Abstract

This article investigates how safety culture impacts the safety performance of blue hydrogen projects. Blue hydrogen refers to decarbonized hydrogen, produced through natural gas reforming with carbon capture and storage (CCS) technology. It is crucial to decide on a suitable safety policy to avoid potential injuries, financial losses, and loss of public goodwill. The system dynamics approach is a suitable tool for studying the impact of factors controlling safety culture. This study examines the interactions between influencing factors and implications of various strategies using what-if analyses. The conventional risk and safety assessments fail to consider the interconnectedness between the technical system and its social envelope. After identifying the key factors influencing safety culture, a system dynamics model will be developed to evaluate the impact of those factors on the safety performance of the facility. The emphasis on safety culture is directed by the necessity to prevent major disasters that could threaten a company’s survival, as well as to prevent minor yet disruptive incidents that may occur during day-to-day operations. Enhanced focus on safety culture is essential for maintaining an organization’s long-term viability. H2-CCS is a complex socio-technical system comprising interconnected subsystems and sub-subsystems. This study focuses on the safety culture sub-subsystem, illustrating how human factors within the system contribute to the occurrence of incidents. The findings from this research study can assist in creating effective strategies to improve the sustainability of the operation. By doing so, strategies can be formulated that not only enhance the integrity and reliability of an installation, as well as its availability within the energy networks, but also contribute to earning a good reputation in the community that it serves.

1. Introduction

Hydrogen is recognized as a technically feasible and environmentally friendly energy carrier suitable for various industries, from providing fuel for rockets and fuel cells for generating electricity and powering vehicles [1,2]. The goal of this energy transition is for hydrogen to satisfy 10–18% of the global energy demand by 2050 [3]. Deep crustal hydrogen (H2) production shows potential as a primary energy source, provided there are significant recoverable accumulations in geological formations. This naturally occurring hydrogen—also known as geologic, white, or gold hydrogen—results from reactions between water and iron-rich minerals. For instance, a high outgassing rate of 84% H2 (by volume) has been recorded from Albania’s deep underground Bulqizë chromite mine [4]. Traditionally, industries like oil refining and fertilizer manufacturing have produced hydrogen through emission-intensive processes such as gasification and fossil fuel reforming [1].

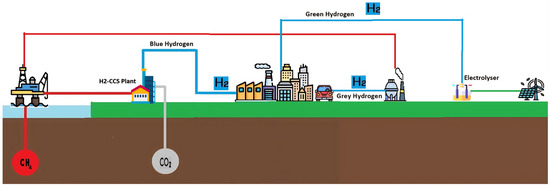

Hydrogen holds promise as an alternative fuel due to its zero carbon emissions and diverse production methods. Depending on how it is produced, hydrogen can be categorized as grey, blue, or green, each with varying environmental impacts and technological considerations [5]:

Grey hydrogen: It is produced from fossil fuels such as natural gas, without capturing the carbon dioxide emitted during the synthesis process. This form of hydrogen, which is widely accessible, is the most commonly available.

Blue hydrogen: It is generated using the same method as grey hydrogen, but the key difference is that the emitted carbon is captured and sequestered during the production process.

Green hydrogen: The most highly desired type of hydrogen is green hydrogen, which is produced using green or renewable energy sources.

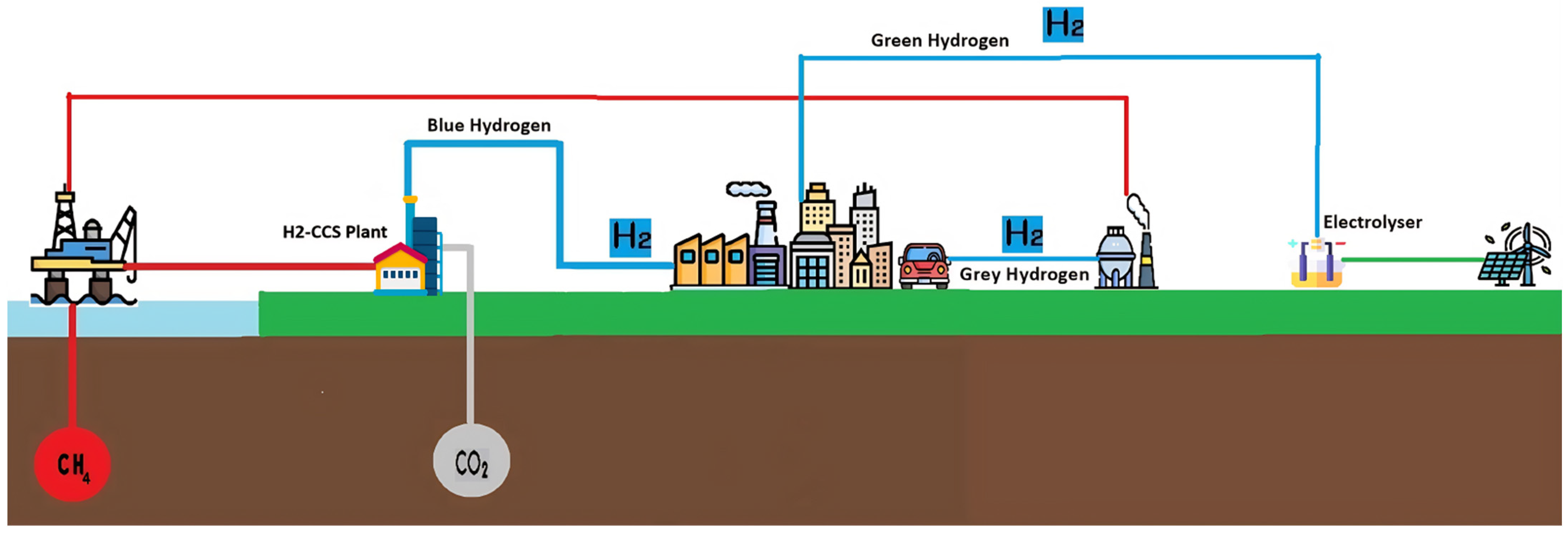

Figure 1 illustrates different hydrogen production processes. These processes can be classified based on source of energy and different type of energy used.

Figure 1.

Blue hydrogen production processes.

Blue hydrogen, generated from fossil fuels alongside CO2 capture, is presently seen as the transitional production between high-emission grey hydrogen and the scarce, zero-emission green hydrogen [3]. However, integrating hydrogen into the global energy system on a larger scale will pose significant complexities that must be addressed.

As indicated in the Introduction, the H2-CCS system can be categorized into four main subsystems: H2 Production and Carbon Capture, Transportation, Storage, and Chain Management. Each of these subsystems comprises multiple sub-subsystems.

2. Materials and Methods

Most reported incidents are linked to the fourth subsystem, specifically due to human factor contribution to risks. This paper examines a particular sub-subsystem within this category: organizational culture. In a developing industry like H2-CCS, there are many uncertainties, including unknown unknowns. Human operators may make incorrect decisions due to knowledge gaps, financial pressures, or reliance on outdated practices from related industries.

2.1. Risk Review

Numerous technological and business challenges must be addressed throughout the H2-CCS chain to facilitate the broader adoption of blue hydrogen. This section will examine earlier studies that specifically address the identification and evaluation of hazards in CCS–hydrogen projects. Table 1 gives a sample of papers that focus on various threats to part of the entire H2-CCS chain.

Table 1.

Examples of blue hydrogen risk review papers.

Researchers working on hydrogen transition have identified several obstacles that highlight the multi-sectoral complexities of scaling economies and gaining social acceptance. Addressing these challenges requires a comprehensive understanding of socio-technical factors across various levels of the hydrogen economy [10]. Key gaps in the study of the social aspect of the technology include the undefined societal value of hydrogen, insufficient research on socio-political aspects such as geopolitics and well-being, limited application of social life cycle assessment, and sparse studies addressing social practices and cultural considerations [19].

2.2. Safety Culture

The concept of safety culture emerged following the 1986 Chernobyl incident [20]. In this context, an “incident” is an occurrence that has happened unintentionally, which may not lead to any damage, injuries, or any other harm, while an “accident” is an incident that occurs unintentionally and may lead to damage, injury, or harm. The common thread among major accidents is that all of them involved significant failures of complex socio-technical systems. This pinpoints issues within the organization’s “safety culture” as a key contributing factor, reflecting broader problems in the organizational culture. No widely agreed-upon definition of safety culture comprehensively includes all viewpoints [21]. Despite this, identifiable elements allow for the formulation of a definition of safety culture as a collection of shared values [22]. Consensus in safety culture is an element of organizational culture that is often defined as “the integration of the individual and group values, attitudes, competencies and patterns of behaviour that determine the commitment to, and the style and proficiency of, an organization’s health and safety programs” [23]. The safety culture within an organization is visible through the actions of its management and employees in prioritizing the elimination or reduction in workplace hazards [24]. This culture includes the following components:

- Making safety and responsible work practices a top priority.

- Safeguarding the well-being of the organization’s staff, equipment, and property.

- Ensuring the safety and welfare of the public.

- Preserving the environment.

- Offering continuous education and training on key principles and optimal practices.

Social life cycle assessment (S-LCA) is a tool used to assess the social impacts, both positive and negative, that a product may have throughout its entire life cycle [25]. The social aspect of safety culture applies to the influence of organizational values, attitudes, and behaviours regarding safety on individuals and groups in a workplace or community. According to their research, poor performance in various industries can be attributed to factors such as insufficient workers’ engagement, inadequate personal risk evaluation, excessive work pressure, lack of worker appreciation, financial constraints, high expenses, inflated raw material costs, and communication breakdowns [26]. In the data provided, it is shown that 1.8 million workers experienced work-related health issues in 2022 and 2023 in Britain, with about half of these instances attributed to stress, depression, or anxiety [27]. The mental health issues could stem from internal pressures within the organization.

The cultural environment shapes individuals’ assessments of the appropriateness of their behaviour. An organization’s culture plays a significant role in shaping employee behaviour and performance in the workplace. Instances of significant incidents and personal injuries have been linked to inadequate safety culture. It is essential to develop a secure work environment with employees committed to safety due to the significant impact of these issues.

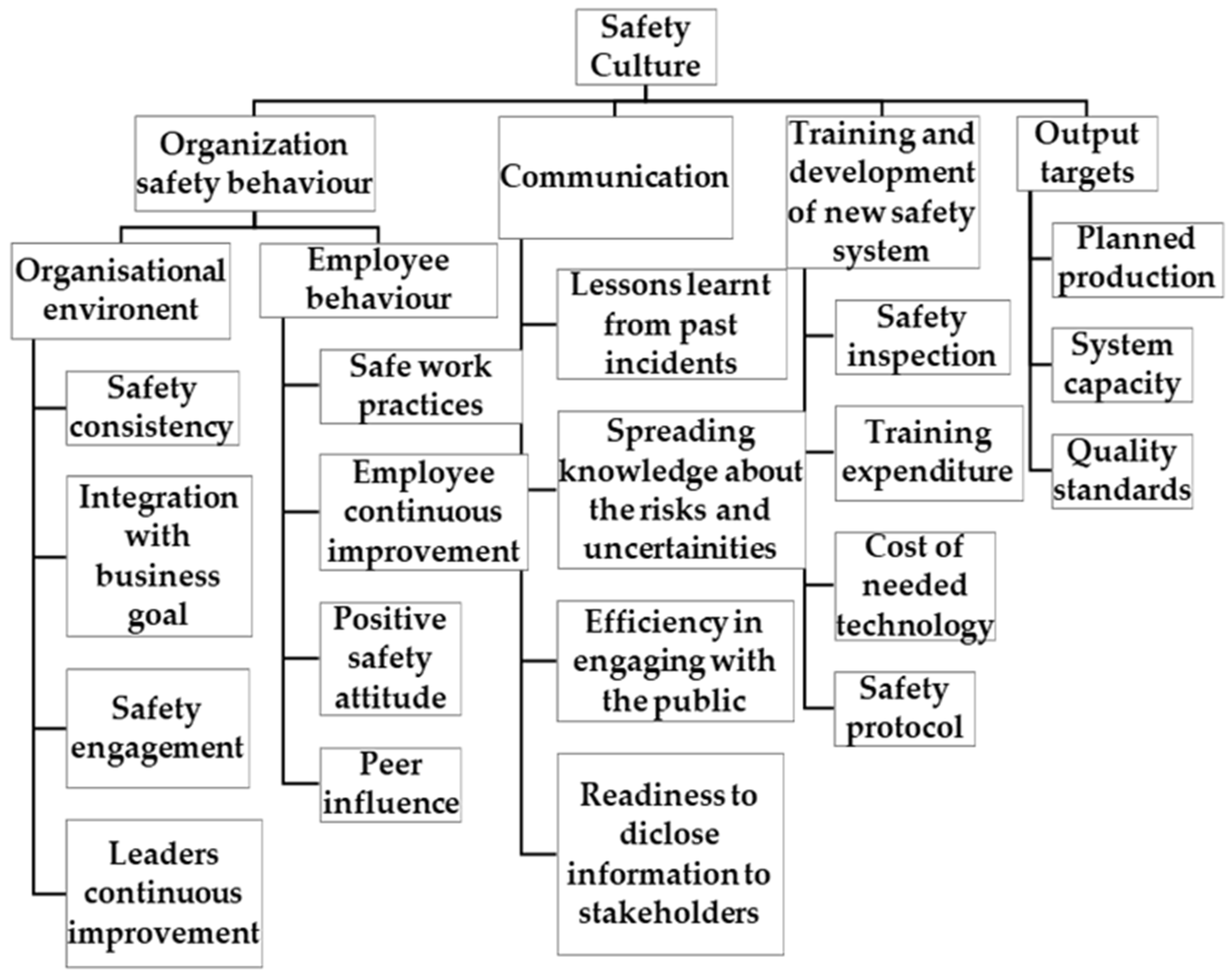

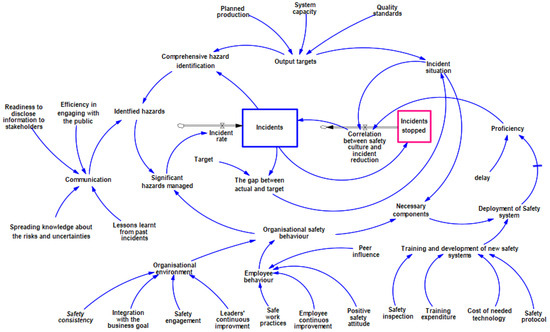

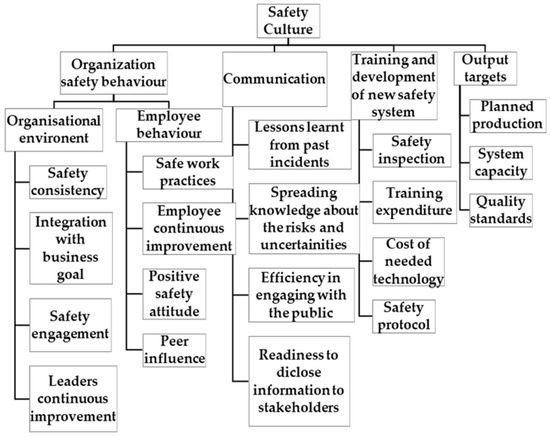

Part of a broader approach to accident prevention, safety culture, along with elements such as technical failures, and human mistakes, has gained increasing attention from various scientific fields over the past thirty years. This trend reflects a shift towards more “socio-technical” and “systemic” safety approaches [28]. The focus on safety culture arises from the aim to prevent major disasters that could greatly impact a company, alongside minor yet disruptive incidents resulting from daily operations. Major multinational corporations seek to reduce their exposure to losses by promoting a consistent global “safety culture,” which may occasionally conflict with their financial goals. This study applies to the five dimensions of safety culture described as the primary framework for analysis. It builds upon prior research on safety culture, providing insights into its evolution within organizations. Previous safety models typically assessed the maturity of an organizational safety culture through surveys. This paper identifies the principal dimensions of safety culture based on its analysis [29]. Figure 2 illustrates the key dimensions of safety culture and demonstrates how these elements are interconnected.

Figure 2.

Safety culture key dimensions.

2.2.1. Management Commitment to Safety

Management’s dedication to safety is the key aspect of safety culture, as it serves as a significant predictor of worker safety behaviours and incidents across various job types [30]. Management commitment results in all members of the management team collectively embracing a consistent safety mindset and integrating this view into their day-to-day decision-making processes [31].

2.2.2. Open Communication

Communication enables individuals, tasks, processes, and systems to interact purposefully and collaboratively to accomplish health, safety, and environmental (HSE) goals [32]. Safety communication involves effectively conveying various hazards and risks to all staff members in a workplace. The objective is to minimize the occurrence of accidents by ensuring that employees are informed about the risks they may encounter during operations [33].

2.2.3. Training Initiatives

The presentation of realistic workplace hazards appears crucial for safety training. From a neuropsychological perception, effectively engaging safety training participants could impact their indirect attitudes, strengthening natural safe behaviours [34].

2.2.4. Organizational Learning

A learning organization positively impacts work safety performance and safety culture [35]. Gaining awareness from failures is a valuable process that enhances organizational performance by generating new knowledge through identifying errors and comprehending their causes and consequences [36]. Organizational training is crucial for safety success and should be continuously improved to enhance safety culture and performance.

2.2.5. Employee Dedication

Employees’ general satisfaction with safety culture is primarily influenced by their commitment. This commitment, in turn, relies significantly on the commitment of top management, which is influenced by supervisor commitment and safety training [22].

In general, blue hydrogen is considered a transitional solution aimed at cutting carbon emissions within industries presently dependent on fossil fuels. The future sustainability and social acceptance of these technological solutions will rely on various factors such as safety, environmental impact, regulatory compliance, and economic feasibility [37]. Public perception, influenced by trust in technology, environmental effects, and economic viability, is key. As awareness of climate change and technology advances, views on blue hydrogen’s role in the energy transition may change. Effective stakeholder engagement, communication, and education regarding both the advantages and obstacles of blue hydrogen are crucial to fostering broad acceptance of this technology. This paper employs a system dynamics approach to analyze how various identified parameters of safety culture impact the number of incidents. By modelling the interactions and feedback loops within the system, this method allows for a comprehensive understanding of how changes in safety culture elements influence incident rates over time. The study aims to identify key factors and influence points within the system that can lead to improved safety outcomes and reduced incident frequency.

3. Results

3.1. System Dynamics Model

The influence of safety culture on H2-CCS plant performance is evaluated using system dynamics. System dynamics proves to be an effective tool as it enables the modelling of complex system interactions and feedback loops present within the system to show how variables are causally related. By utilizing this method, various scenarios, cause-and-effect relationships, and strategic areas can be simulated to enhance safety culture and plant performance in the long run. The safety culture of an organization is shaped by a range of social, organizational, and operational factors, which in turn influence how employees and managers view, prioritize, and implement safety protocols.

System dynamics is an effective tool for understanding complex system behaviours, evaluating decision outcomes, and developing strategies for better performance. It uses a structured approach to analyze, model, and simulate the dynamic interactions within these systems. System dynamics helps analyze complex systems through a structured approach:

- Identify the problem within a dynamic system.

- Define system boundaries by identifying key components and interactions.

- Categorize key variables as stocks (quantities) or flows (rates of change).

- Create a causal loop diagram to visualize feedback loops and relationships.

- Develop a stock and flow diagram to show changes in stocks over time.

- Formulate mathematical equations to describe system behaviour.

- Assign values to parameters in the model.

- Run simulations to analyze system behaviour under different scenarios.

- Evaluate the system’s responses and refine the model for accuracy.

- Test and identify strategies to improve system performance.

- Communicate results clearly to stakeholders and decision-makers.

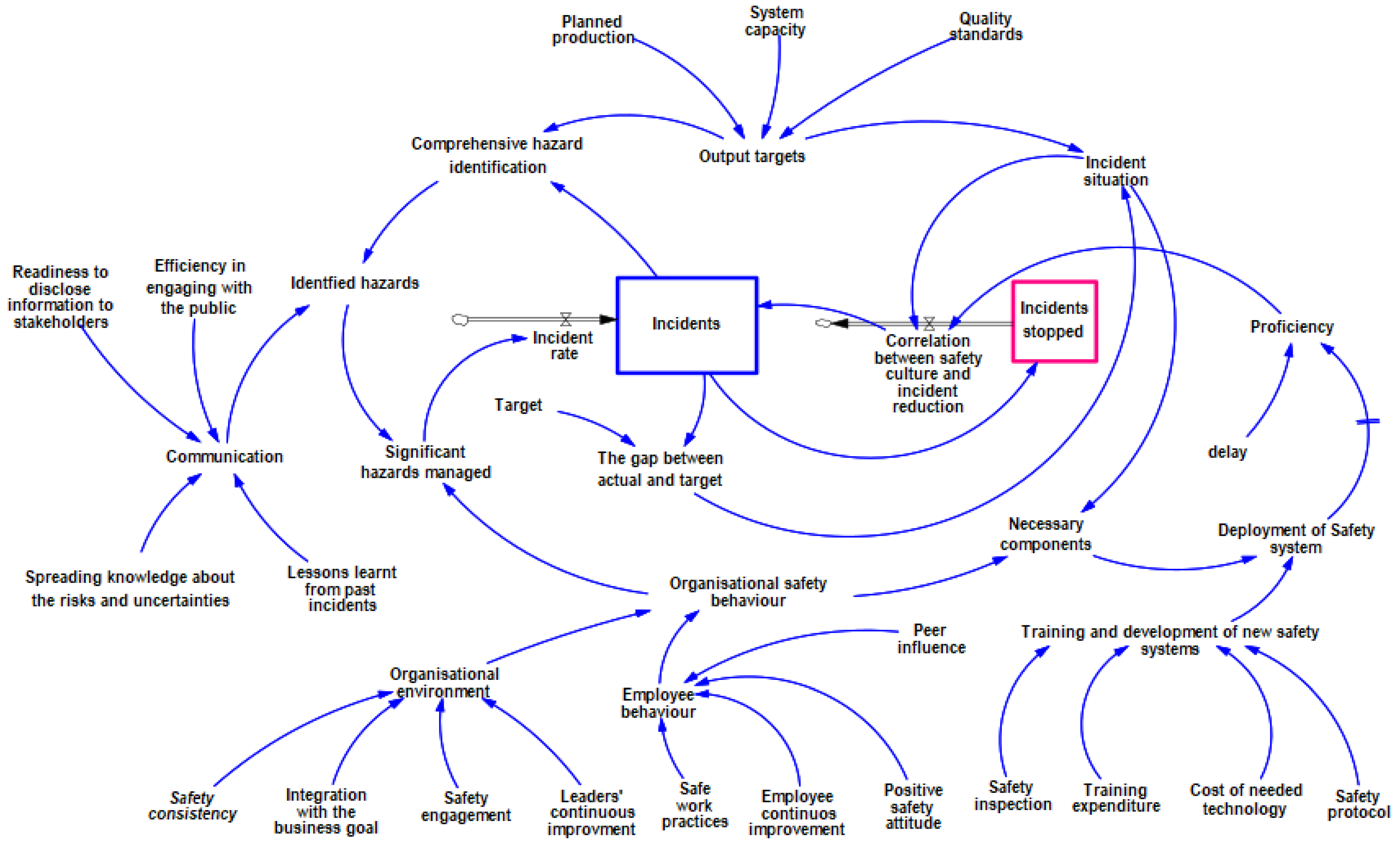

Figure 3 illustrates the system dynamics model representing how safety culture impacts safety performance in a blue hydrogen plant. Appendix A contains all the equations used for the Vensim model.

Figure 3.

System dynamics model of the effect of safety culture on safety performance on blue hydrogen plant.

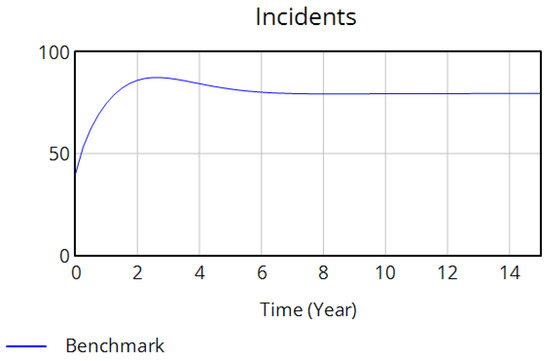

Initiating measurements is just the beginning. Acting upon the results and providing feedback to employees is crucial. Organizations have discovered the value of conducting regular measurements to monitor progress. The model repeats and simulates this process over time. A recommended initial step is to assess the current safety culture, possibly by analyzing the number of initial incidents occurring within the organization. It is assumed that there were initially 40 incidents, and the impact of different factors on the number of incidents over 35 years is examined. The initial figure of 40 incidents per year serves as a baseline assumption derived from prior historical data within similar organizations and industries. This value represents an estimate of the typical incident frequency before any changes or interventions are made to the safety culture. It provides a starting point for the system dynamics analysis, allowing the study to explore how various safety culture factors influence incident rates over 35 years.

A process of cultural change may require several years to complete. This requires releasing old operational methods and progressively adopting a new culture with new expectations for employee performance [38]. This is considered in the model by adding a deferred variable to study the effect of training and the development of safety equipment in the model. Focusing only on the employees below the managers is a common error. Senior managers must be willing to have their perceptions and behaviours examined and questioned. In the model, organizational safety behaviour depends on both managers and employees.

Production pressure is acknowledged as a major factor leading to accidents within modern complex socio-technical organizations. Increased production demands may result in a heavier workload for employees, reduced well-being, higher error rates, decreased attention to detail, a compromised safety culture, acceptance of different behaviours as the norm, and an increase in adverse incidents [39]. In the model, this pressure is referred to as “output targets” which depend on planned production, system capacity, and quality standards. Figure 4 shows the primary constants in the model while Table 2 represents the numerical values assigned to these primary constants, which are derived based on experts judgement.

Figure 4.

The primary constants that rule the safety culture model.

Table 2.

Numerical values of primary constants based on expert opinion (averaged).

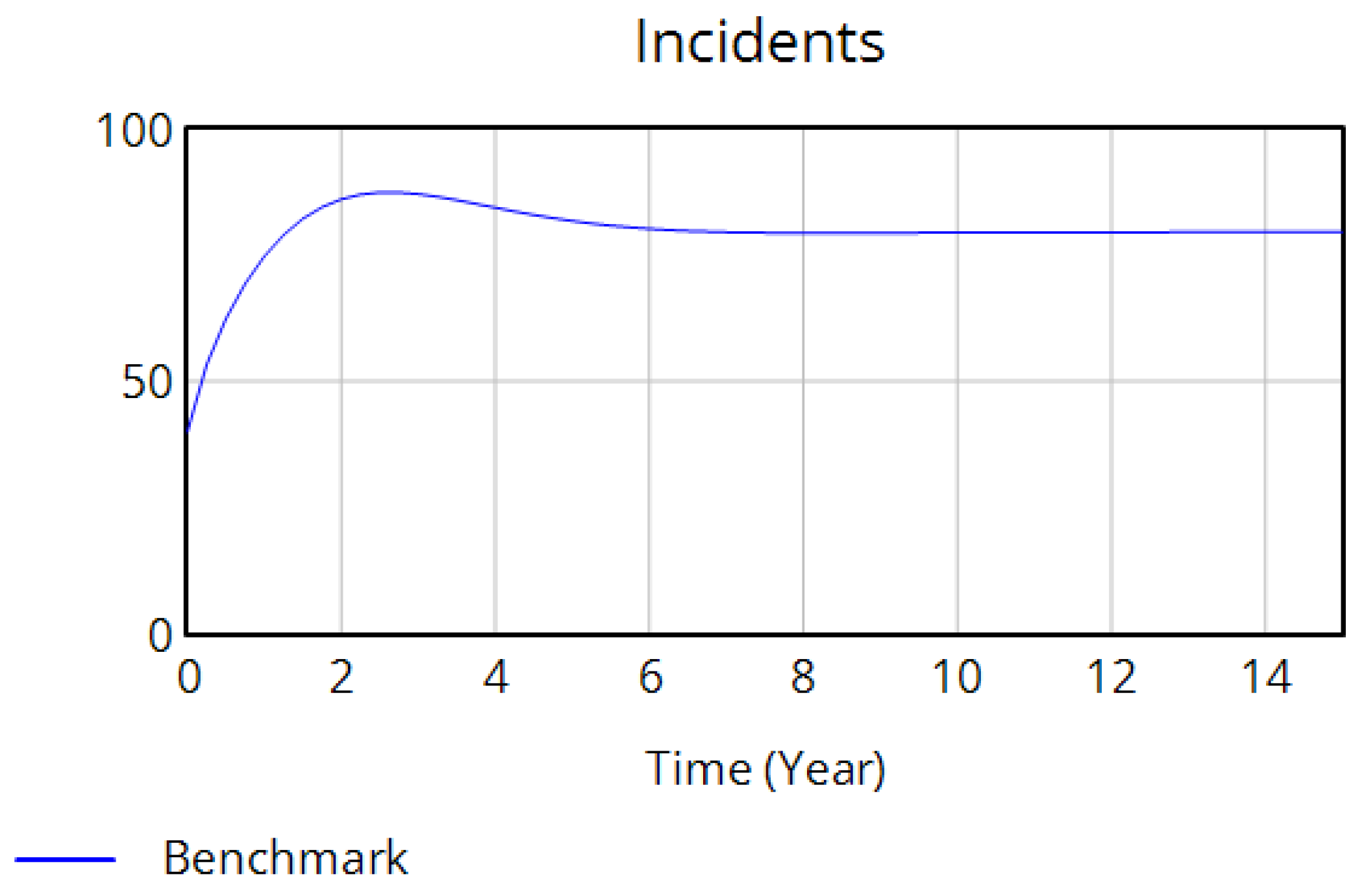

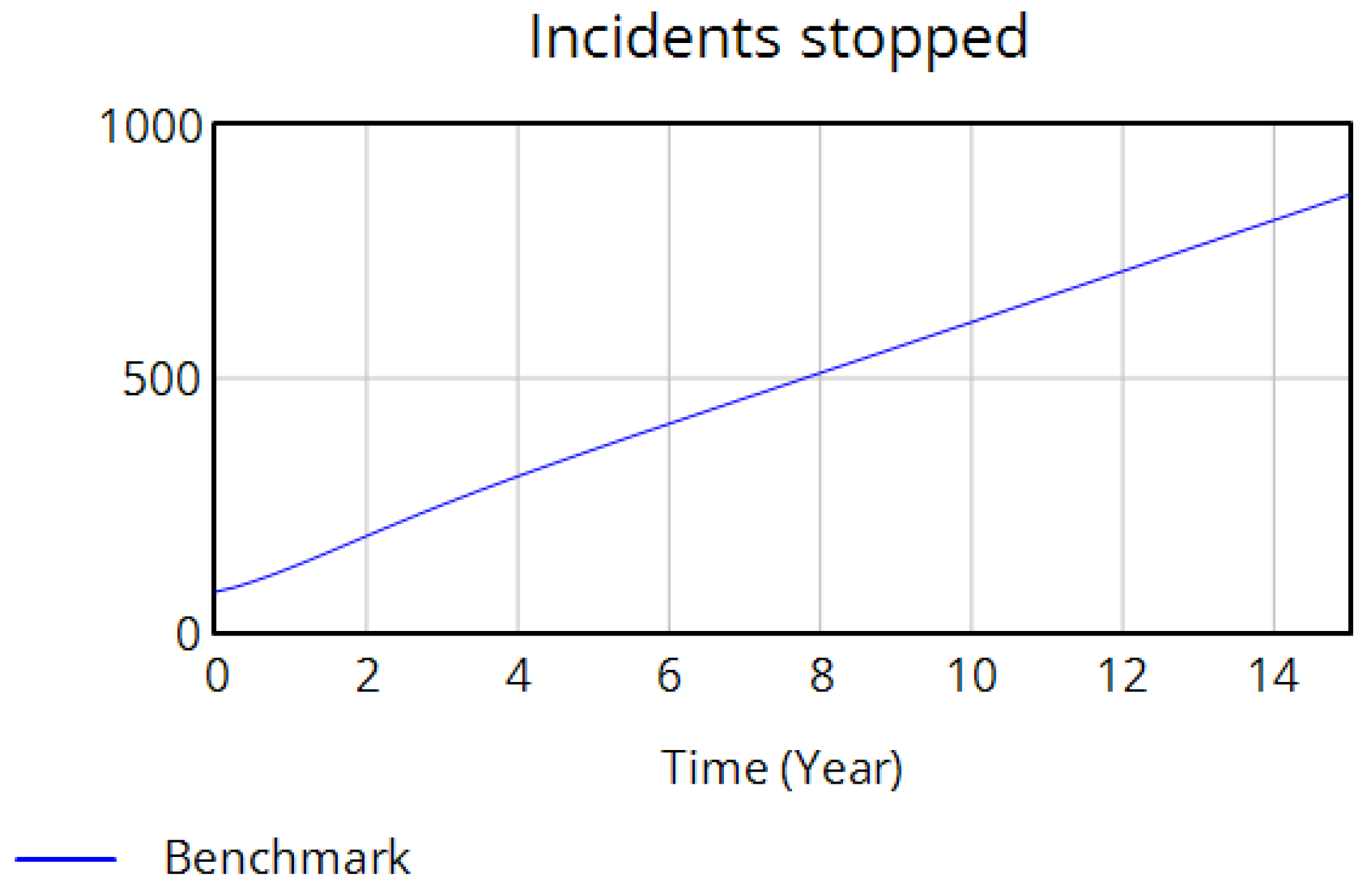

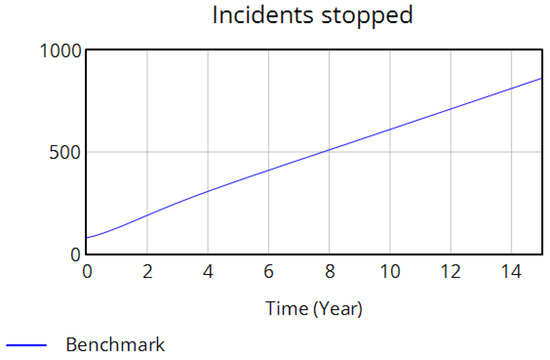

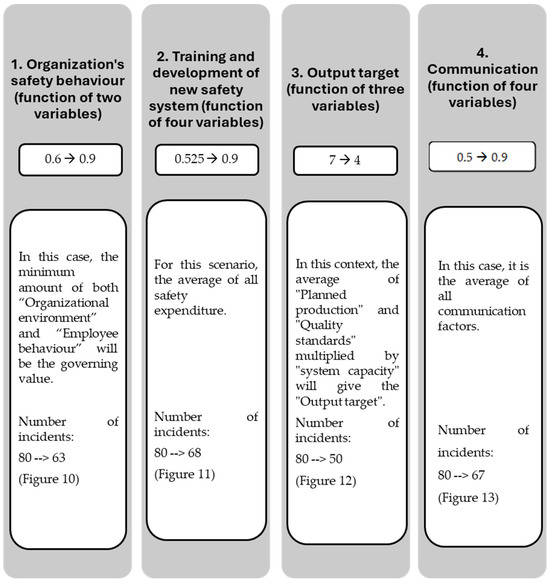

Safety is often linked to the attitude of an industry, organization, or individual [40]. The events that escalate to near-misses or accidents, while undesirable, present opportunities to gain awareness from past experiences, develop procedures, and decrease the probability of similar incidents occurring in the future [41]. The number of incidents and cumulative incidents stopped in 15 years are illustrated in Figure 5 and Figure 6, respectively. The Figure 5 and Figure 6 provide an estimation of the incidents for the entire H2-CCS chain.

Figure 5.

Number of incidents in 15 years.

Figure 6.

Cumulative incidents stopped in 15 years.

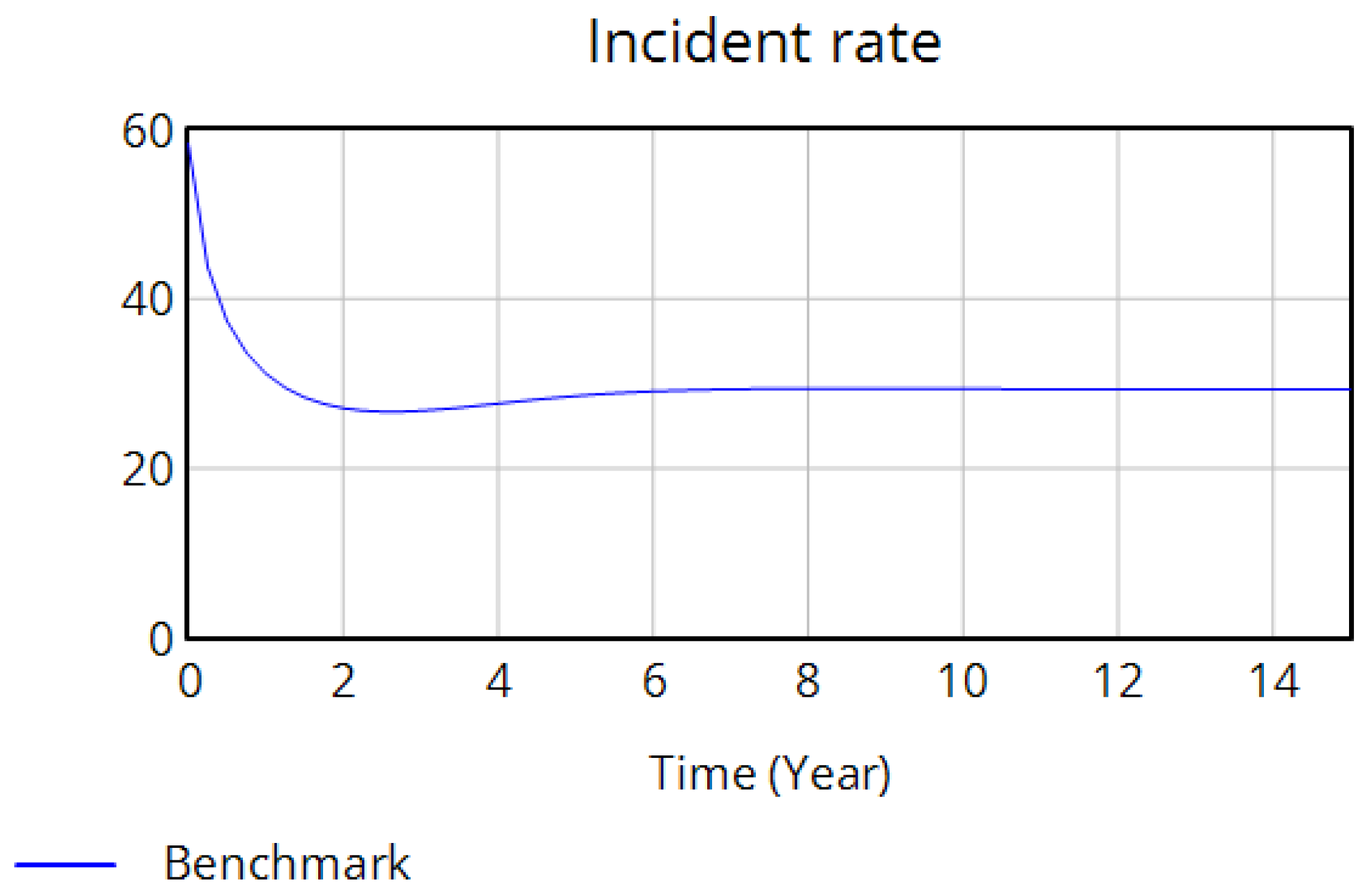

The model calculates the yearly incident count by subtracting the correlation between safety culture and incident reduction from the incident rate. The incident rate is directly dependent on significant hazards managed which is influenced by the organization’s safety behaviour and recorded risk through efficient communication. Figure 7 shows the incident rate in the next 15 years.

Figure 7.

Incident rate in the next 15 years.

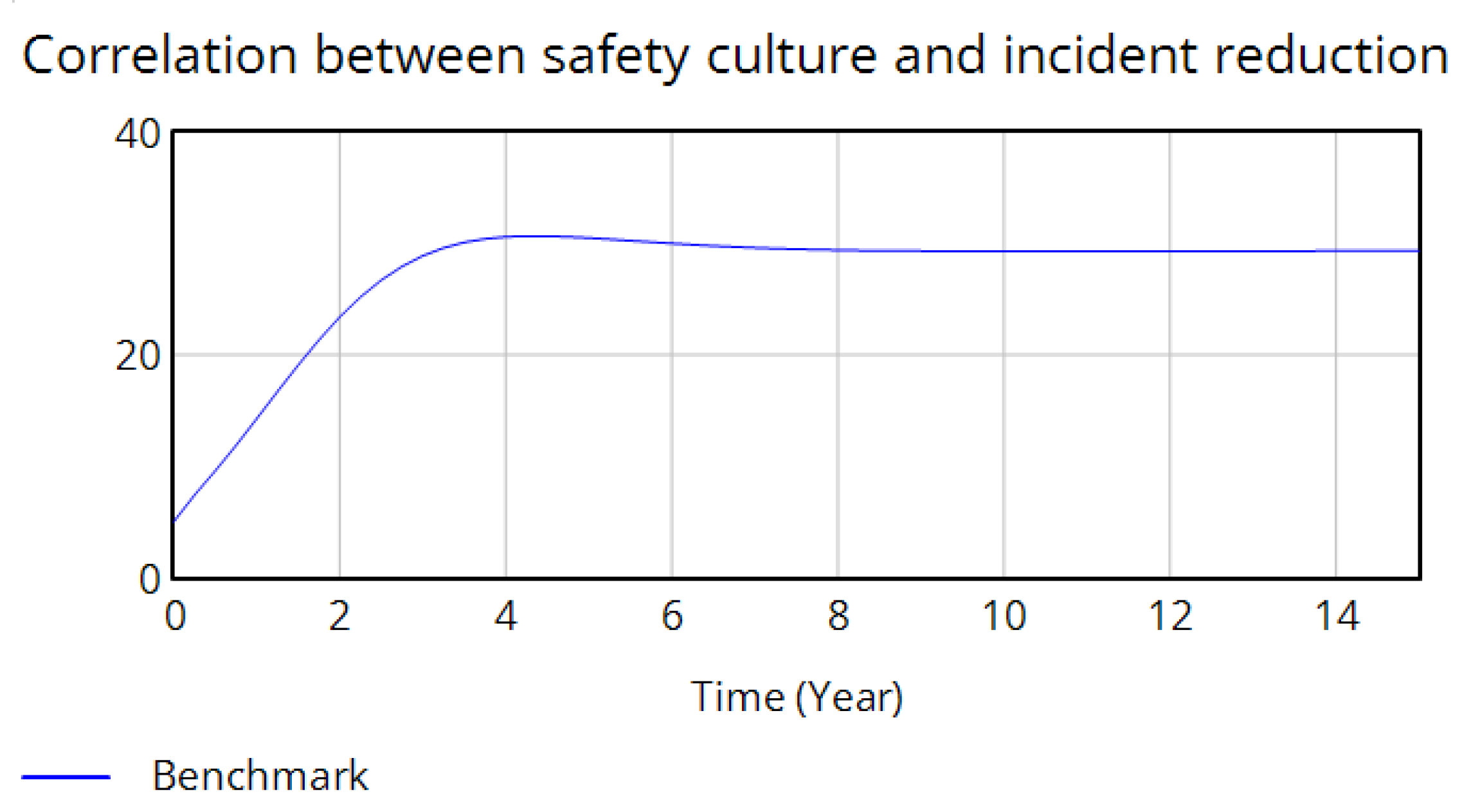

The effect of safety culture on the correlation between safety culture and incident reduction over the next 15 years is shown in Figure 8.

Figure 8.

Correlation between safety culture and incident reduction in 15 years.

The data serve as an early warning system for potential accidents, helping to proactively identify safety vulnerabilities and prevent disasters [40].

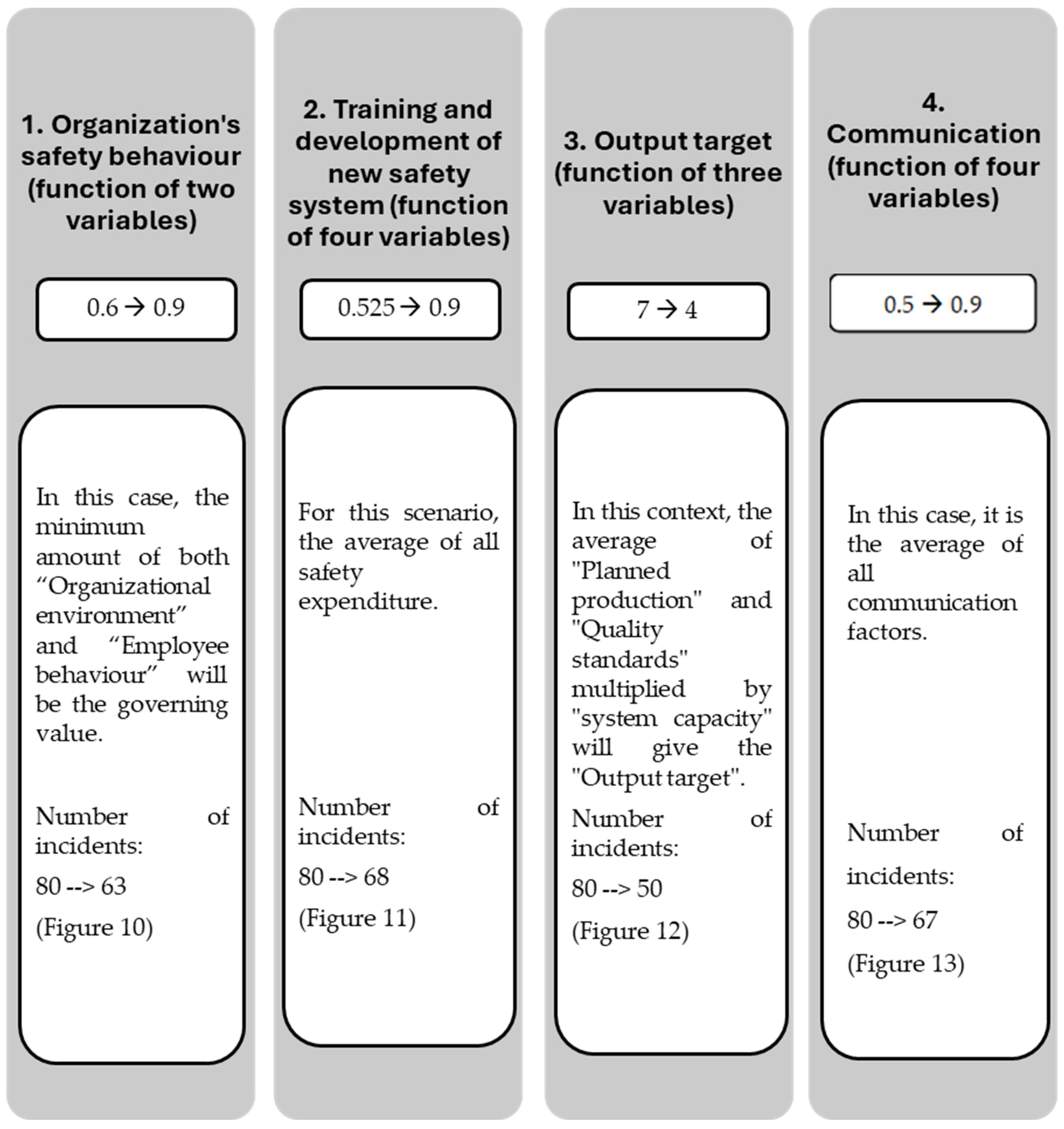

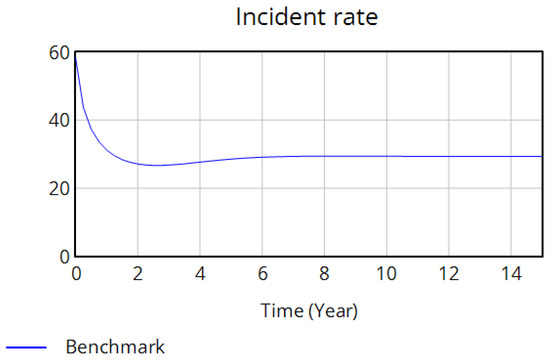

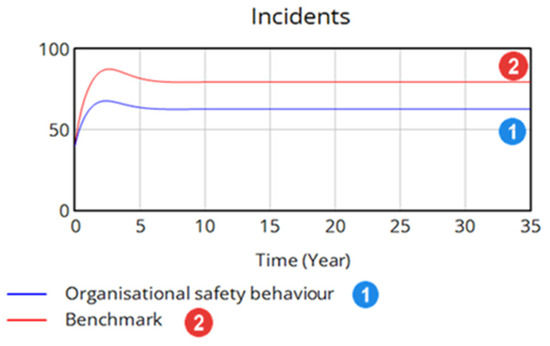

3.2. Scenario Analysis

The impact of safety culture on blue hydrogen production is crucial for protecting the health of workers, preserving the environment, and supporting operational reliability. A strong safety culture facilitates the adoption of hard safety measures, comprehensive risk assessments, and effective emergency response plans across all stages of hydrogen production. Highlighting safety enables organizations to prevent incidents, reduce operational disruptions, and encourage confidence among stakeholders. Ultimately, a positive safety culture promotes a sustainable and responsible approach to producing blue hydrogen. The what-if analysis will help in determining which of the safety culture dimensions has the most influence on safety performance and the number of incidents in blue hydrogen. The what-if analysis aims to identify which dimension of safety culture exerts the greatest influence on safety performance and incident frequency in blue hydrogen production. The scenarios are shown in Figure 9.

Figure 9.

Scenarios to evaluate the impact of various dimensions on the number of incidents.

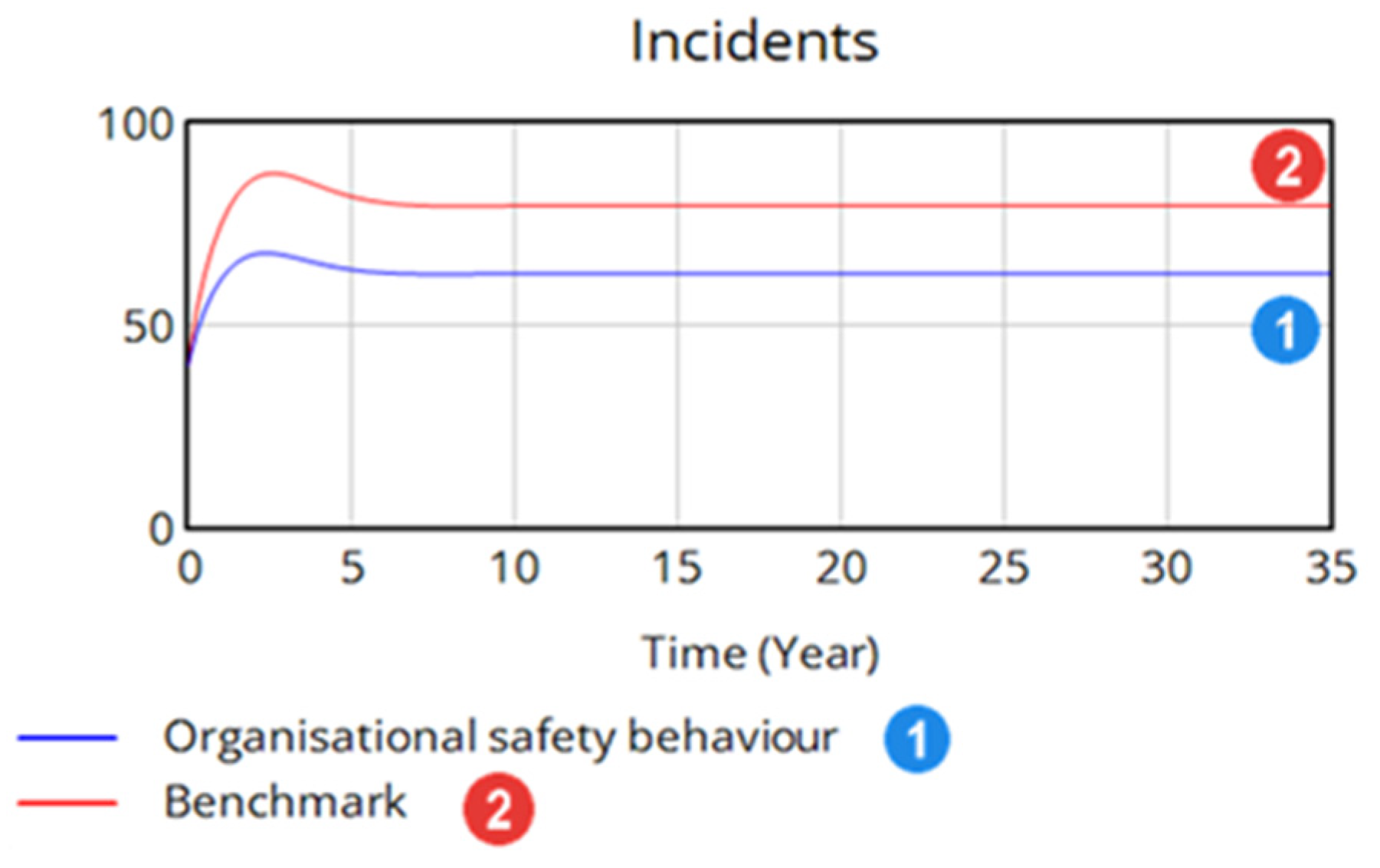

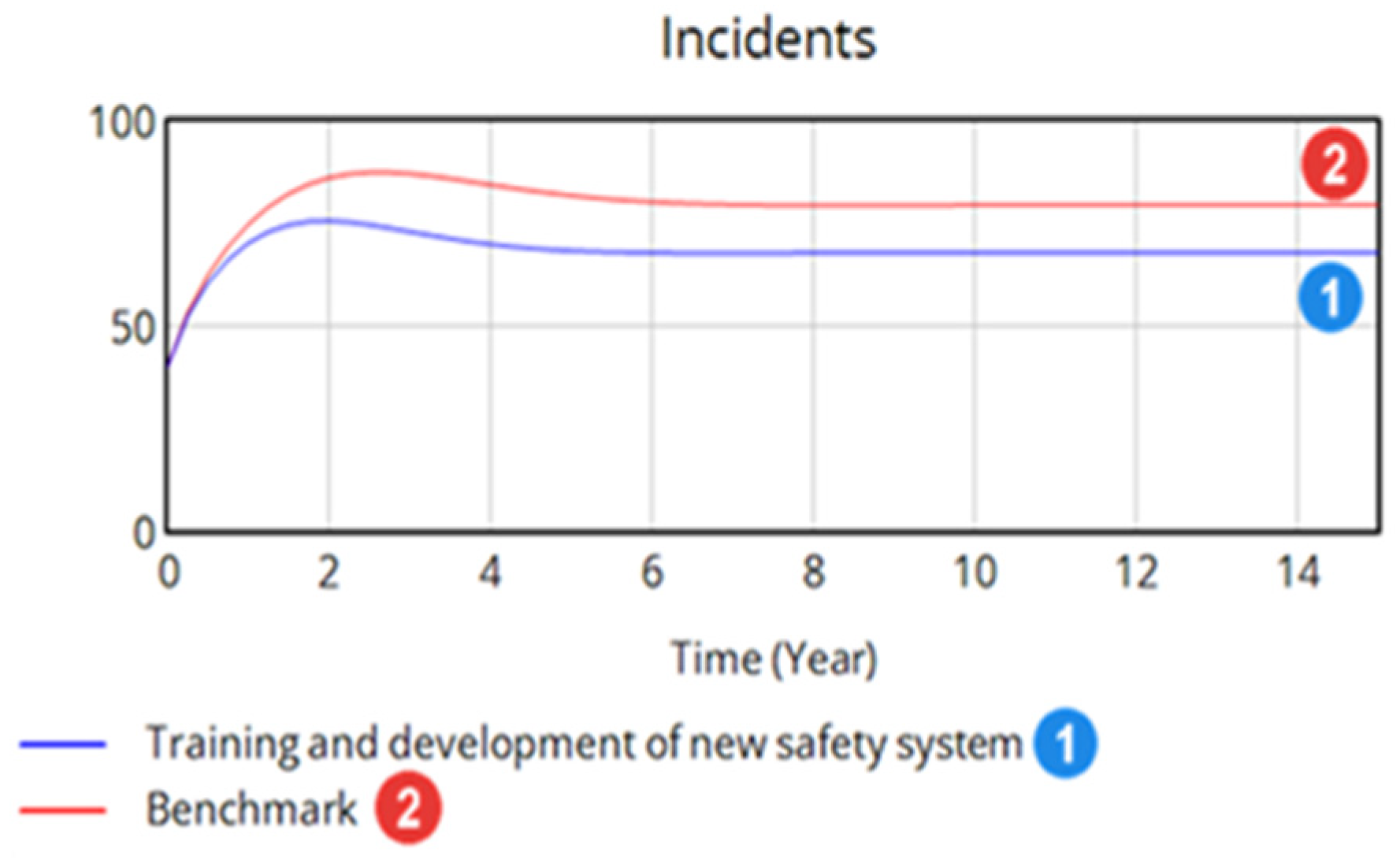

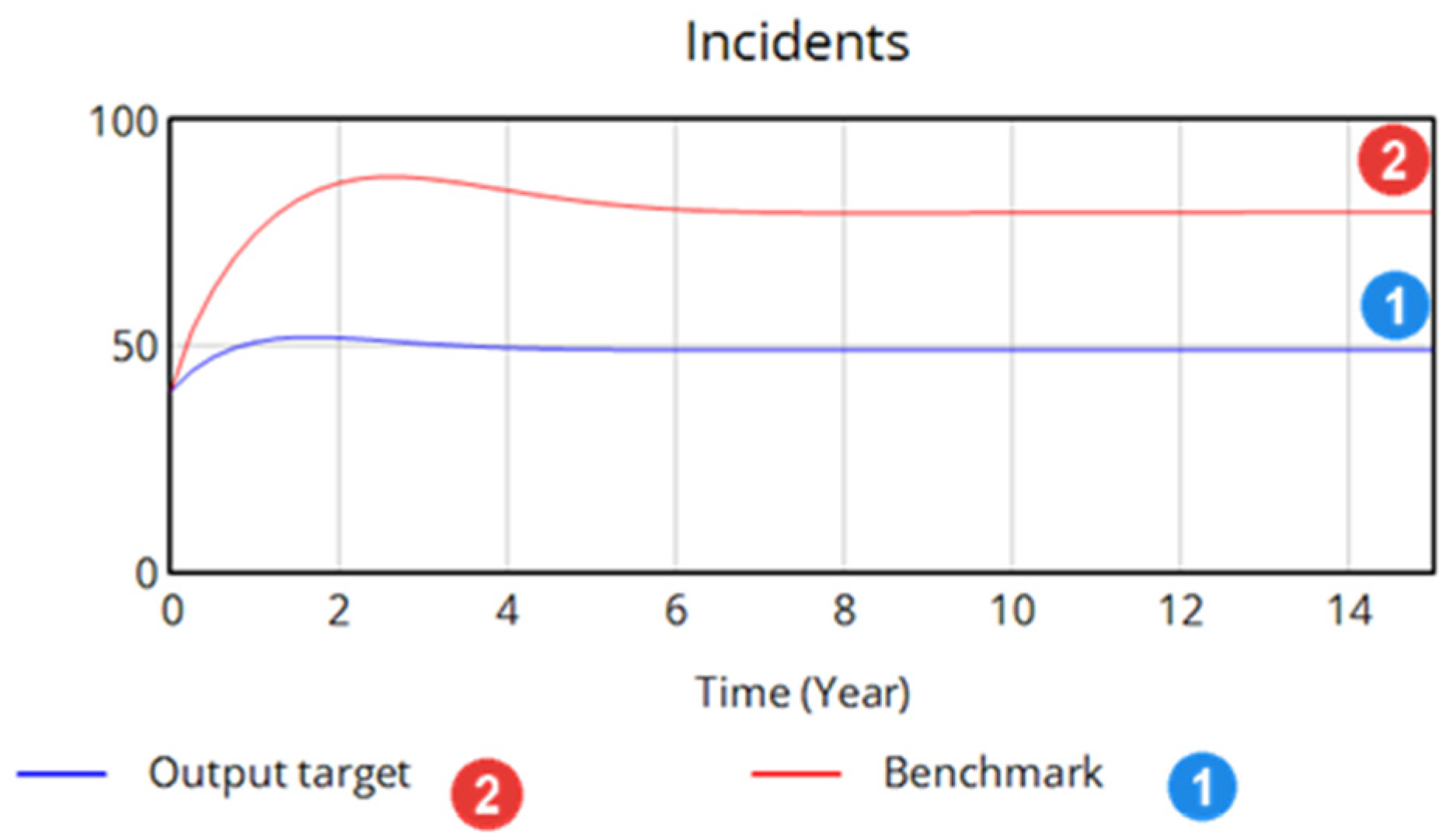

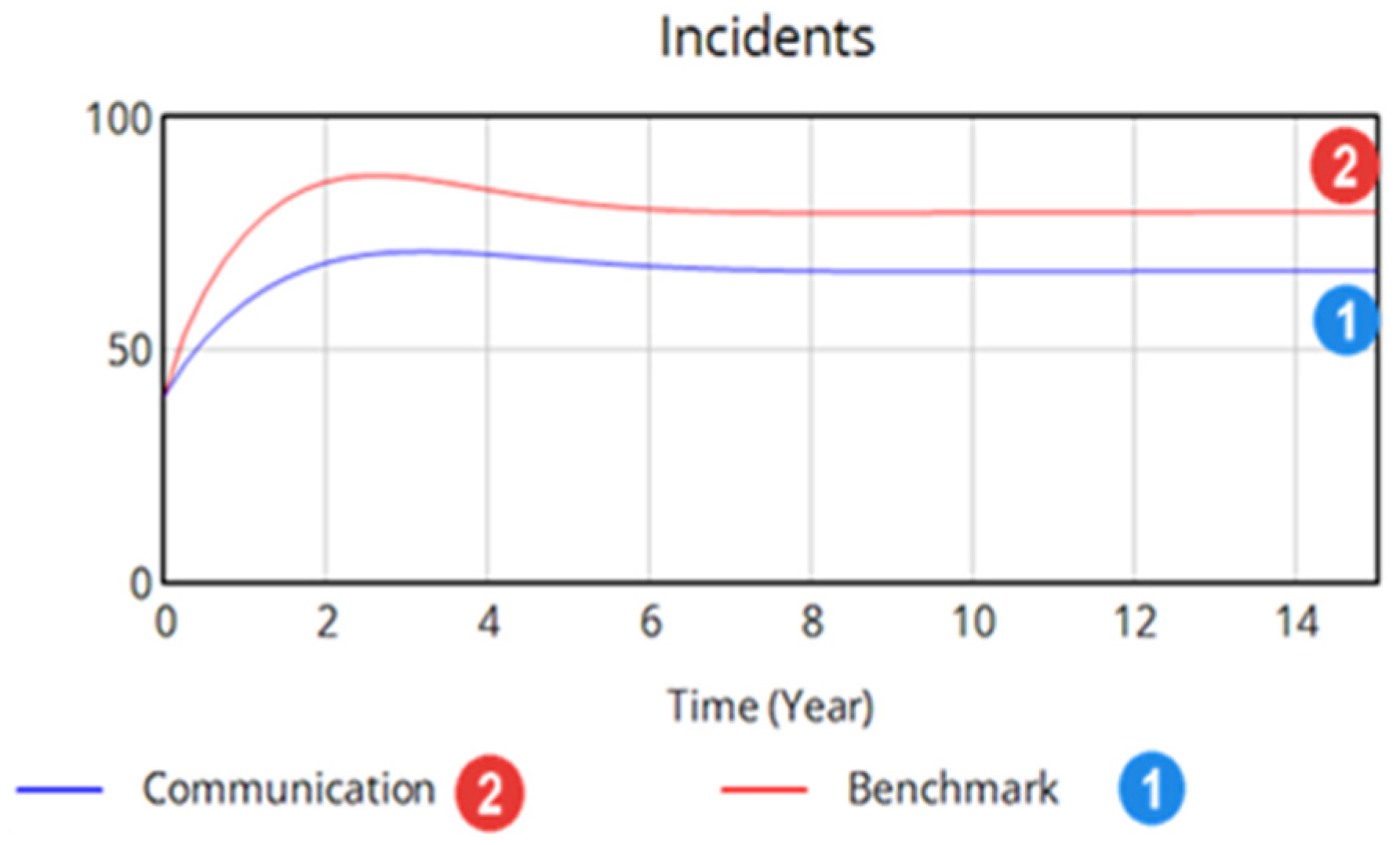

In the analysis, the benchmark scenario is a reference or baseline scenario used to compare with other scenarios. It provides a standard for assessing the impact of various variables, strategies, or interventions within a system. Detailed descriptions of these scenarios and the graphs of incidents can be found in Figure 10, Figure 11, Figure 12 and Figure 13.

Figure 10.

Impact of improvement in organizational safety behaviour on the number of incidents.

Figure 11.

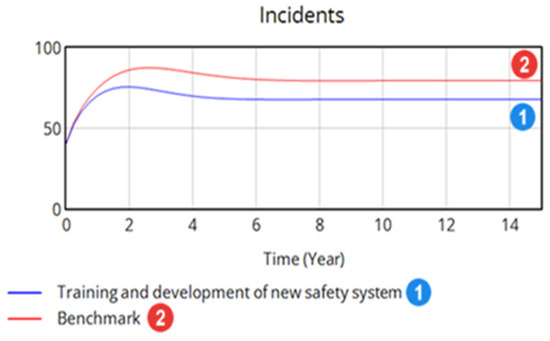

Effect of improvement in the training and development of a new safety system on the number of incidents.

Figure 12.

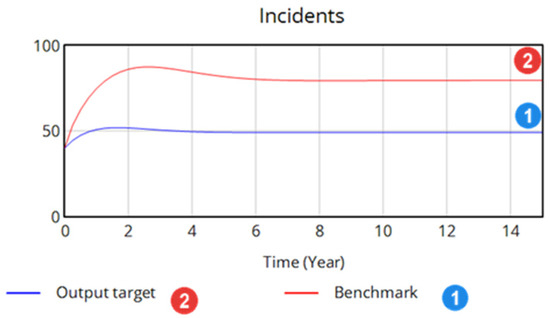

Impact of decrease in the output target on the number of incidents.

Figure 13.

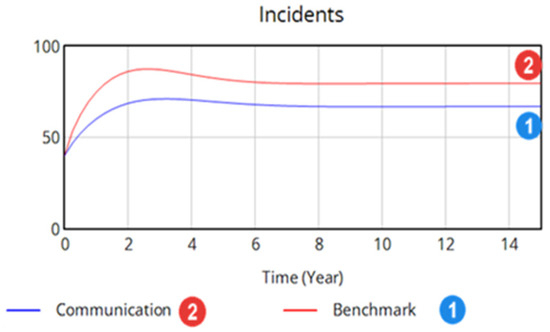

Impact of increase in communication on number of incidents.

4. Discussion

Organizational commitment has been identified as a crucial factor positively influencing job performance, as it is widely recognized as a key determinant of achieving high performance levels. Additionally, the implementation of effective safety procedures and risk management practices has also been shown to significantly enhance job performance. This highlights the importance of encouraging a strong organizational commitment and prioritizing safety measures to optimize overall performance in the workplace [42]. Enhancing employees’ views of management’s actual care for their well-being by prioritizing safety can lead to favourable results beyond just better safety performance. These outcomes suggest a form of social interaction between employees and management that could impact employees in a way, such as apparent organizational support. A company’s leader must show that they care about safety. Businesses that focus on safety could have fewer accidents and notice better employee moods and actions [43]. The impact of improvement in organizational safety behaviour on the number of incidents is shown in Figure 10.

The literature review conducted by Cavazza and Serpe highlights the positive impact of worker training on accident rates and safe behaviours [44]. The findings consistently show a significant decrease in accidents among trained personnel and an increase in safe behaviour among workers who participate in safety training courses. This suggests that investing in worker training can contribute to a safer work environment and reduce the likelihood of accidents [44]. This is also shown in the model outcome as shown in Figure 11.

When workers are rushed, they are more likely to make errors that require rework in their projects [45]. Based on research by Mohammadi and Tavakolian, pressure to produce more can lead to safety issues due to mistakes that require rework and fatigue [39]. Their study found that more rework due to mistakes is linked to a higher risk of injuries because it involves extra tasks, demolitions, time constraints, and unstable processes. Employees who feel significant production pressure not only encountered a higher number of accidents, in general, but also reported fewer of these incidents to the organization [46]. Moreover, external pressure exerted by government policies, regulators, and various stakeholders significantly influences the occurrence of production safety accidents [47]. This pressure can stem from regulatory requirements, public expectations, industry standards, and other external factors, all of which contribute to shaping and influencing safety practices within production environments. This is reflected in the model outcome, as illustrated in Figure 12.

As mentioned earlier, improving the organizational communication machinery is crucial, and this can be achieved by strengthening the commitment of management and supervisors to keep all channels of communication open. Viewing the significance of management and supervisor dedication through the lens of employees’ well-being is essential. Simply using communication to reach safety objectives is inadequate; management must also raise social connections and engage with their employees more actively [48]. Using safety communication methods not only improves working conditions but also positively influences employee behaviour and attitudes towards safety, ultimately resulting in fewer incidents in the workplace [49]. This is also shown in Figure 13.

5. Conclusions

H2-CCS is a complex socio-technical system. This study focuses specifically on the human factors contributing to accidents within the H2-CCS framework. Stakeholders’ commitment, effective safety procedures, and investment in worker training play vital roles in enhancing safety outcomes and reducing accidents in the workplace. Prioritizing employee well-being, fostering a strong organizational commitment, and promoting safety measures are key factors in optimizing overall performance. Additionally, addressing issues such as production pressure, rework (due to poor execution), as well as external influences can further contribute to a safer work environment and fewer incidents. Improving organizational communication and actively engaging with employees can also lead to better safety outcomes. By focusing on these aspects, organizations can create a culture of safety, improve employee safety behaviour, and thus enhance the overall performance of the blue hydrogen plant. Future research should examine the entire H2-CCS system, including the technical aspects influencing safety.

Author Contributions

Validation, S.Y. and H.B.; writing—original draft preparation, M.S.; writing—review and editing, S.Y.; supervision, S.Y and H.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data have been included in the paper, including equations for the Vensim model that is given in Appendix A.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ARAMIS | Accidental Risk Assessment Methodology for Industries |

| CCS | Carbon Capture and Storage |

| CFD | Computational Fluid Dynamics |

| CH4 | Methane |

| CO2 | Carbon Dioxide |

| H2 | Hydrogen |

| HSE | Health, Safety, and Environmental |

| S-LCA | Social Life Cycle Assessment |

Appendix A

FINAL TIME = 15 years. The final time for the simulation.

INITIAL TIME = 0 (year). The initial time for the simulation.

TIME STEP = 0.125

Stocks, Flows, and Variables

| Name | Equation | Description |

| Incidents | =INTEG (Incident rate − Correlation between safety culture and incident reduction), Initial = 40 | The annual number of incidents. The initial value is assumed to be 40. |

| Incidents stopped | =INTEG (Incidents − Correlation between safety culture and incident reduction), Initial = 40 | The number of incidents arrested by the system; procedures and instruments. It is assumed in the first year no incident progressed into an accident. |

| Incident rate | =(1/Significant hazards managed) | The incident emergence rate. |

| Correlation between Safety culture and incident reduction | =Proficiency × incident situation | The impact of safety culture on the number of incidents. |

| Communication | =Readiness to disclose information to stakeholders + Lessons learnt from past incidents + Spreading knowledge about the risks and uncertainties + Efficiency in engaging with the public)/4 | This variable represents the effectiveness of conveying various hazards and risks to others openly. That is the openness of communication channels. |

| Comprehensive hazard identification | =(Incidents/100)/Output targets | The thoroughness of hazard identified and hazards of operation. |

| Deployment of safety system | =Training and development of new safety systems × Necessary components | Represents the impact of training as well as the availability of safety devices. |

| Employee behaviour | =Employee continuous improvement + Peer influence + Positive safety attitude + Safe work practices | A measure of employees’ adherence to the safety protocols. |

| The gap between actual and target | =Incidents − Target | Measures the gap between the reality and the objective. |

| Incident situation | =(Gap between actual and target)/Output targets) | Indication of risky situation. |

| Necessary components | =Incident situation × Organization safety behaviour | Needed for the safety system. |

| Organizational safety behaviour | =min (Employee behaviour, Organizational environment) | The change in attitude of employee regarding the importance of safety. |

| Organizational environment | =Integration with business goal + Leaders’ continuous improvement + Safety consistency + Safety engagement | Effect of the organization’s goals and objectives. |

| Output targets | =System capacity × ((Planned production + Quality standards)/2) | Productivity requirement. |

| Proficiency | =SMOOTH (Deployment of safety system, Defer) | Change in employees’ competency level. |

| Recorded risks | =Communication × Comprehensive hazard identification | An indicator of risks that are monitored continuously. |

| Significant hazards managed | =Recorded risks × Organization safety behaviour | Hazards that cannot be eliminated, must be managed. |

| Training and development of new safety systems | =((Cost of needed technology + Training expenditure + Safety protocol + Safety inspection)/4) | Cost of developing a new safety system. |

Constants: These are user inputs. Values given in this table are for one realization only. See Table 1 for the complete range.

| Name | Value | |

| Cost of needed technology | =0.6 | A fraction between 0 and 1. |

| Defer | =2 | Time required for improvement to take hold in years. |

| Efficiency in engaging with the public | =0.5 | A fraction between 0 and 1. |

| Employee continuous improvement | =0.1 | A fraction between 0 and 1. |

| Integration with the business goal | =0.2 | A fraction between 0 and 1. |

| Leaders’ continuous improvement | =0.1 | A fraction between 0 and 1. |

| Lessons learnt from past incidents | =0.5 | A fraction between 0 and 1. |

| Peer influence | =0.15 | A fraction between 0 and 1. |

| Planned production | =1 | |

| Positive safety attitude | =0.25 | A fraction between 0 and 1. |

| Quality standards | =0.4 | A fraction between 0 and 1. |

| Readiness to disclose information to stakeholders | =0.5 | A fraction between 0 and 1. |

| Safe work practices | =0.2 | A fraction between 0 and 1. |

| Safety consistency | =0.1 | A fraction between 0 and 1. |

| Safety engagement | =0.2 | A fraction between 0 and 1. |

| Safety inspection | =0.5 | A fraction between 0 and 1. |

| Safety protocol | =0.6 | A fraction between 0 and 1. |

| Spreading knowledge about the risks and uncertainties | =0.5 | A fraction between 0 and 1. |

| System capacity | =10 | Varies between 1 and 10. 10 is the maximum capacity. |

| Target | =12 | The number of incidents that can be tolerated until later. |

| Training expenditure | =0.4 | A fraction between 0 and 1. |

References

- Abdin, Z.R.; Zafaranloo, A.; Rafiee, A.; Mérida, B.W.; Lipiński, W.; Khalilpour, K.R. Hydrogen as an energy vector. Renew. Sustain. Energy Rev. 2020, 120, 109620. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration—EIA. Use of Hydrogen. U.S. Energy Information Administration—EIA—Independent Statistics and Analysis. Available online: https://www.eia.gov/energyexplained/hydrogen/use-of-hydrogen.php#:~:text=electric%20power%20generation.-,Hydrogen%20is%20used%20in%20industrial%20processes,the%20sulfur%20content%20of%20fuels (accessed on 21 June 2024).

- AlHumaidan, F.S.; Absi Halabi, M.; Rana, M.S.; Vinoba, M. Blue hydrogen: Current status and Future Technologies. Energy Convers. Manag. 2023, 283, 116840. [Google Scholar] [CrossRef]

- Truche, L.; Donzé, F.-V.; Goskolli, E.; Muceku, B.; Loisy, C.; Monnin, C.; Dutoit, H.; Cerepi, A. A deep reservoir for hydrogen drives intense degassing in the Bulqizë Ophiolite. Science 2024, 383, 618–621. [Google Scholar] [CrossRef] [PubMed]

- Taneja, S.; Jain, A.; Bhadoriya, Y. Green hydrogen as a clean energy resource and its applications as an engine fuel. Eng. Proc. 2024, 50, 159. [Google Scholar]

- Shourideh, M.; Yasseri, S. Uncertainties and Barriers to Carbon Capture and Storage Acceptance & Implementation. Int. J. Coast. Offshore Environ. Eng. 2023, 8, 18–30. [Google Scholar] [CrossRef]

- Shourideh, M.; Yasseri, S.; Bahai, H. Safety culture influence on safety performance of a post-combustion carbon capture facility. Heliyon 2024, 10, e34640. [Google Scholar] [CrossRef]

- Stalker, L.; Roberts, J.J.; Mabon, L.; Hartley, P.G. Communicating leakage risk in the hydrogen economy: Lessons already learned from Geoenergy Industries. Front. Energy Res. 2022, 10, 869264. [Google Scholar] [CrossRef]

- Calabrese, M.; Portarapillo, M.; Di Nardo, A.; Venezia, V.; Turco, M.; Luciani, G.; Di Benedetto, A. Hydrogen Safety Challenges: A Comprehensive Review on production, storage, transport, Utilization, and CFD-based consequence and risk assessment. Energies 2024, 17, 1350. [Google Scholar] [CrossRef]

- Gordon, J.A.; Balta-Ozkan, N.; Nabavi, S.A. Socio-technical barriers to domestic hydrogen futures: Repurposing pipelines, policies, and public perceptions. Appl. Energy 2023, 336, 120850. [Google Scholar] [CrossRef]

- Massarweh, O.; Al-khuzaei, M.; Al-Shafi, M.; Bicer, Y.; Abushaikha, A.S. Blue hydrogen production from Natural Gas Reservoirs: A review of application and feasibility. J. CO2 Util. 2023, 70, 102438. [Google Scholar] [CrossRef]

- Webb, J.; Longden, T.; Boulaire, F.; Gono, M.; Wilson, C. The application of Green Finance to the production of blue and green hydrogen: A comparative study. Renew. Energy 2023, 219, 119236. [Google Scholar] [CrossRef]

- Guo, L.; Su, J.; Wang, Z.; Shi, J.; Guan, X.; Cao, W.; Ou, Z. Hydrogen Safety: An obstacle that must be overcome on the road towards future Hydrogen Economy. Int. J. Hydrogen Energy 2024, 51, 1055–1078. [Google Scholar] [CrossRef]

- Hanekamp, J.C. Hydrogen Hazards and Risks—Physics, Storage, Transport and Application; University College Roosevelt: Middelburg, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Kleszcz, S.; Assadi, M. Hydrogen safety considerations: Mitigating risks and securing operations in enclosed spaces. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1294, 012057. [Google Scholar] [CrossRef]

- Duclos, A.F.; Proust, C.; Daubech, J.; Verbecke, F. Engineering safety in hydrogen-energy applications. In Proceedings of the International Conference on Hydrogen Safety ICHS, Yokohama, Japan, 19–21 October 2015. [Google Scholar]

- Abohamzeh, E.; Salehi, F.; Sheikholeslami, M.; Abbassi, R.; Khan, F. Review of hydrogen safety during storage, transmission, and applications processes. J. Loss Prev. Process Ind. 2021, 72, 104569. [Google Scholar] [CrossRef]

- Ruiz, P.; Vega, L.F.; Arxer del, M.; Jiménez, C.; Rausa, A. Hydrogen: Applications and Safety Considerations; Matgas 2000 AIE: Barcelona, Spain, 2015. [Google Scholar]

- De-León Almaraz, S.; Kocsis, T.; Azzaro-Pantel, C.; Szántó, Z.O. Identifying social aspects related to the hydrogen economy: Review, synthesis, and Research Perspectives. Int. J. Hydrogen Energy 2024, 49, 601–618. [Google Scholar] [CrossRef]

- ILO International Labour Organization. Chernobyl 20 Years After: From Disaster, Breeding a New Safety Culture. 2006. Available online: https://www.ilo.org/resource/article/chernobyl-20-years-after-disaster-breeding-new-safety-culture (accessed on 24 February 2024).

- Bisbey, T.M.; Kilcullen, M.P.; Thomas, E.J.; Ottosen, M.J.; Tsao, K.; Salas, E. Safety culture: An integration of existing models and a framework for understanding its development. Hum. Factors J. Hum. Factors Ergon. Soc. 2019, 63, 88–110. [Google Scholar] [CrossRef]

- Naji, G.M.; Isha, A.S.; Mohyaldinn, M.E.; Leka, S.; Saleem, M.S.; Rahman, S.M.; Alzoraiki, M. Impact of safety culture on safety performance; mediating role of psychosocial hazard: An integrated modelling approach. Int. J. Environ. Res. Public Health 2021, 18, 8568. [Google Scholar] [CrossRef]

- Tullo, F.J. Chapter 2—Teamwork and Organizational Factors. In Crew Resource Management, 2nd ed.; Academic Press: Cambridge, MA, USA, 2010; pp. 59–78. [Google Scholar]

- IAEA International Atomic Energy Agency. Safety Culture. Available online: https://www.iaea.org/services/networks/orpnet/national-arrangements-on-occupational-radiation-protection/safety-culture (accessed on 19 August 2021).

- Yang, S.B.; Ma, K.; Liu, Z.; Ren, J.; Man, Y. Chapter 5—Development and applicability of life cycle impact assessment methodologies. In Life Cycle Sustainability Assessment for Decision-Making: Methodologies and Case Studies; Elsevier: Amsterdam, The Netherlands, 2020; pp. 95–124. [Google Scholar]

- Maliha, M.N.; Abu Aisheh, Y.I.; Tayeh, B.A.; Almalki, A. Safety Barriers Identification, classification, and ways to improve safety performance in the architecture, engineering, and Construction (AEC) industry: Review Study. Sustainability 2021, 13, 3316. [Google Scholar] [CrossRef]

- Clarke, S. Health and safety at work Summary statistics for Great Britain 2023; Health and Safety Executive: Bootle, UK, 2023. [Google Scholar]

- Henriqson, É.; Schuler, B.; van Winsen, R.; Dekker SW, A. The constitution and effects of safety culture as an object in the discourse of accident prevention: A foucauldian approach. Saf. Sci. 2014, 70, 465–476. [Google Scholar] [CrossRef]

- Tappura, S.; Jääskeläinen, A.; Pirhonen, J. Creation of a satisfactory safety culture by developing its key dimensions. Saf. Sci. 2022, 154, 105849. [Google Scholar] [CrossRef]

- McGonagle, A.K.; Essenmacher, L.; Hamblin, L.; Luborsky, M.; Upfal, M.; Arnetz, J. Management commitment to safety, teamwork, and hospital worker injuries. J. Hosp. Adm. 2016, 5, 46. [Google Scholar] [CrossRef] [PubMed]

- Usrey, C. Management Commitment and How It Affects Safety. Safety Status. Available online: https://www.safetystratus.com/blog/management-commitment-what-does-it-mean-for-safety/ (accessed on 21 March 2023).

- Vecchio-Sadus, A. Enhancing Safety Culture Through Effective Communication. Saf. Sci. Monit. 2007, 11, 1–10. [Google Scholar]

- Altomonte, L. What is Safety Communication? SafetyCulture. Available online: https://safetyculture.com/topics/safety-communication/ (accessed on 5 February 2024).

- Marquardt, N.; Hoebel, M.; Lud, D. Safety culture transformation—The impact of training on explicit and implicit safety attitudes. Hum. Factors Ergon. Manuf. Amp Serv. Ind. 2020, 31, 191–207. [Google Scholar] [CrossRef] [PubMed]

- Amri, K.; Kholil, K.; Widowati, D. The effect of Organizational Communication, transformational leadership and organizational learning on OSH performance a case study in PT Waskita Karya. Arch. Bus. Res. 2022, 10, 1–11. [Google Scholar] [CrossRef]

- Monazam Tabrizi, N.; Masri, F. Towards safer healthcare: Qualitative insights from a process view of organisational learning from failure. BMJ Open 2021, 11, e048036. [Google Scholar] [CrossRef]

- Kytömaa, H.; Wechsung, A.; Dimitrakopoulos, G.; Cook, N.; Jaimes, D.; Hur, I.Y.; Faraji, S. Industry R&D needs in hydrogen safety. Appl. Energy Combust. Sci. 2024, 18, 100271. [Google Scholar] [CrossRef]

- Packard, T. 16 Changing Organizational Culture. In Organizational Change for the Human Services; Oxford Academic: Oxford, UK, 2021; pp. 261–272. [Google Scholar]

- Hashemian, S.M.; Triantis, K. Production pressure and its relationship to safety: A systematic review and Future Directions. Saf. Sci. 2023, 159, 106045. [Google Scholar] [CrossRef]

- Al Shaaili, M.; Al Alawi, M.; Ekyalimpa, R.; Al Mawli, B.; Al-Mamun, A.; Al Shahri, M. Near-miss accident data analysis and knowledge dissemination in water construction projects in Oman. Heliyon 2023, 9, e21607. [Google Scholar] [CrossRef]

- Zhang, Q.; Chan, A.P.; Yang, Y.; Guan, J.; Choi, T.N. Influence of learning from incidents, Safety Information Flow, and resilient safety culture on Construction Safety Performance. J. Manag. Eng. 2023, 39, 04023007. [Google Scholar] [CrossRef]

- Kaynak, R.; Tuygun Toklu, A.; Elci, M.; Tamer Toklu, I. Effects of occupational health and safety practices on organizational commitment, work alienation, and job performance: Using the PLS-SEM approach. Int. J. Bus. Manag. 2016, 11, 146. [Google Scholar] [CrossRef]

- Michael, J.H.; Evans, D.D.; Jansen, K.J.; Haight, J.M. Management commitment to safety as organizational support: Relationships with non-safety outcomes in wood manufacturing employees. J. Saf. Res. 2005, 36, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Cavazza, N.S.; Serpe, A. The impact of safety training programs on workers’ psychosocial orientation and behaviour. Rev. Int. Psychol. Soc. 2010, 23, 187–210. [Google Scholar]

- Mohammadi, A.; Tavakolan, M. Modeling the effects of production pressure on safety performance in construction projects using system dynamics. J. Saf. Res. 2019, 71, 273–284. [Google Scholar] [CrossRef] [PubMed]

- Probst, T.M.; Graso, M. Pressure to produce = pressure to reduce accident reporting? Accid. Anal. Amp Prev. 2013, 59, 580–587. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Zhang, J.; Fu, C. Generation paths of major production safety accidents—A fuzzy-set qualitative comparative analysis based on Chinese data. Front. Public Health 2023, 11, 1136640. [Google Scholar] [CrossRef]

- Nordin, S.M.; Rizal, A.R.; Rashid, R.A.; Che Omar, R.; Priyadi, U. Incidents and disaster avoidance: The role of Communication Management and the organizational communication climate in high-risk environments. Sustainability 2021, 13, 10138. [Google Scholar] [CrossRef]

- Naji, G.M.; Isha, A.S.; Alazzani, A.; Saleem, M.S.; Alzoraiki, M. Assessing the mediating role of safety communication between safety culture and employees’ safety performance. Front. Public Health 2022, 10, 840281. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).