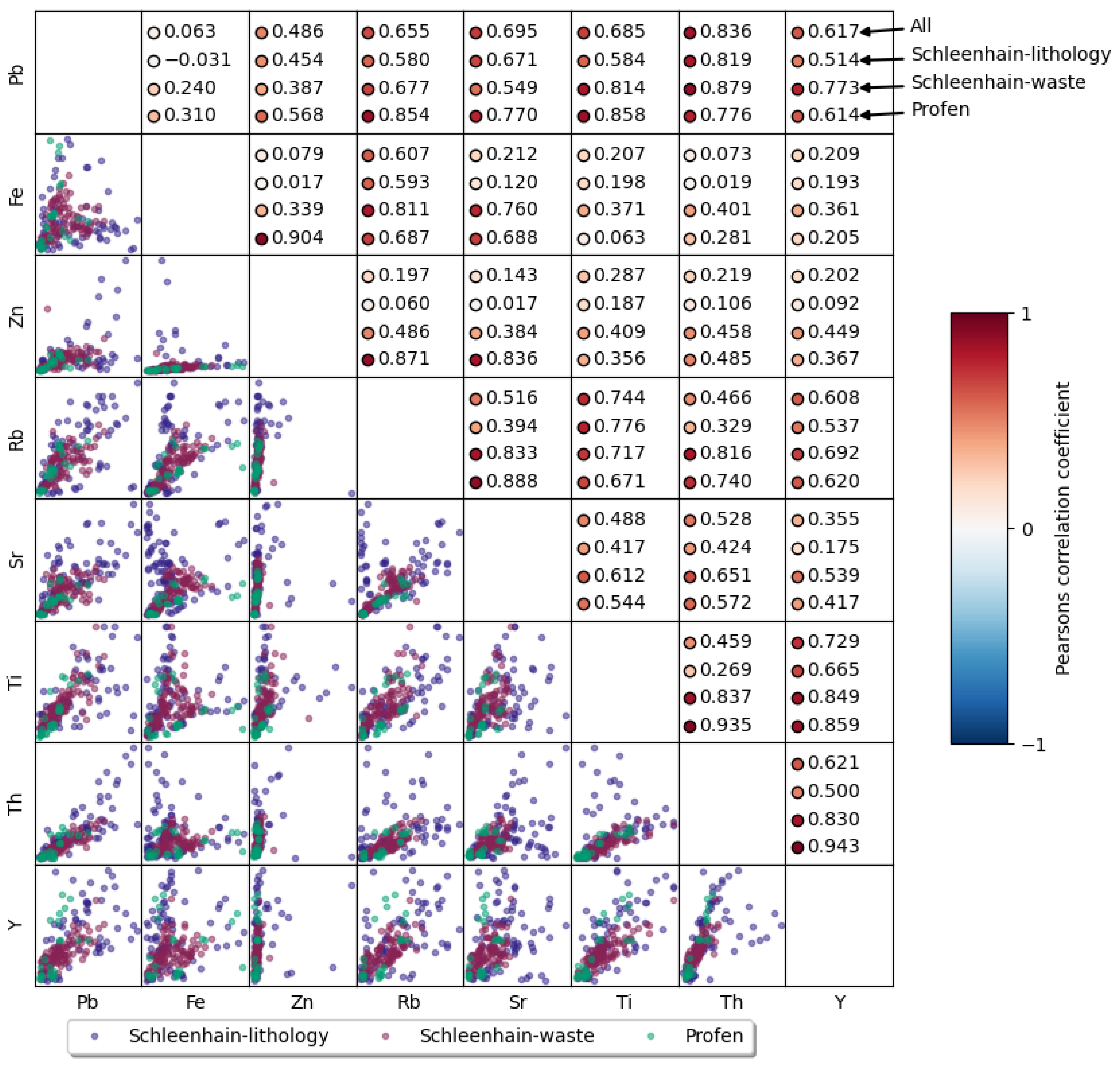

3.3.2. Correlation Matrix

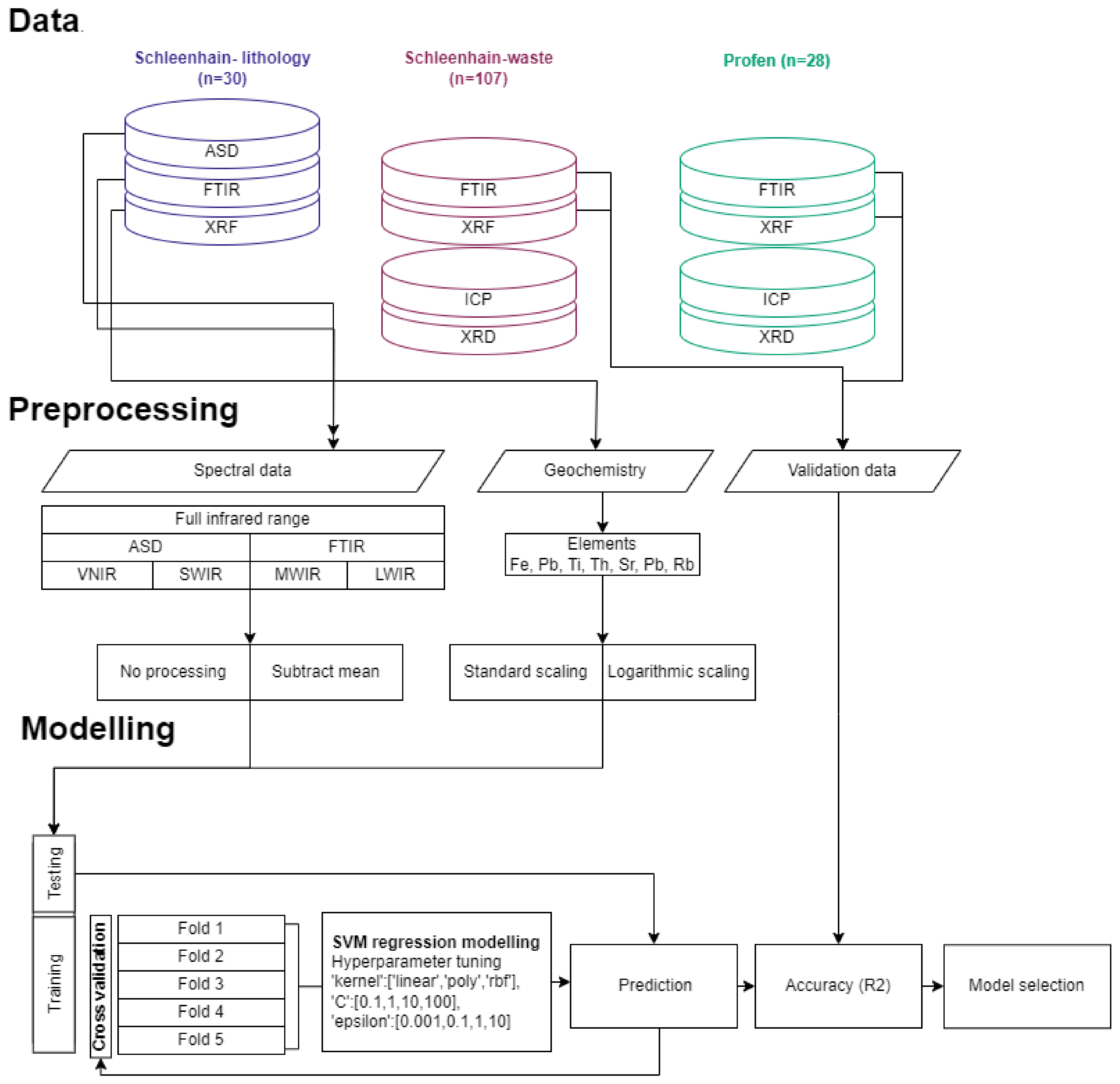

3.4. Geochemical Modelling

3.4.1. Data Preparation

3.4.2. Regression Modelling

4. Results

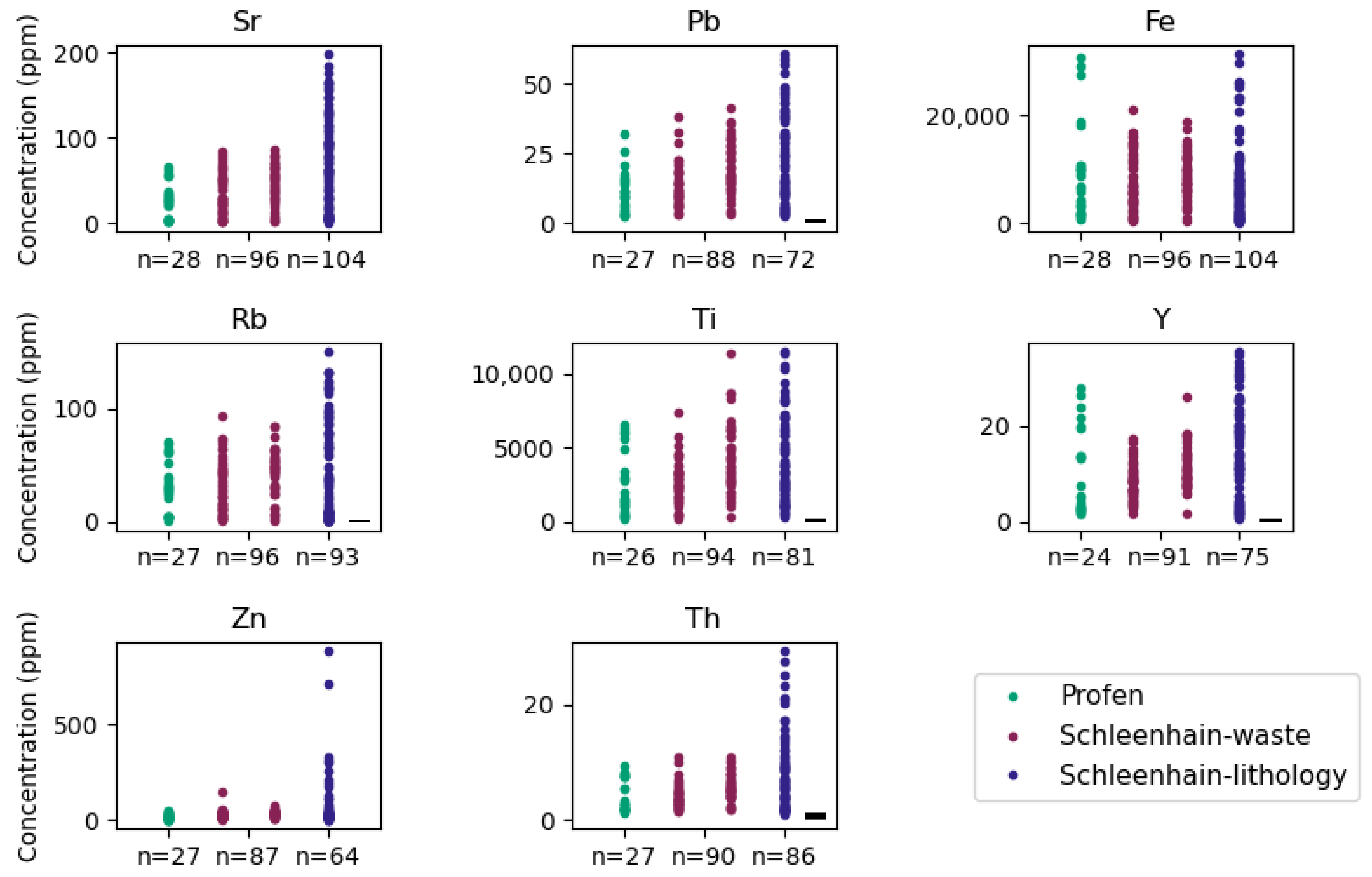

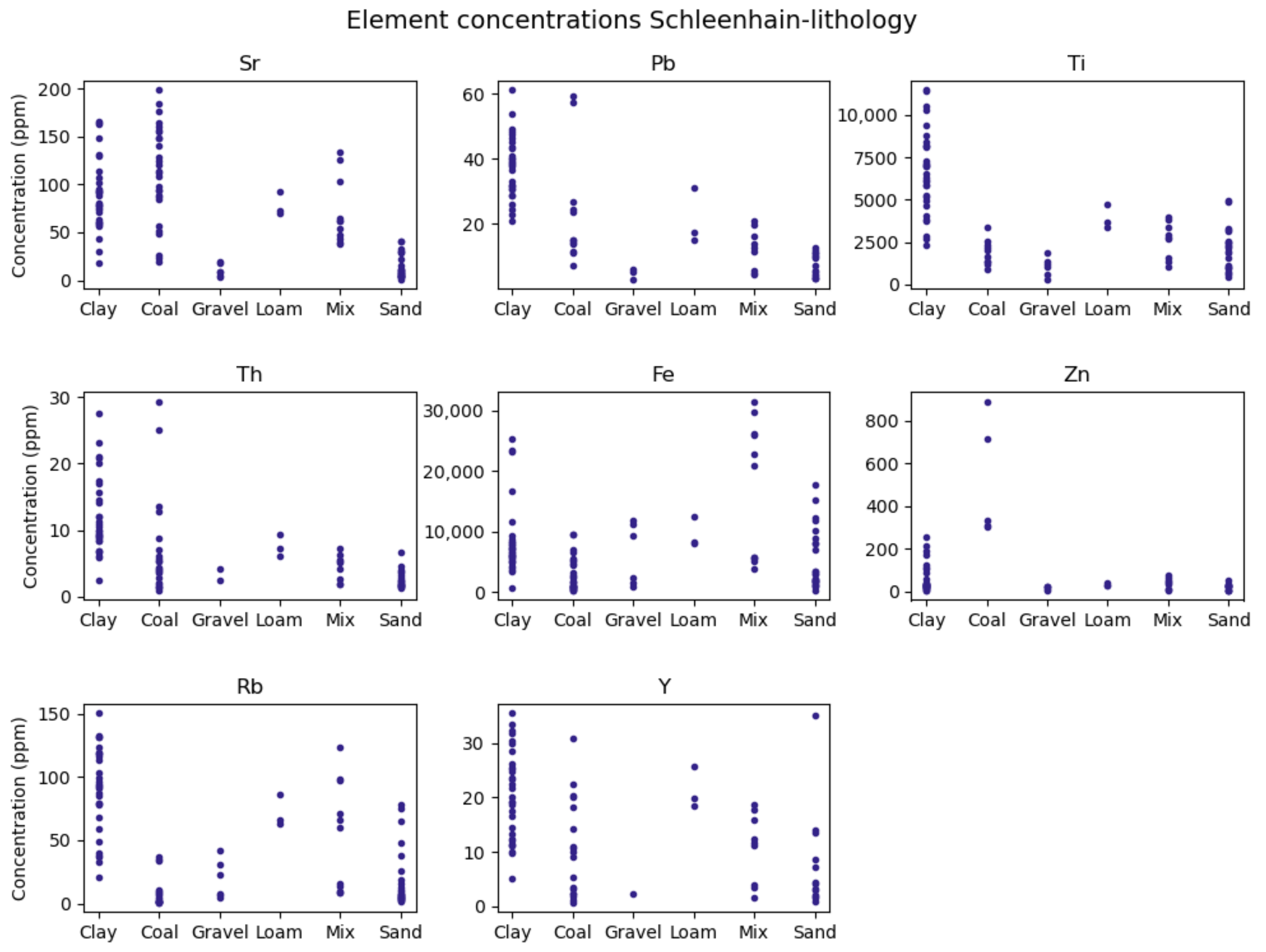

4.1. Geochemical Analysis

4.2. Spectral Analysis

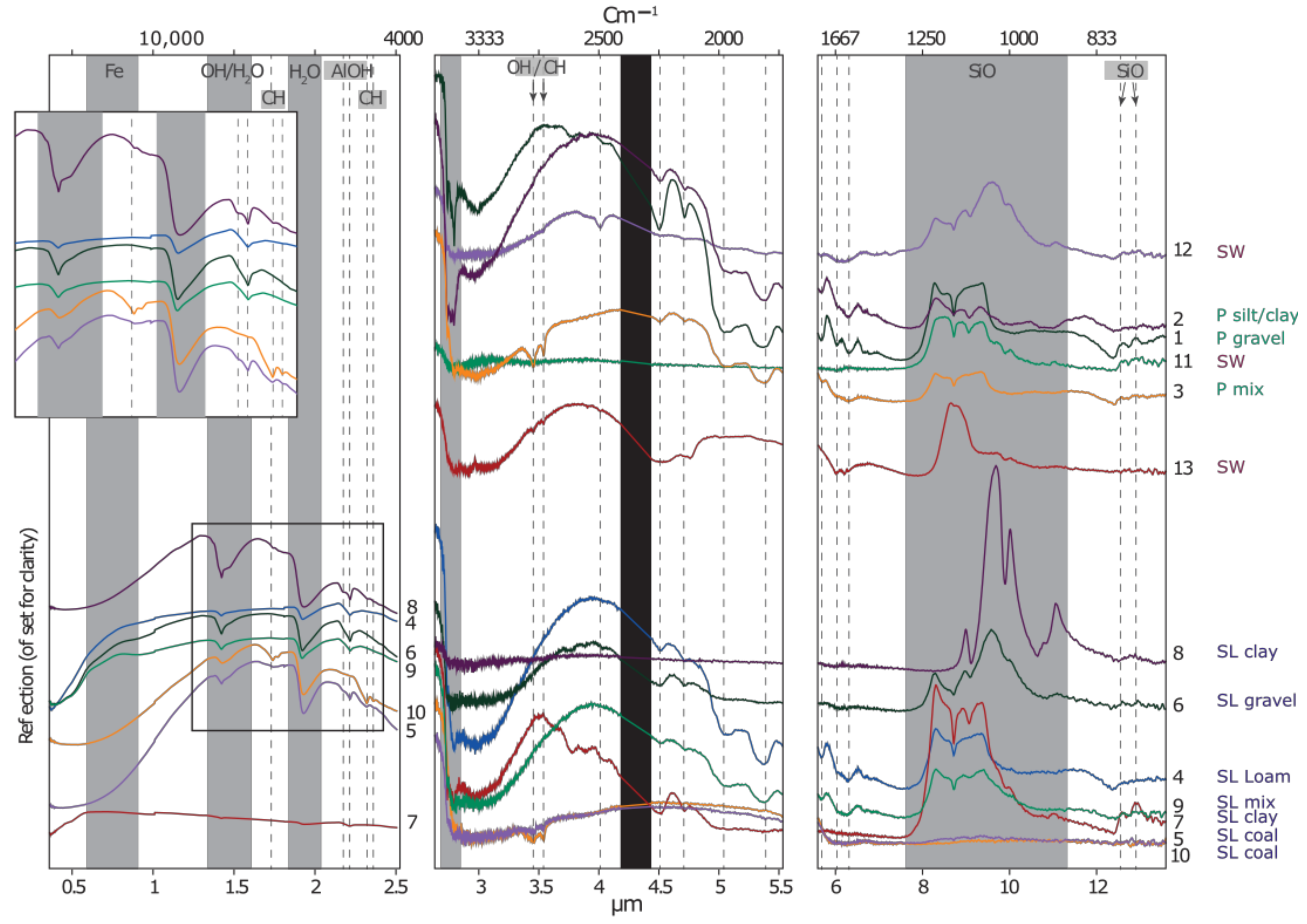

4.2.1. Spectral Difference Datasets

4.2.2. Spectral Differences Wavelength Ranges

4.2.3. Mineralogical Interpretation

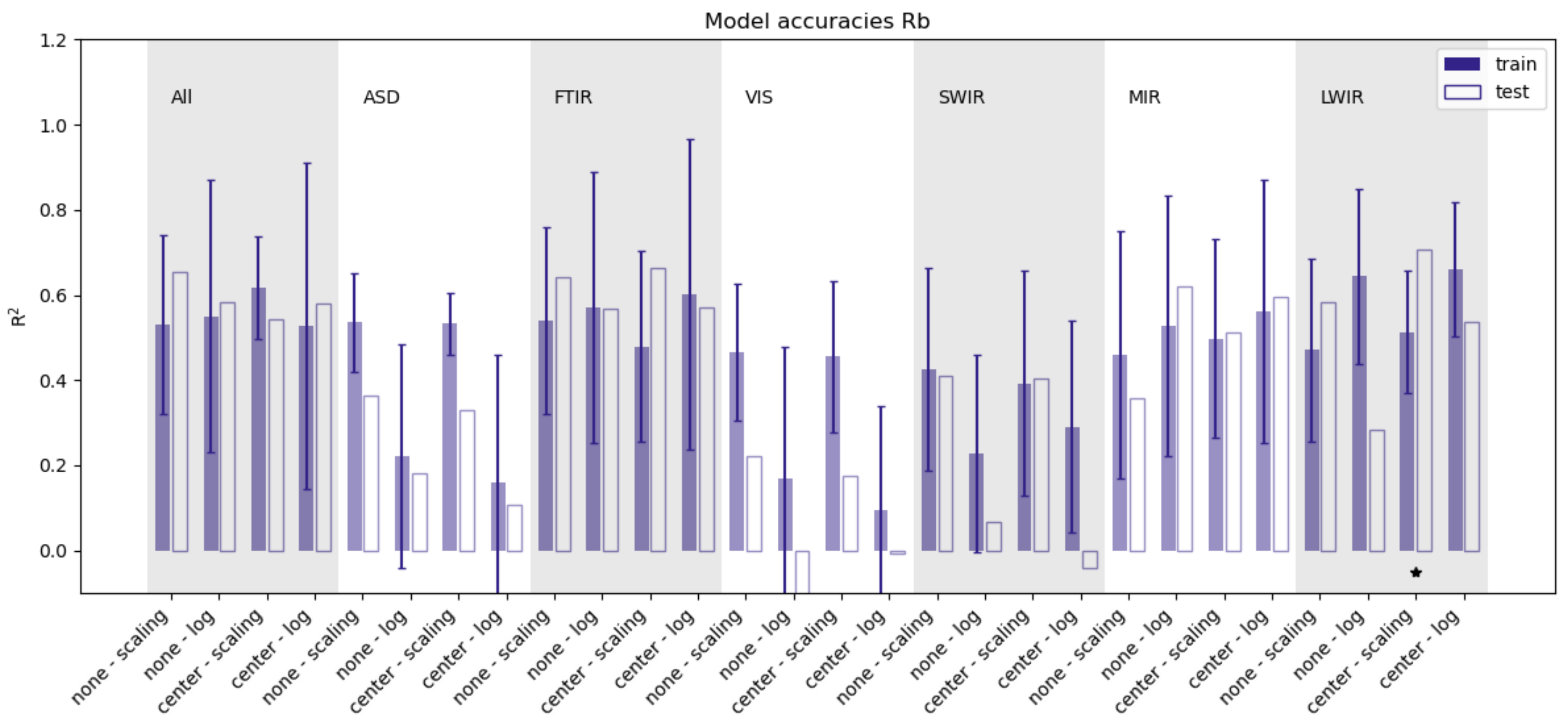

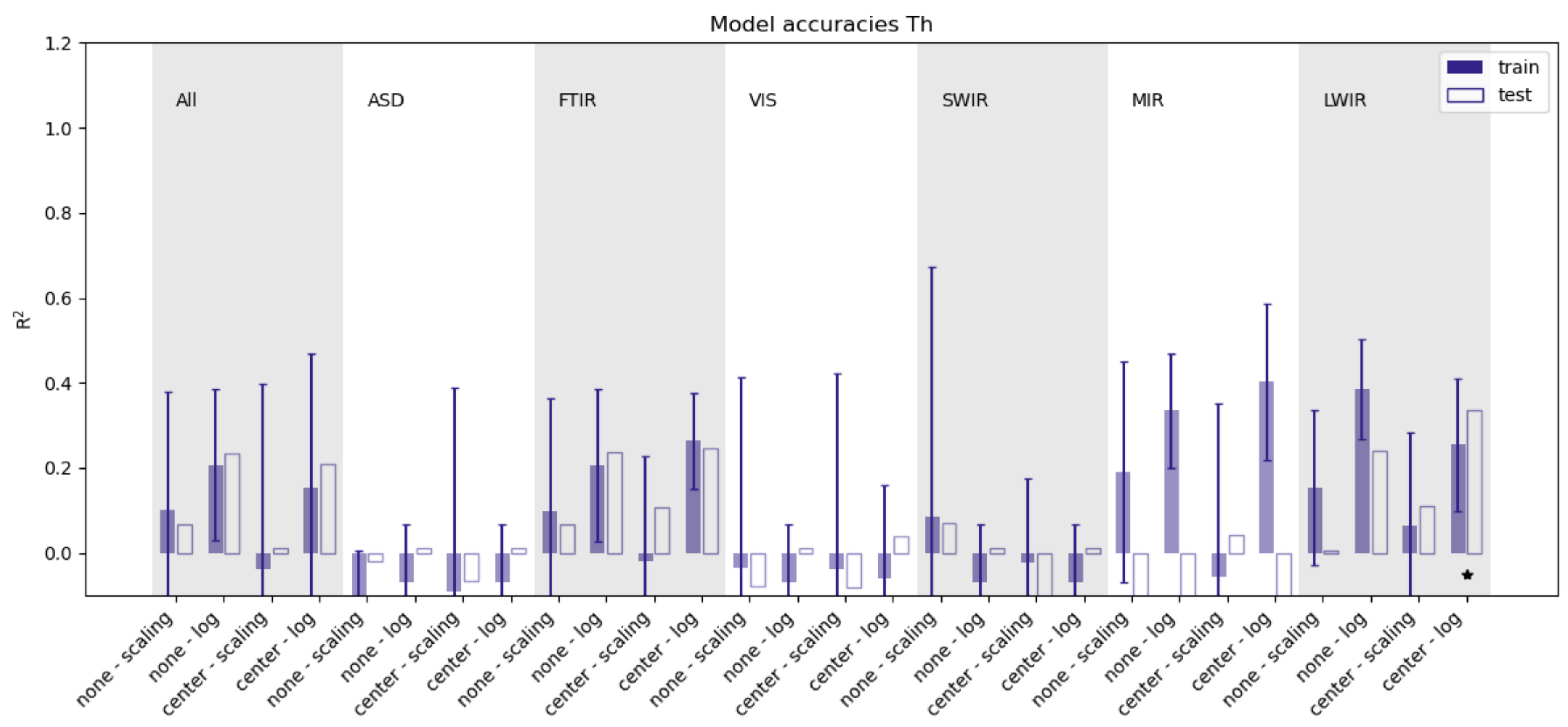

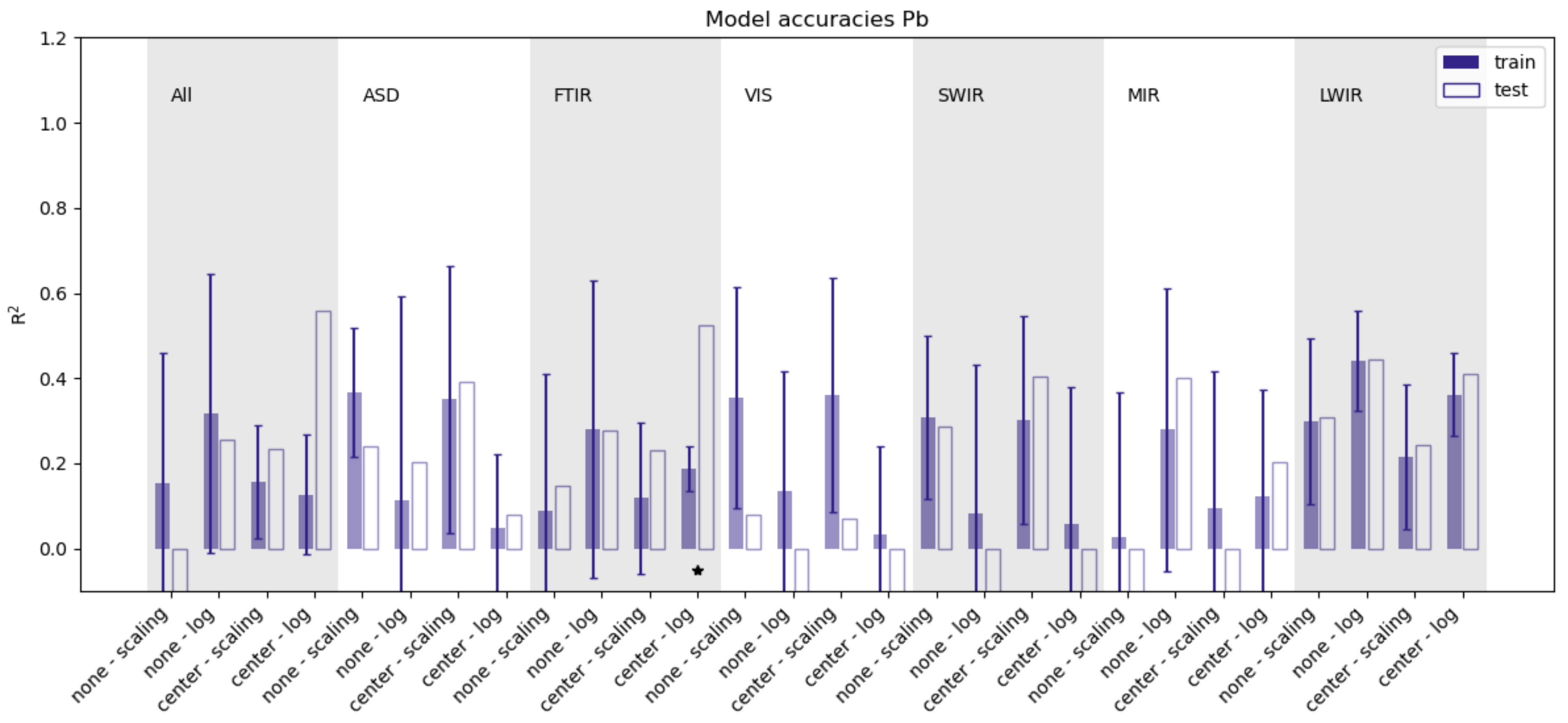

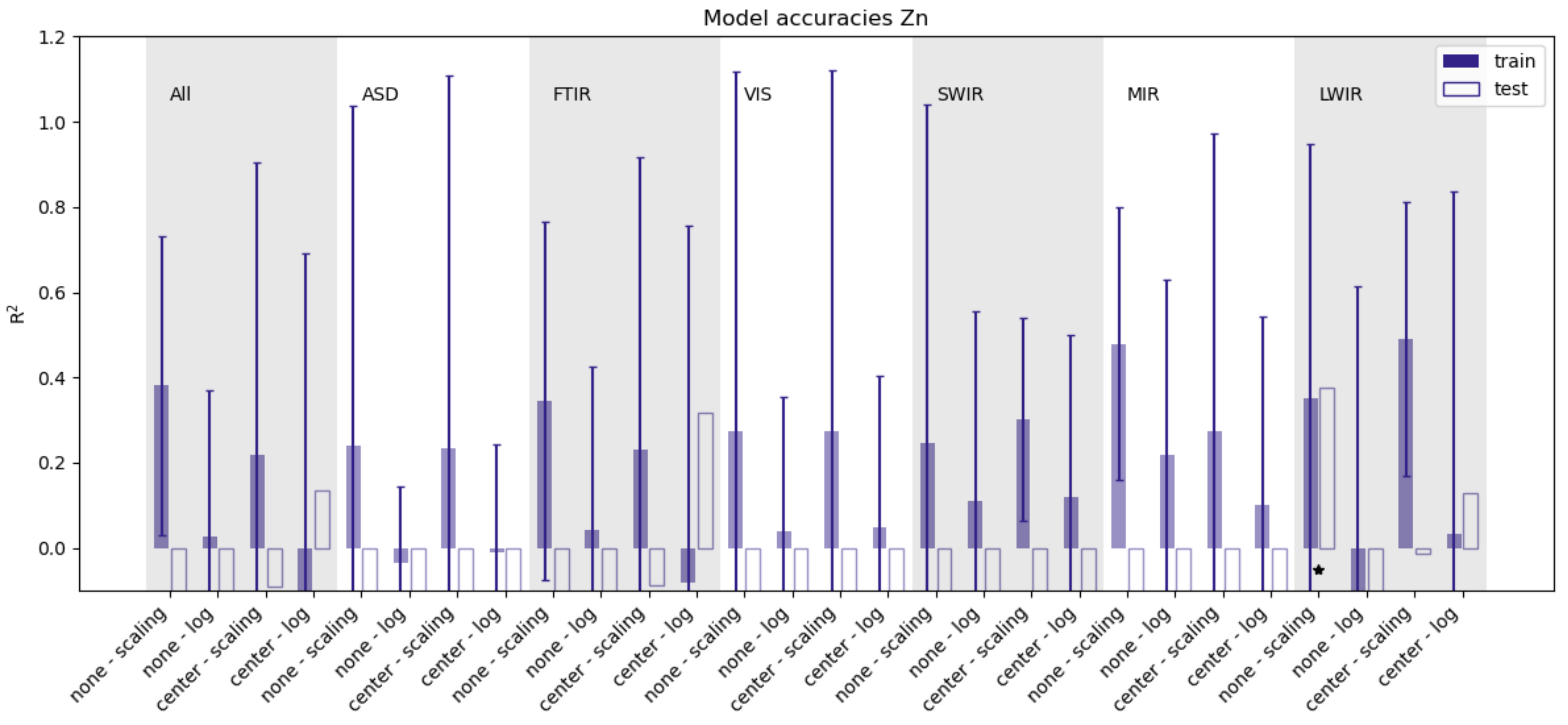

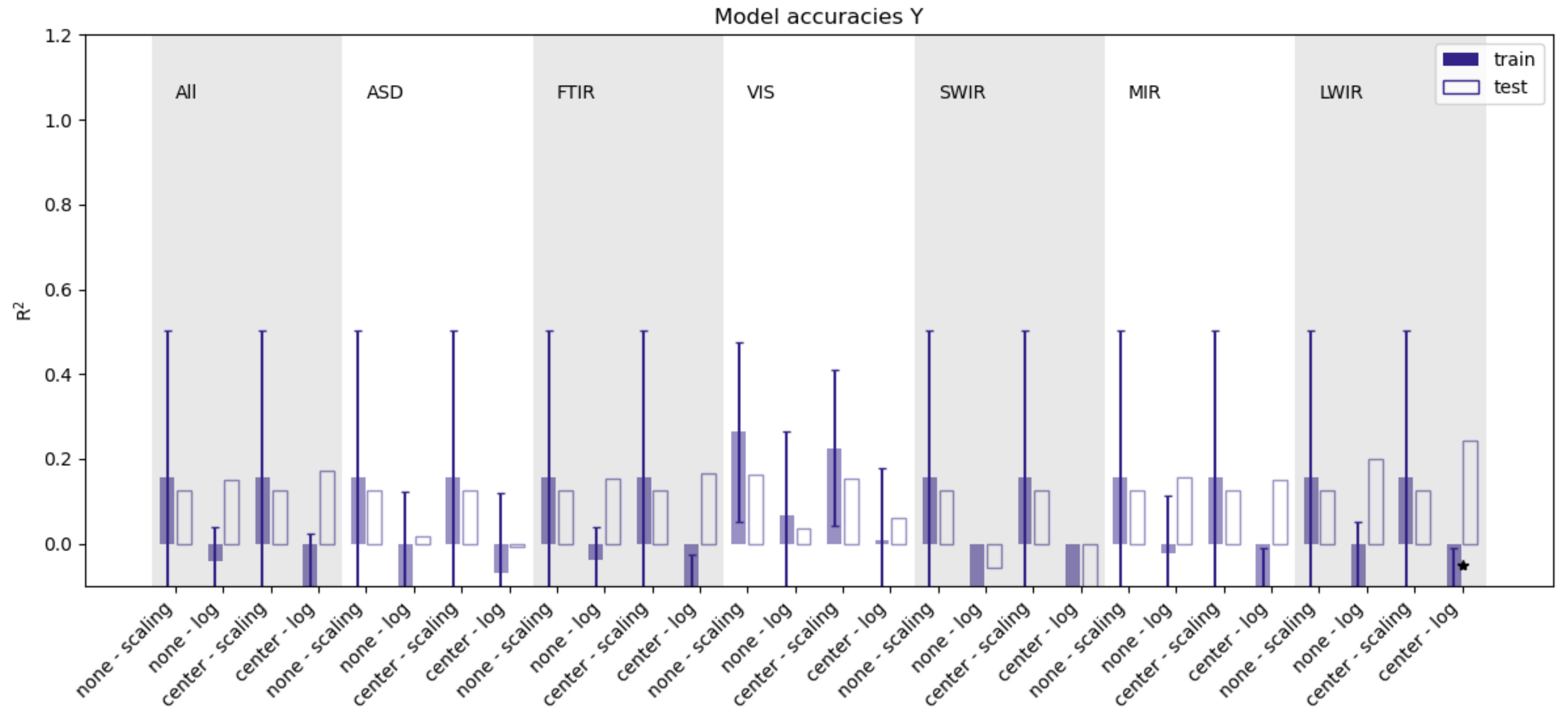

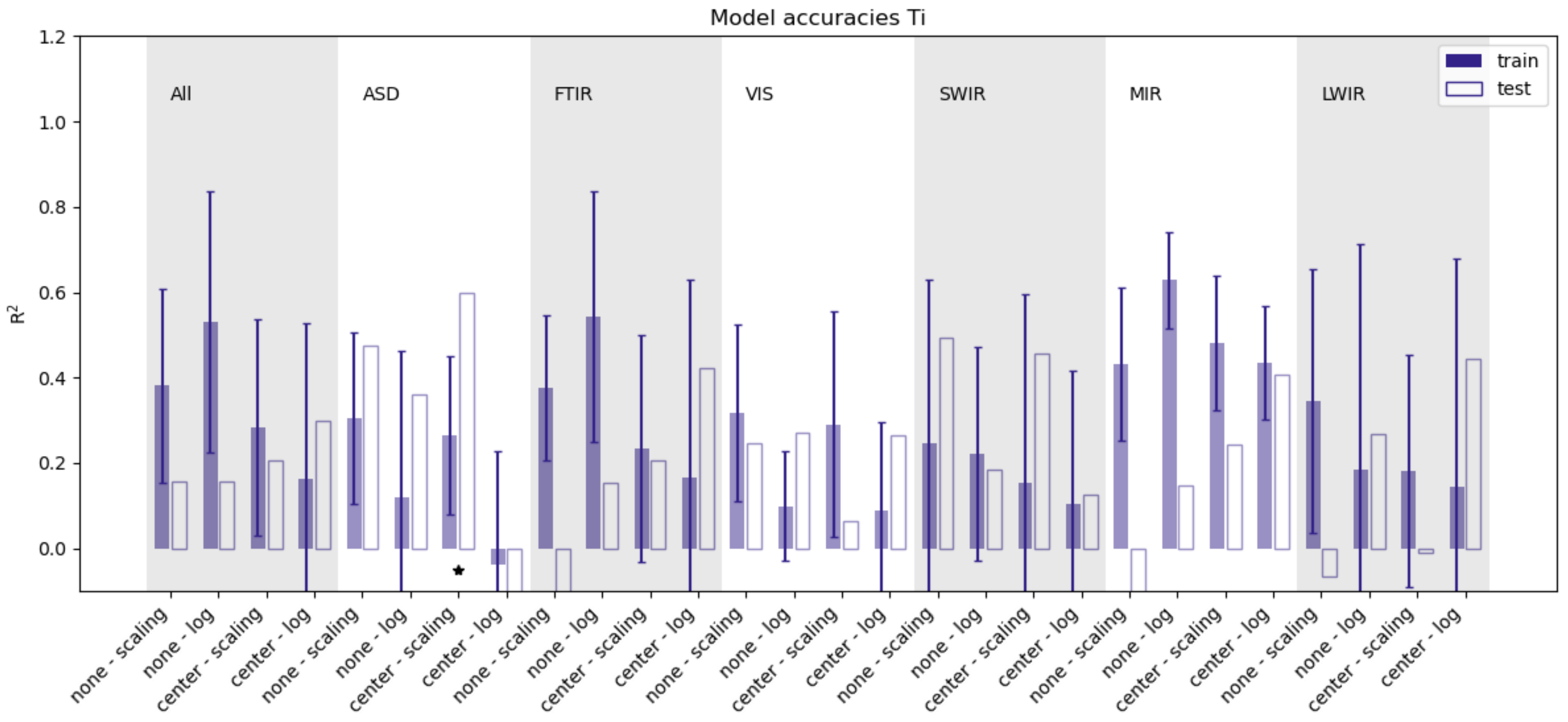

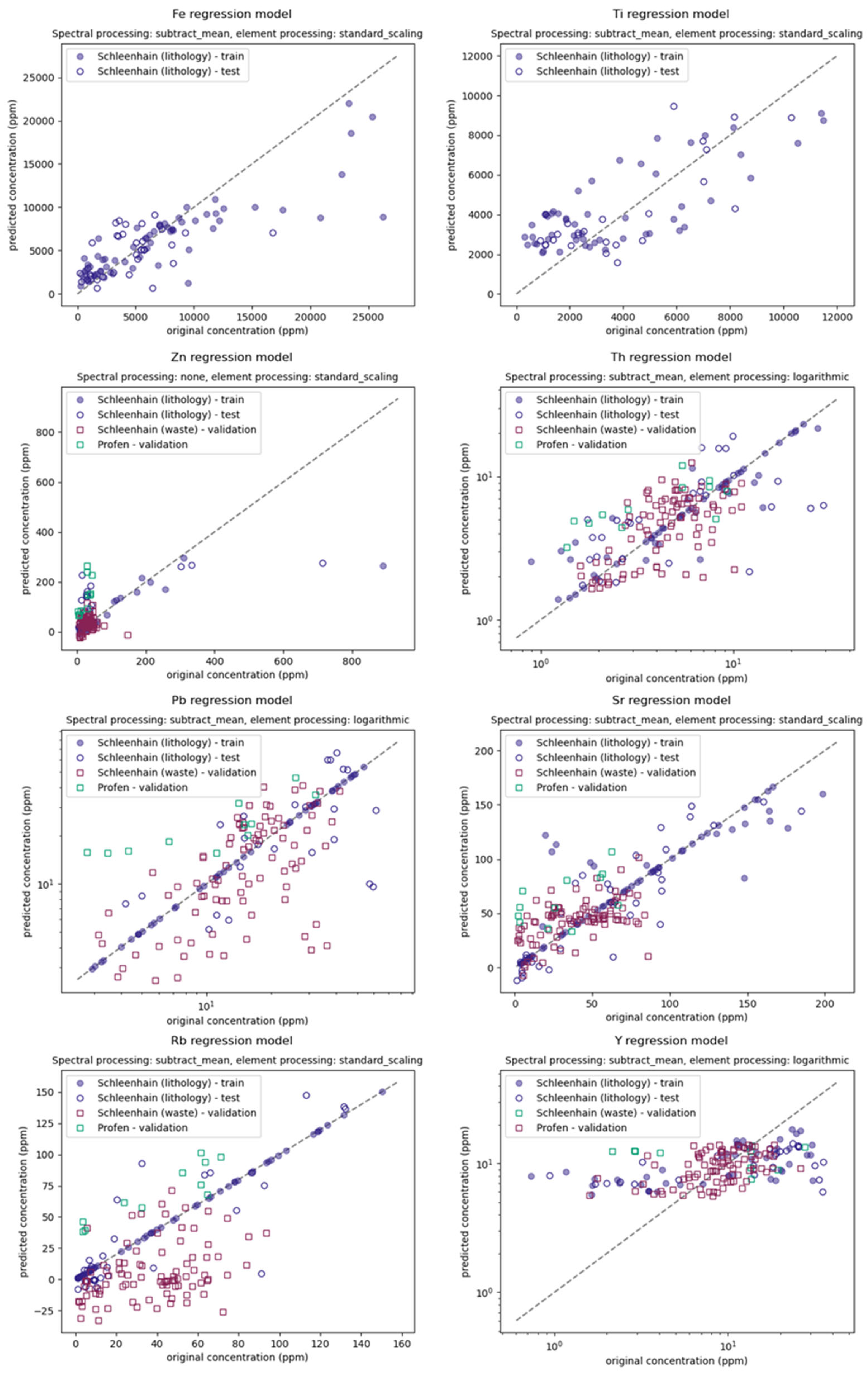

4.3. Geochemical Modelling

5. Discussion

5.1. Compositional Analysis

5.1.1. Geochemistry

5.1.2. Mineralogy

5.2. Infrared Spectroscopy as a Geochemical Indicator

5.3. Integration of Wide Wavelength Range Infrared Data

5.4. Opportunities, Limitations and Recommendations

6. Conclusions

- This paper presents a methodological approach for data integration of a wide wavelength range of an infrared spectral dataset and pXRF geochemical data for a comprehensive characterization of coal mine waste, using ASD, FTIR and pXRF data. These datasets were analyzed using exploratory data-analysis strategies and the geochemistry is quantitatively modelled using support vector machine regression.

- For both the mineralogical and geochemical analysis, the most variance between the samples was found between the coal, clay and sand samples.

- Geochemically there was large compositional variance between the coal and clay samples.

- The spectra did confirm compositional differences for clay, related to kaolinite and montmorillonite; however, there were little spectral differences between the coals.

- The additional value of using a broad wavelength range of infrared spectroscopy is most clear in the geochemical modelling results. Especially for the model of Sr since there are significant differences in model performances between the models trained on the different wavelength ranges.

- The wavelength ranges measured with the FTIR seems best to capture the presence of certain minerals. The ASD data are able to capture minor clay and coal contents and small spectral differences of clay minerals that can be linked to, for example, the crystallinity of the mineral.

- The results show the importance of representative sampling, due to the heterogeneous nature of mine waste material and the different point size of the sensors.

- Based on our exploratory and data integration analysis, it can be concluded that there is no single method nor sensor that fully captures all compositional variance, and thereby this emphasizes the need for sensor integration for comprehensive characterization of the waste.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Sample | Mineral 1 | Mineral 2 | Mineral 3 | Mineral 4 | Mineral 5 | Mineral 6 |

|---|---|---|---|---|---|---|

| 1-01-2 | Quartz | Kaolinite | ||||

| 1-03-1 | Quartz | Illite | Kaolinite | |||

| 1-06-1 | Quartz | Illite | ||||

| 1-07-1 | Quartz | |||||

| 1-08-1 | Montmorillonite | Illite | Kaolinite | Pyrite | Arsenopyrite | Titanite |

| 1-10-1 | Montmorillonite | Illite | Kaolinite | Pyrite | ||

| 1-11-1 | Illite | Montmorillonite | Kaolinite | |||

| 1-12-1 | Quartz | Illite | Montmorillonite | Kaolinite | ||

| 1-14-1 | Quartz | Illite | Kaolinite | |||

| 1-16-1 | Illite | Kaolinite | ||||

| 1-19-1 | Illite | Quartz | Kaolinite | |||

| 1-20-1 | Quartz | Illite | Kaolinite | |||

| 1-22-1 | Quartz | Illite | Kaolinite | |||

| 1-23-1 | Illite | Kaolinite | ||||

| 1-26-1 | Quartz | Illite | Kaolinite | |||

| 1-27-1 | Quartz | Kaolinite | ||||

| 1-30-1 | Quartz | Kaolinite | ||||

| 1-34-1 | Quartz |

References

- Benndorf, J.; Restrepo, D.A.; Merkel, N.; John, A.; Buxton, M.; Guatame-Garcia, A.; Dalm, M.; de Waard, B.; Flores, H.; Möllerherm, S. TRIM4Post-Mining: Transition information modelling for attractive post-mining landscapes—A conceptual framework. Mining 2022, 2, 248–277. [Google Scholar] [CrossRef]

- Gerwin, W.; Raab, T.; Birkhofer, K.; Hinz, C.; Letmathe, P.; Leuchner, M.; Roß-Nickoll, M.; Rüde, T.; Trachte, K.; Wätzold, F. Perspectives of lignite post-mining landscapes under changing environmental conditions: What can we learn from a comparison between the Rhenish and Lusatian region in Germany? Environ. Sci. Eur. 2023, 35, 36. [Google Scholar] [CrossRef]

- Sloss, L.; Coal Mine Site Reclamation. IEA Clean Coal Centre; 2013; p. 70. Available online: https://www.researchgate.net/profile/Lesley-Sloss/publication/337487243_Coal_mine_site_reclamation/links/5ddbb420a6fdccdb446324e4/Coal-mine-site-reclamation.pdf (accessed on 26 March 2024).

- Maest, A.S. Remining for renewable energy metals: A review of characterization needs, resource estimates, and potential environmental effects. Minerals 2023, 13, 1454. [Google Scholar] [CrossRef]

- Mielke, C.; Boesche, N.K.; Rogass, C.; Kaufmann, H.; Gauert, C.; De Wit, M. Spaceborne mine waste mineralogy monitoring in South Africa, applications for modern push-broom missions: Hyperion/OLI and EnMAP/Sentinel-2. Remote Sens. 2014, 6, 6790–6816. [Google Scholar] [CrossRef]

- Ren, H.; Zhao, Y.; Xiao, W.; Hu, Z. A review of UAV monitoring in mining areas: Current status and future perspectives. Int. J. Coal Sci. Technol. 2019, 6, 320–333. [Google Scholar] [CrossRef]

- Peukert, D.; Xu, C.; Dowd, P. A review of sensor-based sorting in mineral processing: The potential benefits of sensor fusion. Minerals 2022, 12, 1364. [Google Scholar] [CrossRef]

- Mibrag. Tagebau Vereinigtes Schleenhain. Available online: https://www.mibrag.de/de-de/geschaeftsfelder/bergbau/tagebau-vereinigtes-schleenhain (accessed on 17 February 2023).

- Eissmann, L. Quaternary geology of eastern Germany (Saxony, Saxon–Anhalt, south Brandenburg, Thüringia), type area of the Elsterian and Saalian stages in Europe. Quat. Sci. Rev. 2002, 21, 1275–1346. [Google Scholar] [CrossRef]

- Eissmann, L. Tertiary geology of the Saale–Elbe region. Quat. Sci. Rev. 2002, 21, 1245–1274. [Google Scholar] [CrossRef]

- Standke, G.; Escher, D.; Fischer, J.; Rascher, J. Das Tertiär Nordwestsachsens–Ein Geologischer Überblick.–1–162; Sächsisches Landesamt Für Umwelt, Landwirtschaft und Geologie: Dresden, Germany, 2010. [Google Scholar]

- Malvadkar, S.B.; Forbes, S.; McGrul, G. Formation of coal resources. Encycl. Energy 2004, 1, 529–550. [Google Scholar] [CrossRef]

- Blodau, C. A review of acidity generation and consumption in acidic coal mine lakes and their watersheds. Sci. Total Environ. 2006, 369, 307–332. [Google Scholar] [CrossRef]

- Chaerun, S.K.; Jeremy, E.; Chaerun, R.I.; Fathira, R.L.; Toynbee, M.I.; Supandi, S.; Sato, T. Coal mine wastes: Effective mitigation of coal waste slurry and acid mine drainage through bioflocculation using mixotrophic bacteria as bioflocculants. Int. J. Coal Geol. 2023, 279, 104370. [Google Scholar] [CrossRef]

- Krümmelbein, J.; Bens, O.; Raab, T.; Anne Naeth, M. A history of lignite coal mining and reclamation practices in Lusatia, eastern Germany. Can. J. Soil Sci. 2012, 92, 53–66. [Google Scholar] [CrossRef]

- Beier, T.; Opp, C.; Hahn, J.; Zitzer, N. Sink and Source Functions for Metal(loid)s in Sediments and Soils of Two Water Reservoirs of the Ore Mountains, Saxony, Germany. Appl. Sci. 2022, 12, 6354. [Google Scholar] [CrossRef]

- Islam, N.; Rabha, S.; Subramanyam, K.; Saikia, B.K. Geochemistry and mineralogy of coal mine overburden (waste): A study towards their environmental implications. Chemosphere 2021, 274, 129736. [Google Scholar] [CrossRef]

- Mach, K.; Teodoridis, V.; Grygar, T.M.; Kvaček, Z.; Suhr, P.; Standke, G. An evaluation of palaeogeography and palaeoecology in the Most Basin (Czech Republic) and Saxony (Germany) from the late Oligocene to the early Miocene. Neues Jahrb. Geol. Paläontol. Abh. 2014, 272, 13–45. [Google Scholar] [CrossRef]

- Rascher, J.; Escher, D.; Fischer, J. Zur stratigraphischen Gliederung des obereozänen Hauptflözkomplexes (Thüringer und Bornaer Hauptflöz) in der Leipziger Bucht. Z. Dtsch. Ges. Geowiss. 2008, 159, 105–116. [Google Scholar]

- Pires, M.; Fiedler, H.; Teixeira, E.C. Geochemical distribution of trace elements in coal: Modelling and environmental aspects. Fuel 1997, 76, 1425–1437. [Google Scholar] [CrossRef]

- Dalm, M.; Buxton, M.; Van Ruitenbeek, F. Ore–waste discrimination in epithermal deposits using near-infrared to short-wavelength infrared (NIR-SWIR) hyperspectral imagery. Math. Geosci. 2019, 51, 849–875. [Google Scholar] [CrossRef]

- Desta, F.; Buxton, M. Image and point data fusion for enhanced discrimination of ore and waste in mining. Minerals 2020, 10, 1110. [Google Scholar] [CrossRef]

- Körting, F.; Hernandez, J.; Koirala, P.; Lehman, M.; Monecke, T.; Lindblom, D. Development of the HySpex hyperspectral drill core scanner: Case study on exploration core from the Au-rich LaRonde-Penna volcanogenic massive sulfide deposit, Quebec, Canada. Hyperspectral Imaging Appl. II 2023, 12338, 25–37. [Google Scholar] [CrossRef]

- Van Duijvenbode, J.; Cloete, L.; Shishvan, M.S.; Buxton, M. Material fingerprinting as a tool to investigate between and within material type variability with a focus on material hardness. Miner. Eng. 2022, 189, 107885. [Google Scholar] [CrossRef]

- Laukamp, C.; Rodger, A.; LeGras, M.; Lampinen, H.; Lau, I.C.; Pejcic, B.; Stromberg, J.; Francis, N.; Ramanaidou, E. Mineral physicochemistry underlying feature-based extraction of mineral abundance and composition from shortwave, mid and thermal infrared reflectance spectra. Minerals 2021, 11, 347. [Google Scholar] [CrossRef]

- Madejová, J.; Gates, W.P.; Petit, S. IR spectra of clay minerals. Dev. Clay Sci. 2017, 8, 107–149. [Google Scholar]

- Burns, R.G. Mineralogical Applications of Crystal Field Theory; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar]

- Van der Meer, F. Near-infrared laboratory spectroscopy of mineral chemistry: A review. Int. J. Appl. Earth Obs. Geoinf. 2018, 65, 71–78. [Google Scholar] [CrossRef]

- Clark, R.N.; King, T.V.; Klejwa, M.; Swayze, G.A.; Vergo, N. High spectral resolution reflectance spectroscopy of minerals. J. Geophys. Res. Solid Earth 1990, 95, 12653–12680. [Google Scholar] [CrossRef]

- Balachandran, M. Role of infrared spectroscopy in coal analysis—An investigation. Am. J. Anal. Chem. 2014, 2014, 45156. [Google Scholar] [CrossRef]

- Cepus, V.; Borth, M.; Seitz, M. IR spectroscopic characterization of lignite as a tool to predict the product range of catalytic decomposition. Int. J. Clean Coal Energy 2016, 5, 13. [Google Scholar] [CrossRef]

- Clark, R.N.; Curchin, J.M.; Hoefen, T.M.; Swayze, G.A. Reflectance spectroscopy of organic compounds: 1. Alkanes. J. Geophys. Res. Planets 2009, 114, E03001. [Google Scholar] [CrossRef]

- Langa, W.; Ndou, C.; Zieger, L.; Harris, P.; Wagner, N. Hyperspectral imaging of coal core: A focus on the visible-near-shortwave infrared (VN-SWIR) region. Int. J. Coal Geol. 2024, 284, 104456. [Google Scholar] [CrossRef]

- Lemiere, B. A review of pXRF (field portable X-ray fluorescence) applications for applied geochemistry. J. Geochem. Explor. 2018, 188, 350–363. [Google Scholar] [CrossRef]

- Jamieson, H.E.; Walker, S.R.; Parsons, M.B. Mineralogical characterization of mine waste. Appl. Geochem. 2015, 57, 85–105. [Google Scholar] [CrossRef]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Freedman, D.A. Statistical Models: Theory and Practice; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Tóth, G.; Hermann, T.; Da Silva, M.; Montanarella, L. Heavy metals in agricultural soils of the European Union with implications for food safety. Environ. Int. 2016, 88, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Hatch, J.; Gluskoter, H.; Lindahl, P. Sphalerite in coals from the Illinois Basin. Econ. Geol. 1976, 71, 613–624. [Google Scholar] [CrossRef]

- Petit, S.; Madejova, J.; Decarreau, A.; Martin, F. Characterization of octahedral substitutions in kaolinites using near infrared spectroscopy. Clays Clay Miner. 1999, 47, 103–108. [Google Scholar] [CrossRef]

- Uddin, M.K. A review on the adsorption of heavy metals by clay minerals, with special focus on the past decade. Chem. Eng. J. 2017, 308, 438–462. [Google Scholar] [CrossRef]

- Ugwu, I.M.; Igbokwe, O.A. Sorption of heavy metals on clay minerals and oxides: A review. Adv. Sorpt. Process Appl. 2019, 2019, 1–23. [Google Scholar] [CrossRef]

- Salisbury, J.W.; Wald, A. The role of volume scattering in reducing spectral contrast of reststrahlen bands in spectra of powdered minerals. Icarus 1992, 96, 121–128. [Google Scholar] [CrossRef]

- Liu, H.-C.; Hsieh, J.-Y.; Chen, Y.-H.; You, C.-F.; Jiang, W.-T.; Wen, H.-Y. Adsorption and Desorption Behaviors of Sr on Montmorillonite: A Triple Sr Isotope Perspective. ACS Earth Space Chem. 2022, 6, 2250–2260. [Google Scholar] [CrossRef]

- Pineau, M.; Mathian, M.; Baron, F.; Rondeau, B.; Deit, L.L.; Allard, T.; Mangold, N. Estimating kaolinite crystallinity using near-infrared spectroscopy: Implications for its geology on Earth and Mars. Am. Mineral. 2022, 107, 1453–1469. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kamps, O.; Desta, F.; Maghsoudi Moud, F.; Buxton, M. Multi-Level Characterization of Lignite Mine Waste by the Integration of Wide Wavelength Range Infrared Spectroscopy. Mining 2024, 4, 588-612. https://doi.org/10.3390/mining4030033

Kamps O, Desta F, Maghsoudi Moud F, Buxton M. Multi-Level Characterization of Lignite Mine Waste by the Integration of Wide Wavelength Range Infrared Spectroscopy. Mining. 2024; 4(3):588-612. https://doi.org/10.3390/mining4030033

Chicago/Turabian StyleKamps, Oscar, Feven Desta, Fardad Maghsoudi Moud, and Mike Buxton. 2024. "Multi-Level Characterization of Lignite Mine Waste by the Integration of Wide Wavelength Range Infrared Spectroscopy" Mining 4, no. 3: 588-612. https://doi.org/10.3390/mining4030033

APA StyleKamps, O., Desta, F., Maghsoudi Moud, F., & Buxton, M. (2024). Multi-Level Characterization of Lignite Mine Waste by the Integration of Wide Wavelength Range Infrared Spectroscopy. Mining, 4(3), 588-612. https://doi.org/10.3390/mining4030033