Abstract

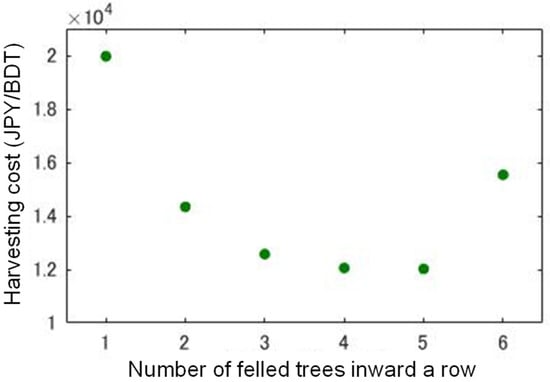

In order to secure the supply source as well as promote the further utilization of forest biomass following the completion of the Feed-in Tariff Scheme for Renewable Energy (FIT), small-diameter trees such as not only cleanings from young planted forests but also broad-leaved trees from coppice forests can be expected to be prospective in Japan. With the aim of discussing the effective method of harvesting such small-diameter trees as unutilized forest biomass appropriate for Japan, a simplified model forest was assumed in this study, while the harvesting of small-diameter trees was experimented with a truck-mounted multi-tree felling head and time-studied. As a result, the machine used in the experiment could fell the maximum six trees inward a row from a forest road, but the harvesting (felling, accumulating, and chipping) cost was the cheapest when the machine felled five trees inward a row.

1. Introduction

The Feed-in-Tariff Scheme for Renewable Energy (FIT) was launched in Japan in 2012, and the scheme has been increasing the energy utilization of forest biomass. In the case of biomass, the electric utilities have committed to buying the electricity derived from biomass at a higher price than the normal retail one for 20 years. Thus, power-generation plants that accept unused forest biomass (such as thinnings and logging residues, rather than wood-based materials like mill residues and imported woods) have been built and the initiation of plant operations are progressing, in part due to the purchase price incentive [1]. As a result, 3.03 million bone dry tons (BDT) of wood chips derived from thinnings and logging residues were used as energy in Japan in 2019 [2].

The use of small-diameter trees is also promising. The area covered by planted forests that have undergone final cutting and subsequent reforestation is now gradually increasing. Thus, a cleaning operation in young planted forests will be necessary 15–20 years from now, when the FIT will expire. The development of efficient harvesting technology for small-diameter trees can thus be expected to contribute not only to securing a source of forest biomass for power-generation plants, but also to the continuous tending of young planted forests after regeneration.

Broad-leaved woody coppices have huge potential. Before and during World War II, an average of 50 million m3/y of naturally regenerated forest was felled and harvested for energy use in the form of charcoal and firewood in Japan. The annual available amount of naturally regenerated broad-leaved trees for energy is estimated to be 9 million BDT/y [3]. The rich ecosystems of coppice forests were traditionally maintained by periodic cutting. Broad-leaved forests are now left unutilized, and degradation is progressing. Therefore, a new approach to hardwood forest management under cyclic logging for the purpose of energy use is proposed so that the former rich ecosystems can be restored.

The authors’ research group has studied technologies and systems for harvesting, transporting, and chipping logging residues on steep terrain in Japan [4,5,6,7,8,9,10]. In the case of logging residues, calculation of the procurement cost begins from the harvesting process at a logging site where the process of limbing and bucking is carried out, while the felling and accumulating processes have to be considered additionally to calculate the procurement cost of small-diameter trees. Thus, in Japan, forest biomass from small-diameter trees is considered to be a resource second to that from logging residues in the Biomass Nippon Strategy [11]. In this study, with the aim of discussing the effective method of harvesting such small-diameter trees as unutilized forest biomass appropriate for Japan, the harvesting of small-diameter trees was experimented with a truck-mounted multi-tree felling head and time-studied.

Harvesting small-diameter trees has never been examined in Japan since the Japanese forestry fell behind in mechanization. Nitami et al. just proposed the harvesting of small-diameter trees by introducing accumulative felling and compressing machines [12], but the developed one has never been demonstrated. In Nordic countries, the accumulative function which can be equipped with by feller-bunchers and harvesters is utilized in harvesting small-diameter trees for the purpose of bioenergy use. Belbo compared two working methods for small tree harvesting with a multi-tree felling head mounted on a farm tractor [13]. Laitila et al. examined forwarding of whole trees after manual and mechanized felling and bunching in pre-commercial thinnings [14].

2. Materials and Methods

In this study, the effective method of harvesting small-diameter trees as unutilized forest biomass appropriate for Japan was discussed with a simplified model forest, where a broad-leaved coppice forest was on either side of a forest road of which width was 3 m. The stand density and the biomass per unit area were assumed to be 12,000 trees/ha (growing 0.91 m apart in a reticular pattern) and 30 BDT/ha, respectively. When a felling machine harvested the coppice trees repeatedly with moving each operation point in turn, the number of felled trees inward a row that minimized the harvesting cost was examined.

The following harvesting operations by two machines were assumed: The first machine was a chipper that equipped with a multi-tree felling head. It felled and accumulated trees, and then the trees were comminuted. The second machine had a container, followed after the first one, and received the comminuted wood chips. This study calculated the costs taken to fell, accumulate, and chip trees, and regarded the sum as a harvesting cost.

The harvesting experiment was carried out with the multi-tree felling head (ENERGY WOOD GRAPPLE 300, Biojack, Finland; weight: 260 kg), which was utilized for the felling and accumulating of small-diameter trees in Nordic countries, as an attachment of the crane (LOGLIFT 61Z, Hiab, Malmö, Sweden) mounted on a log transportation truck (Figure 1). Felling and accumulating coppice trees alongside a forest road was time-studied in order to collect basic data, e.g., maximum reach and moving velocity of the felling head, time for felling a tree, maximum number of trees that could be held at a time, machine’s moving time among operation points.

Figure 1.

Harvesting experiment with a truck-mounted multi-tree felling head.

3. Results and Discussion

The maximum reach of the felling head used in the experiment was 6.7 m so that the machine could fell, in the model forest, the maximum six trees inward a row from a forest road with 3 m of road width taken into consideration. Figure 2 shows the relationship between the number of felled trees inward a row and the harvesting cost, and the harvesting cost was the cheapest when the machine felled five trees inward a row. The following reasons were considered to lie behind this result: The more trees inward a row the machine felled, the more trees were harvested at one operation point. In this case, however, the machine’s total moving time markedly increased because the frequency of moving among operation points increased. Therefore, it was concluded that there was the optimum number of felled trees inward a row that could minimize the harvesting cost.

Figure 2.

Relationship between the number of felled trees inward a row and the harvesting cost.

In order to increase the harvest amount of trees, it seemed to be effective to lengthen the maximum reach of a felling head and fell deeper trees inward a row; thus, the following two factors were examined in the case that the length of the maximum reach of a felling head was changed: (1) the maximum number of felled trees inward a row that minimized the harvesting cost, and (2) the minimum of the harvesting cost itself. With regard to the factor (1), twelve trees inward a row from a forest road was the most when the length of the maximum reach was 18.2 m. This means that felling trees deeper than the twelfth one inward a row by using a longer reach felling head cannot diminish the harvesting cost. Concerning the factor (2), the harvesting cost of 10,658 JPY/BDT was the cheapest when the length of the maximum reach was 10.4 m (the exchange rate was roughly 1 EUR = 125 JPY in October 2020). This means that using a felling head of which maximum reach is longer than 10.4 m cannot diminish the harvesting cost. Consequently, it was indicated that, from a point of view of minimizing the harvesting cost, there were upper limits to the number of felled trees inward a row as well as the maximum reach of a felling head.

Finally, although this study was the limited examination based on various kinds of assumption, general trend concerning the procurement cost of wood chips from forest biomass in Japan was identified; that is, the cost from small-diameter trees calculated in this study was more expensive than that from logging residues [15] but was cheaper than that from short rotation woody crops [16].

Author Contributions

T.Y., T.T., and T.N. conceived, designed, and performed the field experiment; T.Y. and T.T. analyzed the data; T.T. contributed the simulation model; T.Y. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported in part by JSPS KAKENHI Grant Number JP20K06121.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully appreciate Kin’ichi Suzuki, the president of Amerikaya Co., Ltd. for his great cooperation in the field experiment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Feed-in Tariff Scheme in Japan. Available online: https://www.meti.go.jp/english/policy/energy_environment/renewable/pdf/summary201207.pdf (accessed on 6 October 2020).

- Survey on Woody Biomass Energy Use Trend in 2019. Available online: https://www.maff.go.jp/j/tokei/kouhyou/mokusitu_biomass/attach/pdf/index-1.pdf (accessed on 6 October 2020).

- Yoshioka, T.; Hirata, S.; Matsumura, Y.; Sakanishi, K. Woody biomass resources and conversion in Japan: The current situation and projections to 2010 and 2050. Biomass Bioenergy 2005, 29, 336–346. [Google Scholar] [CrossRef]

- Yoshioka, T.; Iwaoka, M.; Sakai, H.; Kobayashi, K. Feasibility of a harvesting system for logging residues as unutilized forest biomass. J. For. Res. 2000, 5, 59–65. [Google Scholar] [CrossRef]

- Yoshioka, T.; Aruga, K.; Sakai, H.; Kobayashi, H.; Nitami, T. Cost, energy and carbon dioxide (CO2) effectiveness of a harvesting and transporting system for residual forest biomass. J. For. Res. 2002, 7, 157–163. [Google Scholar] [CrossRef]

- Yoshioka, T.; Aruga, K.; Nitami, T.; Kobayashi, H.; Sakai, H. Energy and carbon dioxide (CO2) balance of logging residues as alternative energy resources: System analysis based on the method of a life cycle inventory (LCI) analysis. J. For. Res. 2005, 10, 125–134. [Google Scholar] [CrossRef]

- Yoshioka, T.; Sakai, H. Amount and availability of forest biomass as an energy resource in a mountainous region in Japan: A GIS-based analysis. Croat. J. For. Eng. 2005, 26, 59–70. Available online: https://hrcak.srce.hr/3989 (accessed on 6 October 2020).

- Yoshioka, T.; Aruga, K.; Nitami, T.; Sakai, H.; Kobayashi, H. A case study on the costs and the fuel consumption of harvesting, transporting, and chipping chains for logging residues in Japan. Biomass Bioenergy 2006, 30, 342–348. [Google Scholar] [CrossRef]

- Yoshioka, T.; Sakurai, R.; Aruga, K.; Nitami, T.; Sakai, H.; Kobayashi, H. Comminution of logging residues with a tub grinder: Calculation of productivity and procurement cost of wood chips. Croat. J. For. Eng. 2006, 27, 103–114. Available online: https://hrcak.srce.hr/7617 (accessed on 6 October 2020).

- Yoshioka, T.; Sakurai, R.; Aruga, K.; Sakai, H.; Kobayashi, H.; Inoue, K. A GIS-based analysis on the relationship between the annual available amount and the procurement cost of forest biomass in a mountainous region in Japan. Biomass Bioenergy 2011, 35, 4530–4537. [Google Scholar] [CrossRef]

- Yokoyama, S.Y. Appendix: Biomass-Nippon Strategy (Provisional Translation) Decided at the Cabinet Meeting, Government of Japan, 27 December 2002. Biomass Bioenergy 2005, 29, 375–398. [Google Scholar] [CrossRef]

- Nitami, T.; Iizawa, T.; Suk, S.-I.; Sakurai, R. New mechanism and efficiency of bundler for forest harvesting residuals. Int. For. Rev. 2010, 7, 266. [Google Scholar]

- Belbo, H. Comparison of two working methods for small tree harvesting with a multi tree felling head mounted on farm tractor. Silva Fenn. 2010, 44, 453–464. [Google Scholar] [CrossRef]

- Laitila, J.; Asikainen, A.; Nuutinen, Y. Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. Int. J. For. Eng. 2007, 18, 29–39. [Google Scholar] [CrossRef]

- Yoshioka, T.; Kameyama, S.; Inoue, K.; Hartsough, B. A cost breakdown structure analysis on the grinding of logging residues: A comparative study of Japanese and American operations. In Proceedings of the Grand Renewable Energy 2018: International Conference and Exhibition, Yokohama, Japan, 17–22 June 2018; Japan Council for Renewable Energy: Tokyo, Japan, 2018; p. 4. [Google Scholar] [CrossRef]

- Yoshioka, T.; Inoue, K.; Hartsough, B. Cost and greenhouse gas (GHG) emission analysis of a growing, harvesting, and utilizing system for willow trees aimed at short rotation forestry (SRF) in Japan. J. Jpn. Inst. Energy 2015, 94, 576–581. [Google Scholar] [CrossRef][Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).