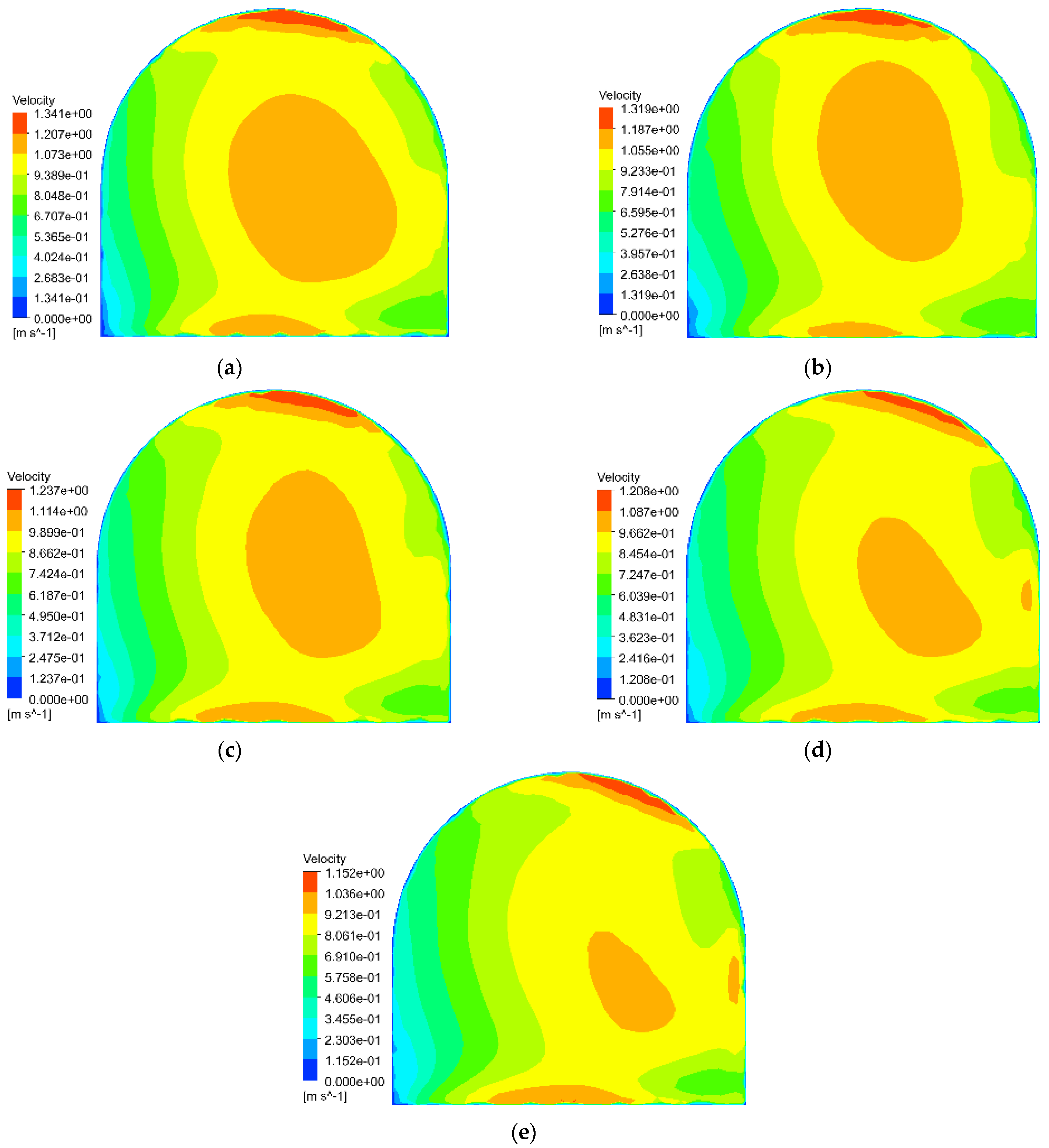

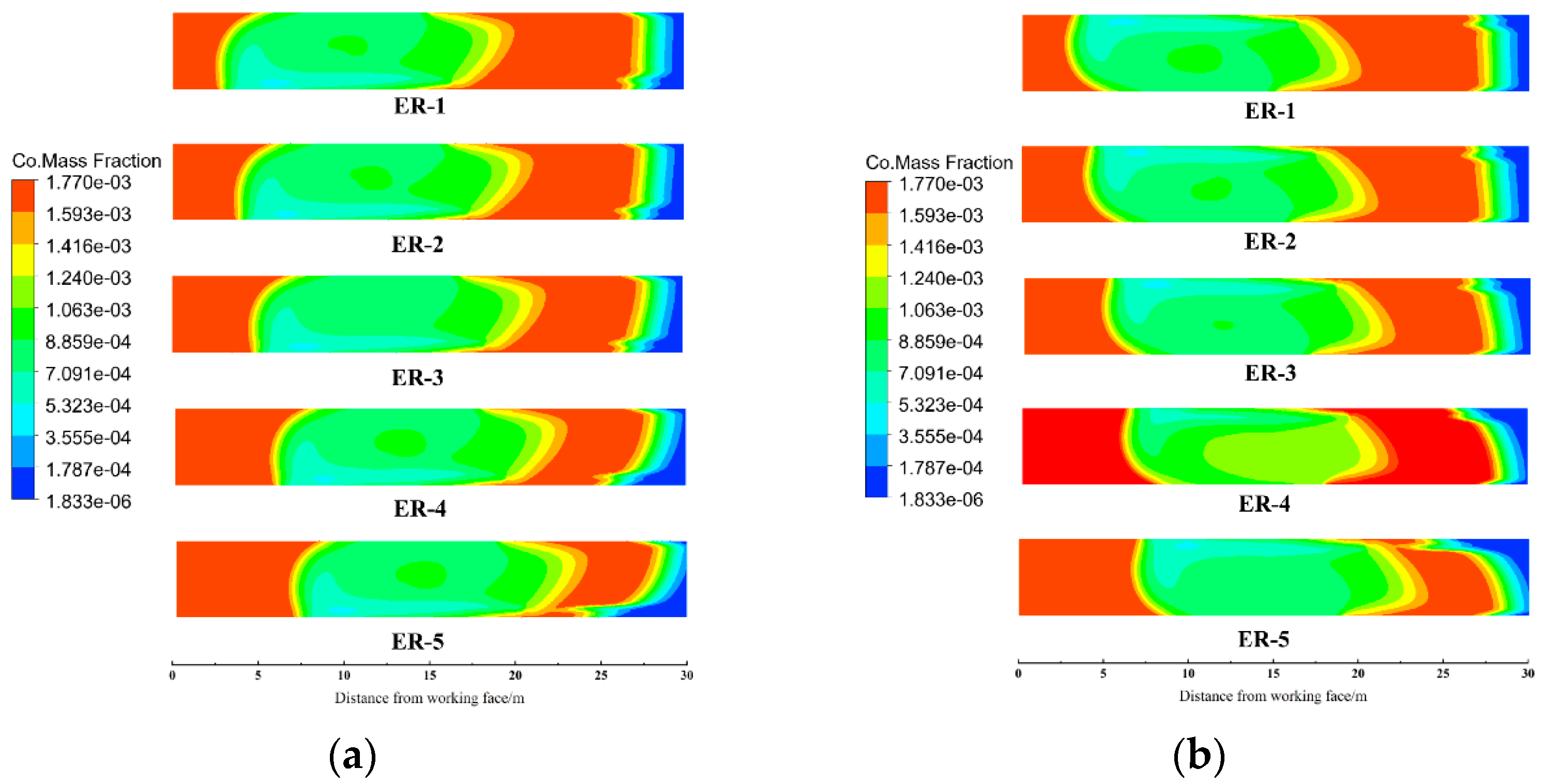

4.1. Horizontal and Overall Spatial Concentration Distribution Law

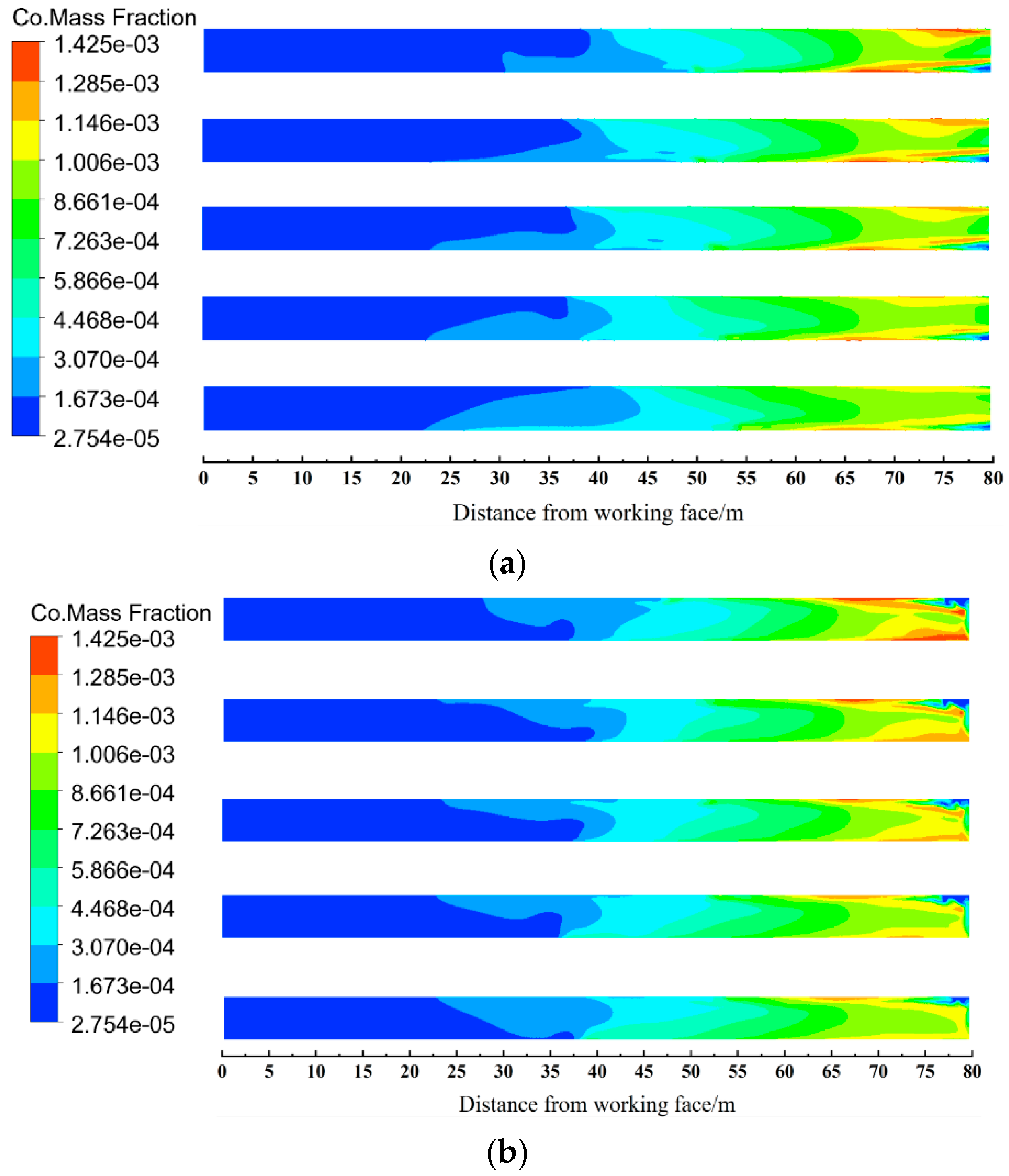

Figure 10 displays the CO concentration distribution at the 1.5 m horizontal plane (human breathing height) after 60 s, demonstrating how the duct outlet jet airflow dilutes surrounding CO concentrations. In the absence of intermediate roadway, the CO in the space of about 3.5 m (ER–1), 4.2 m (ER–2), 5.5 m (ER–3), 6.7 m (ER–4) and 8.9 m (ER–5) from the working face is not diluted. With a middle roadway, these distances shift slightly to 3.6 m, 4.4 m, 5.2 m, 7.2 m, and 8.6 m, respectively. While peak concentrations remain unaffected, CO removal efficiency progressively declines with increasing effective range due to the local fan’s diminished dispersion capability. Due to the presence or absence of the middle roadway, the length of the CO air mass in the stope is not diluted, so the influence of the middle roadway on the airflow distribution in the jet zone can be ignored.

At 500 s, the CO concentration distribution on the 1.5 m horizontal plane (human breathing height) is illustrated in

Figure 11. Significant CO has been expelled and transported through the middle roadway. Without the middle roadway, the breathing–level CO concentrations at ER–1, ER–2, ER–3, ER–4, and ER–5 were 1425 ppm, 1372 ppm, 1310 ppm, 1287 ppm, and 1230 ppm, respectively. In contrast, with the middle roadway, the corresponding concentrations decreased to 1381 ppm, 1359 ppm, 1304 ppm, 1262 ppm, and 1222 ppm. ER–1 exhibited the highest CO removal efficiency in the absence of the middle roadway, attributed to its optimal performance. As the effective range increases, the airflow velocity reaching the working face diminishes. According to momentum conservation, the reduced momentum transfer during air–CO molecular collisions leads to weaker CO transport and diffusion, explaining ER–1’s superior removal efficiency. Although the presence of the middle roadway slightly influences the working face airflow velocity, the maximum velocity difference is only 0.028 m/s. Consequently, the middle roadway has a negligible impact on CO transport, with a maximum concentration deviation of merely 44 ppm.

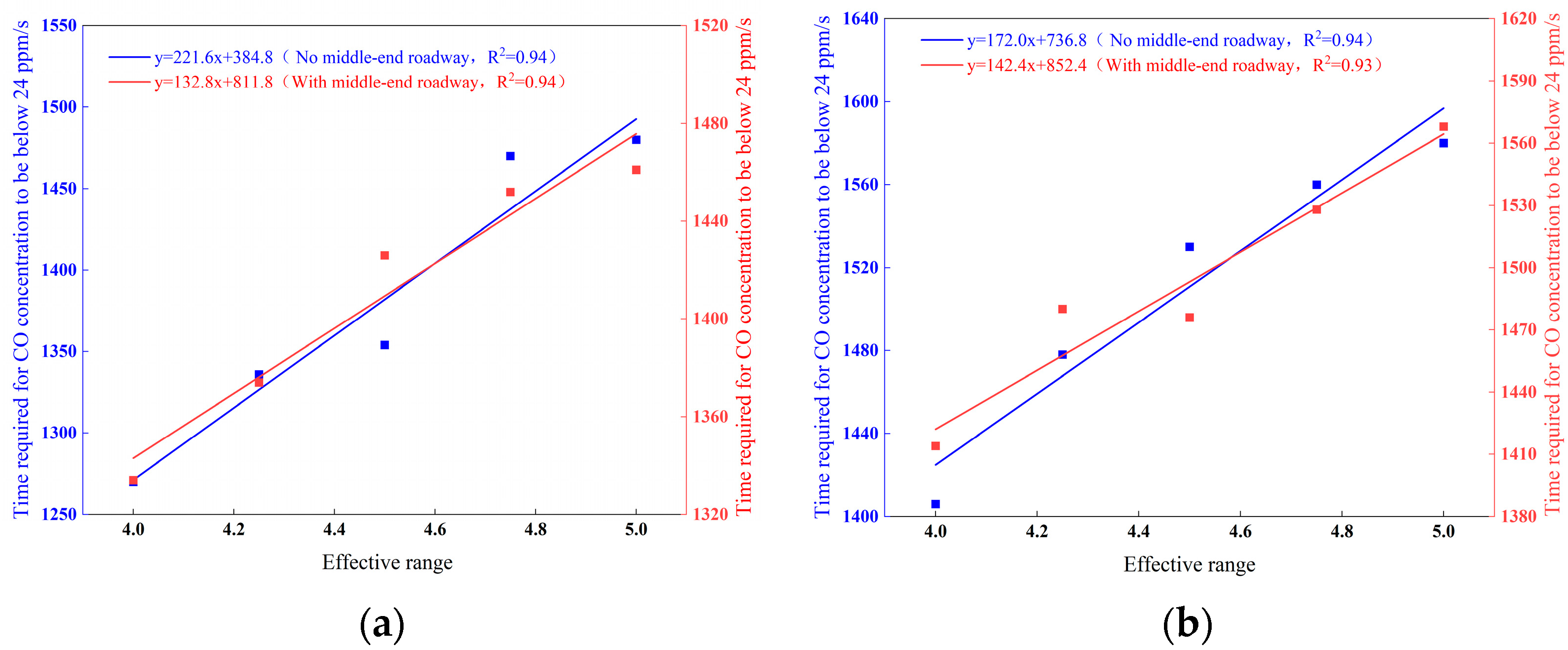

To further elucidate the differences in CO migration and diffusion with and without a middle roadway across varying effective ranges, we compared the time required for CO concentration to decrease to the safe threshold of 24 ppm at both the 1.5 m breathing–height cross–section and throughout the entire space. Through the post–processing module in ANSYS, in the absence of intermediate roadway, the CO concentration of the respiratory surface of ER–1 to ER–5 reached a safe level at 1270 s (23.81 ppm), 1336 s (23.92 ppm), 1352 s (23.99 ppm), 1470 s (23.9 ppm), and 1480 s (23.69 ppm) for ER–1 through ER–5, respectively. Correspondingly, the entire space achieved safe CO concentrations at 1406 s (23.83 ppm), 1478 s (23.88 ppm), 1530 s (23.87 ppm), 1560 s (23.95 ppm), and 1580 s (23.84 ppm) for the same effective ranges, as detailed in

Table 1. These results demonstrate a consistent temporal delay in whole–space clearance compared to the breathing plane, with both clearance times progressively increasing with greater effective ranges.

When incorporating a middle roadway, the time required for CO concentration reduction followed distinct patterns across different effective ranges. At the breathing plane (1.5 m height), safe CO levels (<24 ppm) were achieved at 1334 s (21.52 ppm), 1374 s (23.44 ppm), 1426 s (21.36 ppm), 1452 s (23.78 ppm), and 1461 s (20.02 ppm) for ER–1 through ER–5, respectively. For complete spatial clearance, the system required 1414 s (23.85 ppm), 1480 s (23.61 ppm), 1576 s (23.87 ppm), 1528 s (23.56 ppm), and 1568 s (23.79 ppm) to reach safe concentrations under the same effective range conditions (

Table 2). These results demonstrate that while the middle roadway configuration extended clearance times at the breathing plane compared to the no–roadway scenario, it maintained similar whole–space clearance durations, suggesting its influence primarily affects localized rather than global CO dispersion patterns.

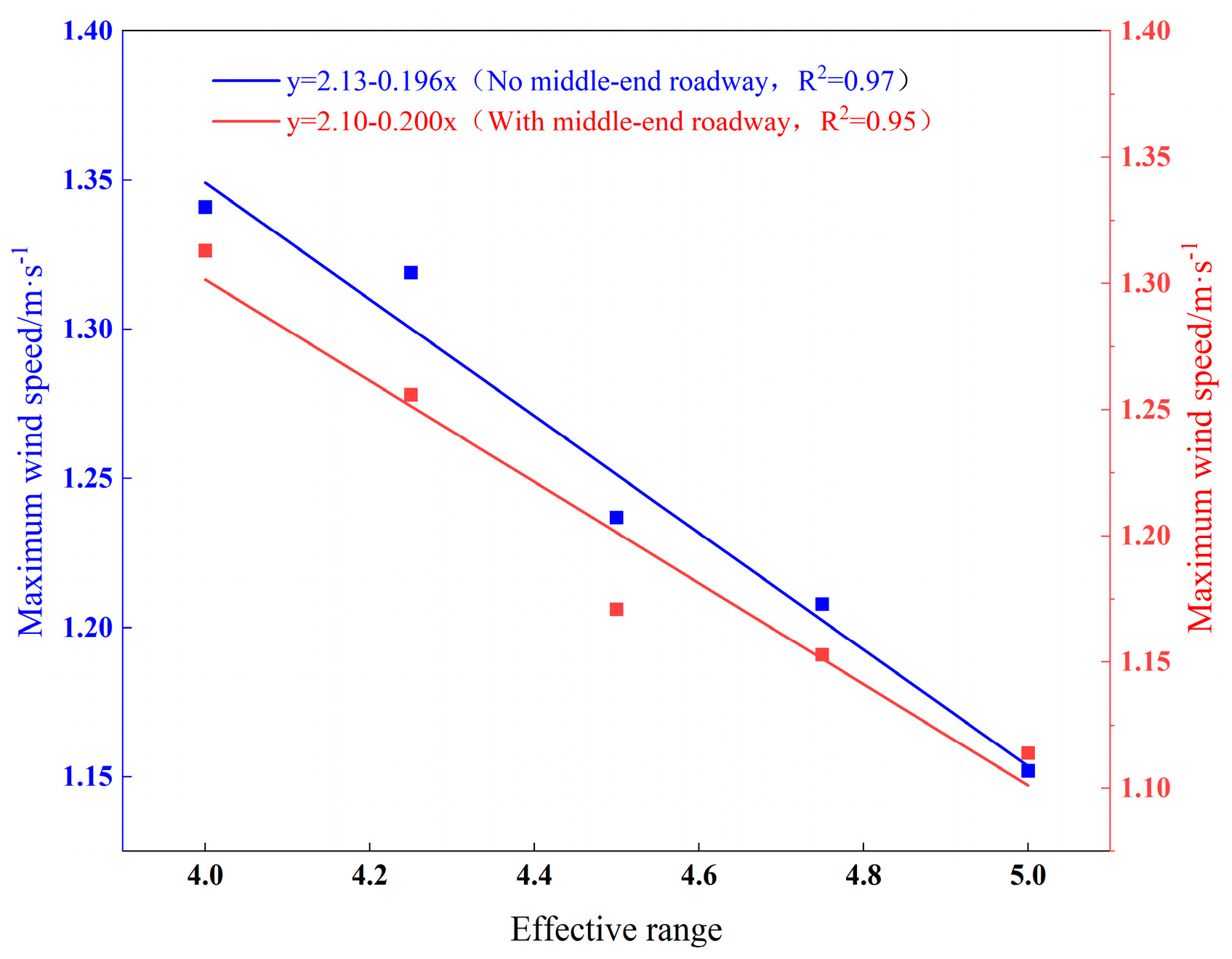

As shown in

Figure 12, the time required for the CO concentration to decrease to 24 ppm exhibits a linear increase with the effective range, irrespective of the presence of a middle roadway. Without a middle roadway, the clearance time for the respiration plane and the entire space increases linearly from 1270 s to 1406 s to 1480 s to 1580 s, respectively, while with a middle roadway, it rises from 1334 s to 1414 s to 1461 s to 1568 s, respectively. The shortest clearance time occurs under ER–1 due to its minimal vortex zone, which reduces energy loss and maximizes the energy acting on CO dispersion. The absence of a middle roadway further shortens the required time because the airflow velocity at the working face under ER–1 is 0.006 m/s higher than that with a middle roadway. According to momentum conservation, the higher momentum imparted to CO molecules enhances dispersion efficiency. However, since the maximum velocity difference is negligible, the time difference is merely 8 s, indicating that the presence of a middle roadway has a marginal impact on blast fume migration. Therefore, in the complex mining environment, moving the trolley and other equipment to the middle roadway before blasting can improve the efficiency of smoke diffusion.

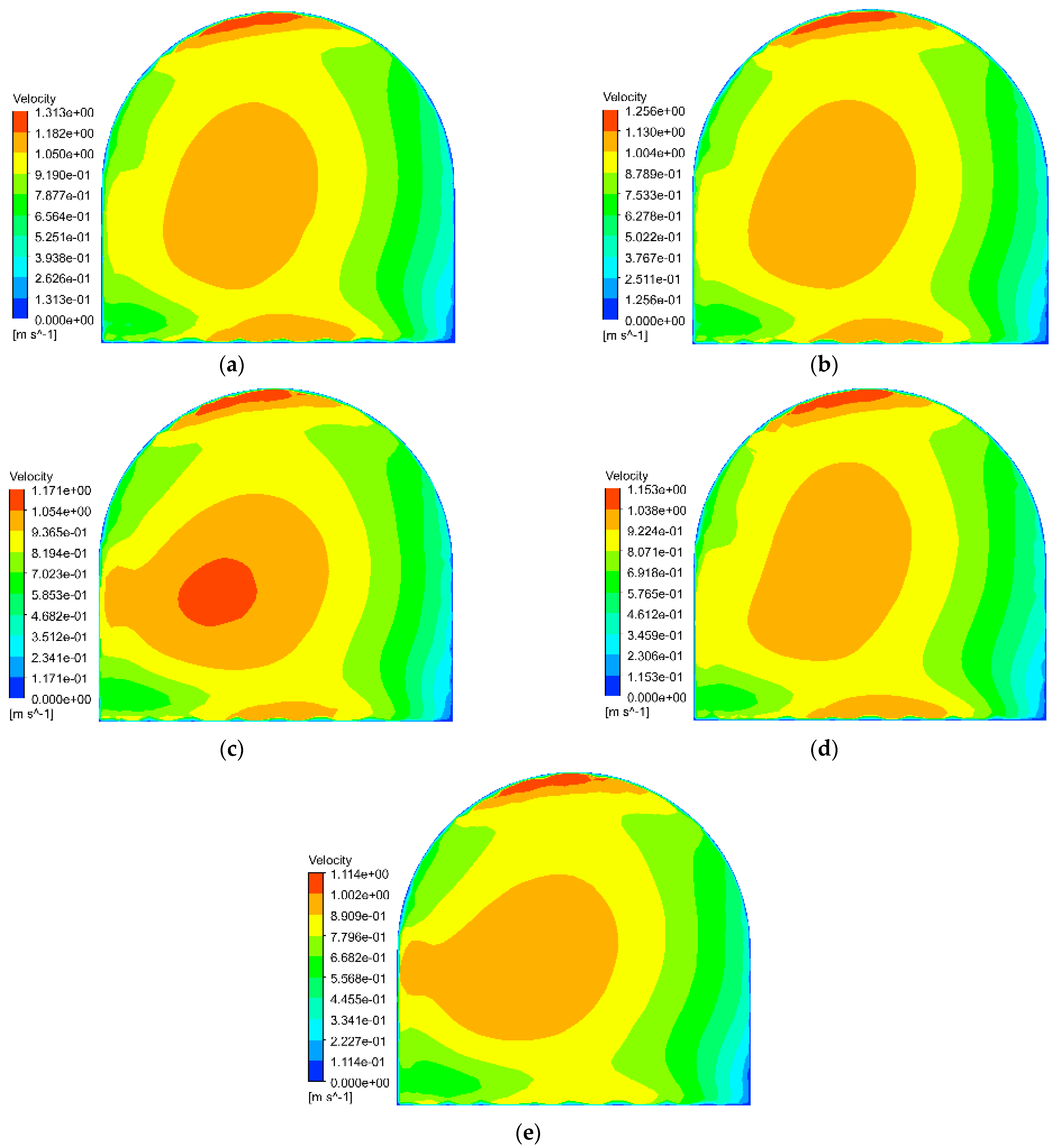

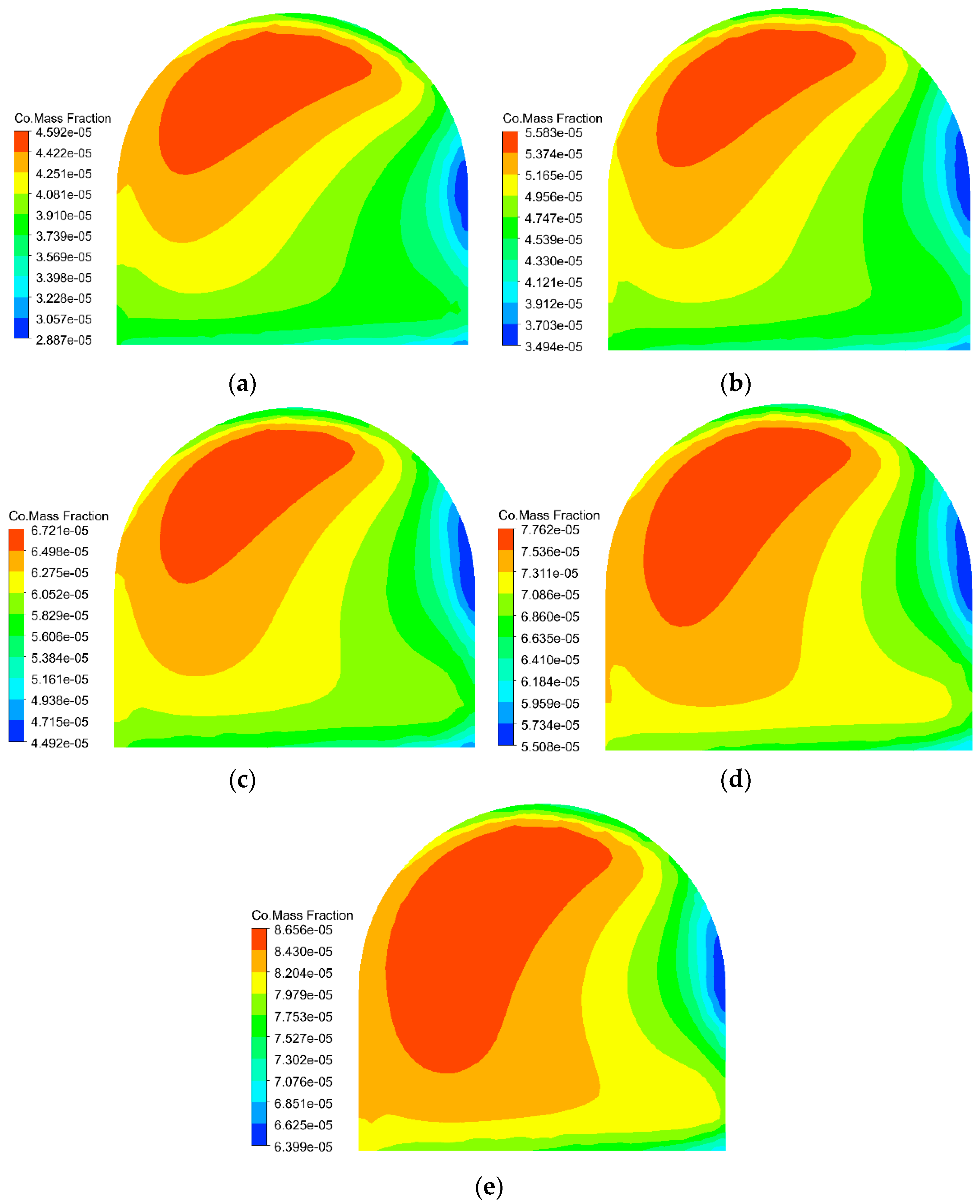

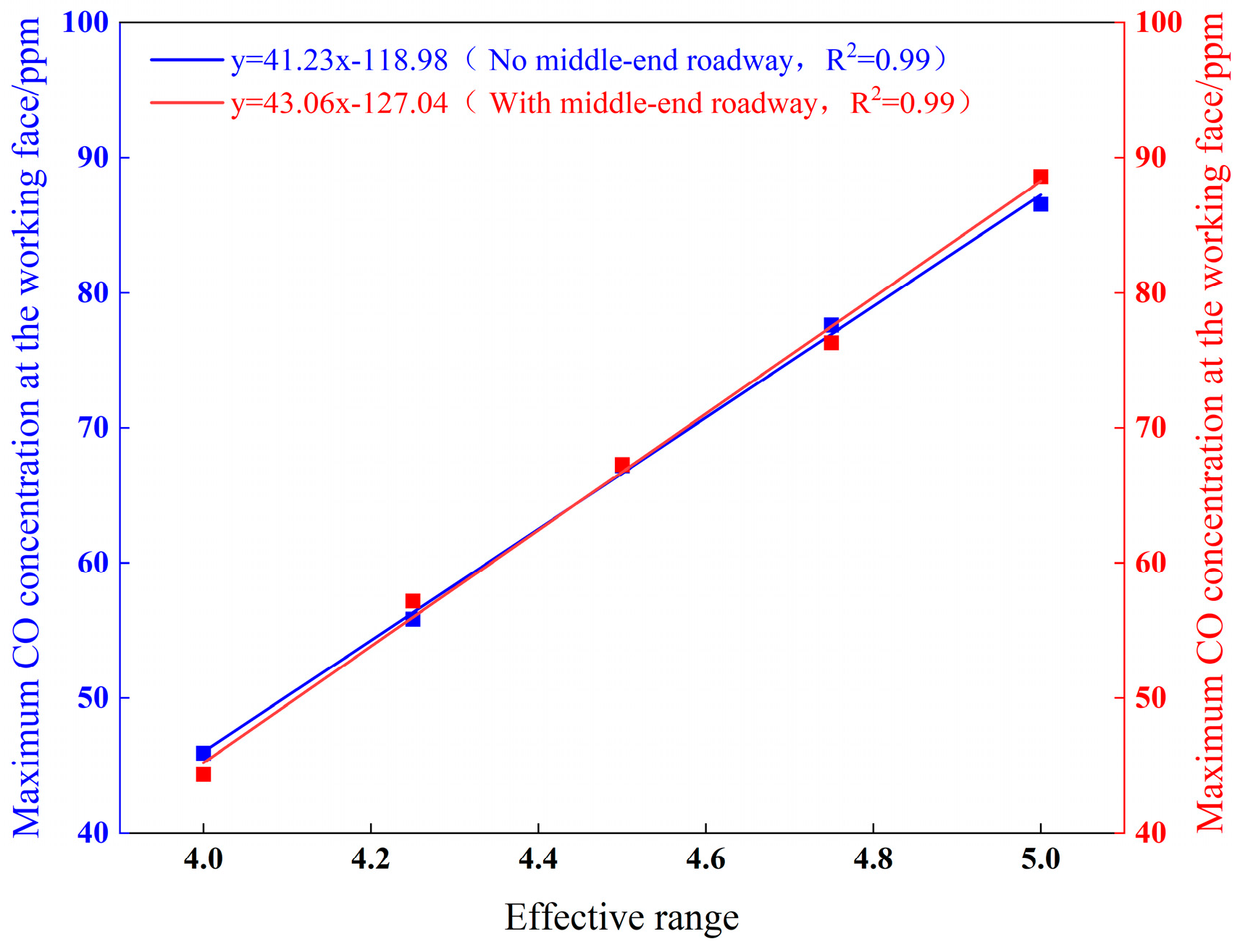

4.2. Concentration Distribution Law at Working Face

Figure 13 presents the CO concentration distribution at the working face after 500 s without a middle roadway. Across all effective ranges, the CO concentration demonstrates higher values in the upper left region and lower values in the lower right, exhibiting a gradual decreasing gradient from the upper left to the lower right. However, the peak CO concentrations vary significantly with different effective ranges: under ER–1, ER–2, ER–3, ER–4, and ER–5 conditions, they reach 45.92 ppm, 55.83 ppm, 67.21 ppm, 77.62 ppm, and 86.56 ppm, respectively.

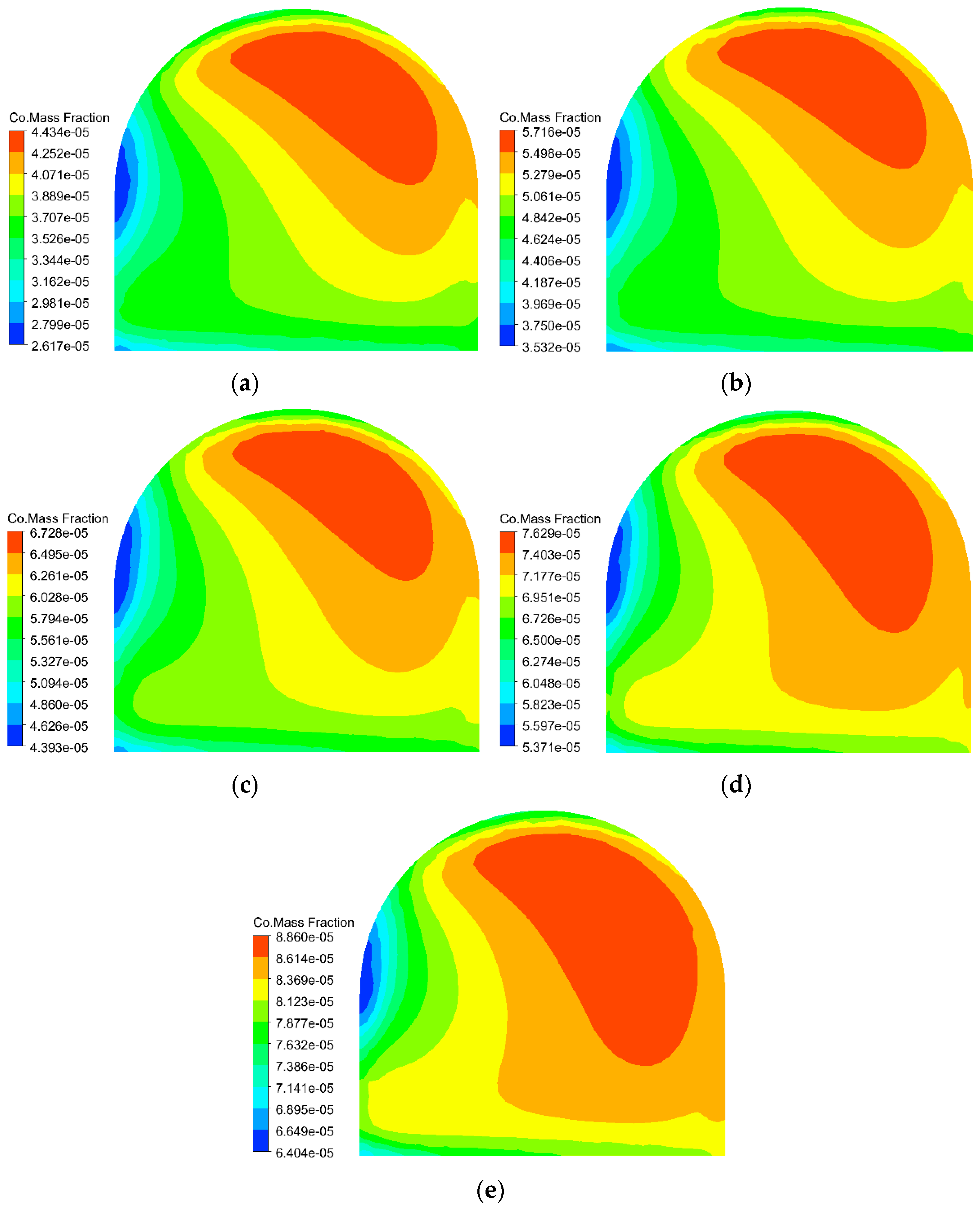

Figure 14 illustrates the CO concentration distribution at the working face after 500 s with a middle roadway. In this configuration, the CO concentration displays higher values in the upper right region and lower values in the lower left, showing a consistent decreasing gradient from upper right to lower left. Notably, despite examining the same time point and cross–section, the peak CO concentrations vary significantly across different effective ranges: measuring 44.34 ppm (ER–1), 57.16 ppm (ER–2), 67.28 ppm (ER–3), 76.29 ppm (ER–4), and 88.6 ppm (ER–5), demonstrating the substantial influence of effective range on fume dispersion patterns.

Figure 15 presents the fitted maximum CO concentrations at the working face, revealing a consistent linear increase with effective range regardless of middle roadway presence. In configurations without a middle roadway, concentrations rise from 45.92 ppm to 86.56 ppm, while those with a middle roadway increase from 44.34 ppm to 88.6 ppm. This trend stems from varying airflow velocities influencing CO transport capacity–higher velocities enhance momentum transfer to CO particles during collisions according to momentum conservation principles, thereby accelerating migration and improving dispersion. The negligible impact of roadway configuration (demonstrated by a maximum velocity difference of merely 0.028 m/s) confirms that middle roadway presence minimally affects CO dispersion dynamics near the working face.

4.3. The Variation Law of Concentration at Monitoring Points

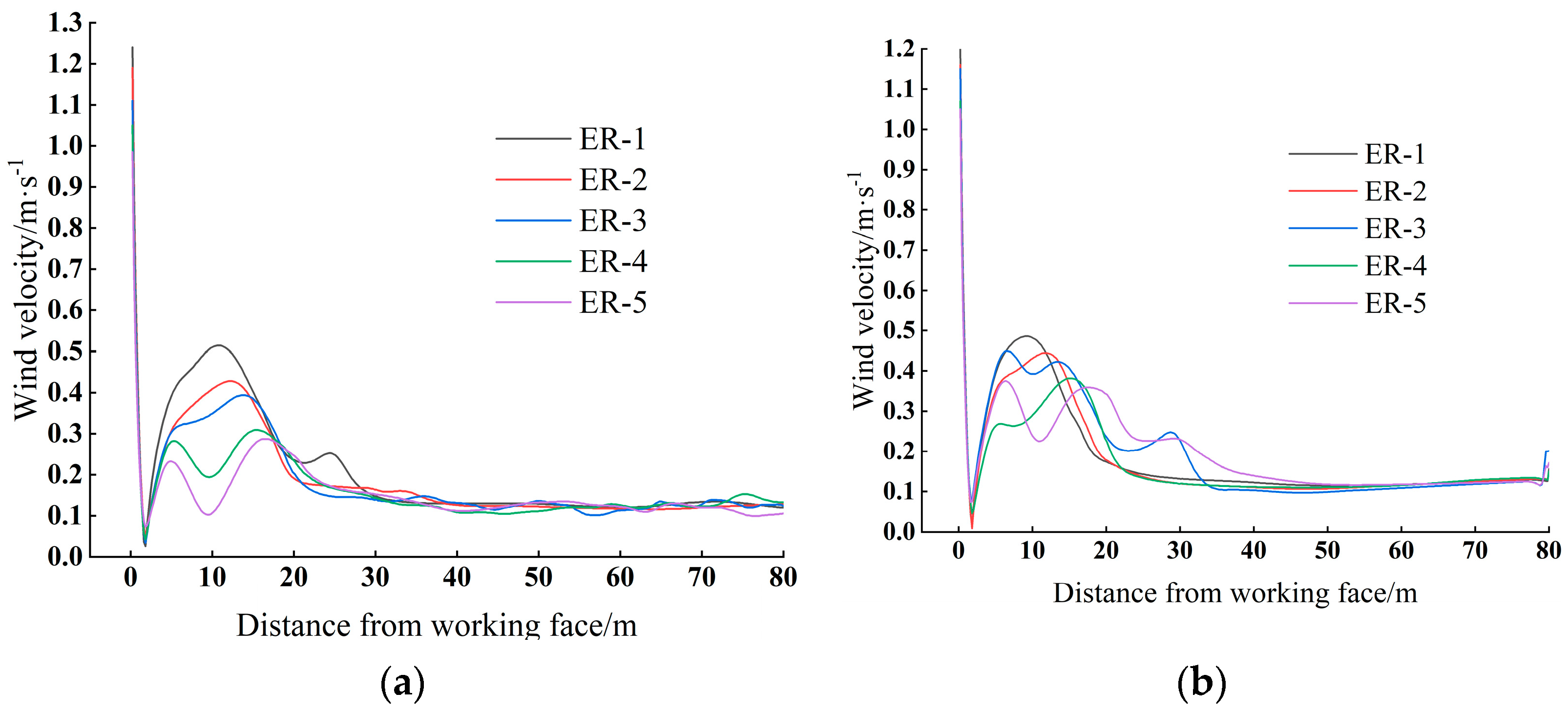

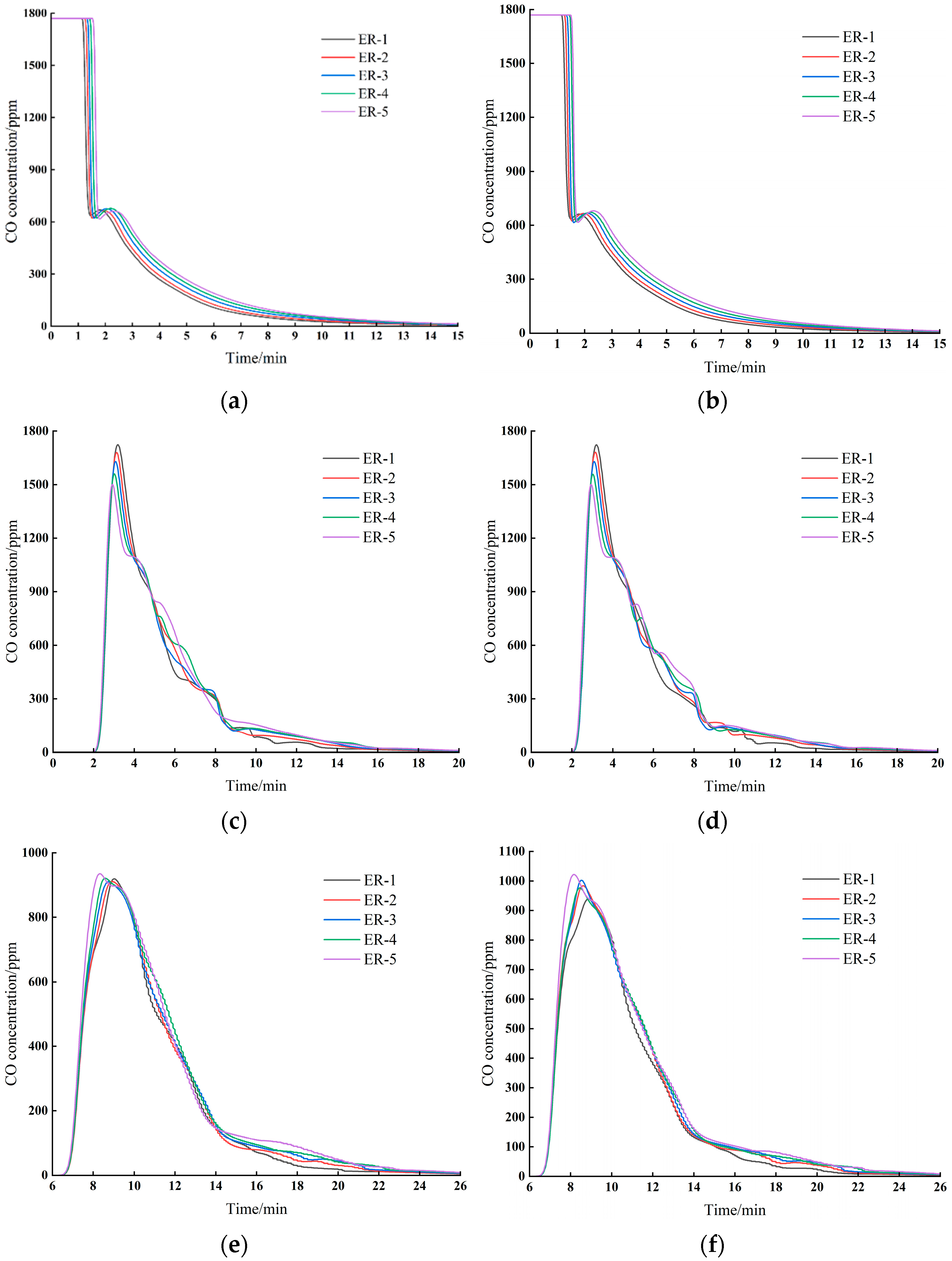

As illustrated in

Figure 16a, for point A11 under ER–1 to ER–5, the CO concentration initiates its decline from 1770 ppm at 68 s, 74 s, 80 s, 86 s, and 92 s, respectively, and requires 616 s, 664 s, 710 s, 750 s, and 786 s, respectively, to fall below 24 ppm. Similarly,

Figure 16b shows that for point B11 under ER–1 to ER–5, the CO concentration begins decreasing from 1770 ppm at 70 s, 76 s, 80 s, 86 s, and 90 s, respectively, and takes 604 s, 668 s, 708 s, 744 s, and 784 s, respectively, to reach below 24 ppm. The relative error in the time required for the CO concentration to drop below 24 ppm between points A11 and B11 (with and without a middle roadway) is 2%, 0.6%, 0.2%, 0.8%, and 0.2%, respectively.

As depicted in

Figure 16c, for monitoring point A12 under ER–1 to ER–5, the CO concentration decreased below the safety threshold (24 ppm) at 808 s, 892 s, 916 s, 985 s, and 956 s, with corresponding concentrations of 23.8 ppm, 23.7 ppm, 23.6 ppm, 24.0 ppm, and 23.8 ppm, respectively. Similarly,

Figure 16d shows that for point B12 under ER–1 to ER–5, the CO concentration fell below the safety level at 806 s, 904 s, 912 s, 944 s, and 1034 s, with measured values of 23.9 ppm, 23.8 ppm, 23.9 ppm, 24.0 ppm, and 23.9 ppm, respectively. The relative error in the time required to reach sub–24 ppm levels between A12 and B12 (with and without a middle roadway) was 0.2%, 1.3%, 0.4%, 4.3%, and 7.5%, respectively.

Figure 16e shows that the CO concentration at monitoring point A13 under ER–1 to ER–5 decreased below the safety threshold (24 ppm) at 1126 s, 1226 s, 1282 s, 1338 s, and 1356 s, with corresponding concentrations of 23.8 ppm, 23.7 ppm, 23.9 ppm, 23.7 ppm, and 23.8 ppm, respectively. Similarly,

Figure 16f demonstrates that the CO concentration at point B13 under ER–1 to ER–5 fell below the safety level at 1204 s, 1264 s, 1280 s, 1330 s, and 1346 s, with measured concentrations of 23.6 ppm, 23.8 ppm, 23.8 ppm, 23.9 ppm, and 23.7 ppm, respectively. The relative time differences for the CO concentration to drop below 24 ppm between points A13 and B13, with and without a middle roadway, were 6.9%, 3.1%, 0.1%, 0.6%, and 0.7%, respectively.

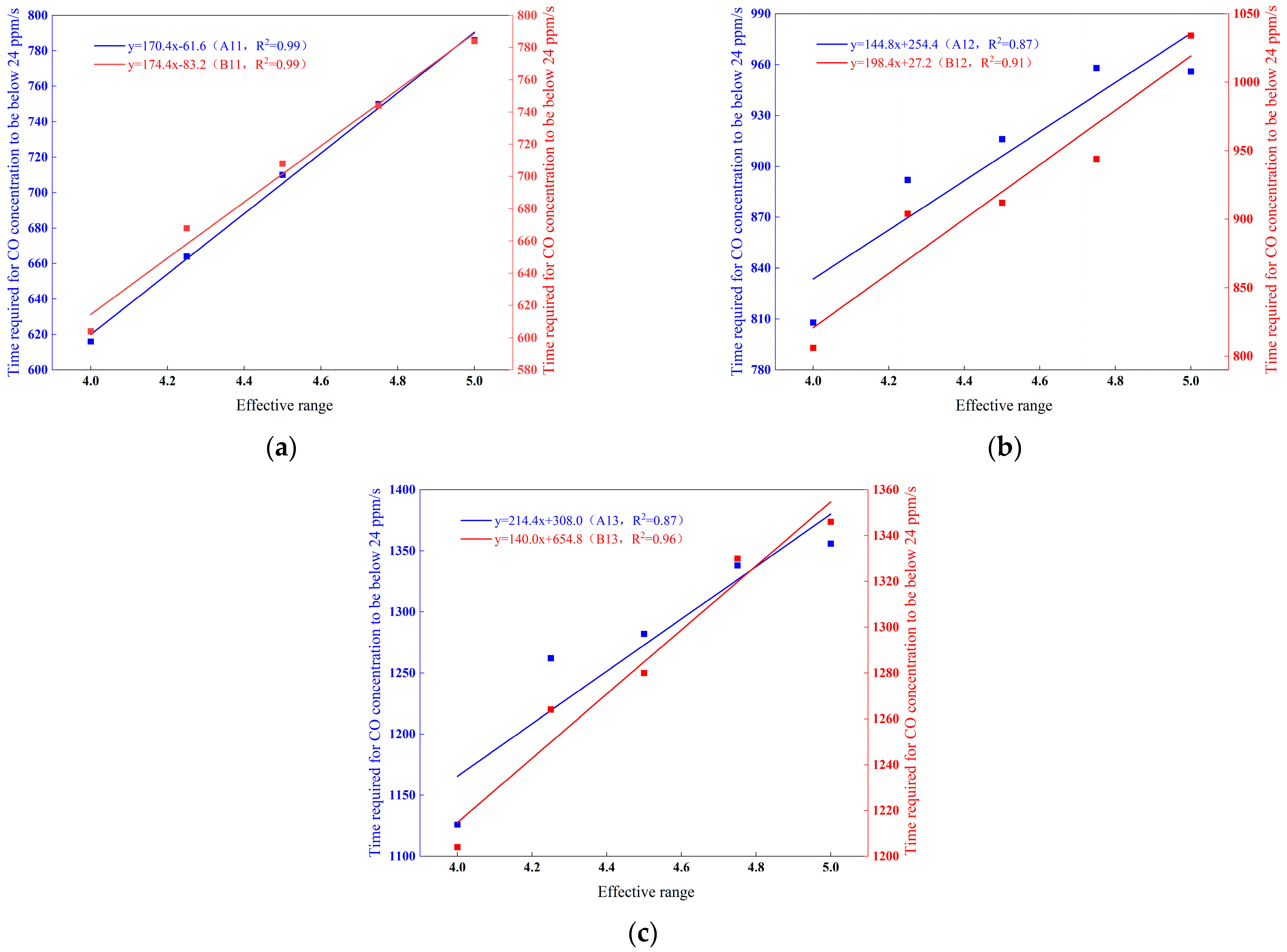

The time required for CO concentration to decrease to 24 ppm at each monitoring point was fitted as shown in

Figure 17.

The results demonstrate a linear increase in the required time for CO concentration to decrease below 24 ppm with increasing effective range. This trend occurs because longer effective ranges produce extended vortex zones, leading to greater wind energy dissipation. The enhanced energy loss reduces momentum transfer to CO particles during collisions, thereby weakening their migration toward the stope exit and prolonging the clearance time. For monitoring points A11, A12, A13, B11, B12, and B13, the required time increases linearly from 616 s, 808 s, 1126 s, 604 s, 806 s, and 1206 s to 786 s, 956 s, 1356 s, 784 s, 1034 s, and 1346 s, respectively. The presence or absence of a middle roadway exhibits negligible influence on CO migration at these points, as the airflow velocity difference at the working face remains marginal in both configurations.

In summary, regardless of a middle roadway, CO concentration in the throwing zone decreases overall. Upon fan activation, blasting fumes disperse, reducing CO levels. Vortex zones temporarily hinder migration, causing a slight rise near 2 min, but continuous ventilation introduces fresh air, eventually lowering CO below 24 ppm. Initially confined to the throwing zone, CO later migrates outward, increasing external concentrations before declining as fumes exit the stope. Thus, outside the throwing zone, CO follows an initial rise followed by a drop.

4.4. Comparative Analysis of Experiment and Simulation

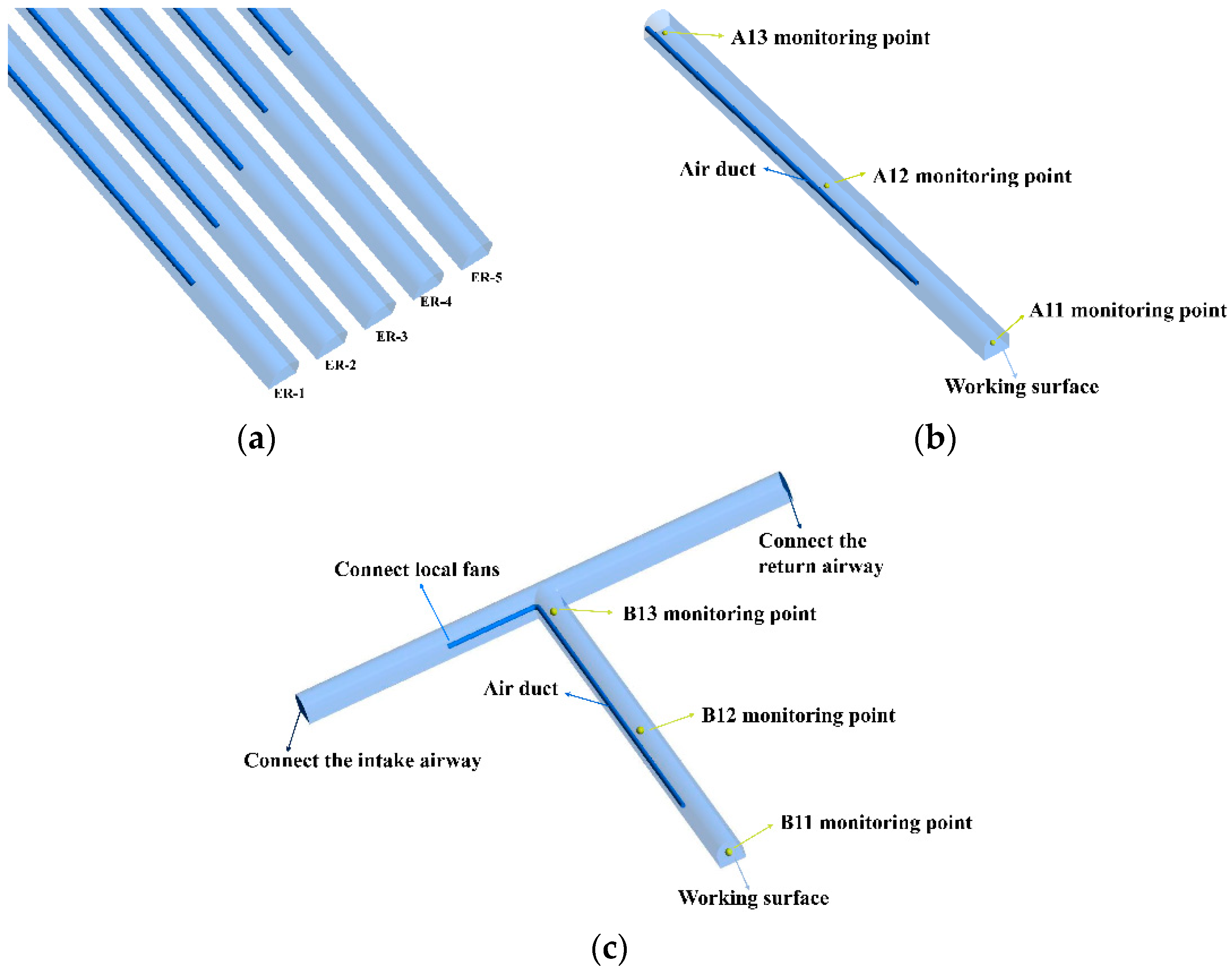

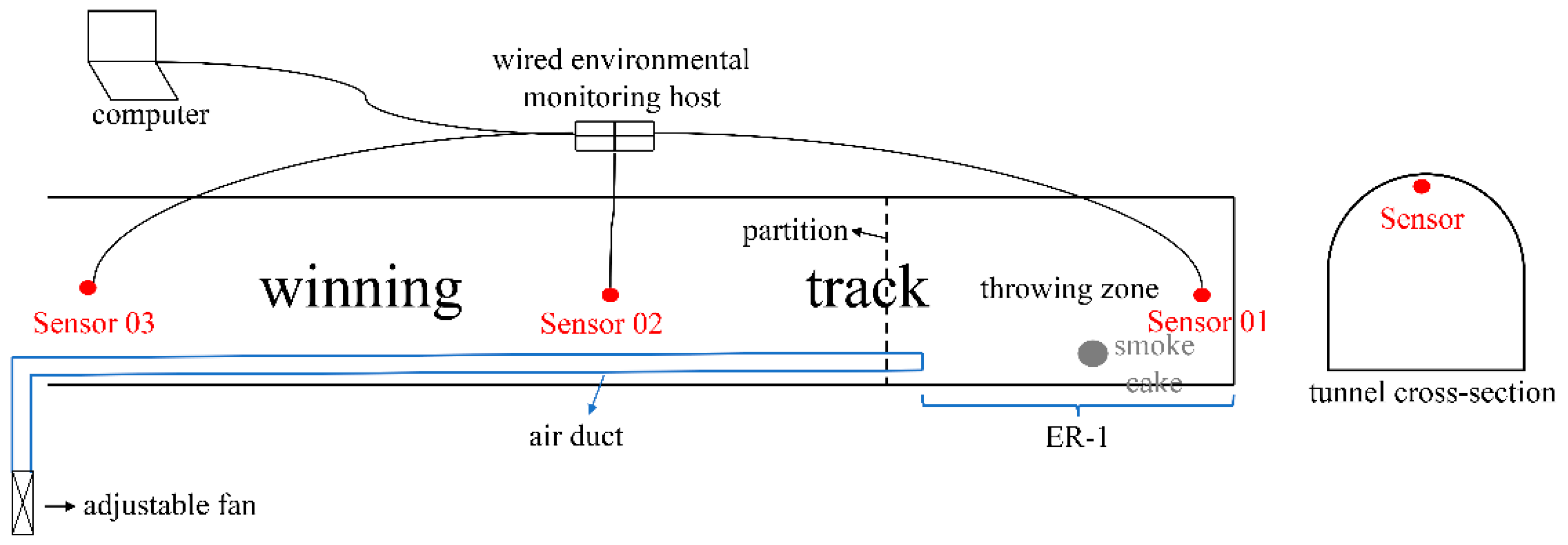

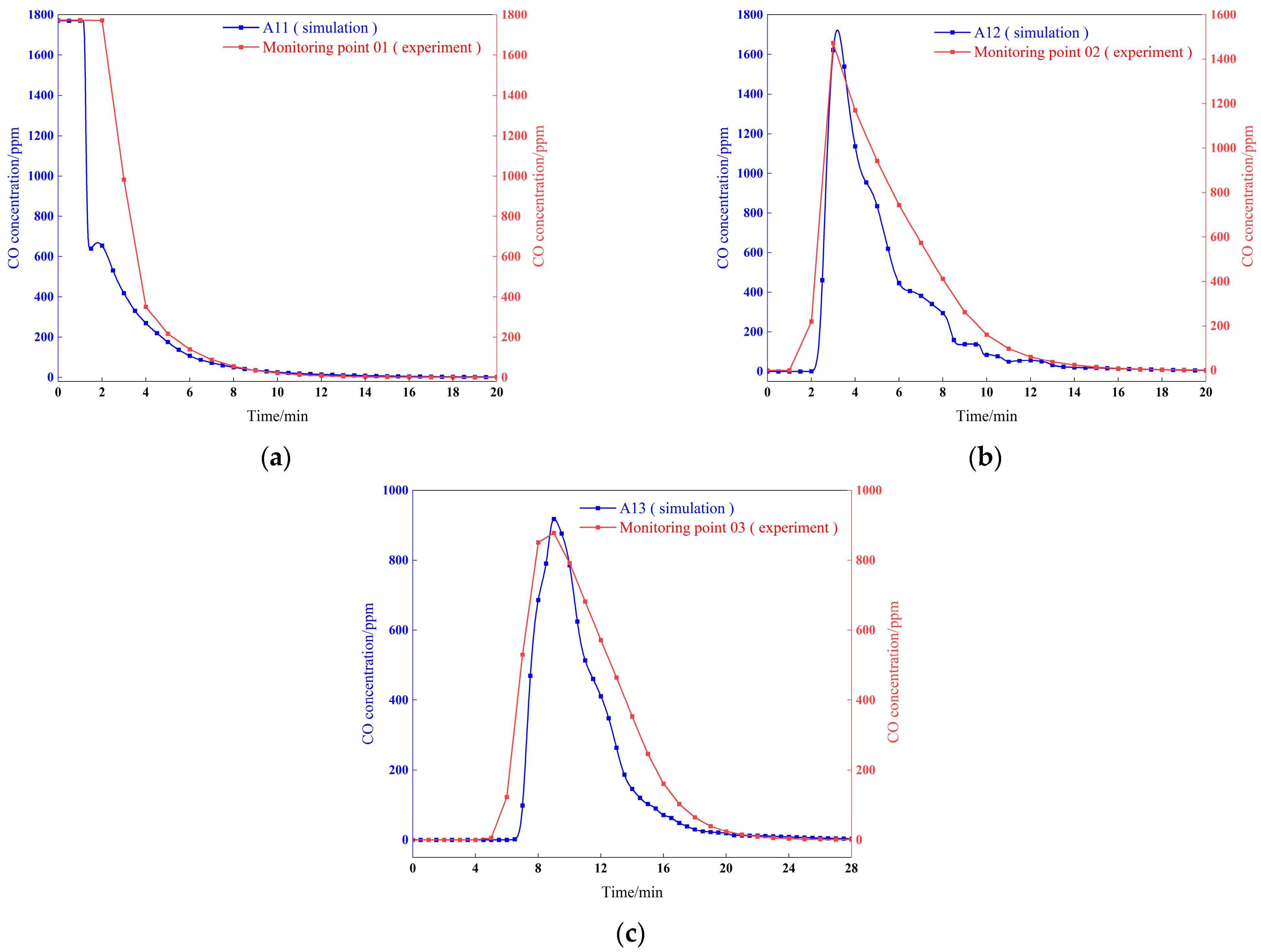

In this section, the accuracy of the simulation is verified through experimental research, as illustrated in

Figure 18. In the initial stage, a partition is strategically placed at the boundary of the smoke–generating area to effectively control the smoke produced by the combustion of the smoke cake and prevent its diffusion into other areas of the tunneling roadway. The primary objective of this partition is to limit the spread of smoke using physical barriers, thereby ensuring both the safety of the experimental environment and the accuracy of the experimental results. To meet the required air volume, the JYF–50S adjustable fan has been selected as the air supply equipment, and CO sensors have been installed at three monitoring points.

Due to the constraints imposed by the test site, the experimental system was constructed following a scale ratio of 1:16. The experimental model featured a stope length of 5 m, a roadway section wall height of 0.13 m, and a diameter of 0.28 m. The air duct had a diameter of 0.05 m, and the distance from the air duct outlet to the working face was 1.03 m. Carbon monoxide (CO) sensors were installed at distances of 13 cm, 250 cm, and 488 cm from the heading face. Additionally, the local fan was positioned 0.94 m from the excavation roadway exit, while the length of the throwing area was 1.31 m. Given the limitations of the experimental conditions, strict adherence to dynamic similarity was not required. The wind speed at the air duct outlet was scaled down, resulting in an air duct wind speed of 0.25 m/s, thereby ensuring that the flow processes of the experiment and simulation occurred on the same time scale [

9]. The curve depicting CO concentration over time at each corresponding point in both the simulation and experiment is illustrated in

Figure 19. Both the experiment and simulation indicate that the CO concentration within the throwing area consistently decreases, while the CO concentration outside the throwing area initially increases before subsequently decreasing. The simulation results align with the experimental findings, as the experimental design preserved the consistency of geometric and flow rate ratios, thus ensuring equivalence in the time scale. This similarity in design allows the gas concentration change curves obtained from both the experiment and simulation to exhibit comparable trends and morphological characteristics. The experimental data validate the concentration diffusion law derived from numerical simulation, encompassing the fundamental characteristics of concentration fluctuations.

At the monitoring points A11, A12, A13, 01, 02, and 03, the time required for the carbon monoxide (CO) concentration to decrease to 24 ppm was recorded as 616 s, 808 s, 1126 s, 600 s, 840 s, and 1260 s, respectively. The CO concentration peaked at the monitoring points A12, A13, 02, and 03 at 192 s, 542 s, 180 s, and 540 s, respectively, with peak values of 1723 ppm, 919 ppm, 1473 ppm, and 878 ppm, respectively. When the time required to reduce CO to 24 ppm is used as the criterion, the error between A11 and 01 is 2.67%, the error between A12 and 02 is 3.96%, and the error between A13 and 03 is 11.90%. Conversely, when the peak value is used as the criterion, the error between A12 and 02 is 16.97%, while the error between A13 and 03 is 4.67%. In summary, the error between the simulation and experimental results is within 16.97%.

There are several reasons for the observed error. First, this study employs a geometric scale of 1:16 to design the experimental model. If the Reynolds similarity criterion were strictly adhered to in determining the outlet wind speed parameters, the wind speed would theoretically need to be set at 64 m/s to satisfy complete similarity conditions. However, due to safety concerns and the practical operability of the experimental equipment, achieving such a high wind speed in a laboratory environment poses significant challenges and safety hazards. Consequently, the similarity criterion is simplified in the experimental design, with wind speed parameters being reduced directly in accordance with the geometric scale. While this simplification ensures the feasibility of the experiment, it inevitably results in a deviation between the measured concentration peak values and the predicted values from the numerical simulation, thereby affecting the accuracy of the time required for CO concentration to decrease to 24 ppm. Secondly, the location of the concentration sensor used in the experiment does not correspond precisely to the monitoring points in the numerical simulation. This slight discrepancy in spatial location is directly reflected in the concentration measurement results.