Comparing Suitability of Distillation and Membrane for Production of Heavy-Duty 5% Propane

Abstract

1. Introduction

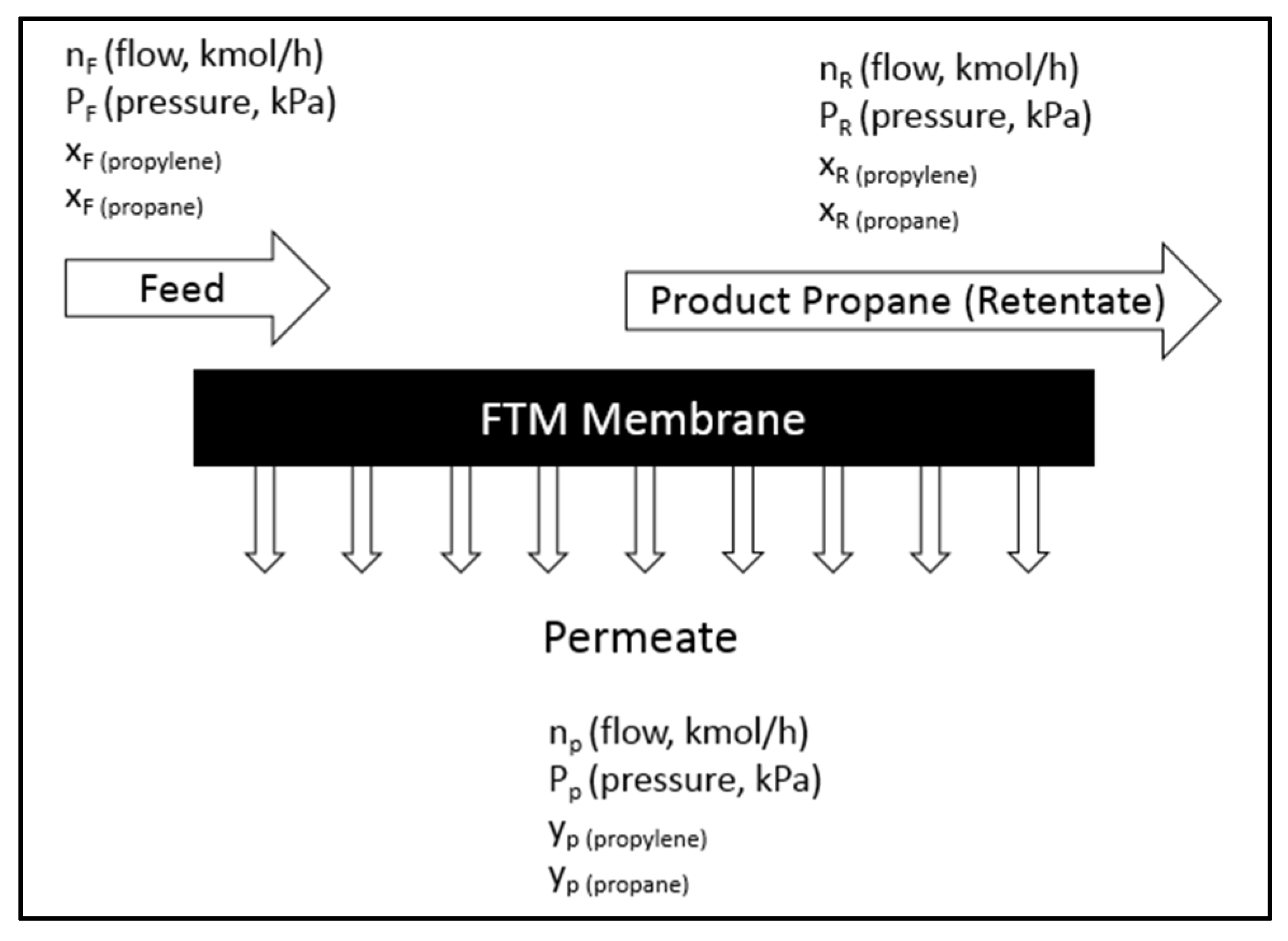

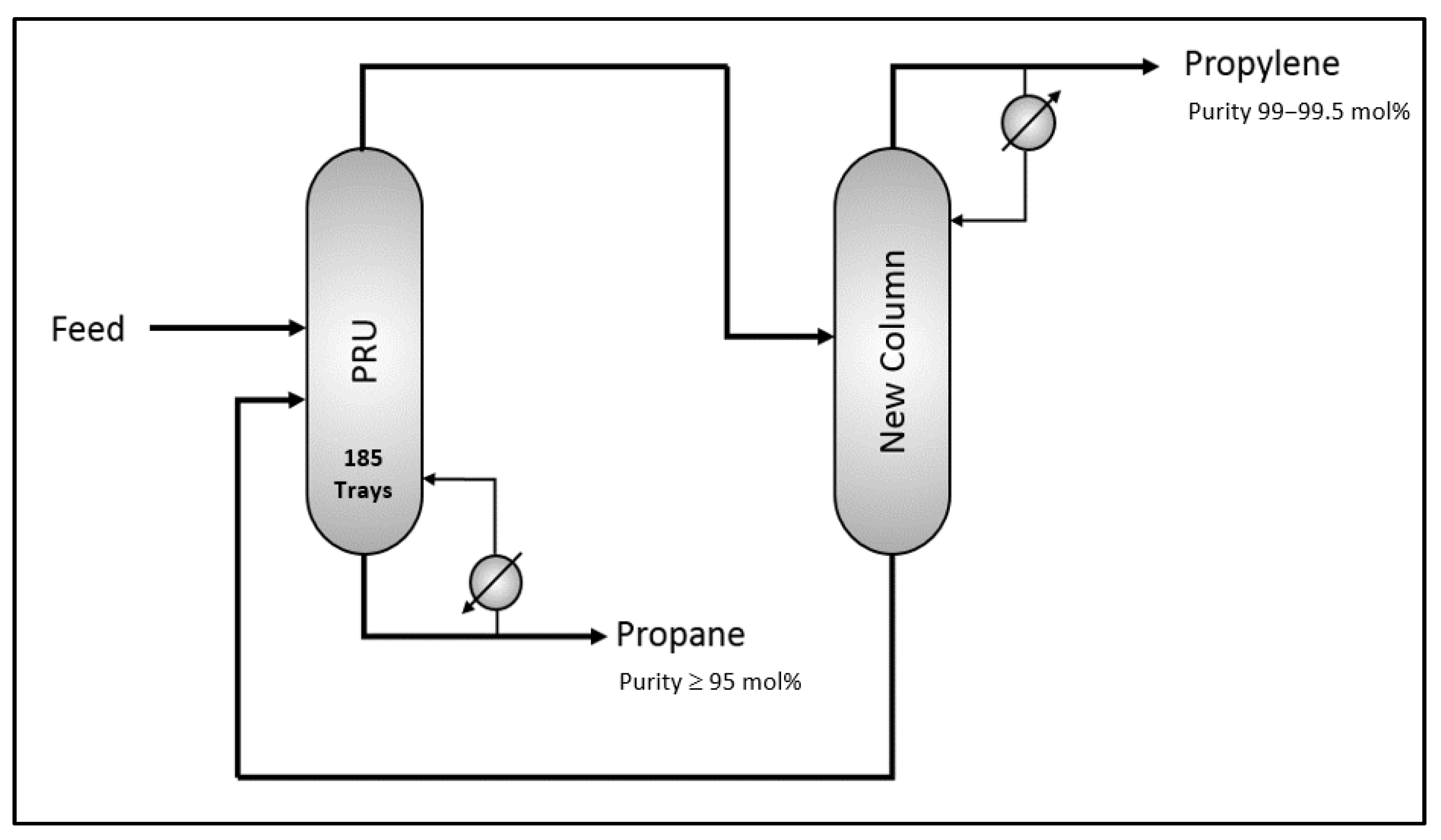

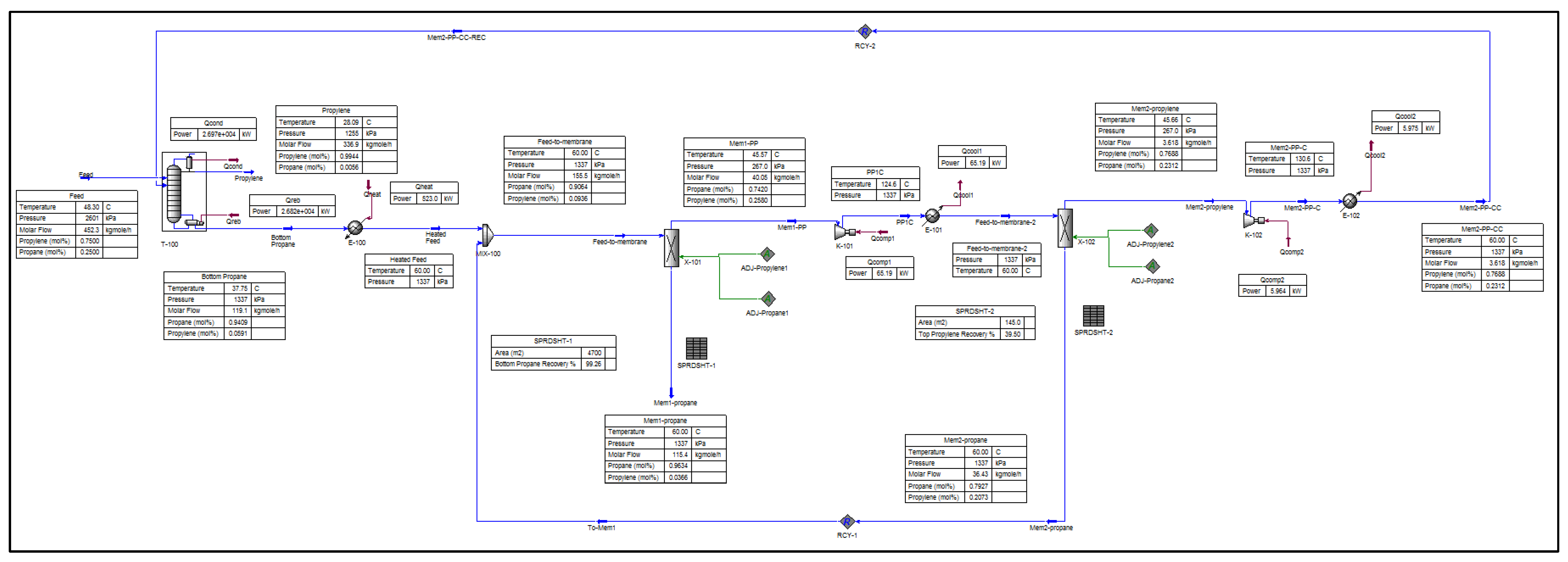

2. Materials and Methods

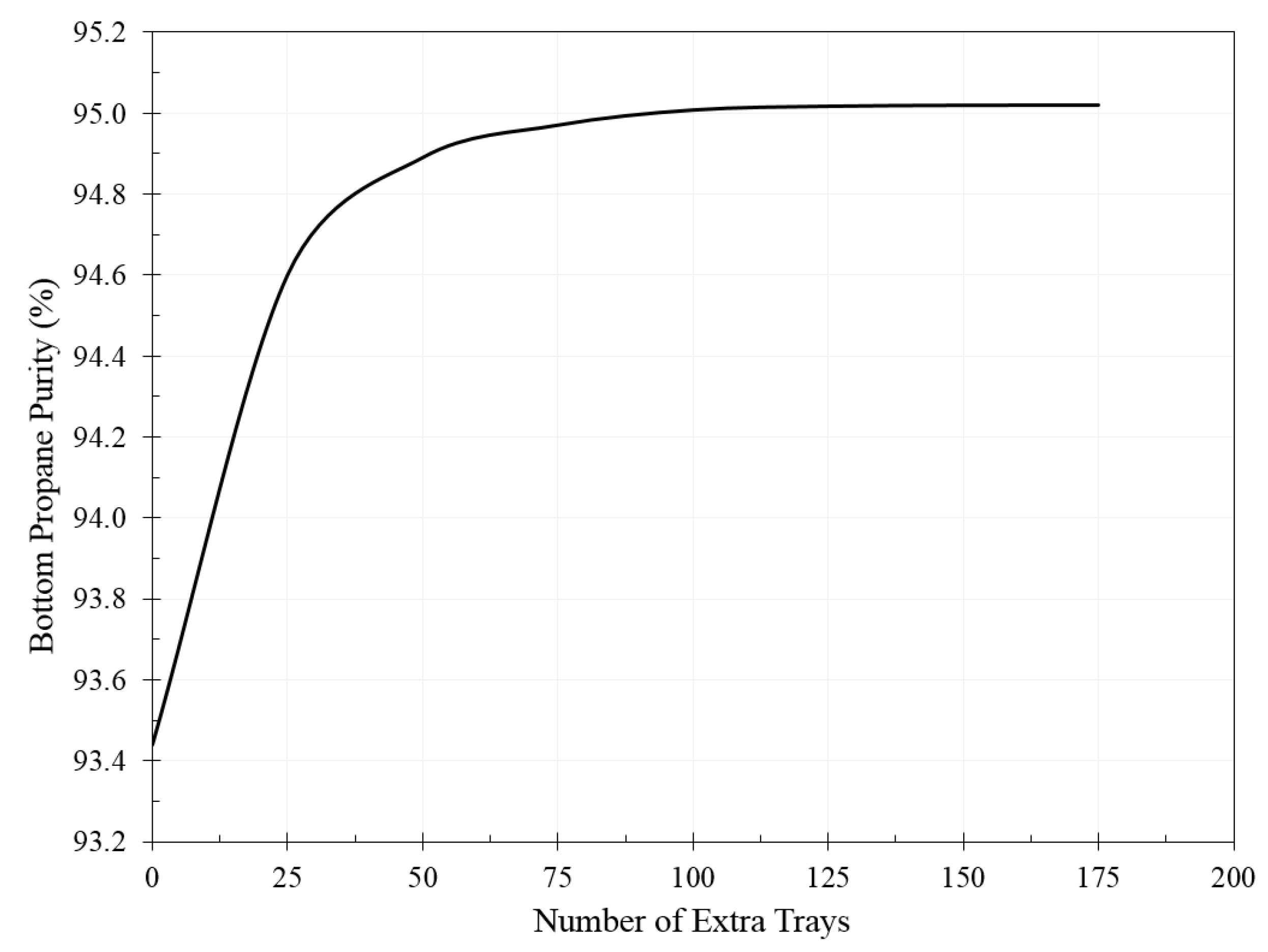

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heselton, K. Boiler Operator’s Handbook; Lulu: Morrisville, NC, USA, 2015. [Google Scholar]

- Balloon Flying Handbook; U.S. Department of Transportation: Washington, DC, USA, 2007.

- Safetyline; United States Naval Safety Center: Norfolk, VA, USA, 1991.

- Mokhatab, S.; Poe, W.; Mak, J. Handbook of Natural Gas Transmission and Processing: Principles and Practices; Elsevier Science: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Fahim, M.; Al-Sahhaf, T.; Elkilani, A. Fundamentals of Petroleum Refining; Elsevier Science: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Sadeghbeigi, R. Fluid Catalytic Cracking Handbook: An Expert Guide to the Practical Operation, Design, and Optimization of FCC Units; Elsevier Science: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Folkson, R.; Sapsford, S. Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance: Towards Zero Carbon Transportation; Woodhead Publishing: Cambridge, UK, 2022. [Google Scholar]

- Abbasi, S.; Khosravi-Nikou, M.; Shariati, A. Removal of propylene from fuel-grade propane. Sep. Purif. Rev. 2007, 33, 157–182. [Google Scholar]

- Yamaki, T.; Thuy, N.; Hara, N.; Taniguchi, S.; Kataoka, S. Design and evaluation of two-stage membrane-separation processes for propylene–propane mixtures. Membranes 2022, 12, 163. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Kanezashi, M. Recent progress in a membrane-based technique for propylene/propane separation. Membranes 2021, 11, 310. [Google Scholar] [CrossRef] [PubMed]

- Su, Y.; Cong, S.; Shan, M.; Zhang, Y. Enhanced propylene/propane separation in facilitated transport membranes containing multisilver complex. AIChE J. 2022, 68, e17410. [Google Scholar] [CrossRef]

- Zhang, J.; Shahidi, K.; Sekhon, G.; Hudson, A.; Hatahet, M.; Salih, F.; Wang, X. Permylene™ membrane technology: An efficient approach to separate propylene from propane. J. Membr. Sci. 2024, 690, 122204. [Google Scholar] [CrossRef]

- Kasahara, S.; Kamio, E.; Minami, R.; Matsuyama, H. A facilitated transport ion-gel membrane for propylene/propane separation using silver ion as a carrier. J. Membr. Sci. 2013, 431, 121–130. [Google Scholar] [CrossRef]

- CMS. OptipermTM Membrane Demonstrates Stable Performance in Pilot Study of HD5 Propane Production. 2017. Available online: https://compactmembrane.com/wp-content/uploads/2019/10/DCRC-Pilot-Study-White-Paper.pdf (accessed on 1 April 2024).

- Alqaheem, Y. Accuracy of Mathematical Models and Process Simulators for Predicting the Performance of Gas-Separation Membranes. Eng 2024, 5, 3137–3147. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Propylene permeance | 150 GPU |

| Propylene/propane selectivity (α) | 30 |

| Maximum operating temperature/pressure | 70 °C/18 bar |

| Property | Value |

|---|---|

| Distillation bottom propane pressure | 13.3 bar |

| Distillation bottom propane temperature | 37.7 °C |

| Distillation bottom propane flow rate | 10.3 m3 h−1 |

| Membrane retentate pressure | 13.3 bar |

| Membrane permeate pressure | 2.7 bar |

| Membrane area | 500 to 5000 m2 |

| Property | PRU | Membrane | Distillation |

|---|---|---|---|

| Propane purity (mol%) | 93.4 | 96.3 | 95.0 |

| Propane recovery (%) | 98.3 | 99.3 | 99.9 |

| Propylene purity (mol%) | 99.4 | 99.4 | 99.9 |

| Propylene recovery (%) | 97.7 | 98.8 | 98.2 |

| Energy consumption (kWh) | – | 669 | 540 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqaheem, Y.; Alomair, A.A.; Alobaid, M. Comparing Suitability of Distillation and Membrane for Production of Heavy-Duty 5% Propane. Gases 2025, 5, 27. https://doi.org/10.3390/gases5040027

Alqaheem Y, Alomair AA, Alobaid M. Comparing Suitability of Distillation and Membrane for Production of Heavy-Duty 5% Propane. Gases. 2025; 5(4):27. https://doi.org/10.3390/gases5040027

Chicago/Turabian StyleAlqaheem, Yousef, Abdulaziz A. Alomair, and Mohammad Alobaid. 2025. "Comparing Suitability of Distillation and Membrane for Production of Heavy-Duty 5% Propane" Gases 5, no. 4: 27. https://doi.org/10.3390/gases5040027

APA StyleAlqaheem, Y., Alomair, A. A., & Alobaid, M. (2025). Comparing Suitability of Distillation and Membrane for Production of Heavy-Duty 5% Propane. Gases, 5(4), 27. https://doi.org/10.3390/gases5040027