Thermodynamic Analysis of Low-Emission Offshore Gas-to-Wire Firing CO2-Rich Natural Gas: Aspects of Carbon Capture and Separation Systems

Abstract

1. Introduction

2. Methods

2.1. Process Framework

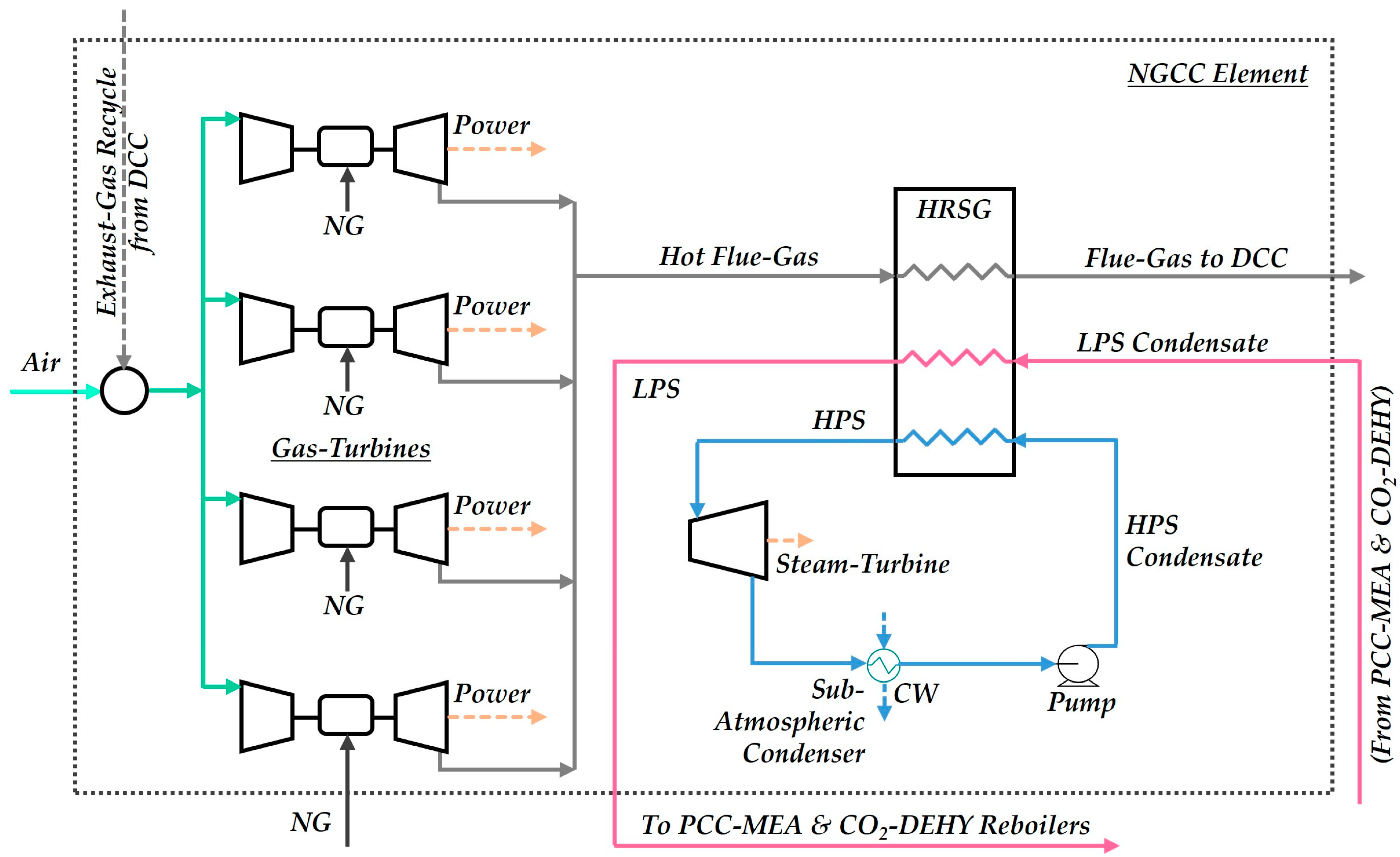

2.1.1. Natural Gas Combined Cycle Plant

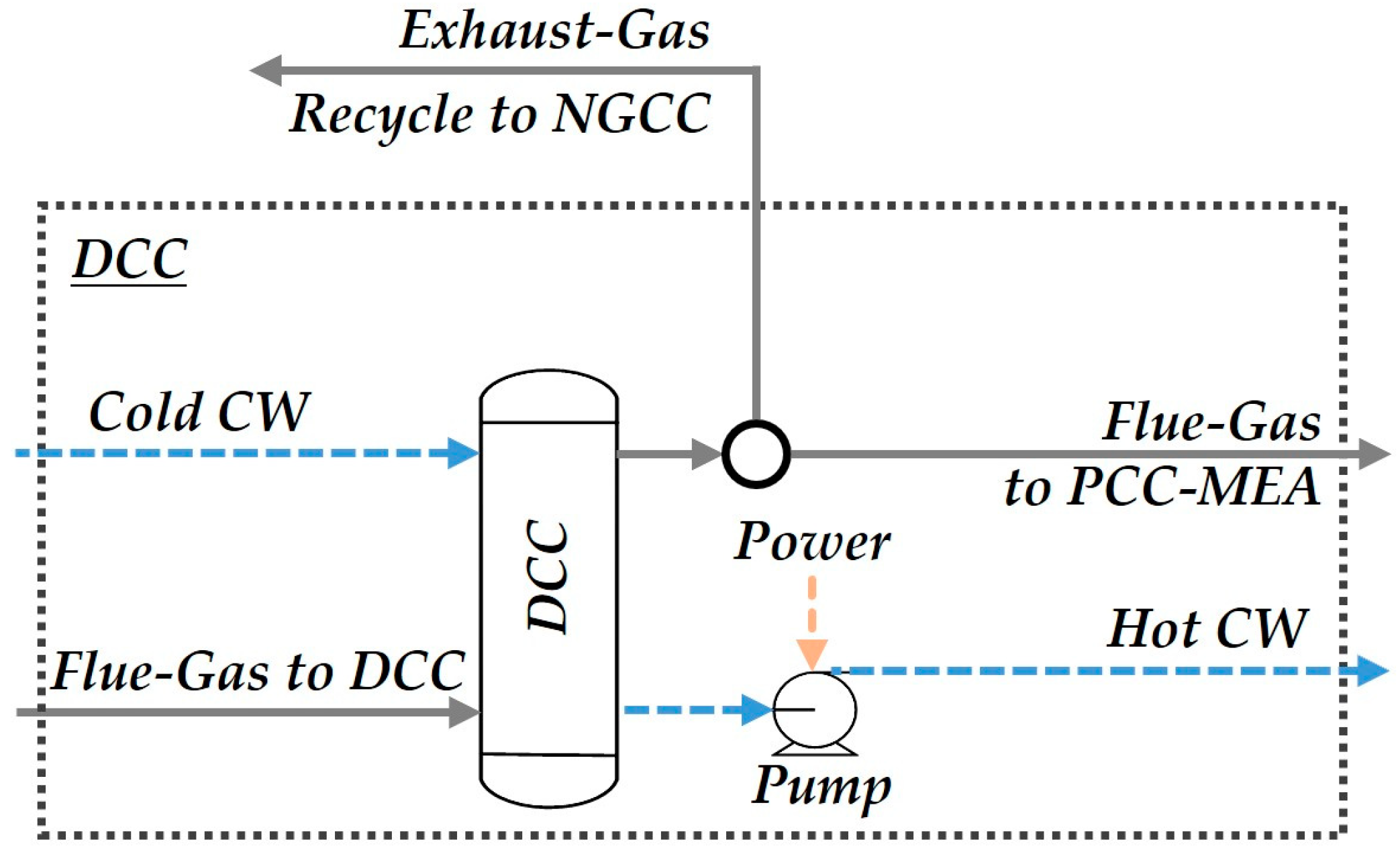

2.1.2. Direct-Contact Column

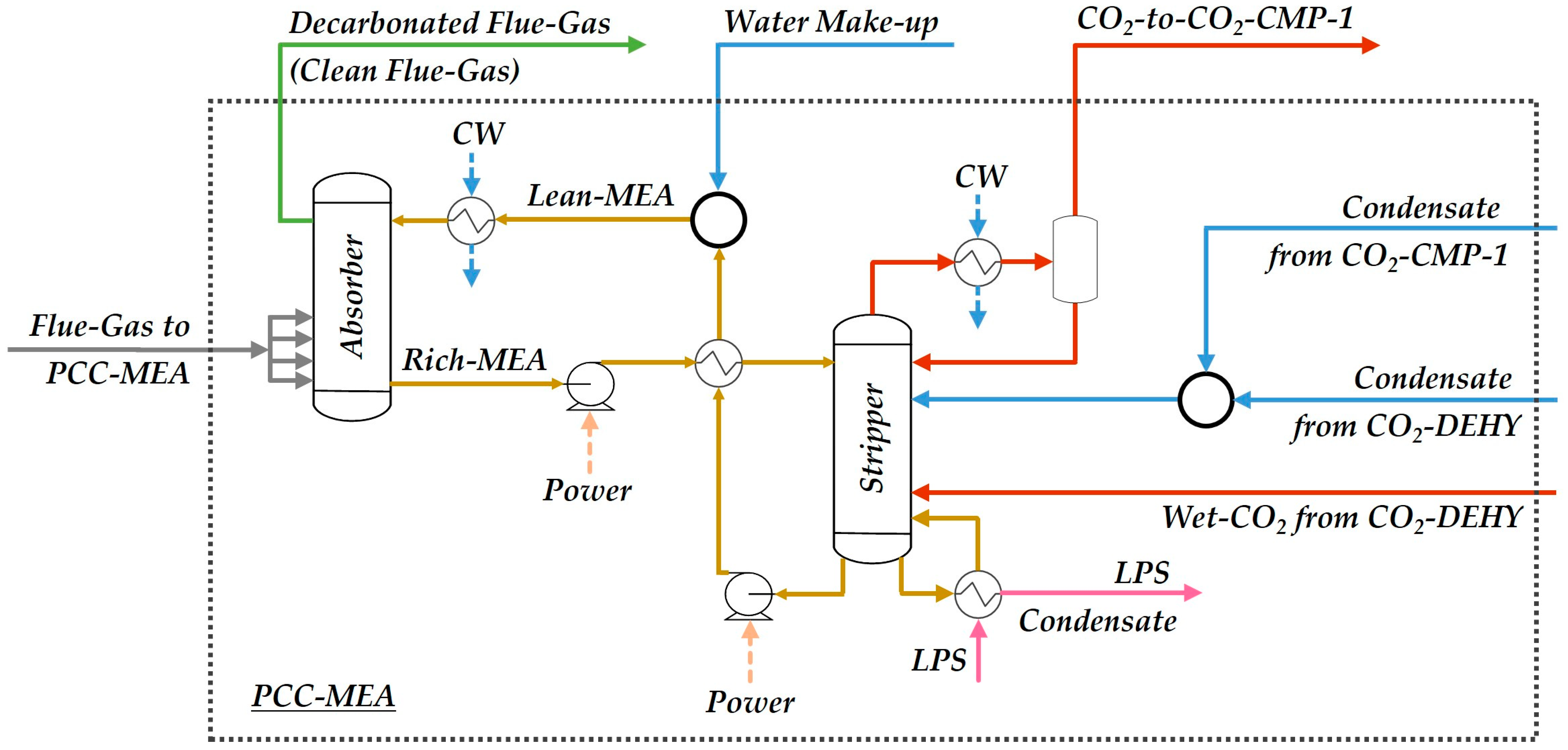

2.1.3. Post-Combustion Capture with Aqueous-MEA

2.1.4. CO2 Dehydration TEG Unit and CO2 Stripping Gas Unit

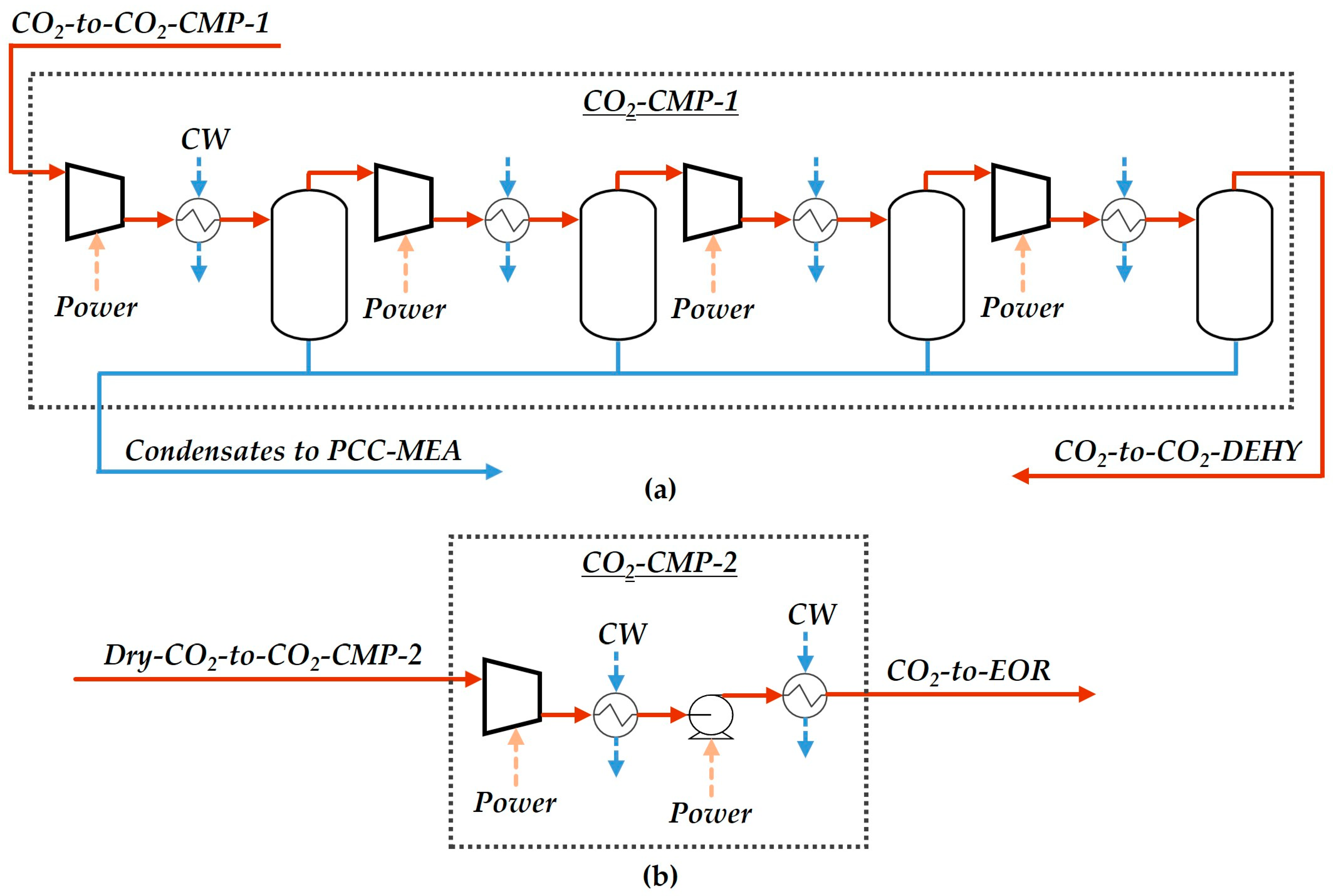

2.1.5. CO2 Compression Units

2.1.6. Equipment Conditions and Process Simulation Assumptions

| Item | Assumption | |

|---|---|---|

| A1 | Thermodynamic Models | Gas streams: Peng–Robinson equation of state; Rankine cycle: ASME steam table; PCC-MEA: HYSYS Acid-Gas Package; CO2-DEHY: HYSYS Glycol package. |

| A2 | Air | T = 25 °C; P = 1.013 bar; N2 = 77.14%mol; O2 = 20.51%mol; H2O = 2.35%mol; [31]. |

| A3 | Raw CO2-rich NG | 6.5 MMSm3/d; T = 40 °C; P = 25 bar; CH4 = 49.82%mol, CO2 = 43.84%mol, C2H6 = 2.99%mol, C3H8 = 1.99%mol, iC4H10 = 0.3%mol, C4H10 = 0.2%mol, iC5H12 = 0.2%mol, C5H12 = 0.1%mol, C6H14 = 0.1%mol, C7H16 = 0.05%mol, C8H18 = 0.03%mol, C9H20 = 0.01%mol, C10H22 = 0.01%mol, H2O = 0.36%mol [2,31]. |

| A4 | Gas turbine | Aero-Derivative GE LM2500 + G4; EfficiencyLHV = 36.5%; PInlet = 23 bar; [2,31] Air-Ratio = 6.2 mol/mol; TFlue Gas = 549 °C. |

| A5 | Steam turbine | HPS: PInlet = 24 bar; POutlet = 0.12 bar; TInlet = 524 °C; Outlet-Quality = 98.1%; [31]. |

| A6 | Compressors | Stage–compression ratio = 2.85; [2,31] Intercoolers: TGas-Outlet = 35 °C; ΔTApproach = 5 °C; ∆P = 0.5 bar.H |

| A7 | Adiabatic efficiencies | ηPumps = ηCompressors = ηSteam Turbine = 75%; Gas Turbines:ηAir Compressor = 87%, ηExpander = 85.4%; [31]. |

| A8 | HRSG | ∆PFlue Gas = 0.025 bar; ∆PSteam = 0.05 bar; ΔTApproach = 25 °C; [24]. |

| A9 | Exchangers | ΔTApproach = 10 °C (gas-gas, liq-liq); ΔTApproach = 5 °C (gas-liq); ΔP = 0.5 bar; [31]. |

| A10 | DCC | StagesTheoretical = 10; PTop = 1.053 bar; TTop-Flue Gas = 40 °C. |

| A11 | PCC-MEA | Absorber: StagesTheoretical = 40; PTop = 1.013 bar; TInlet-Top = 40 °C; Capture = 90%; [31] Stripper: StagesTheoretical = 10; PTop = 1.013 bar; TTop = 40 °C; TReboiler = 103 °C; [31] Lean-MEA: H2O = 63.3%w/w, MEA = 31.6%w/w, CO2 = 5.1%w/w; [31] Capture Ratio: CR ≈ 14 kgSolvent/kgCO2; stripping Heat Ratio: HR ≈ 225 kJ/molCO2; [31]. |

| A12 | CO2-DEHY | Absorber: StagesTheoretical = 15; P = 50 bar; TInlet = 35 °C; Solvent: TEG = 98.5%w/w; Stripper: StagesTheoretical = 10; PTop = 1.013 bar; TTop = 40 °C; TReboiler = 128 °C. |

| A13 | CO2-to-EOR | T = 35 °C; P = 300 bar; Purity: CO2 ≥ 99.9%mol; [31]. |

| A14 | LPS | PLPS= 6 bar, TLPS = 160 °C. |

| A15 | Cooling Water | CW: TInlet = 30 °C; TOutlet = 45 °C; PInlet = 4 bar; POutlet = 3.5 bar. |

| A16 | Steam production | Priority: LPSPCC-MEA + LPSCO2-DEHY; Surplus: HPSRankine-Cycle. |

2.1.7. Complexity and Limitations of the New Offshore GTW-EGR-CCS-CO2-DEHY Process

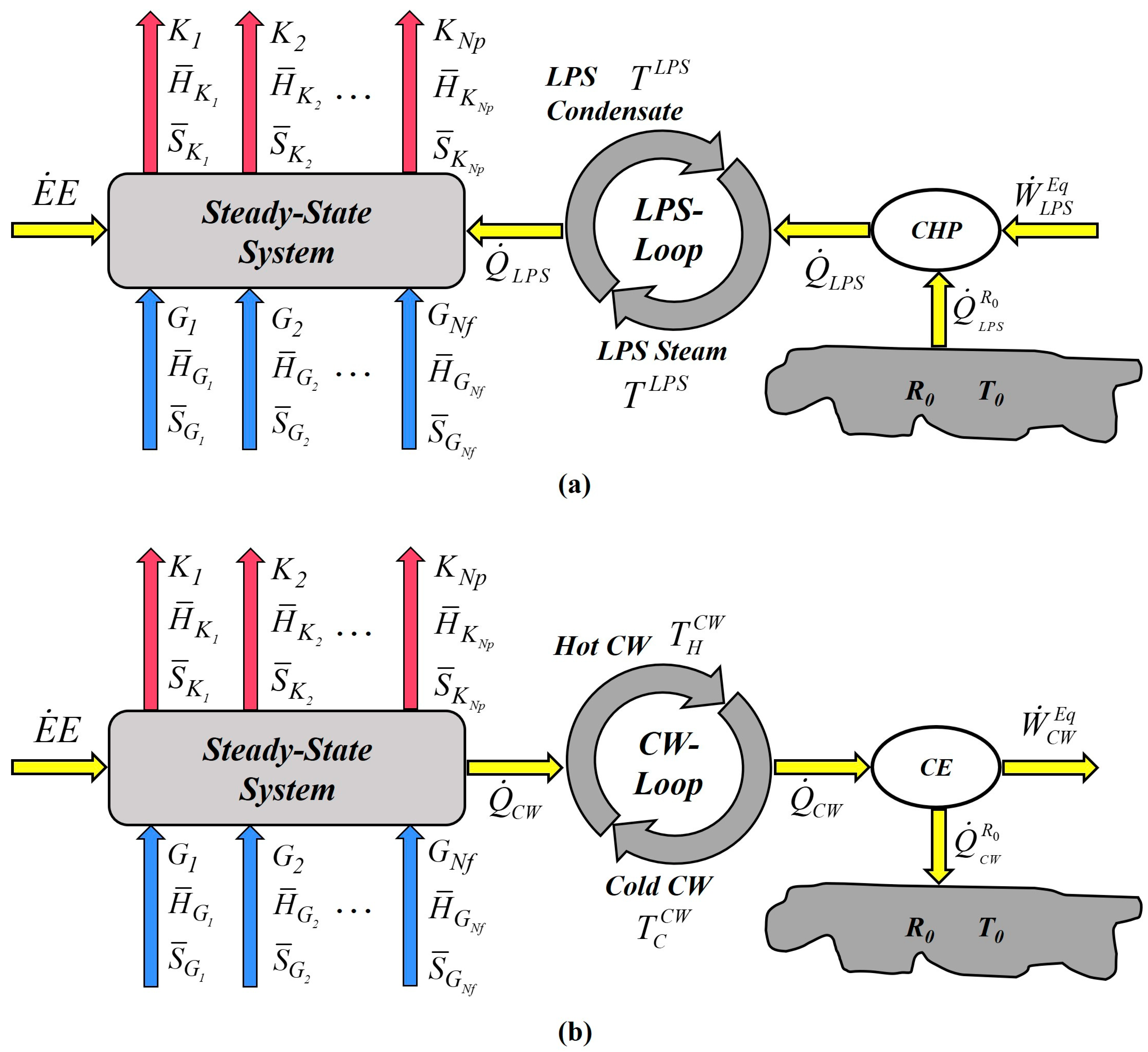

2.2. Thermodynamic Analysis of Steady-State Processes

2.2.1. Maximum Power

2.2.2. Equivalent Power

2.2.3. Thermodynamic Efficiency

2.2.4. Lost-Work

3. Results and Discussion

3.1. Technical Assessment

3.2. Thermodynamic Analysis

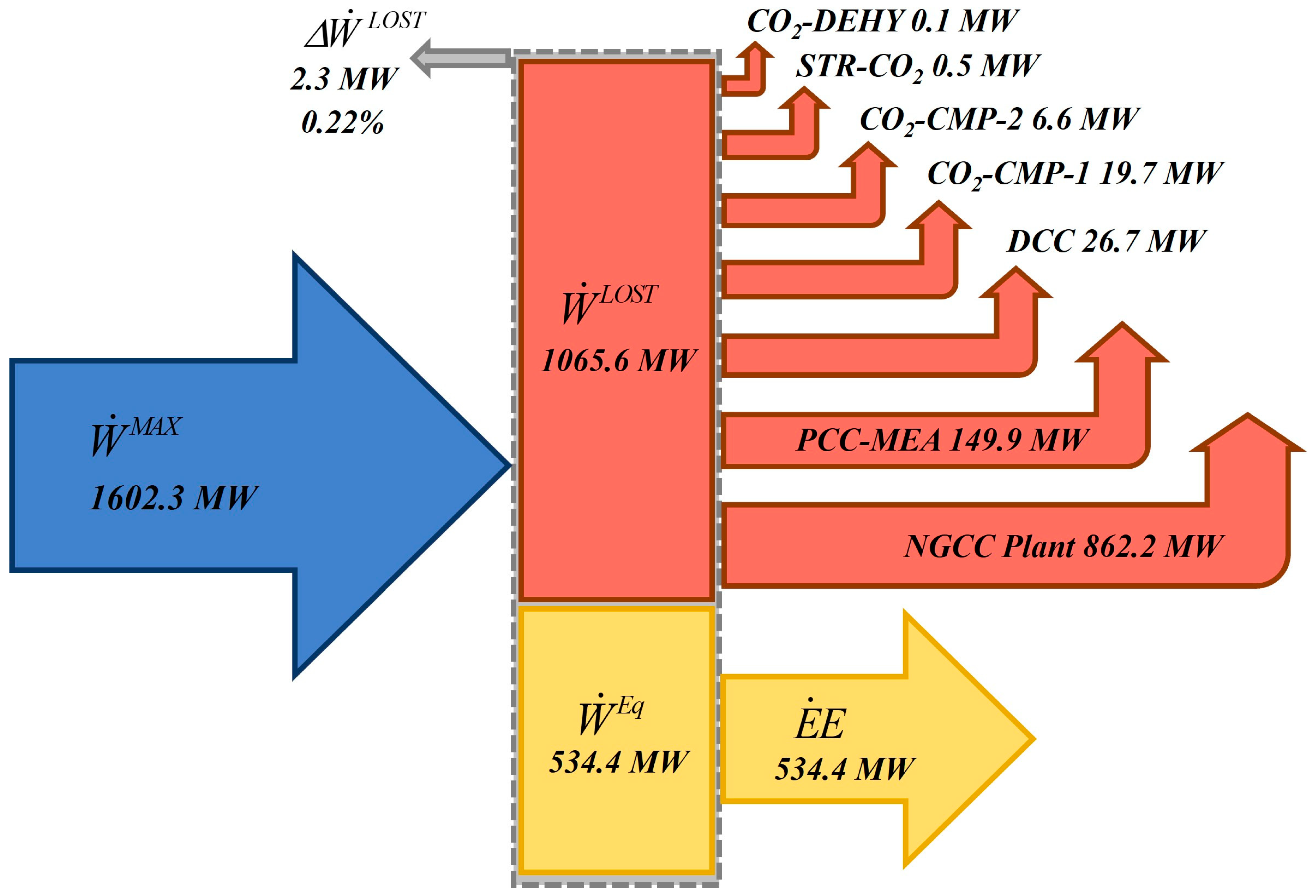

3.2.1. Maximum Power, Equivalent Power, and Thermodynamic Efficiency Results

3.2.2. Lost-Work Analysis

4. Conclusions

5. Suggestions for Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Electricity (MW) | |

| Gi | Flowrate of ith feed stream (kmol/s) |

| Molar enthalpy (MJ/kmol) | |

| Ki | Flowrate of ith product stream (kmol/s) |

| Nf | Number of feed streams (inputs) |

| Np | Number of product streams (outputs) |

| P | Pressure (bar) |

| , | Heat duty (MW), molar entropy (MJ/K·kmol) |

| T, W | Temperature (K), power (MW) |

| η | Thermodynamic efficiency (%) |

| CW, Eq, LPS | Cooling Water, equivalent, Low-Pressure Steam |

References

- Neseli, M.A.; Ozgener, O.; Ozgener, L. Energy and exergy analysis of electricity generation from natural gas pressure reducing stations. Energy Convers. Manag. 2015, 93, 109–120. [Google Scholar] [CrossRef]

- de Freitas, V.A.; Vital, J.C.S.; Rodrigues, B.R.; Rodrigues, R. Source rock potential, main depocenters, and CO2 occurrence in the pre-salt section of Santos Basin, southeast Brazil. J. S. Am. Earth Sci. 2022, 115, 103760. [Google Scholar] [CrossRef]

- Andrei, M.; Sammarco, G. Gas to wire with carbon capture & storage: A sustainable way for on-site power generation by produced gas. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 January 2017. [Google Scholar] [CrossRef]

- Ojijiagwo, E.; Oduoza, C.F.; Emekwuru, N. Economics of gas to wire technology applied in gas flare management. Eng. Sci. Technol. Int. J. 2016, 19, 2109–2118. [Google Scholar] [CrossRef]

- Sayed, S.; Massoud, A. Minimum transmission power loss in multi-terminal HVDC systems: A general methodology for radial and mesh networks. Alex. Eng. J. 2019, 58, 115–125. [Google Scholar] [CrossRef]

- Watanabe, T.; Inoue, H.; Horitsugi, M.; Oya, S. Gas to Wire (GTW) system for developing ‘small gas field’ and exploiting ‘associated gas’. In Proceedings of the SPE International Oil and Gas Conference and Exhibition in China, Beijing, China, 5–7 December 2006; Volume 1, pp. 310–315. [Google Scholar]

- Brito, T.L.F.; Galvão, C.; Fonseca, A.F.; Costa, H.K.M.; Moutinho dos Santos, E. A review of gas-to-wire (GtW) projects worldwide: State-of-art and developments. Energy Policy 2022, 163, 112859. [Google Scholar] [CrossRef]

- Zhou, D.; Li, P.; Liang, X.; Liu, M.; Wang, L. A long-term strategic plan of offshore CO2 transport and storage in northern South China Sea for a low-carbon development in Guangdong province, China. Int. J. Greenh. Gas. Control 2018, 70, 76–87. [Google Scholar] [CrossRef]

- Roussanaly, S.; Aasen, A.; Anantharaman, R.; Danielsen, B.; Jakobsen, J.; Heme-De-Lacotte, L.; Neji, G.; Sødal, A.; Wahl, P.; Vrana, T.; et al. Offshore power generation with carbon capture and storage to decarbonise mainland electricity and offshore oil and gas installations: A techno-economic analysis. Appl. Energy 2019, 233–234, 478–494. [Google Scholar] [CrossRef]

- Zhao, H.; Chang, Y.; Feng, S. Influence of produced natural gas on CO2-crude oil systems and the cyclic CO2 injection process. J. Nat. Gas. Sci. Eng. 2016, 35, 144–151. [Google Scholar] [CrossRef]

- Monson, C.C.; Korose, C.P.; Frailey, S.M. Screening methodology for regional-scale CO2 EOR and storage using economic criteria. Energy Procedia 2014, 63, 7796–7808. [Google Scholar] [CrossRef]

- Hassanpouryouzband, A.; Yang, J.; Tohidi, B.; Chuvilin, E.; Istomin, V.; Bukhanov, B. Geological CO2 Capture and Storage with Flue Gas Hydrate Formation in Frozen and Unfrozen Sediments: Method Development, Real Time-Scale Kinetic Characteristics, Efficiency, and Clathrate Structural Transition. ACS Sustain. Chem. Eng. 2019, 7, 5338–5345. [Google Scholar] [CrossRef]

- Hassanpouryouzband, A.; Yang, J.; Tohidi, B.; Chuvilin, E.; Istomin, V.; Bukhanov, B.; Cheremisin, A. CO2 Capture by Injection of Flue Gas or CO2–N2 Mixtures into Hydrate Reservoirs: Dependence of CO2 Capture Efficiency on Gas Hydrate Reservoir Conditions. Environ. Sci. Technol. 2018, 52, 4324–4330. [Google Scholar] [CrossRef]

- Wu, M.; Jiang, C.; Song, R.; Liu, J.; Li, M.; Liu, B.; Shi, D.; Zhu, Z.; Deng, B. Comparative study on hydraulic fracturing using different discrete fracture network modeling: Insight from homogeneous to heterogeneity reservoirs. Eng. Fract. Mech. 2023, 284, 109274. [Google Scholar] [CrossRef]

- Huang, L.; Dontsov, E.; Fu, H.; Lei, Y.; Weng, D.; Zhang, F. Hydraulic fracture height growth in layered rocks: Perspective from DEM simulation of different propagation regimes. Int. J. Solids Struct. 2022, 238, 111395. [Google Scholar] [CrossRef]

- Araújo, O.Q.F.; Reis, A.d.C.; de Medeiros, J.L.; Nascimento, J.F.D.; Grava, W.M.; Musse, A.P.S. Comparative analysis of separation technologies for processing carbon dioxide rich natural gas in ultra-deepwater oil fields. J. Clean. Prod. 2017, 155, 12–22. [Google Scholar] [CrossRef]

- Hetland, J.; Kvamsdal, H.M.; Haugen, G.; Major, F.; Kårstad, V.; Tjellander, G. Integrating a full carbon capture scheme onto a 450 MWe NGCC electric power generation hub for offshore operations: Presenting the Sevan GTW concept. Appl. Energy 2009, 86, 2298–2307. [Google Scholar] [CrossRef]

- Hachem, J.; Schuhler, T.; Orhon, D.; Cuif-Sjostrand, M.; Zoughaib, A.; Molière, M. Exhaust gas recirculation applied to single-shaft gas turbines: An energy and exergy approach. Energy 2022, 238, 121656. [Google Scholar] [CrossRef]

- Li, H.; Ditaranto, M.; Yan, J. Carbon capture with low energy penalty: Supplementary fired natural gas combined cycles. Appl. Energy 2012, 97, 164–169. [Google Scholar] [CrossRef]

- Li, H.; Ditaranto, M.; Berstad, D. Technologies for increasing CO2 concentration in exhaust gas from natural gas-fired power production with post-combustion, amine-based CO2 capture. Energy 2011, 36, 1124–1133. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Soleimani, R.; Bahadori, A. A computational intelligence scheme for prediction equilibrium water dew point of natural gas in TEG dehydration systems. Fuel 2014, 137, 145–154. [Google Scholar] [CrossRef]

- Kloster, P. Energy Optimization on Offshore Installations with Emphasis on Offshore Combined Cycle Plants. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 7–10 September 1999; Society of Petroleum Engineers: Aberdeen, UK, 1999. Epub ahead of print. [Google Scholar] [CrossRef]

- GE LM2500+G4 Marine Gas Turbine. 2021. Available online: https://www.geaviation.com/sites/default/files/datasheet-lm2500plusg4.pdf (accessed on 2 August 2022).

- Følgesvold, E.R.; Skjefstad, H.S.; Riboldi, L.; Nord, L.O. Combined heat and power plant on offshore oil and gas installations. J. Power Technol. 2017, 97, 117–126. [Google Scholar]

- Oh, S.-Y.; Binns, M.; Cho, H.; Kim, J.-K. Energy minimization of MEA-based CO2 capture process. Appl. Energy 2016, 169, 353–362. [Google Scholar] [CrossRef]

- Araújo, O.Q.F.; de Medeiros, J.L. Carbon capture and storage technologies: Present scenario and drivers of innovation. Curr. Opin. Chem. Eng. 2017, 17, 22–34. [Google Scholar] [CrossRef]

- Liu, G.; Zhu, L.; Hong, J.; Liu, H. Technical, Economical, and Environmental Performance Assessment of an Improved Triethylene Glycol Dehydration Process for Shale Gas. ACS Omega 2022, 7, 1861–1873. [Google Scholar] [CrossRef] [PubMed]

- Neagu, M.; Cursaru, D.L. Technical and economic evaluations of the triethylene glycol regeneration processes in natural gas dehydration plants. J. Nat. Gas. Sci. Eng. 2017, 37, 327–340. [Google Scholar] [CrossRef]

- Chebbi, R.; Qasim, M.; Abdel Jabbar, N. Optimization of triethylene glycol dehydration of natural gas. Energy Rep. 2019, 5, 723–732. [Google Scholar] [CrossRef]

- Mokhatab, S.; Poe, W.A.; Mak, J.Y. Natural Gas Dehydration and Mercaptans Removal. Handb. Nat. Gas. Transm. Process 2019, 4, 307–348. [Google Scholar] [CrossRef]

- Milão, R.d.F.D.; de Medeiros, J.L.; Interlenghi, S.F.; Araújo, O.d.Q.F. Low-emission Gas-to-Wire with thermodynamic efficiency: Monetization of carbon dioxide rich natural gas from offshore fields. Gas Sci. Eng. 2023, 115, 205021. [Google Scholar] [CrossRef]

| GTW-EGR-CCS-CO2-DEHY | Utilities Demand | Power (MW) | LPS (t/h) | CW (t/h) | |

|---|---|---|---|---|---|

| CO2 flue gas (t/h) (PCC-MEA Feed) | 557.2 | NGCC plant | 0.15 | - | 6109 |

| CO2 emissions (t/h) (atmosphere) | 59.6 | PCC-MEA | 0.35 | 1230 | 36,249 |

| Gross power (MW) | 599.3 | CO2-DEHY | 0.00355 | 1.1 | 22.4 |

| Power demand (MW) | 64.9 | CO2-CMP-1 | 50.9 | - | 3894 |

| Net power (MW) | 534.4 | CO2-CMP-2 | 13.17 | - | 2324 |

| DCC | 0.36 | - | - | ||

| STR-CO2 | - | - | - | ||

| Total | 64.9 | 1231 | 48,598 | ||

| PCC-MEA Results | CO2-DEHY Results | ||||

| Flue gas inlet (%molCO2) | 17.3 | CO2 inlet (ppm-mol H2O) | 2690.2 | ||

| Decarbonated flue gas (%molCO2) | 1.8 | CO2 outlet (ppm-mol H2O) | 192.8 | ||

| CO2 to CO2-CMP-1 (%molCO2) | 92.7 | Capture Ratio (kgTEG/kgH2O) | 3.7 | ||

| Capture Ratio (kgSolvent/kgCO2) | 13.7 | Lean solvent (t/h) | 2.1 | ||

| CO2Captured (tCO2/h) | 497.6 | Absorber: TTop (°C)/TBottom (°C) | 36.4/35.3 | ||

| Lean solvent (t/h) | 6814 | Stripper: TFeed (°C)/TTop (°C)/TBottom (°C) | 62/40/138 | ||

| Absorber: TTop (°C)/TBottom (°C) | 62.2/61.9 | Reboiler duty (MW) | 0.6 | ||

| Stripper: TFeed (°C)/TTop (°C)/TBottom (°C) | 83/40/103 | ||||

| Heat Ratio (kJ/molCO2) | 225 | ||||

| Reboiler duty (MW) | 722 | ||||

| Second Law Analysis | Lost-Work Validation | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sub-System | (MW) | (MW) | (MW) | (MW) | (MW) | (MW) * | (MW) # | (%) | |

| NGCC plant | 1678.12 | 212.37 | 4.40 | 599.18 | 815.96 | 48.62% | 862.16 | 860.66 | 0.17 |

| PCC-MEA | −31.29 | 212.19 | 31.41 | 0.35 | 181.14 | 17.27% | 149.85 | 149.03 | 0.55 |

| CO2-DEHY | −0.00014 | 0.18 | 0.07 | 0.00355 | 0.12 | 0.12% | 0.1193 | 0.1189 | 0.34 |

| CO2-CMP-1 | −28.41 | - | 2.81 | 50.90 | 48.09 | 59.09% | 19.67 | 19.74 | −0.36 |

| CO2-CMP-2 | −4.88 | - | 1.68 | 13.17 | 11.49 | 42.49% | 6.61 | 6.59 | 0.30 |

| DCC | 26.31 | - | - | −0.36 | −0.36 | −1.37% | 26.67 | 26.50 | 0.64 |

| STR-CO2 | 0.48 | - | - | - | - | 0.00% | 0.480 | 0.478 | 0.42 |

| Sum-crosscheck | 1065.56 | 1063.12 | 0.23 | ||||||

| Overall system | 1602.33 | - | - | 534.40 | 534.40 | 33.35% | 1067.93 | 1061.74 | 0.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, A.d.C.; Araújo, O.d.Q.F.; de Medeiros, J.L. Thermodynamic Analysis of Low-Emission Offshore Gas-to-Wire Firing CO2-Rich Natural Gas: Aspects of Carbon Capture and Separation Systems. Gases 2024, 4, 41-58. https://doi.org/10.3390/gases4020003

Reis AdC, Araújo OdQF, de Medeiros JL. Thermodynamic Analysis of Low-Emission Offshore Gas-to-Wire Firing CO2-Rich Natural Gas: Aspects of Carbon Capture and Separation Systems. Gases. 2024; 4(2):41-58. https://doi.org/10.3390/gases4020003

Chicago/Turabian StyleReis, Alessandra de Carvalho, Ofélia de Queiroz Fernandes Araújo, and José Luiz de Medeiros. 2024. "Thermodynamic Analysis of Low-Emission Offshore Gas-to-Wire Firing CO2-Rich Natural Gas: Aspects of Carbon Capture and Separation Systems" Gases 4, no. 2: 41-58. https://doi.org/10.3390/gases4020003

APA StyleReis, A. d. C., Araújo, O. d. Q. F., & de Medeiros, J. L. (2024). Thermodynamic Analysis of Low-Emission Offshore Gas-to-Wire Firing CO2-Rich Natural Gas: Aspects of Carbon Capture and Separation Systems. Gases, 4(2), 41-58. https://doi.org/10.3390/gases4020003