Abstract

Nanocellulose can be obtained from low-cost sources and has been extensively studied in the last decades due to its biodegradability, biocompatibility, low weight, large specific surface area, and good mechanical and optical properties. The nanocellulose properties palette can be greatly expanded by incorporating different metals, metal oxides or carbon nanomaterials, with the formation of multifunctional hybrids. Nanocellulose–nanocarbon hybrids are emerging nanomaterials that can respond to many current challenges in areas such as water purification, energy storage and conversion, or biomedicine for drug delivery, tissue engineering, antitumor and antimicrobial therapies, and many others. Although nanocellulose–nanodiamonds hybrids are still in their infancy, these nanomaterials are extremely promising for applications requiring good thermal conductivity and mechanical strength along with optical transparency. A strong increase in the thermal conductivity of a nanocellulose film of about 150 times was obtained after the addition of 90 wt% single-crystal nanodiamonds and a 70% increase in the Young’s modulus of nanocellulose films was produced by the addition of 5 wt% nanodiamonds. Therefore, in this review, data related to the manufacturing routes, main properties, and applications of nanocellulose–nanodiamonds hybrids are presented and discussed. This review paves the way for new methods and procedures to obtain nanocellulose–nanodiamonds hybrids better adapted to practical needs.

1. Introduction

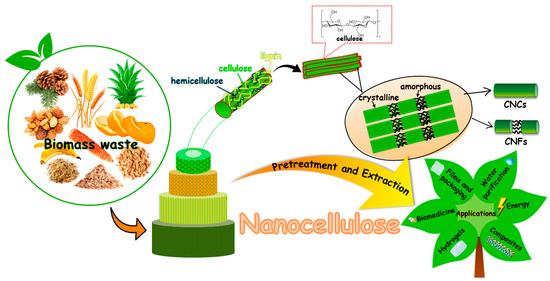

Cellulose, the most widespread biopolymer on the planet, lives a new youth through nanocellulose, the nanomaterial obtained from cellulose by mechanical, enzymatic and/or chemical treatments [1,2,3]. Cellulose can be extracted from a multitude of sources, including plants, algae or tunicates, and can also be synthesized by bacteria. The extraction of cellulose from agricultural, forestry, and industrial wastes has received much attention due to both economic and environmental advantages [1,4,5,6]. Agricultural waste and industrial byproducts such as wheat straw, rice husk and straw, corn cob, sunflower shells, barley straw, sugarcane bagasse, legume straw, fruit seed shells, and others were used in recent works as sources for the production of nanocellulose, demonstrating the huge interest in this new feedstock [5,6,7,8].

Due to the possibility of isolation from low-cost sources, low weight, high strength and rigidity, biodegradability, and biocompatibility, nanocellulose has been extensively studied in the last decades [1,2,3,4,5,6]. Compared to cellulose, nanocellulose presents a much higher specific surface area, superior chemical reactivity due to the greater number of -OH groups located on its surface which are available for chemical modification reactions, superior tensile strength and specific modulus of elasticity, as well as improved optical transparency [9,10]. Nanocellulose is a generic term used to describe the cellulosic materials having at least one dimension in the nanometric range (<100 nm) that include cellulose nanocrystals (CNCs), cellulose nanofibers or nanofibrillated cellulose (CNFs), and bacterial cellulose (BC) (Figure 1) [1,3,11,12,13]. The list of nanocellulose’s applications is long and it is growing fast [14]. To mention just a few, so far nanocellulose has found its way as a reinforcing agent in (bio)polymer nanocomposites [3,15], as key-component in the preparation of drug-delivery systems, wound dressings, and other biomedical products [1,12,16], in the fabrication of paper or textiles with special properties [17], in the food industry (as stabilizer, emulsifier, or thickener) [18], in water purification [19], cosmetics [20] or electronics [21]. While in most of these applications, nanocellulose acts as filler or modifier for polymeric or non-polymeric matrices, it can also serve as a dispersing agent or matrix.

Figure 1.

Nanocellulose extraction from agricultural waste, forestry residues and food industry by-products.

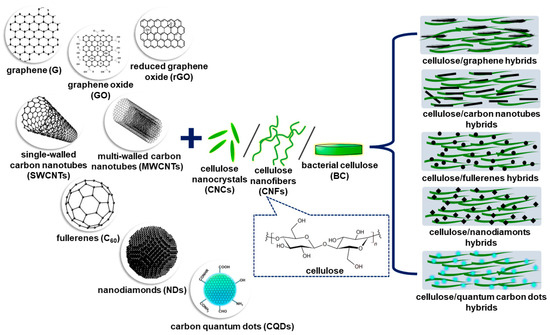

Hybrid materials, which are organic–inorganic materials assembled at the nanometer or molecular level, have shown remarkable advances in the last decades due to the progress in nanotechnology [22,23]. Nanocellulose, unmodified or surface-modified by various chemical routes, may be coupled with different metals, metal oxides or carbon nanomaterials with the formation of multifunctional hybrids [24]. From these, nanocellulose–nanocarbon hybrids obtained by the association of nanocellulose (in the form of CNCs, CNFs or BC) with carbon nanomaterials (e.g., graphene (G), carbon nanotubes (CNTs), nanodiamonds (NDs), fullerenes (C60), carbon nanofibers, carbon quantum dots (CQDs) (Figure 2) [25] have gained particular interest due to the advantages arising from combining the bio-based origin, biodegradability, non-toxicity, and good water dispersion of cellulose with the remarkable mechanical strength, electrical conductivity, and/or thermal conductivity of the carbon-based nanomaterials. Due to their outstanding properties, these hybrids have potential uses in a variety of applications in biomedicine, as well as in the manufacture of functional composites, sensors, electrically conductive films, energy storage devices, adsorbents, catalysts, coatings, and others [26].

Figure 2.

Nanocellulose–nanocarbon hybrids containing different types of carbon nanomaterials.

Graphene consists of a single layer of sp2 hybridized carbon atoms arranged in a two-dimensional (2D) honeycomb network [27,28]. The special interest given to this material is due to its reduced thickness, low weight, high specific surface area, optical transparency, excellent electrical and thermal conductivity, and particularly high modulus of elasticity, of approximately 1060 GPa [29]. In particular, aerogels obtained from 2,2,6,6-tetramethylpiperidine-1-oxyl (TEMPO)-oxidized CNFs and graphene showed a specific capacitance of 361.74 F/g at a current density of 0.5 A/g after combustion at 1100 °C, being recommended as electrode materials for supercapacitors [30]. The exceptional thermal and electrical conductivity of G can be attributed to the delocalized π electrons from the graphene plane that can move freely in the graphene structure [28]. A disadvantage of graphene is, however, its strong tendency to agglomerate due to the van der Waals interactions and π–π stacking interactions that arise between the graphene layers. Graphene oxide (GO) is a derivative of graphene resulting from the oxidation–exfoliation of graphite. It can be described as a single layer of graphite bearing carboxyl (-COOH), hydroxyl (-OH), epoxy, and ketone (-C(=O)-) functional groups on its surface [27]. Due to the presence on its surface of these polar groups and the repulsive forces that are established between the negatively charged -COO− groups, GO presents a better dispersion in aqueous media than graphene and a higher ability to form composites with hydrophilic polymers [31]. However, the electrical and thermal conductivity of GO is much lower compared to those of graphene due to structural defects induced by the generation of oxygen-bearing groups on its surface [32]. Reduced graphene oxide (rGO) results from an exfoliation–reduction process of GO and greatly recovers the good electrical conductivity of pure graphene [27].

Carbon nanotubes are tubular materials formed by rolling a single graphene sheet, in the case of single-walled carbon nanotubes (SWCNTs), or several graphene sheets, in the case of multi-walled carbon nanotubes (MWCNTs). CNTs are characterized by high aspect ratio and specific surface as well as excellent mechanical and electrical properties [33]. Similar to graphene, CNTs are difficult to disperse in water and organic solvents, having a strong tendency to agglomerate due to the multiple van der Waals-type interactions and π–π stacking forces which lead to a decrease in their specific surface area and electrical and optical properties [34]. Fullerenes are another type of carbon nanomaterial that are considered an allotrope of carbon. They have the form of closed hollow cages consisting of sp2 hybridized carbon atoms [25]. Regardless of their type, carbon-based nanomaterials are expensive and difficult to process due to their strong aggregation tendency [35,36]. Nanocellulose can act as a support or dispersing agent for carbon-based nanomaterials to increase their colloidal stability in aqueous media and thus, their processability into final products [35,37]. Furthermore, nanocellulose is cheaper as compared to C60, G, CNTs, or NDs, which means that a lower cost of production is obtained for the final hybrid materials than for the ones based entirely on nanocarbon. On the other hand, the association of nanocellulose with carbon nanomaterials confers new functionalities to nanocellulose-based materials (e.g., electrical conductivity, thermal conductivity, antibacterial activity etc.), opening the way to new applications.

Nanocellulose–nanocarbon hybrids containing G, GO, rGO, CNTs, C60, or CQDs have been intensively studied and are the subject of detailed reviews [22,25,37,38,39,40]. The application of these materials in various fields is determined by the interactions arising between the components of the hybrids [22]. In particular, good electrical and mechanical properties were obtained in the case of TEMPO oxidized CNFs–CNTs hybrids due to the hydrogen bonding interactions arising between the hydroxyl groups of CNFs and the carboxyl groups from the surface of CNTs [41]. Moreover, the van der Waals forces between the carbon nanomaterials and the hydrophobic backbone of nanocellulose also improve the stability of the hybrids [22]. Additionally, electrostatic or hydrophobic interactions may occur in these hybrid systems, enhancing their properties and stability [22].

It is worth remarking that nanocellulose–nanodiamonds hybrids are still in their infancy as less than 20 papers on this topic have been published so far. Although the literature on these nanohybrids is not very extensive their importance in many fields seems to be great. Therefore, in the following, data related to the nanocellulose–nanodiamonds hybrid materials are presented and discussed for a clearer picture of the stage reached so far and the shortcomings that must be overcome. The data presented in this review regarding the manufacturing routes, main properties, and applications of nanocellulose–nanodiamonds hybrids pave the way for more targeted research and better adapted solutions to practical needs.

2. Nanocellulose–Nanodiamonds Hybrids

2.1. Nanocellulose

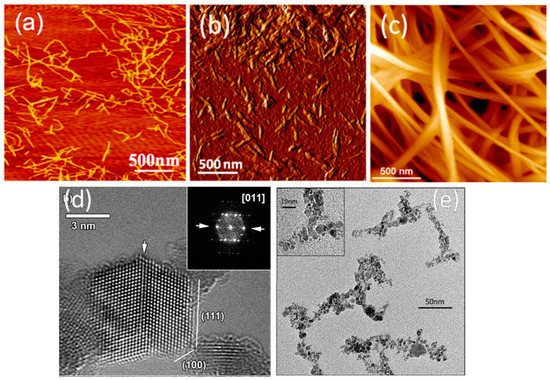

CNCs, CNFs and BC are characterized by different aspect ratios and cross sectional morphology, depending on the source of cellulose and the methods used for their synthesis or extraction [42]. CNCs are obtained by the acid hydrolysis of different cellulose sources using strong acid solutions of various concentrations, and controlled temperature [1,5]. Due to being obtained by the acid hydrolysis of the amorphous regions from cellulose, CNCs are characterized by a high crystallinity, superior mechanical strength, and a thermal stability dependent on the type of acid used for hydrolysis. In particular, the acid hydrolysis of cellulose with sulfuric acid leads to the generation of sulphate groups on the surface of CNCs which were shown to decrease the thermal stability of CNCs [5]. In general, CNCs exhibit a couple of nanometers in width and hundreds of nanometers in length, which endows them with aspect ratio values from 10 to more than 50 [42]. As CNFs and BC, CNCs are assemblies of cellulose elementary fibrils packed into microfibrils. Intermolecular and intramolecular hydrogen bonds along with van der Waals forces keep the cellulose chains aggregated in microfibrils. The polymeric chains of cellulose are made up of D-anhydroglucose units linked together by β-1,4-glycosidic bonds, each D-anhydroglucose unit being rotated 180° in relation to the previous unit. Two units of D-anhydroglucose linked together by β-1,4-glycosidic bonds form the disaccharide called cellobiose, which is considered the repeating unit of cellulose [43]. Each D-anhydroglucose unit in cellulose possesses three -OH groups that may participate in the formation of hydrogen bonds both intramolecularly and intermolecularly endowing nanocellulose with high crystallinity and stiffness as well as insolubility in water and most organic solvents [44,45,46].

CNFs are obtained by the mechanical disintegration of the cellulose bundles from cellulose sources that were previously treated using chemical, enzymatic, or other mechanical methods [5,12,47,48]. As compared to CNCs, CNFs are characterized by a higher aspect ratio and lower crystallinity due to the different processes employed in their isolation. Additionally, as a consequence of the lower degree of crystallinity and higher lengths, CNFs possess superior flexibility when compared to CNCs. However, the morphological characteristics, thermal, and mechanical properties of CNFs strongly depend on the cellulose source [5]. Recent studies have shown that the CNFs obtained from agricultural waste or industrial by-products have similar performance to wood-based CNFs and the isolation process is more efficient due to their lower lignin content [6,12]. This is of huge importance in the promotion of new sources and methods for the CNFs’ production.

The nanocelluloseknown under the name of microbial cellulose or bacterial cellulose (BC) is synthesized as an exo-polysaccharide by different species of bacteria following the metabolism of various carbon sources, such as glucose, sucrose, fructose, mannitol, sorbitol, etc. While the most commonly exploited species for the production of BC remains Komagataeibacter (formerly Gluconacetobacter) xylinus [49], BC can also be produced by other bacterial species such as Aerobacter, Agrobacterium, Alcaligenes, Azobacter, Gluconobacter, Pseudomonas, etc. [1,15]. BC consists of an ultrafine network of nanofibers with a ribbon-like appearance, having a diameter of 20–100 nm and a length of 1–10 μm and, therefore, a higher aspect ratio compared to other types of nanocelluloses [50]. Compared to nanocellulose isolated from plants, BC shows a higher purity and degree of crystallinity due to the lack of hemicellulose and lignin impurities, two polymers found alongside cellulose in the plant cell walls [51]. Moreover, its mechanical properties are higher than those of plant-derived nanocelluloses [15,16]. Additionally, BC shows good biocompatibility, non-toxicity, and increased water retention capacity [52]. Due to its high purity, high water-holding capacity, and superior mechanical strength, BC is the preferred nanocellulose for biomedical applications [3]. The nanofibrillar network structure of BC enriches it with distinct features for medical and industrial applications such as bioseparation, scaffolding, immobilization reactions, drug delivery, and others [3,15]. The atomic force microscopy (AFM) images of cellulose nanofibers, cellulose nanocrystals, and bacterial cellulose are shown in Figure 3a–c.

2.2. Nanodiamonds

NDs are three-dimensional carbon nanomaterials characterized by remarkable mechanical properties, optical transparency, fluorescence, high heat conductivity, biocompatibility, and non-toxicity; therefore, they are suitable for multiple applications in both industrial and biomedical areas [53,54]. NDs consist of a tridimensional (3D) lattice of covalently bonded sp3 carbon atoms (tetrahedral hybridization), which confers excellent hardness, rigidity, incompressibility, a low friction coefficient, and high chemical resistance (Figure 3d,e) [55,56,57]. However, nanodiamonds also contain sp2 hybridized carbon as surface termination due to surface reconstruction [53,56]. The NDs’ properties can be improved by applying different surface treatments, modifying the preparation conditions, or by compounding NDs with other materials. The particle size and shape, surface functionalization, and the presence of defects such as vacancies or impurity atoms significantly influence the properties of NDs and their application fields [55]. NDs with perfect crystalline structure and tiny amounts of graphitic shell may be obtained by different purification methods [53,56]. In Figure 3d, a transmission electron microscopy image showing the highly ordered NDs core and the main surface facets of the NDs particles, {111} and {100}-like, witha scarce presence of sp and sp2 carbon atoms is shown [56].

Figure 3.

AFM images of (a) cellulose nanofibers (CNFs), (b) cellulose nanocrystals (CNCs) and (c) bacterial cellulose (BC) [51]; Transmission electron micrograph showing the ordered nanodiamond core and a minimal presence of non-sp3 carbon atoms. Reprinted with permission from [56]. Copyright 2011 American Chemical Society (d); Transmission electron microscopy image of nanodiamond particles. Reprinted with permission from [57]. Copyright 2018 American Chemical Society (e).

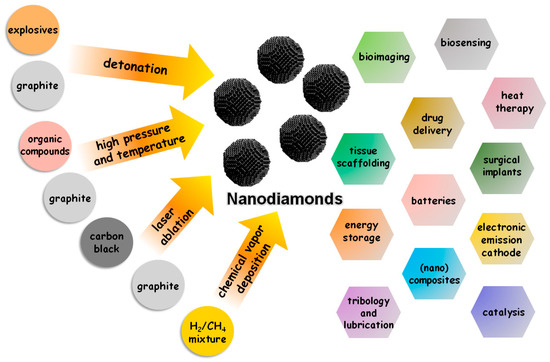

NDs can be obtained by the detonation of a graphite source or a carbon-rich explosive, or by the shock compression of graphite or organic compounds under high pressure and temperature followed, or not, by ball milling, which are the methods preferred at an industrial scale (Figure 4) [53,58]. Other methods to obtain NDs include laser ablation applied to a graphite or carbon black source, plasma-assisted chemical vapor deposition, ion irradiation of graphite, and others [53,58].

Figure 4.

Schematic representation of NDs fabrication routes and main applications of NDs.

As they combine a high thermal conductivity with electrical insulation properties, NDs can solve several problems related to the market needs for efficient heat dissipation and prevention of overheating in electronic devices. Therefore, the addition of NDs improves the thermal conductivity of substrates by removing large amounts of heat or by dissipating the concentrated heat [59]. The high thermal conductivity of NDs may be explained by the highly ordered lattice and long phonon mean free path. This makes NDs induce a higher increase in the thermal conductivity of a substrate when used in lower concentrations than boron nitride nanosheets (BNNS), a common filler employed to increase the thermal conductivity of different substrates or matrices [59].

Besides their high thermal conductivity and dielectric properties, NDs possess special optical and mechanical properties along with biocompatibility and non-toxicity. Due to these cumulated properties, they were tested for drug delivery, biosensing, magnetic resonance imaging, heat therapy, tissue scaffolding, surgical implants, tribology and lubrication, catalysis, energy storage, or as a nanofiller in polymer nanocomposites (Figure 4) [53,58]. For the effective application of NDs in these fields and other new applications, the nanodimensions of NDs below 10 nm (Figure 3e) should be preserved and their high tendency to re-aggregate during drying or surface treatments should be suppressed. Treatment of NDs by ultrasound in the presence of a NaCl solution and NaCl-assisted milling were proposed to overcome this issue [53].

Another route to better exploit the properties of NDs is the manufacture of nanocellulose/NDs hybrids. In these hybrids, nanocellulose has multiple roles, to assist the dispersion of the ND particles in fluids, to prevent their aggregation in time, and to obtain stable homogeneous suspensions [25]. In the following, the main methods used to obtain nanocellulose/ND hybrids and their defining properties are presented.

2.3. Preparation of Nanocellulose–Nanodiamonds Hybrids

In a first attempt, NDs–ethyl cellulose mixtures were obtained for the development of screen-printed films for electron emission cathodes [60]. In this case, nano-graphite, NDs, and ethyl cellulose were mixed in the proportion 2:5:6, and ethyl cellulose was used only as an organic binding material. The first hybrids containing NDs and nanocellulose were produced using chitosan (CS, deacetylation degree 85%), BC nanofibers, and 5 nm NDs and the resulting materials were studied for potential application as wound dressings in biomedicine [61]. A solvent casting approach in which a chitosan solution in acetic acid was mixed with a BC gel dispersed in acetic acid and NDs dispersed in water, stirred for 24 h, sonicated until achieving a homogeneous suspension, and then poured in Petri dishes followed by evaporation of the solvent was employed for the preparation of the BC/NDs hybrids. Simultaneously, hybrid materials were prepared by freeze-drying the same suspension to ensure a porous structure [61].

Drug releasing, transparent and porous cellulose-NDs hybrids were also developed as wound dressing materials [62]. Prior to the preparation of the hybrids, the NDs were surface functionalized to obtain carboxylated NDs (CNDs) using a mixture of sulfuric acid and nitric acid (3:1), and thermal treatment. Further, NaOH and urea were added to the homogeneous dispersion of functionalized NDs in deionized water, and the mixture was ultrasonicated and cooled to −12.5 °C before the addition of cellulose from cotton linter. The hybrid membrane was obtained by casting the mixed solution and immersing the obtained gel-like sheet in a 5 wt% H2SO4 aqueous solution followed by successive washings and freeze-drying [62]. Afterwards, the freeze-dried membranes were immersed in a doxorubicin solution, which was used as a model drug for studying the drug loading and release properties of the resulting hybrids.

Nanocellulose-NDs hybrids with a porous structure were also obtained by electrospinning. For this, a CS:BC:polyethylene oxide (PEO) (45:45:10) suspension was prepared by mixing an aqueous solution of chitosan in acetic acid with a BC gel dissolved in acetic acid, and a PEO solution in water [63]. The resulting suspension was mixed with different amounts of medical grade NDs of 2–6 nm, previously dispersed in water by sonication. Fibrous mats designed for wound dressing and skin regeneration were further obtained from these suspensions by electrospinning [63].

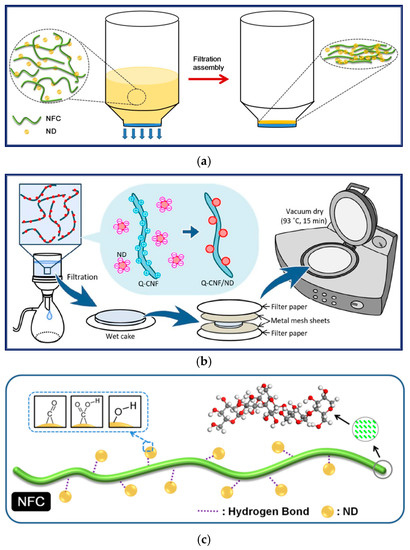

Based on their remarkable thermal conductivity and mechanical properties, NDs were employed in the preparation of nanocellulose/NDs films with enhanced thermal conductivity and/or mechanical strength [57,59,64,65,66]. Vacuum-assisted filtration (Figure 5a) [59,64] or filtration [57,67], and more rarely solution casting [66] were used for the preparation of the nanocellulose/NDs films. Thus, hybrid films were obtained by the vacuum filtration of a mixture of TEMPO-oxidized nanofibrillated cellulose (NFC in Figure 5a,c) and NDs (0–10 wt%) in deionized water using a cellulose ester membrane with 0.45 μm pore size, followed by drying under vacuum at 40 °C overnight [64]. Similarly, single-crystal nanodiamond (SCND) flakes, 100 nm in size, were mixed in different proportions with CNFs in deionized water, and vacuum-filtered using a polycarbonate filter with 0.22 μm pore size [59]. Hybrid films containing 0, 10, 30, 50, 70, and 90 wt% SCND flakes were obtained after filtration and drying at room temperature.

Figure 5.

Preparation routes of nanocellulose–ND hybrids: (a) vacuum filtration. Reprinted with permission from [64]. Copyright 2017 American Chemical Society, and (b) filtration-drying between metal sheets. Reprinted with permission from [57]. Copyright 2018 American Chemical Society; (c) intermolecular hydrogen bonding between the C=O, COOH and C-OH groups of NDs and the OH groups of nanocellulose (NFC) [64].

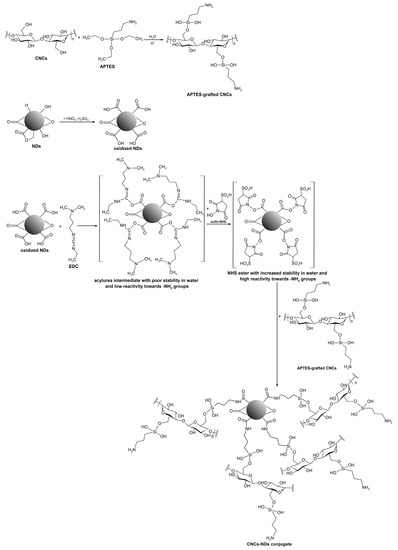

For a better dispersion of the NDs in the water suspension of nanocellulose and stronger nanodiamond–cellulose interactions, CNFs were surface modified by two chemical routes: TEMPO oxidation (TOCNFs) and glycidyltrimethylammonium chloride (GTAC) modification (QCNFs) [67]. Hybrid materials containing TOCNFs or QCNFs and NDs of about 10 nm in size in different proportions (1, 2.5, 5, 10, 33, and 50 wt%) were obtained by mixing the water suspensions of the modified celluloses and NDs, followed by filtration [67]. In another attempt, a water suspension of cationic cellulose nanofibers (Q-CNF) obtained using GTAC as a surface modification agent was added over a NDs aqueous suspension, and the mixture was stirred for 48 h and filtered [57]. Hybrid films with a NDs content of 0.5, 1.0, 2.5 and 5 wt% were produced by drying the wet cakes obtained after filtration between metal sheets at 93 °C for 15 min and then under vacuum (Figure 5b) [57]. A different route was proposed to synthesize CNCs/NDs conjugates for biomedical application [68]. In this case, surface aminated CNCs via aminopropyltriethyoxysilane (APTES) grafting and NDs bearing carboxyl groups on their surface resulting from the oxidation of NDs with a mixture of HNO3 and H2SO4 were covalently linked using an 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC)/N-hydroxysulfosuccinimide (sulfo-NHS) mediated amidation (Scheme 1) and the final nanostructures were obtained by lyophilization [68].

Scheme 1.

Synthesis of CNC/NDs conjugates via covalently linking APTES silylated CNCs with oxidized NDs.

A colloidal processing method was proposed for tuning the nanostructure of CNFs/NDs composite films [69]. This was based on the electrostatic attractions between surface negatively charged CNFs and positively charged NDs when they were added dropwise and mixed into ultrapure water as a highly polar medium. The composite films obtained by the filtration of the CNFs/NDs suspension showed high flexibility and an in-plane thermal conductivity of about 2.7 Wm−1K−1. This combination of flexibility and conductivity was explained by the structure of the composite films consisting of cellulose nanofibers covered with ND particles due to electrostatic and van der Waals interactions [69]. When the simple mixing of the suspensions was replaced by a wet-rotating disc milling (WRDM) process, an increase of 82% in the in-plane thermal conductivity of CNFs/NDs composites was obtained [70]. This improvement is due to the higher aspect ratio of the CNFs and the good dispersion of the NDs particles in the composites obtained by the high-shear WRDM process [70].

Another route to obtain cellulose/NDs composites consists of mixing a cellulose solution in NaOH/urea cooled to 0 °C with a NDs suspension in water, followed by vacuum filtration and hydrogel formation [71]. The cellulose/NDs composites obtained from these hydrogels by hot pressing at 70 °C for 48 h showed a high thermal conductivity of 5.37 Wm−1K−1 when the concentration of NDs in the composite was only 5 wt% [71].

2.4. Main Characteristics of Nanocellulose–Nanodiamonds Hybrids

2.4.1. Thermal Conductivity

Nanocellulose–nanodiamonds hybrids have been developed for obtaining materials with new or special properties or for improving the properties of nanocellulose-based materials. Heat dissipation is now a major problem for electronic devices due to the high frequency and high power density of the new systems developed to meet the needs of increased performance, integration, and miniaturization [59]. A higher power density level implies a higher heat flux density, which may raise reliability and equipment lifetime issues, hindering the development of high-performance devices.

Therefore, an increased thermal conductivity for the polymeric materials used in the manufacture of electronics is a major and urgent requirement. Nanodiamonds stand out by their high thermal conductivity at room temperature (2000 Wm−1K−1) and remarkable electrical insulation properties, which promote them as a valuable material for electric and electronic devices [59]. Several nanocellulose/NDs hybrids have been developed for this purpose. Thus, CNFs/SCND hybrids showed up to 145.6 times increase in thermal conductivity as compared to the neat nanocellulose film [59]. The thermal conductivity of the hybrids was measured by a laser-flash method, which measured the temperature rise when the sample was heated on one side by a short laser pulse. The improvement in the heat dissipation coincided with an increase in the mechanical properties of the hybrid materials containing up to 30 wt% NDs due to the reinforcing effect of NDs.

Nevertheless, achieving increased levels of thermal conductivity using the smallest possible amounts of NDs is desirable from the point of view of costs. A remarkable increase of 7.75 times in the in-plane thermal conductivity of a nanocellulose/0.5 wt% ND hybrid film compared to that of neat nanocellulose was reported by Song et al. [64]. However, the corresponding increase in the through-plane thermal conductivity of the nanocellulose/0.5 wt% NDs hybrid film was very small. This behavior was explained by the hierarchical organization of the nanocellulose in the hybrid film and the intermolecular hydrogen bonds between the oxidized carbon atoms from the ND particles’ surface (−OH/−COOH) and the hydroxyl groups of nanocellulose (Figure 5c) [64].

Good thermal conductivity and superior mechanical properties were also reported for sandwiched structures obtained by a layer-by-layer vacuum-assisted self-assembly method starting from a CNFs–BNNS mixture and micro/nanodiamonds [65]. Thus, the CNFs–BNNS–NDs hybrid containing microdiamonds (MDs) and nanodiamonds and a 48.2 vol.% filler content showed the greatest thermal conductivity, of 45.76 Wm−1K−1 for the in-plain direction, and 3.17 Wm−1K−1 for the through-plain direction. The CNFs–BNNS–micro/nanodiamond hybrids displayed suitable properties for application in electronic packaging or as dielectric layer for computer processing units [65].

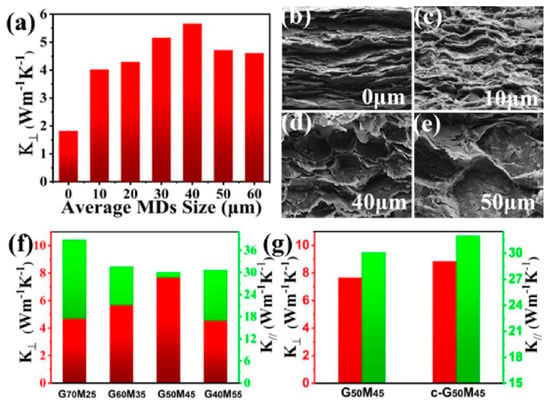

The dissipation of heat in highly integrated circuits is currently an important issue because most of the composite materials dissipate heat well only in one direction, being anisotropic materials. An increase of only 10 °C in the temperature of a light-emitting diode (LED) device leads to a reduced luminous efficiency and a halving of the LED’s lifetime [72]. Materials showing a high bidirectional thermal conductivity are required in these applications for an efficient in-plane and through-plane spreading of heat in advanced electronic devices. Incorporating microdiamonds (M) in anisotropic nanofibrillated cellulose (CNF)–graphene nanoplatelets (G) films can enhance the thermal conductivity in both in-plane and through-plane directions by constructing three-dimensional heat dissipating pathways and reducing phonon scattering [66]. Thus, more balanced in-plain (k‖)/through-plain (k⊥) thermal conductivity results were obtained for CNF/G/M hybrids due to the addition of M of different sizes [66]. The k⊥ of CNFs/G/35 wt% M films increased with the increase in the M size up to 40 µm and then decreased for the hybrids incorporating M of 50 and 60 µm (Figure 6a) due to the decrease in the thermally conductive paths (Figure 6b–e). SEM images of the hybrids illustrate the morphological changes from a highly orientated graphene structure in the CNF/G hybrid (Figure 6b) to an undulating morphology for the CNF/G/M hybrid with 10 µm M (Figure 6c) and a foam-like morphology for larger sized M (40 and 50 µm) (Figure 6d,e) [66]. The highest k⊥ value and better matching between the thermal conductivity values in the two directions were obtained for the CNF/G/M film containing 45 wt% microdiamonds with an average size of 40 µm (Figure 6f). The heat dissipated by the selected hybrid film (G/M 50/45, M 40 µm) was much higher as compared to that dissipated by the pure cellulose paper, ensuring a lower rate of temperature increase at the surface of high-power LEDs used as heat source. These hybrids show excellent bidirectional thermal conductivity, flame retardancy, and good electromagnetic shielding properties and were proposed as electronic packaging materials [66].

Figure 6.

(a) Thermal conductivity (k⊥) of CNF/G/M films as a function of M size; (b–e) SEM images (fracture) of hybrid films incorporating M with different sizes; (f) In-plane and out-of-plane thermal conductivity of hybrid films as a function of G/M content. (g) Comparison of thermal conductivities for G/M (50/45) before and after carbonization. Reprinted with permission from [66]. Copyright 2022 Elsevier.

2.4.2. Mechanical Properties

The mechanical properties of the nanocellulose/nanodiamonds hybrids depend primarily on the dispersion of the ND nanoparticles in the hybrids and the NC/NDs interface strength as well as on the ratio between the components in the formulationsand the preparation method [22]. In particular, CNFs/NDs hybrid films obtained by the vacuum filtration of the CNFs/NDs mixtures with a NDs content of 0.5–10 wt% showed a decrease in the tensile strength of up to 25% as compared to the tensile strength of the NC film [64]. The tensile properties were determined through dynamic thermomechanical analysis using a Q800 from TA Instruments (USA). The CNFs/0.5 wt% NDs hybrid film was proposed as a lateral heat spreader for portable electronic devices due to its good thermal conductivity, satisfactory tensile strength, good toughness, as well as its electrical insulation and optical transparency properties [64].

Nanocellulose/nanodiamonds hybrids with improved tensile strength and modulus and high heat dissipation capacity were obtained by using up to 30 wt% SCND flakes. An important role in the improvement of the thermal and mechanical properties of these hybrids was attributed to the hydrogen bonds between the CNFs and SCND and the ordered layered structure of the SCND flakes. The CNFs/70 wt% SCND hybrid showed excellent flexibility and mechanical strength, a tensile strength of 113.4 MPa and a tensile modulus of 10.8 GPa that were proven by the easy bending and folding of the film [59].

A remarkable reinforcing effect of the NDs was observed for cationic cellulose nanofibers/NDs hybrids [57]. In this case, the ionic interactions between the electropositive charges on the nanocellulose surface and the electronegative NDs had a significant role in increasing the strength and preserving the ductility of the hybrid material. Thus, the Young’s modulus increased from 9.8 to 16.6 GPa with an increase in the NDs content from 0 to 5 wt% [57]. Strong interactions between NCs and NDs were obtained by the surface functionalization of nanocellulose by TEMPO-oxidation [67]. Moreover, the hybrids obtained from TEMPO-oxidized cellulose nanofibers and NDs showed better mechanical properties and optical transparency than those obtained from cationic cellulose nanofibers and NDs and all the hybrids were characterized by an increase in thermal conductivity with the increase in the NDs’ concentration in the hybrids [67].

Besides the chemical treatment of the NC’ and/or NDs’ surface for promoting stronger interactions between the components of the hybrids, the application of a process involving the gelation transition of the composite hydrogel may also lead to improved mechanical properties due to the action of NDs as linkers between the cellulose macromolecular chains [71]. Thus, a cellulose/5 wt% NDs hybrid showed a Young’s modulus of about 3 GPa and a 367% increase in toughness as compared to neat cellulose. These remarkable mechanical properties of the hybrid were explained by the aligned structure of cellulose and the uniform dispersion of the NDs due to the multiple hydrogen bonds established between the hydroxyl groups of cellulose and surface polar groups of NDs [71].

More complex structures were also studied as solutions for enhancing the thermal conductivity and mechanical properties of the nanocellulose/NDs hybrids. Thus, sandwiched structures comprising CNFs, BNNSs and diamond micro and nanoparticles showed good mechanical properties when tested using tensile, bending, and cyclic mechanical tests [65]. This was explained by the special construction of these structures, highlighted by SEM, with the NDs, the microdiamonds and their mixture constituted in a support layer and the BNNSs appearing on both sides of these structures [65].

2.4.3. Optical Properties

The optical transparency of the nanocellulose film, also known as nanopaper, is an important property when the application of cellulose as a substrate for electronics is pursued [73]. Although characterized by high optical transparency, NDs may change the optical transparency of the NC hybrid films. Thus, the transparency in the visible region of CNFs/NDshybrid films with a thickness of 50–60 μm decreased when the concentration of the ND particles in the hybrids increased from 0 to 10 wt% [64]. As a measure of the transparency of the hybrid films, the light transmittance at 550 nm wavelength decreased from more than 75% for the unmodified CNFs film, to about 20% for the CNFs/10 wt% ND hybrid film. This was due to the light scattering created by the ND particles and possible agglomerations when their concentration in the hybrids increased [64]. A similar decrease in transparency at a wavelength of 600 nm was observed for the cellulose/5 wt% NDs hybrid as compared to the neat cellulose film, from 75% to 38%, which was due to the light scattering effect of the ND particles [71]. However, a lower decrease in transmittance (at 550 nm) was obtained in the case of TEMPO-oxidized-CNFs/NDs hybrids, from about 70% to more than 45%, when the amount of NDs increased from 0 to 10 wt% [67]. This result may be determined by the good dispersion of the ND particles in the hybrids [67].

Optical transparency is also important in the wound dressing application of the NC/CNDs membranes, because it allows the visualization of the wound without removing the wound dressing and therefore the dressing is changed less often [62]. The light transmittance at 800 nm determined on wet membranes decreased from 96% for the neat cellulose membranes to 92% and 89% for the hybrid membranes containing 1.0 and 1.5 wt% of CNDs. Therefore, in small concentrations, CNDs did not significantly change the transparency of the membranes. The most important data regarding the preparation methods, main properties, and applications of NC/NDs hybrids are given in Table 1.

Table 1.

Components, composition, preparation methods, main properties and applications of NC/NDs hybrids.

2.5. Applications of Nanocellulose–Nanodiamond Hybrids

Materials more appropriate for the new electronic devices and, in particular, for power electronics are in great demand. These materials must have very good heat dissipation properties to be used in applications such as portable electronic devices or energy storage systems. Nanodiamonds stand out due to their remarkable thermal conductivity, of 2000 Wm−1K−1 at room temperature, which makes them the correct choice when an increase in the conductivity of various polymers is desired. NC/NDs hybrids benefit from the properties of both materials, combining good mechanical properties, high thermal conductivity, andelectrical insulation, with biodegradability, and lack of toxicity. Thus, CNFs/NDs hybrid films with a low content of NDs showing good thermal conductivity and mechanical properties as well as optical transparency were developed for the lateral heat spreader in portable electronic devices [64]. At only 1 wt% NDs in the hybrid, an in-plane thermal conductivity of about 11 Wm−1K−1 was obtained, which is much higher than that reported for other polymer/nanostructured carbon materials [64]. Much higher in-plane thermal conductivity (76.23 Wm−1K−1) was reported for CNFs/90 wt% SCND hybrid films [59]. However, for balanced thermal conductivity and mechanical properties (in particular, flexibility), a medium or low concentration of SCND is indicated in the CNFs/SCND hybrid films, which are a solution for high frequency, high power density electronic equipment [59].

Two fillers with different geometry were used in NC hybrids to ensure a high bidirectional thermal conductivity for the development of thermal interface materials. Thus, new materials based on NC, graphene nanoplatelets, and micro or nanodiamonds were designed for this purpose [66]. Similarly, hybrids containing NC, BNNS and micro/nanodiamonds were fabricated and tested with good results in the heat dissipation system of a main processor [65]. Reportedly, the temperature of the processor recorded during 100% utilization was lower than the limit temperature for stable operation (53 °C) when the CNFs/BNNS/NDs hybrid used as a thermal interface material in the computer contained both nano and microdiamonds [65]. An even lower difference between the in-plane and through-plane thermal conductivity was reported for a CNFs/BNNS/NDs hybrid obtained via an electrostatic self-assembly route [75]. In another study, Ti3C2 MXene nanosheets were used to obtain CNFs/NDs/MXene hybrids with a nacre-like structure, which showed good mechanical properties and flexibility along with high thermal conductivity [76]. These materials were designed to prevent overheating in high-power flexible electronic devices. Cellulose derivatives have also been used as matrices in cellulose/NDs hybrids for flexible electronics [77].

CNCs/NDs hybrid materials were also tested for humidity detection and humidity level measurement [78]. The detection and control of humidity are vital in several fields such as food and drug storage, medical health, industry, and agriculture. A humidity sensor should measure humidity over a large range, with high sensitivity and accuracy and it must show cyclic responsiveness [79]. The CNCs/NDs hybrid acting as an adsorption layer was combined with a quartz crystal microbalance (QCM) and its humidity-sensing properties were tested for a wide range of humidity, from 11.3% to 97.3% [78]. The encouraging results, fast response, high sensitivity (54.1 Hz/%RH), and small humidity hysteresis (3.2%RH) recommended this hybrid as a humidity sensor in breath monitoring [78].

The favorable chemical stability, mechanical strength, and biocompatibility recommend NDs for biomedical applications such as wound dressing, wound healing, skin tissue engineering, bone tissue regeneration, and drug delivery [61,62,63,68,80]. Moreover, the optical transparency of NC/NDs films makes them more suitable for wound dressing because the direct inspection of wounds reduces the need for dressing changes [25].

CNCs/NDs conjugates obtained by covalently bonding silylated CNCs and oxidized NDs were designed as a biointerface material for bone tissue regeneration [68]. In vitro biocompatibility investigations were conducted by studying the proliferation and differentiation of human fetal osteoblastic cells (hFOB) using the CNCs/NDs conjugates as cell culture substrates. The cytotoxicity tests showed that the CNCs/NDs conjugates induce cell growth and showed no cytotoxic effects after 7 days of culture [68]. Moreover, hFOB cells seeded on the CNCs/NDs substrate expressed bone sialoprotein and osteocalcin proteins suggesting that this substrate promotes and enhances the expression of proteins involved in the extracellular matrix mineralization [68].

Chitosan/bacterial cellulose/nanodiamonds (CS/BC/NDs) hybrid films were recommended as wound dressings [61]. The hybrid films containing 2 wt% NDs showed enhanced mechanical properties and only a slight decrease in transparency as compared to the CS/BC film without NDs. Moreover, the mouse skin fibroblast cells’ (L929) viability on this hybrid film (CS/BC/2 wt% NDs), evaluated using the MTT assay, was higher than 90% after 24 h incubation and exceeded 75% after 48 h incubation, showing a good biocompatibility [61]. Similarly, CS/BC/NDs hybrids produced by electrospinning were recommended for wound healing and skin regeneration [63]. An increase in the tensile modulus and a decrease in the tensile strength of the fibrous mat were obtained after the addition of 1–3 wt% NDs in the electrospun CS/BC mat. The cytocompatibility to L929 cells was evaluated using MTT test after 24 h and 72 h incubation, and the results showed that cell viability was close to 90% after one day and about 70–75% after 3 days, depending on the concentration of NDs in the hybrid mats [63]. The CS/BC/1 wt% NDs fibrous mat was considered promising for tissue engineering applications [63].

Nanocellulose/NDs hybrids were also tested for the delivery of drugs, using doxorubicin as a model drug [62]. The addition of CNDs to cellulose greatly improved the modulus of elasticity and tensile strength of the hybrid films without significantly modifying their elongation at break and transparency. This improvement in properties was explained by the good dispersion of the CND particles as well as the strong interactions established between the hydroxyl groups of nanocellulose and the carboxylic groups of carboxylated NDs [62]. The doxorubicin loading was investigated by immersing the hybrid membranes in a doxorubicin solution overnight. A higher amount of NDs in the hybrid material led to a higher content of doxorubicin loaded in the porous films while the drug release profile was influenced by the pH. The cytotoxicity of the hybrid membrane was evaluated by the MTT assay using HeLa cells. The results showed very good cell viability (>95%) in the absence of doxorubicin after 48 h. These results were considered strong evidence of the feasibility of these hybrid materials as systems for the loading and release of bioactive compounds [62].

3. Conclusions and Future Perspectives

Excellent expressions of the synergy between natural and synthetic, NC/NDs hybrids appear as innovative materials that combine the bio-based origin, biodegradability, good dispersion in water, and non-toxicity of nanocellulose with the high thermal conductivity, excellent mechanical resistance, and great structural stability of nanodiamonds. As the association of NC with NDs has been shown to lead to an impressive increase in the thermal conductivity of nanocellulose, NC/NDs hybrids seem promising as sustainable materials for heat dissipation in electronic devices. However, while the thermal conductivity in the in-plane direction has been reported as satisfactory, the through-plane thermal conductivity of these hybrids remains poor due to the alignment of the nanodiamonds in a preferential direction. Therefore, finding an easy and green procedure to obtain NC/NDs hybrids with a satisfactory bidirectional thermal conductivity, possibly by tailoring the orientation and distribution of the NDs in the NC/ND hybrids, while using a concentration of NDs as small as possible, remains an open challenge.

A significant obstacle in the preparation and application of the NC/ND hybrids on a larger scale is the pronounced tendency of NDs to agglomerate during the hybrids’ manufacturing, which on the one hand may alter the mechanical properties and transparency of the hybrids and, on the other hand may render them cytotoxic. The chemical modification of the NC’ and/or NDs’ surface seems an attractive technique to increase the interactions at the interface between the two materials, stabilize the NDs in aqueous media, and decrease the self-aggregation tendency of NDs, but the subject itself and the consequences of the chemical modification on the other properties of NC and NDs has been little studied so far. At the same time, optimizing the techniques and the ratios between components for producing NC/NDs hybrids with balanced thermal conductivity, mechanical, and optical properties constitute another direction of research that must be addressed.

Although still in the early stages of their development, the NC/NDs hybrids have not enjoyed the same interest from the scientific world as the hybrids based on nanocellulose and other allotropic forms of carbon such as G, GO, rGO, CNTs or C60. This may be attributed to the lack of electrical conductivity, antimicrobial activity, photodynamic activity, etc. of NDs with which graphene, CNTs, or fullerenes are endowed. However, in the future, it may be taken into consideration that methods like doping or chemical modification of NDs with different agents can enrich NDs with new properties such as electrical conductivity, photodynamic activity, fluorescence, antibacterial activity etc. This can expand the study and use of the NC/NDs hybrids in many other applications including cancer therapy, bioimaging, biosensing, drug delivery, etc.

Author Contributions

Writing—original draft preparation, C.D.U. and D.M.P.; writing—review and editing D.M.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by a grant of the Ministry of Research, Innovation and Digitization−UEFISCDI, project number PN-III-P2-2.1-PED-2021-2559 (BIOPLASM) contract 632PED/2022 within PNCDI III.

Data Availability Statement

The data are fully included in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zinge, C.; Kandasubramanian, B. Nanocellulose based biodegradable polymers. Eur. Polym. J. 2020, 133, 109758. [Google Scholar] [CrossRef]

- Magalhães, M.I.; Almeida, A.P.C. Nature-Inspired Cellulose-Based Active Materials: From 2D to 4D. Appl. Biosci. 2023, 2, 94–114. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Chiulan, I. Nanostructured biocomposites from aliphatic polyesters and bacterial cellulose. Ind. Crops Prod. 2016, 93, 251–266. [Google Scholar] [CrossRef]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A review of cellulose and its derivatives in biopolymer-based for food packaging application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and crop wastes: A new source for nanocellulose biorefinery. Ind. Crops Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Frone, A.N.; Chiulan, I.; Panaitescu, D.M.; Nicolae, C.A.; Ghiurea, M.; Galan, A.-M. Isolation of cellulose nanocrystals from plum seed shells, structural and morphological characterization. Mater. Lett. 2017, 194, 160–163. [Google Scholar] [CrossRef]

- Méndez-Loranca, E.; Vidal-Ruiz, A.M.; Martínez-González, O.; Huerta-Aguilar, C.A.; Gutierrez-Uribe, J.A. Beyond cellulose extraction: Recovery of phytochemicals and contaminants to revalorize agricultural waste. Bioresour. Technol. 2023, 21, 101339. [Google Scholar] [CrossRef]

- Pennells, J.; Godwin, I.D.; Amiralian, N.; Martin, D.J. Trends in the production of cellulose nanofibers from non-wood sources. Cellulose 2020, 27, 575–593. [Google Scholar] [CrossRef]

- Chen, L.; Yu, H.; Dirican, M.; Fang, D.; Tian, Y.; Yan, C.; Xie, J.; Jia, D.; Liu, H.; Wang, J.; et al. Highly Transparent and Colorless Nanocellulose/Polyimide Substrates with Enhanced Thermal and Mechanical Properties for Flexible OLED Displays. Adv. Mater. Interfaces 2020, 7, 2000928. [Google Scholar] [CrossRef]

- Usurelu, C.D.; Badila, S.; Frone, A.N.; Panaitescu, D.M. Poly(3-hydroxybutyrate) Nanocomposites with Cellulose Nanocrystals. Polymers 2022, 14, 1974. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose Processing Properties and Potential Applications. Curr. For. Rep. 2019, 5, 76–89. [Google Scholar] [CrossRef]

- Qian, H.; Liu, J.; Wang, X.; Pei, W.; Fu, C.; Ma, M.; Huang, C. The state-of-the-art application of functional bacterial cellulose-based materials in biomedical fields. Carbohydr. Polym. 2023, 300, 120252. [Google Scholar] [CrossRef] [PubMed]

- Panaitescu, D.M.; Frone, A.N.; Chiulan, I.; Casarica, A.; Nicolae, C.A.; Ghiurea, M.; Trusca, R.; Damian, C.M. Structural and morphological characterization of bacterial cellulose nano-reinforcements prepared by mechanical route. Mater. Des. 2016, 110, 790–801. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Etale, A.; Wang, J.; Berglund, L.A.; Li, Y.; Cai, Y.; Chen, C.; Cranston, E.D.; Johns, M.A.; Fang, Z.; et al. Current international research into cellulose as a functional nanomaterial for advanced applications. J. Mater. Sci. 2022, 57, 5697–5767. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Pradeep, H.K.; Patel, D.H.; Onkarappa, H.S.; Pratiksha, C.C.; Prasanna, G.D. Role of nanocellulose in industrial and pharmaceutical sectors—A review. Int. J. Biol. Macromol. 2022, 207, 1038–1047. [Google Scholar] [CrossRef] [PubMed]

- Spagnuolo, L.; D’Orsi, R.; Operamolla, A. Nanocellulose for Paper and Textile Coating: The Importance of Surface Chemistry. ChemPlusChem 2022, 87, e202200204. [Google Scholar] [CrossRef] [PubMed]

- Gómez, C.; Serpa, A.; Velásquez-Cock, J.; Gañán, P.; Castro, C.; Vélez, L.; Zuluaga, R. Vegetable nanocellulose in food science: A review. Food Hydrocoll. 2016, 57, 178–186. [Google Scholar] [CrossRef]

- Voisin, H.; Bergström, L.; Liu, P.; Mathew, A.P. Nanocellulose-Based Materials for Water Purification. Nanomaterials 2017, 7, 57. [Google Scholar] [CrossRef]

- Perumal, A.B.; Nambiar, R.B.; Moses, J.A.; Anandharamakrishnan, C. Nanocellulose: Recent trends and applications in the food industry. Food Hydrocoll. 2022, 127, 107484. [Google Scholar] [CrossRef]

- Luo, Q.; Shen, H.; Zhou, G.; Xu, X. A mini-review on the dielectric properties of cellulose and nanocellulose-based materials as electronic components. Carbohydr. Polym. 2023, 303, 120449. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Kong, H.; Chen, Y.; Liu, B.; Zhu, D.; Guo, L.; Wei, G. Recent advances in the hybridization of cellulose and carbon nanomaterials: Interactions, structural design, functional tailoring, and applications. Carbohydr. Polym. 2022, 279, 118947. [Google Scholar] [CrossRef]

- Valencia, L.; Handa, R.; Monti, S.; Jasso-Salcedo, A.B.; Georgouvelas, D.; Magana, I.; Dıaz de Leon, R.; Velikov, K.P.; Mathew, A.J.; Kumar, S. On the mineralization of nanocellulose to produce functional hybrid materials. J. Mater. Chem. A 2022, 10, 9248–9276. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Bacakova, L.; Pajorova, J.; Tomkova, M.; Matejka, R.; Broz, A.; Stepanovska, J.; Prazak, S.; Skogberg, A.; Siljander, S.; Kallio, P. Applications of Nanocellulose/Nanocarbon Composites: Focus on Biotechnology and Medicine. Nanomaterials 2020, 10, 196. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K. Nanocellulose and Nanocarbons Based Hybrid Materials: Synthesis, Characterization and Applications. Nanomaterials 2020, 10, 1800. [Google Scholar] [CrossRef]

- Nauman Javed, R.M.; Al-Othman, A.; Tawalbeh, M.; Olabi, A.G. Recent developments in graphene and graphene oxide materials for polymer electrolyte membrane fuel cells applications. Renew. Sustain. Energy Rev. 2022, 168, 112836. [Google Scholar] [CrossRef]

- Yildiz, G.; Bolton-Warberg, M.; Awaja, F. Graphene and graphene oxide for bio-sensing: General properties and the effects of graphene ripples. Acta Biomater. 2021, 131, 62–79. [Google Scholar] [CrossRef]

- Lin, P.-C.; Wu, J.-Y.; Liu, W.-R. Green and facile synthesis of few-layer graphene via liquid exfoliation process for Lithium-ion batteries. Sci. Rep. 2018, 8, 9766. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Song, Y.; Yang, Q.; Xiong, C.; Shi, Z. Porous and three-dimensional carbon aerogels from nanocellulose/pristine graphene for high-performance supercapacitor electrodes. Diam. Relat. Mater. 2023, 132, 109626. [Google Scholar] [CrossRef]

- Panda, P.K.; Dash, P.; Yang, J.M.; Chang, Y.H. Development of chitosan, graphene oxide, and cerium oxide composite blended films: Structural, physical, and functional properties. Cellulose 2022, 29, 2399–2411. [Google Scholar] [CrossRef]

- Mohan, V.B.; Jakisch, L.; Jayaraman, K.; Bhattacharyya, D. Role of chemical functional groups on thermal and electrical properties of various graphene oxide derivatives: A comparative X-ray photoelectron spectroscopy analysis. Mater. Res. Express 2018, 5, 035604. [Google Scholar] [CrossRef]

- Khalid, A.; Yi, W.; Yoo, S.; Abbas, S.; Si, J.; Hou, X.; Hou, J. Single-chirality of single-walled carbon nanotubes (SWCNTs) through chromatography and its potential biological applications. New J. Chem. 2023, 47, 992. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Athira, C.B.; Rubiyah, M.H.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a Versatile Green Platform: From Biosources to Materials and Their Applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef] [PubMed]

- Smirnov, V.V.; Manevitch, L.I. Carbon Nanotubes in Arrays: Competition of van-der-Waals and Elastic Forces. Dokl. Phys. 2019, 64, 218–221. [Google Scholar] [CrossRef]

- Milano, F.; Guascito, M.R.; Semeraro, P.; Sawalha, S.; Da Ros, T.; Operamolla, A.; Giotta, L.; Prato, M.; Valli, L. Nanocellulose/Fullerene Hybrid Films Assembled at the Air/Water Interface as Promising Functional Materials for Photo-Electrocatalysis. Polymers 2021, 13, 243. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Abdelaziz, A.; Bessa, W.; Hussin, M.H.; Brosse, N.; Thakur, V.K. Cellulose nanofibrils-graphene hybrids: Recent advances in fabrication, properties, and applications. Nanoscale 2022, 14, 12515–12546. [Google Scholar] [CrossRef]

- Miyashiro, D.; Hamano, R.; Umemura, K. A Review of Applications Using Mixed Materials of Cellulose, Nanocellulose and Carbon Nanotubes. Nanomaterials 2020, 10, 186. [Google Scholar] [CrossRef]

- Danial, W.H.; Md Bahri, N.F.; Abdul Majid, Z. Preparation, Marriage Chemistry and Applications of Graphene Quantum Dots–Nanocellulose Composite: A Brief Review. Molecules 2021, 26, 6158. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, H.; Wang, Y.; Ray, U.; Zhu, S.; Dai, J.; Chen, C.; Fu, K.; Jang, S.-H.; Henderson, D.; et al. Cellulose-Nanofiber-Enabled 3D Printing of a Carbon-Nanotube Microfiber Network. Small Methods 2017, 1, 1700222. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.M.; Saxena, I.M.; Kudlicka, K. Cellulose biosynthesis in higher plants. Trends Plant Sci. 1996, 1, 149–156. [Google Scholar] [CrossRef]

- Romeo, I.; Olivito, F.; Tursi, A.; Algieri, V.; Beneduci, A.; Chidichimo, G.; Maiuolo, L.; Sicilia, E.; De Nino, A. Totally green cellulose conversion into bio-oil and cellulose citrate using molten citric acid in an open system: Synthesis, characterization and computational investigation of reaction mechanisms. RSC Adv. 2020, 10, 34738–34751. [Google Scholar] [CrossRef]

- Kono, H.; Oshima, K.; Hashimoto, H.; Shimizu, Y.; Tajima, K. NMR characterization of sodium carboxymethyl cellulose: Substituent distribution and mole fraction of monomers in the polymer chains. Carbohydr. Polym. 2016, 146, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Simmons, B.A.; Vogel, K.P. Visualization of biomass solubilization and cellulose regeneration during ionic liquid pretreatment of switchgrass. Biotechnol. Bioeng. 2009, 104, 68–75. [Google Scholar] [CrossRef] [PubMed]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated Cellulose Surface Modification: A Review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef]

- Singhania, R.R.; Patel, A.K.; Tsai, M.-L.; Chen, C.-W.; Dong, C.D. Genetic modification for enhancing bacterial cellulose production and its applications. Bioengineered 2021, 12, 6793–6807. [Google Scholar] [CrossRef]

- Lei, W.; Jin, D.; Liu, H.; Tong, Z.; Zhang, H. An Overview of Bacterial Cellulose in Flexible Electrochemical Energy Storage. ChemSusChem 2020, 13, 3731–3753. [Google Scholar] [CrossRef]

- Oprea, M.; Panaitescu, D.M. Nanocellulose Hybrids with Metal Oxides Nanoparticles for Biomedical Applications. Molecules 2020, 25, 4045. [Google Scholar] [CrossRef] [PubMed]

- Pang, M.; Huang, Y.; Meng, F.; Zhuang, Y.; Liu, H.; Du, M.; Ma, Q.; Wang, Q.; Chen, Z.; Chen, L.; et al. Application of bacterial cellulose in skin and bone tissue engineering. Eur. Polym. J. 2020, 122, 109365. [Google Scholar] [CrossRef]

- Mochalin, V.N.; Shenderova, O.; Ho, D.; Gogotsi, Y. The properties and applications of nanodiamonds. Nat. Nanotechnol. 2012, 7, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Zhai, W.; Srikanth, N.; Kong, L.B.; Zhou, K. Carbon nanomaterials in tribology. Carbon 2017, 119, 150–171. [Google Scholar] [CrossRef]

- Vejpravová, J. Mixed sp2–sp3 Nanocarbon Materials: A Status Quo Review. Nanomaterials 2021, 11, 2469. [Google Scholar] [CrossRef] [PubMed]

- Shenderova, O.; Koscheev, A.; Zaripov, N.; Petrov, I.; Skryabin, Y.; Detkov, P.; Turner, S.; Van Tendeloo, G. Surface Chemistry and Properties of Ozone-Purified Detonation Nanodiamonds. J. Phys. Chem. C 2011, 115, 9827–9837. [Google Scholar] [CrossRef]

- Morimune-Moriya, S.; Salajkova, M.; Zhou, Q.; Nishino, T.; Berglund, L.A. Reinforcement Effects from Nanodiamond in Cellulose Nanofibril Films. Biomacromolecules 2018, 19, 2423–2431. [Google Scholar] [CrossRef]

- Qin, J.-X.; Yang, X.-G.; Lv, C.-F.; Li, Y.-Z.; Liu, K.-K.; Zang, J.-H.; Yang, X.; Dong, L.; Shan, C.-X. Nanodiamonds: Synthesis, properties, and applications in nanomedicine. Mater. Des. 2021, 210, 110091. [Google Scholar] [CrossRef]

- Gong, P.; Li, L.; Fu, G.-E.; Shu, S.; Li, M.; Wang, Y.; Qin, Y.; Kong, X.; Chen, H.; Jiao, C.; et al. Highly flexible cellulose nanofiber/single-crystal nanodiamond flake heat spreader films for heat dissipation. J. Mater. Chem. C 2022, 10, 12070. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, S.; Lei, C.; Wei, J.; Lu, B.; Ding, Y.; Zhu, C. Application of printed nanocrystalline diamond film for electron emission cathode. Appl. Surf. Sci. 2011, 257, 5185–5189. [Google Scholar] [CrossRef]

- Ostadhossein, F.; Mahmoudi, N.; Morales-Cid, G.; Tamjid, E.; Navas-Martos, F.J.; Soriano-Cuadrado, B.; Paniza, J.M.L.; Simchi, A. Development of Chitosan/Bacterial Cellulose Composite Films Containing Nanodiamonds as a Potential Flexible Platform for Wound Dressing. Materials 2015, 8, 6401–6418. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Zhang, H.; Cao, Z.; Cai, N.; Xue, Y.; Yu, F. A simple route to develop transparent doxorubicin-loaded nanodiamonds/cellulose nanocomposite membranes as potential wound dressings. Carbohydr. Polym. 2016, 143, 231–238. [Google Scholar] [CrossRef]

- Mahdavi, M.; Mahmoudi, N.; RezaieAnaran, F.; Simchi, A. Electrospinning of Nanodiamond-Modified Polysaccharide Nanofibers with Physico-Mechanical Properties Close to Natural Skins. Mar. Drugs 2016, 14, 128. [Google Scholar] [CrossRef]

- Song, N.; Cui, S.; Hou, X.; Ding, P.; Shi, L. Significant Enhancement of Thermal Conductivity in Nanofibrillated Cellulose Films with Low Mass Fraction of Nanodiamond. ACS Appl. Mater. Interfaces 2017, 9, 40766–40773. [Google Scholar] [CrossRef]

- Li, L.; Li, M.; Zhang, Z.; Qin, Y.; Shui, X.; Xia, J.; Xiong, S.; Wang, B.; Zhang, Z.; Wei, Z.; et al. Robust composite film with high thermal conductivity and excellent mechanical properties by constructing a long-range ordered sandwich structure. J. Mater. Chem. A 2022, 10, 9922–9931. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, F.; Huang, L.; Dai, K.; Li, C.; Liu, D.; Sun, Y.; Ren, D.; Wu, J.; et al. Micro-diamond assisted bidirectional tuning of thermal conductivity in multifunctional graphene nanoplatelets/nanofibrillated cellulose films. Carbon 2022, 189, 265–275. [Google Scholar] [CrossRef]

- Kato, T.; Matsumoto, T.; Hongo, C.; Nishino, T. Mechanical and thermal properties of cellulose nanofiber composites with nanodiamond as nanocarbon filler. Nanocomposites 2018, 4, 127–136. [Google Scholar] [CrossRef]

- Vega-Figueroa, K.; Santillán, J.; García, C.; González-Feliciano, J.A.; Bello, S.A.; Rodríguez, Y.G.; Ortiz-Quiles, E.; Nicolau, E. Assessing the suitability of cellulose-nanodiamond composite as a multifunctional biointerface material for bone tissue regeneration. ACS Biomater. Sci. Eng. 2017, 3, 960–968. [Google Scholar] [CrossRef] [PubMed]

- Sato, K.; Tominaga, Y.; Hotta, Y.; Shibuya, H.; Sugie, M.; Saruyama, T. Cellulose nanofiber/nanodiamond composite films: Thermal conductivity enhancement achieved by a tuned nanostructure. Adv. Powder Technol. 2018, 29, 972–976. [Google Scholar] [CrossRef]

- Tominaga, Y.; Sato, K.; Hotta, Y.; Shibuya, H.; Sugie, M.; Saruyama, T. Improvement of thermal conductivity of composite film composed of cellulose nanofiber and nanodiamond by optimizing process parameters. Cellulose 2018, 25, 3973–3983. [Google Scholar] [CrossRef]

- Song, N.; Cao, D.; Luo, X.; Guo, Y.; Gu, J.; Ding, P. Aligned cellulose/nanodiamond plastics with high thermal conductivity. J. Mater. Chem. C 2018, 6, 13108. [Google Scholar] [CrossRef]

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal conductivity of polymer-based composites: Fundamentals and applications. Prog. Polym. Sci. 2016, 59, 41–85. [Google Scholar] [CrossRef]

- Zhu, H.; Parvinian, S.; Preston, C.; Vaaland, O.; Ruan, Z.; Hu, L. Transparent nanopaper with tailored optical properties. Nanoscale 2013, 5, 3787–3792. [Google Scholar] [CrossRef]

- Hu, D.; Liu, H.; Yang, M.; Guo, Y.; Ma, W. Construction of boron nitride nanosheets-based nanohybrids by electrostatic self-assembly for highly thermally conductive composites. Adv. Compos. Hybrid. Mater. 2022, 5, 3201–3211. [Google Scholar] [CrossRef]

- Jiao, E.; Wu, K.; Liu, Y.; Zhang, H.; Zheng, H.; Xu, C.; Shi, J.; Lu, M. Nacre-like robust cellulose nanofibers/MXene films with high thermal conductivity and improved electrical insulation by nanodiamond. J. Mater. Sci. 2022, 57, 2584–2596. [Google Scholar] [CrossRef]

- Balandin, A. Thermal properties of graphene and nanostructured carbon materials. Nature Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Palmieri, E.; Pescosolido, F.; Montaina, L.; Carcione, R.; Petrella, G.; Cicero, D.O.; Tamburri, E.; Battistoni, S.; Orlanducci, S. A Sustainable Hydroxypropyl Cellulose-Nanodiamond Composite for Flexible Electronic Applications. Gels 2022, 8, 783. [Google Scholar] [CrossRef]

- Chen, Q.; Mao, K.; Yao, Y.; Huang, X.; Zhang, Z. Nanodiamond/cellulose nanocrystals composite-based acoustic humidity sensor. Sens. Actuators B Chem. 2022, 373, 132748. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Xu, Y.; Shen, M.; Duan, C.; Dai, L.; Ni, Y. Green and sustainable cellulose-derived humidity sensors: A review. Carbohydr. Polym. 2021, 270, 118385. [Google Scholar] [CrossRef]

- Das, D.; Dey, R.; Das, S.; Hussain, S.; Ghosh, A.K.; Pal, A.K. Nano-Ag/DLC/Cellulose Free-Standing Films towards Anti-bacterial and Bio-compatible Futuristic Bandage Applications. J. Polym. Environ. 2020, 28, 284–294. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).