The Dresden Model of Adaptability: A Holistic Approach to Human-Centeredness, Resilience, Sustainability, and the Impact on the Sustainable Development Goals in the Era of Industry 5.0

Abstract

1. Introduction

2. State of the Art

2.1. Adaptability of Production Systems

2.2. Conserving Resources in Production Systems

2.3. Related Work on Sustainability Development Goals and the Influence of Manufacturing

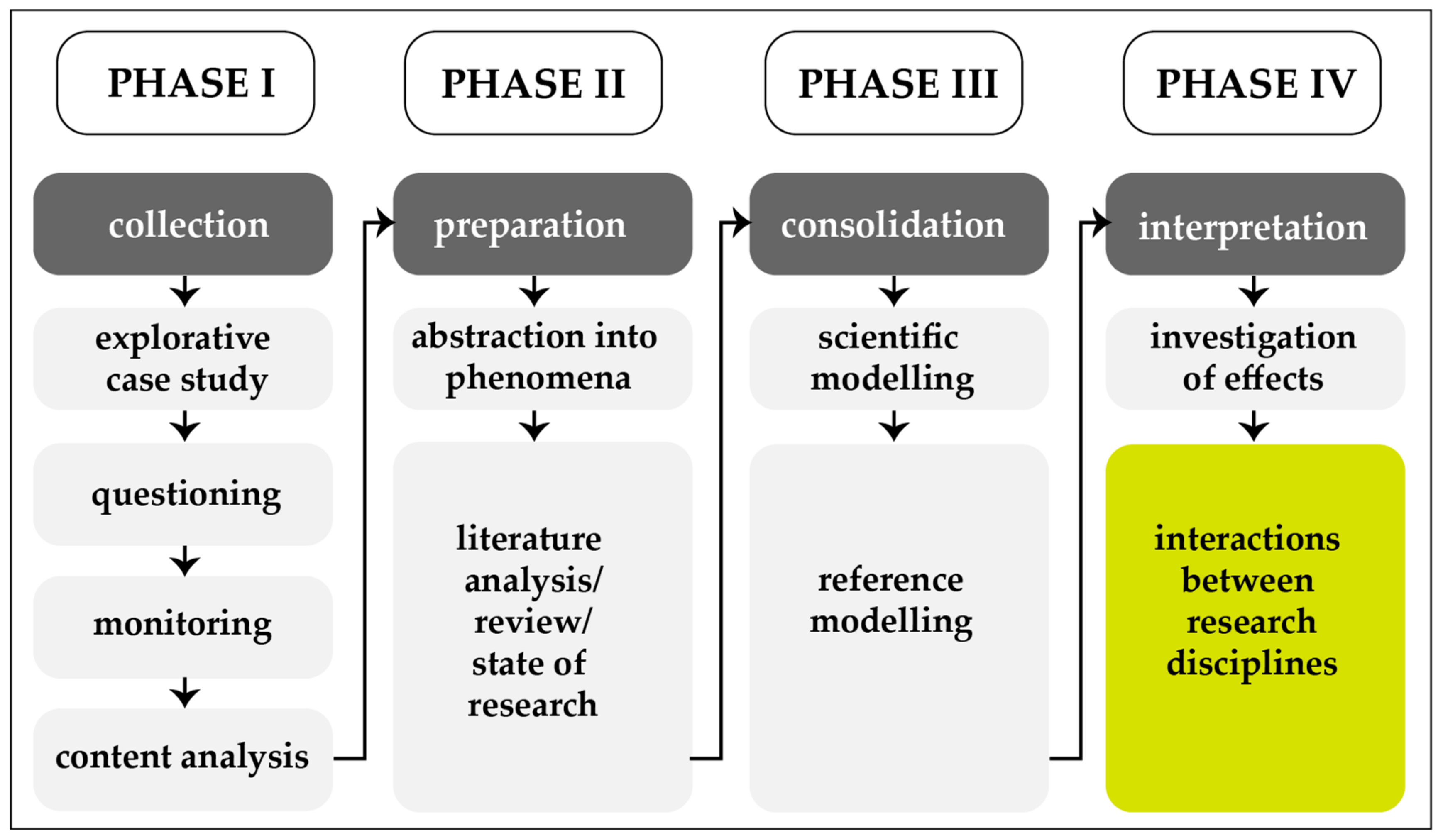

3. Research Methods

4. The Materials and Models That Are Used

4.1. Dresden Model of Adaptability and Its Components

4.2. Assignment of the SDGs to the Overarching Sustainability Aspects

5. Investigation of the Correlation of DreMoWabe to Sustainability Dimensions and Their Goals

5.1. Examples of Use and Possible Combinations of the Model

5.2. Presentation of the Causal Relationship between DreMoWabe and the Sustainability Goals and Their Overarching Dimensions

5.2.1. Coding: Human–Mobile–Company Level

5.2.2. Coding: Technology–Modular–Factory Level

5.2.3. Summary of Other Positive Interactions

6. Critical Consideration of the Effects of DreMoWabe on Sustainability

7. Conclusions and Research Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission: Directorate-General for Research and Innovation; Breque, M.; de Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Brüssel, Belgium, 2021.

- Bundesministerium für Wirtschaft und Klimaschutz. Was Ist Industrie 4.0? Available online: https://www.plattform-i40.de/IP/Navigation/DE/Industrie40/WasIndustrie40/was-ist-industrie-40.html (accessed on 27 February 2024).

- European Commission, Directorate-General for Research and, Innovation; Renda, A.; Schwaag Serger, S.; Tataj, D.; Morlet, A.; Isaksson, D.; Martins, F.; Mir Roca, M.; Hidalgo, C.; Huang, A.; et al. Industry 5.0, a Transformative vision for Europe: Governing Systemic Transformations towards a Sustainable Industry; ESIR Policy Brief No. 3; Publications Office of the European Union: Brüssel, Belgium, 2021.

- Bundesministerium für wirtschaftliche Zusammenarbeit und Entwicklung (BMZ). Nachhaltig in die Zukunft: Das Initiativprogramm Agenda 2030; Referat 410; Agenda 2030 für nachhaltige Entwicklung; Bundesministerium für wirtschaftliche Zusammenarbeit und Entwicklung (BMZ): Bonn, Germany, 2019.

- United Nations. The Sustainable Development Goals Report 2023: Special Edition; Towards a Rescue Plan for People and Planet; United Nations: New York, NY, USA, 2023.

- Jäpel, N.; Bielitz, P.; Stoll, E.; Reichelt, D. DreMoWabe—Dresdner Modell der Wandlungsbefähigung. Z. Wirtsch. Fabr. 2024, 119, 432–439. [Google Scholar] [CrossRef]

- Kropp, A. (Ed.) Die Dimensionen der Nachhaltigkeit. In Essentials, Grundlagen der Nachhaltigen Entwicklung: Handlungsmöglichkeiten und Strategien zur Umsetzung, 1st ed.; Springer Gabler: Wiesbaden, Germany, 2019; pp. 11–12. [Google Scholar]

- Herath, H.; Rathnayake, R. A Critical Approach towards Sustainable Development Models—A Review. Int. J. Agric. Innov. Res. 2019, 7, 446–454. [Google Scholar]

- Morales, R.H. Systematik der Wandlungsfähigkeit in der Fabrikplanung. Dissertation, VDI Verlag GmbH, Düsselsdorf, Germany, 2003. [Google Scholar]

- Lanza, G.; Nyhuis, P.; Fisel, J.; Jacob, A.; Nielsen, L.; Schmidt, M.; Stricker, N. Wandlungsfähige, Menschzentrierte Strukturen in Fabriken und Netzwerken der Industrie 4.0: Acatech Studie; Herbert Utz Verlage: München, Germany, 2018. [Google Scholar]

- Steegmüller, D.; Zürn, M. Wandlungsfähige Produktionssysteme für den Automobilbau der Zukunft. In Springer NachschlageWissen, Handbuch Industrie 4.0: Produktion, Automatisierung und Logistik; Vogel-Heuser, B., Bauernhansl, T., Hompel, M.T., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2015; pp. 1–18. Available online: https://link.springer.com/referenceworkentry/10.1007/978-3-662-45537-1_23-1 (accessed on 15 April 2024).

- Bauernhansl, T.; Fechter, M.; Dietz, T. (Eds.) Entwicklung, Aufbau und Demonstration einer Wandlungsfähigen (Fahrzeug-) Forschungsproduktion; Springer Vieweg: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Jürgensmeyer, N.; Osenberg, D.; Reitze, A.; Riese, J.; Lier, S. Entwicklung eines Transformationsmodells—Modularisierung schrittweise gedacht. Chem. Ing. Tech. 2020, 92, 1998–2004. [Google Scholar] [CrossRef]

- Heinen, T.; Rimpau, C.; Wörn, A. Wandlungsfähigkeit als Ziel der Produktionssystemgestaltung. In Wandlungsfähige Produktionssysteme: Heute die Industrie von Morgen Gestalten; Nyhuis, P., Reinhart, G., Abele, E., Eds.; PZH Produktionstechnisches Zentrum: Garbsen, Germany, 2008; pp. 19–32. [Google Scholar]

- Jäpel, N.; Bielitz, P.; Reichelt, D. Beschreibung und Bewertung der Wandlungsfähigkeit: Mit Fokus auf produzierenden mittleren Unternehmen. Z. Wirtsch. Fabr. 2023, 118, 10–14. [Google Scholar] [CrossRef]

- Bielitz, P.; Jäpel, N.; Heik, D.; Reichelt, D. Ganzheitliche Wandlungsfähigkeit von Produktionssystemen—Der Schlüssel zur Ressourcenwende? HMD Prax. Wirtsch. 2023, 60, 1222–1236. [Google Scholar] [CrossRef]

- Ulich, E. Arbeitspsychologie; vdf Hochschulverlag: Zollikon, Switzerland, 2020. [Google Scholar]

- Hinterberger, F. Ressourcenschutz ist nicht nur der beste Klimaschutz. Fact. Mag. Nachhalt. Wirtsch. 2022, 18, 9–15. [Google Scholar]

- Akenji, L.; Bengtsson, M. Making Sustainable Consumption and Production the Core of Sustainable Development Goals. Sustainability 2014, 6, 513–529. [Google Scholar] [CrossRef]

- Malcolm, P.; Louise, S.; Thurley, A.; Killmeyer-Oleche, A.; Sorensen, B.; De Marco, N. Delivering the Sustainable Development Goals: Seizing the Opportunity in Global Manufacturing. 2017. Available online: https://www.pwc.com/m1/en/publications/documents/delivering-sustainable-development-goals.pdf (accessed on 15 April 2024).

- Klandt, H.; Heidenreich, S. Empirische Forschungsmethoden in der Betriebswirtschaftslehre: Von der Forschungsfrage zum Untersuchungsdesign, Eine Einführung; De Gruyter Oldenbourg: Berlin/Boston, Germany, 2017. [Google Scholar]

- Pyo, J.; Lee, W.; Choi, E.Y.; Jang, S.G.; Ock, M. Qualitative Research in Healthcare: Necessity and Characteristics. J. Prev. Med. Public Health 2023, 56, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Fleischmann, A.; Oppl, S.; Schmidt, W.; Stary, C. Ganzheitliche Digitalisierung von Prozessen: Perspektivenwechsel—Design Thinking—Wertegeleitete Interaktion; Springer Vieweg: Wiesbaden, Germany, 2018. [Google Scholar]

- Becker, J.; Delfmann, P. (Eds.) Referenzmodellierung: Grundlagen, Techniken und domänenbezogene Anwendung; Physica-Verlag HD: Heidelberg, Germany, 2004. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; A/RES/70/1; United Nations: New York, NY, USA, 2015. Available online: https://digitallibrary.un.org/record/3923923?ln=en (accessed on 16 April 2024).

- Mangukiya, R.D.; Sklarew, D.M. Analyzing three pillars of sustainable development goals at sub-national scales within the USA. World Dev. Sustain. 2023, 2, 100058. [Google Scholar] [CrossRef]

- Deni Design. Logo-Vorlage für nachhaltige Entwicklungsziele. Available online: https://de.vecteezy.com/search-de?content_type=vector&qterm=hintergrund%E2%80%9Dhintergrund-vektoren-von-vecteezy (accessed on 16 April 2024).

- Böhm, S.A.; Götz, T.; Baumgärtner, M.K. Social Health@Work: Eine Studie zur Auswirkung der Digitalisierung der Arbeitswelt auf die Gesundheit der Beschäftigten in Deutschland: BARMER. 2020. Available online: https://www.alexandria.unisg.ch/entities/publication/74bacbc7-3be3-4ff8-97cd-378073ee469d/details (accessed on 16 April 2024).

- Stein Baker, M. Gender Inequality—How Online Learning and Remote Work Could Level the Playing Field for Women. Available online: https://www.weforum.org/agenda/2023/06/online-learning-remote-work-gender-gap/ (accessed on 12 March 2024).

- Auth, M.; Held, G. Remote Work im Grenzüberschreitenden Kontext: Ergebnisse Einer Qualitativen Unternehmensbefragung zu Herausforderungen und Lösungen, 2022. Available online: https://www.rkw-kompetenzzentrum.de/publikationen/studie/remote-work-im-grenzueberschreitenden-kontext/ (accessed on 30 April 2024).

- Flüter-Hoffmann, C.; Traub, P. Menschen mit Behinderungen im Homeoffice—Erleichterung für die Inklusion?: Eine Gegenüberstellung von Deutschland und einigen angelsächsischen Ländern. 2023. Available online: https://www.iwkoeln.de/studien/christiane-flueter-hoffmann-menschen-mit-behinderungen-im-homeoffice-erleichterung-fuer-die-inklusion.html (accessed on 30 April 2024).

- Landesamt für politische Bildung Baden-Württemberg. 17 SDGs: Ziele für Nachhaltige Entwicklung: Agenda 2030: Sustainable Development Goals der Vereinten Nationen. Dossier. Available online: https://www.lpb-bw.de/17-sdgs#c100660 (accessed on 12 March 2024).

- Tao, Y.; Yang, L.; Jaffe, S.; Amini, F.; Bergen, P.; Hecht, B.; You, F. Climate mitigation potentials of teleworking are sensitive to changes in lifestyle and workplace rather than ICT usage. Proc. Natl. Acad. Sci. USA 2023, 120, e2304099120. [Google Scholar] [CrossRef] [PubMed]

- Europäisches Parlament. Kreislaufwirtschaft: Definition und Vorteile. Available online: https://www.europarl.europa.eu/news/de/headlines/economy/20151201STO05603/kreislaufwirtschaft-definition-und-vorteile (accessed on 29 March 2023).

- Hellmich, A.; Zumpe, F.; Zumpe, M.; Münnich, M.; Wiese, T.; Büttner, T.; Ihlenfeldt, S.; Foith-Förster, P.; Trierweiler, M.; Ranke, D.; et al. Umsetzung von cyber-physischen Matrixproduktionssystemen. In Forschungsbeirat Industrie 4.0; acatech–Deutsche Akademie der Technikwissenschaften: Munich, Germany, 2022. [Google Scholar]

- Randecker, L.; Heinzel, V.; Engstler, M. Remote Work als Standard, auch nach der Pandemie. In GI-Edition. Proceedings, Volume P-327, Projektmanagement und Vorgehensmodelle 2022 (PVM 2022): Virtuelle Zusammenarbeit und verlorene Kulturen?: Gemeinsame Tagung der Fachgruppen Projektmanagement (WI-PM) und Vorgehensmodelle (WI-VM) im Fachgebiet Wirtschaftsinformatik der Gesellschaft für Informatik e.V. in Kooperation mit der Fachgruppe IT-Projektmanagement der GPM e.V. und dem PMI Germany Chapter e.V. Trier 2022; Masud, F.-B., Oliver, L., Alexander, V., Enes, Y., Martin, E., Martin, B., Axel, K., Eds.; Gesellschaft für Informatik e.V. (GI): Bonn, Germany, 2022; pp. 63–77. [Google Scholar]

- Comella-Dorda, S.; Garg, L.; Thareja, S.; Vasquez-McCall, B. Revisiting Agile Teams after an Abrupt Shift to Remote: Organization Practice. 2020. Available online: https://www.mckinsey.com/capabilities/people-and-organizational-performance/our-insights/revisiting-agile-teams-after-an-abrupt-shift-to-remote#/ (accessed on 16 April 2024).

- Redaktion Böckler Impuls. Homeoffice Stärkt Tradierte Arbeitsteilung; Böckler Impuls: Düsseldorf, Germany, 2020; p. 2. [Google Scholar]

- Jahn, S.; Boberach, M.; Till, V. Digitales Leben: Rollenbilder und Geschlechterunterschiede im Privaten, Professionellen und im Zwischenmenschlichen. 2020. Available online: https://www.heise.de/downloads/18/2/9/9/3/8/0/6/studie_digitales_leben.pdf (accessed on 16 April 2024).

- Emanuel, N.; Harrington, E. Working Remotely? Selection, Treatment, and the Market for Remote Work; No. 1061; Federal Reserve Bank of New York Staff Reports: New York, NY, USA, 2023. [Google Scholar]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; Planbureau voor de Leefomgeving: The Hague, The Netherlands, 2017. [Google Scholar]

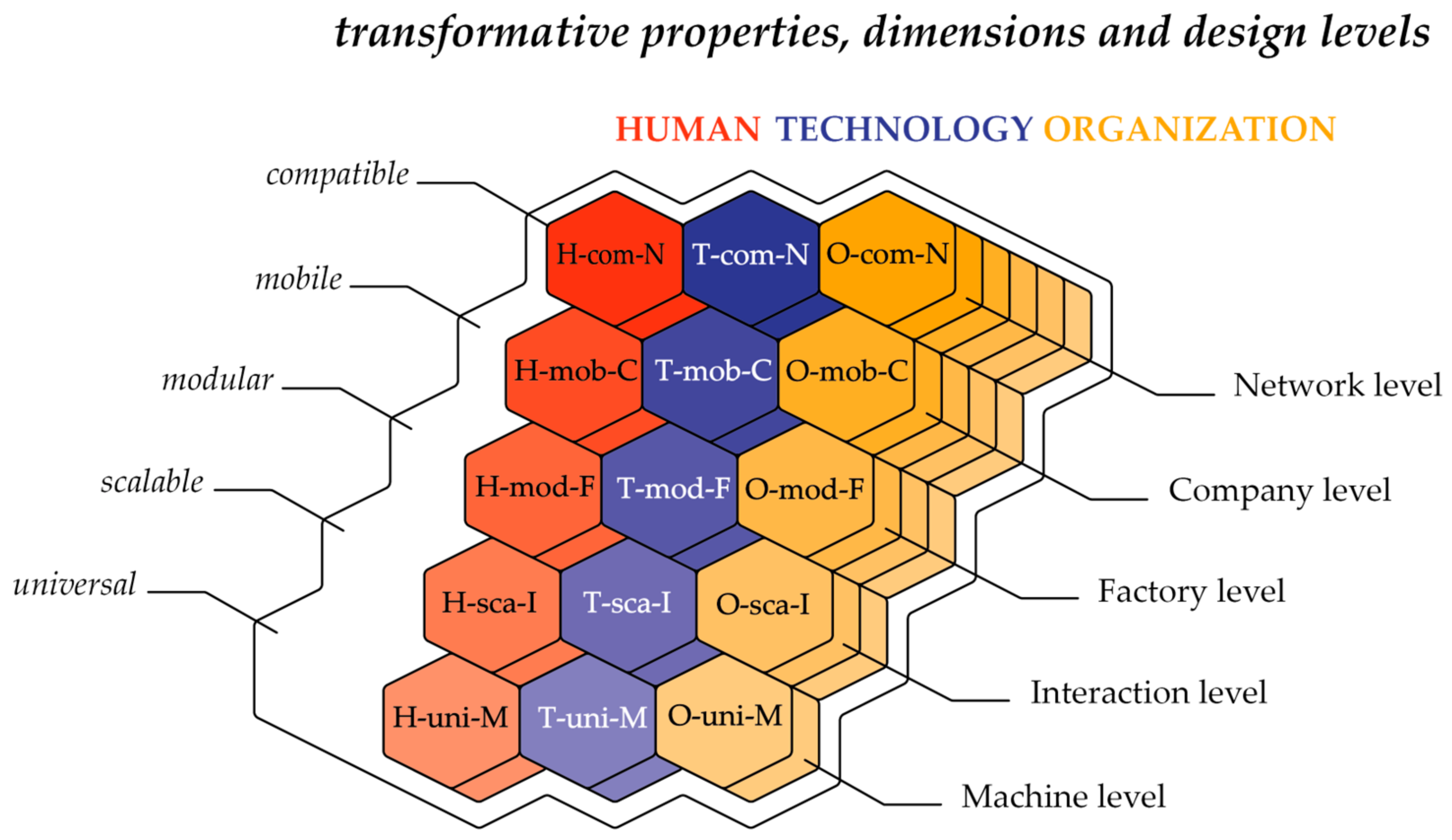

| H-com-N | T-com-N | O-com-N |

| Adaptability of employees to change work tasks due to the opening and flexibilization of the value chain | Integration capability and networkability of systems, production, and assembly stations across company boundaries | Compatibility of corporate goals with those of the value creation network |

| H-mob-C | T-mob-C | O-mob-C |

| Local independence for the completion of work tasks | Local mobility of objects as well as production and assembly assets in industrial production/processing | Local mobility of organizational units |

| H-mod-F | T-mod-F | O-mod-F |

| Allocability of qualification and further training measures for employees | Divisibility and interaction capability of production components | Divisibility and reconfigurability of process flows and the necessary authorizations and qualification requirements |

| H-sca-I | T-sca-I | O-sca-I |

| Expandability or reducibility of the interaction of hybrid teams from the employees’ perspective | Expandability or reducibility of the interaction of hybrid teams in terms of hardware and software | Expandability or reducibility of the interaction of hybrid teams from an organizational perspective |

| H-uni-M | T-uni-M | O-uni-M |

| Universal deployability of employees on various machines, modules, and systems | Universal applicability of machines and systems for a wide range of work processes | Universal applicability of processes and workflows to production changes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jäpel, N.; Bielitz, P.; Reichelt, D. The Dresden Model of Adaptability: A Holistic Approach to Human-Centeredness, Resilience, Sustainability, and the Impact on the Sustainable Development Goals in the Era of Industry 5.0. Digital 2024, 4, 726-739. https://doi.org/10.3390/digital4030037

Jäpel N, Bielitz P, Reichelt D. The Dresden Model of Adaptability: A Holistic Approach to Human-Centeredness, Resilience, Sustainability, and the Impact on the Sustainable Development Goals in the Era of Industry 5.0. Digital. 2024; 4(3):726-739. https://doi.org/10.3390/digital4030037

Chicago/Turabian StyleJäpel, Nicole, Pia Bielitz, and Dirk Reichelt. 2024. "The Dresden Model of Adaptability: A Holistic Approach to Human-Centeredness, Resilience, Sustainability, and the Impact on the Sustainable Development Goals in the Era of Industry 5.0" Digital 4, no. 3: 726-739. https://doi.org/10.3390/digital4030037

APA StyleJäpel, N., Bielitz, P., & Reichelt, D. (2024). The Dresden Model of Adaptability: A Holistic Approach to Human-Centeredness, Resilience, Sustainability, and the Impact on the Sustainable Development Goals in the Era of Industry 5.0. Digital, 4(3), 726-739. https://doi.org/10.3390/digital4030037