Carbon Footprint of Thermal Energy Production from Poplar Short-Rotation Coppice Plantations †

Abstract

:1. Introduction

2. Material and Methods

2.1. Study Area, Poplar SRC Plantations and Harvesting Systems

2.2. Biomass and Diesel Boilers

2.3. Environmental Analisys

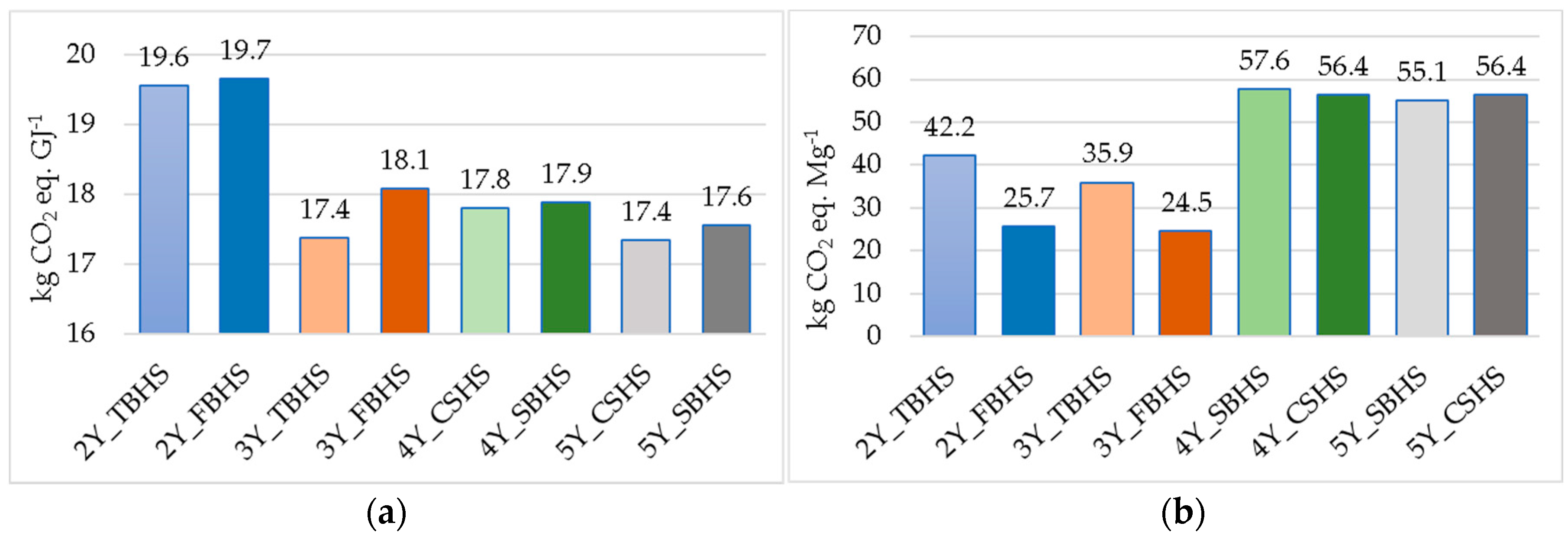

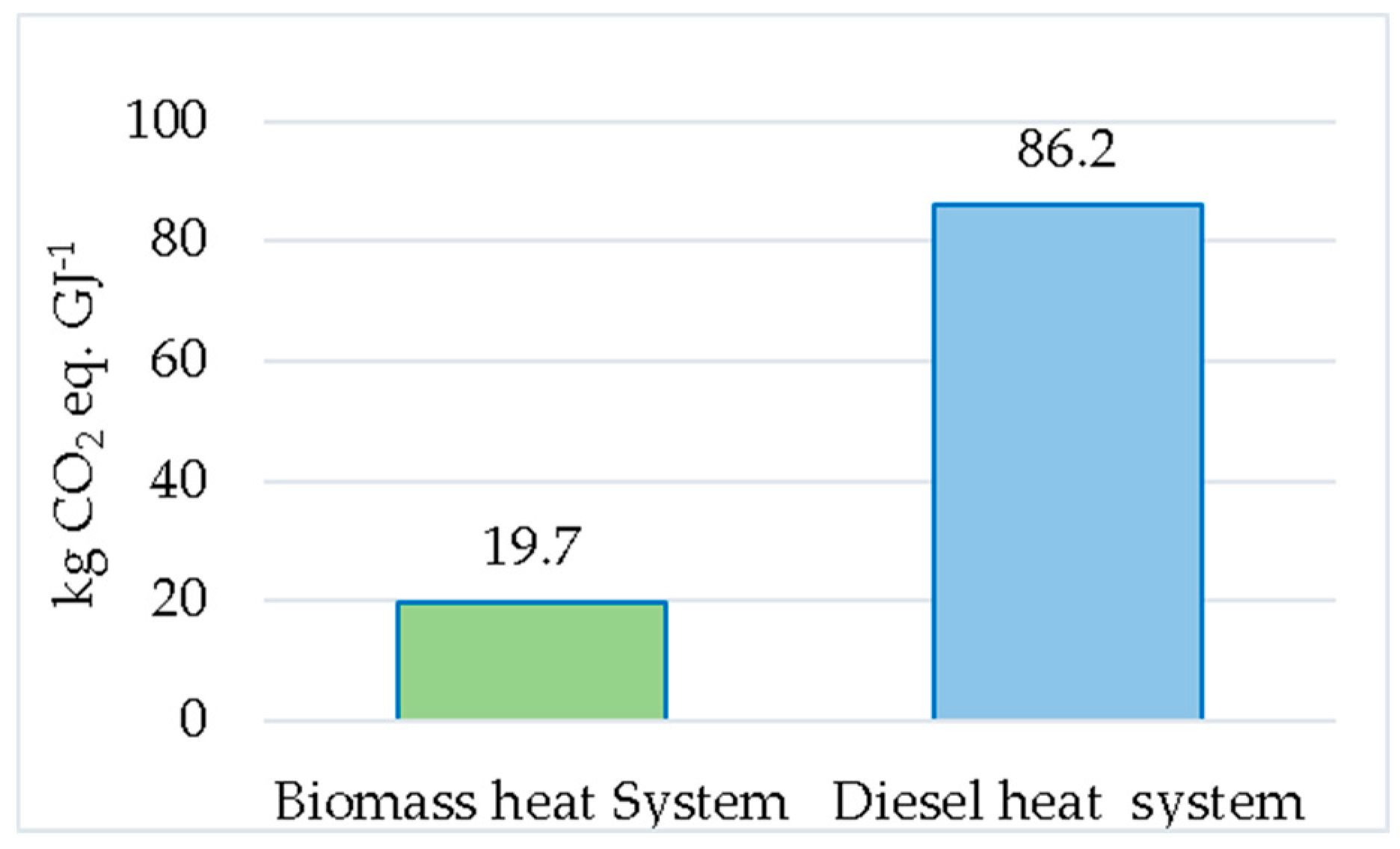

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- International Energy Agency. Renewables 2017. Analysis and Forecasts. Executive Summary; IEA: Paris, France, 2017. [Google Scholar]

- International Energy Agency. Renewables 2018. Analysis and Forecasts. Executive Summary; IEA: Paris, France, 2018. [Google Scholar]

- Punter, G.; Rickeard, D.; Larivé, J.F.; Edwards, R.; Mortimer, N.; Horne, R.; Bauen, A.; Woods, J. Well-to-Wheel Evaluation for Production of Ethanol from Wheat; A Report by the LowCVP Fuels Working Group, WTW Sub-Group, FWG-P-04-024; The Low Carbon Vehicle Partnership: London, UK, 2004; 40p. [Google Scholar]

- Kim, S.; Dale, B.E. Life cycle assessment of various cropping systems utilized for producing biofuels: Bioethanol and biodiesel. Biomass Bioenergy 2005, 29, 426–439. [Google Scholar] [CrossRef]

- Farrell, A.E.; Plevin, R.J.; Turner, B.T.; Jones, A.D.; O’hare, M.; Kammen, D.M. Ethanol can contribute to energy and environmental goals. Science 2006, 31, 506–508. [Google Scholar] [CrossRef] [PubMed]

- Fritsche, U.R.; Hünecke, K.; Hermann, A.; Schulze, F.; Wiegmann, K.; Adolphe, M. Sustainability Standards for Bioenergy; WWF: Frankfurt am Main, Germany, 2006. [Google Scholar]

- Dias, G.M.; Ayer, N.W.; Kariyapperuma, K.; Thevathasan, N.; Gordon, A.; Sidders, D.; Johannesson, G.H. Life cycle assessment of thermal energy production from short-rotation willow biomass in Southern Ontario, Canada. Appl. Energy 2017, 204, 343–352. [Google Scholar] [CrossRef]

- Di Matteo, G.; Sperandio, G.; Verani, S. Field performance of poplar for bioenergy in southern Europe after two coppicing rotations: Effects of clone and planting density. IForest 2012, 5, 224–229. [Google Scholar] [CrossRef]

- Costa, C.; Sperandio, G.; Verani, S. Use of multivariate approaches in biomass energy plantation harvesting: Logistics advantages. Agric. Eng. Int. CIGR J. 2014, 70–79. [Google Scholar]

- Solomon, S.; Manning, M.; Marquis, M.; Qin, D.; Chen, Z.; Avery, K.B.; Tignor, M.; Miller, H.L. Climate Change 2007—The Physical Science Basis: Working Group I Contribution to the Fourth Assessment Report of the IPCC; Assessment Report (Intergovernmental Panel on Climate Change): Working Group; Cambridge University Press: Cambridge, UK, 2007; ISBN 9780521705967. [Google Scholar]

- Verani, S.; Sperandio, G.; Picchio, R.; Marchi, E.; Costa, C. Sustainability assessment of a self-consumption wood-energy chain on small scale for heat generation in central Italy. Energies 2015, 8, 5182–5197. [Google Scholar] [CrossRef]

- Brentrup, F.; Kusters, J.; Lammel, J.; Kuhlmann, H. Methods to estimate on-field nitrogen emissions from crop production as an input to LCA studies in the agricultural sector. Int. J. Life Cycle Assess. 2000, 5, 349–357. [Google Scholar] [CrossRef]

- De Klein, C.; Novoa, R.S.A.; Ogle, S.; Smith, K.A.; Rochette, P.; Wirth, T.C.; McConkey, B.G.; Mosier, A.; Rypdal, K.; Walsh, M. N2O emissions from managed soils, and CO2 emissions from lime and urea application. In 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2006; Volume 4, pp. 1–54. [Google Scholar]

- Dijkman, T.J.; Birkved, M.; Hauschild, M.Z. PestLCI 2.0: A second generation model for estimating emissions of pesticides from arable land in LCA. Int. J. Life Cycle Assess. 2012, 17, 973–986. [Google Scholar] [CrossRef]

- Pecenka, R.; Lenz, H.; Hering, T. Options Optimizing the Drying Process and Reducing Dry Matter Losses in Whole-Tree Storage of Poplar from Short-Rotation Coppices in Germany. Forests 2020, 11, 374. [Google Scholar] [CrossRef]

| Boilers | ||

|---|---|---|

| Biomass | Diesel | |

| Building volume (m3) | 9450 | 9450 |

| Operating period (days year−1) | 130 | 130 |

| Heating period (h year−1) | 3120 | 1560 |

| Rated thermal power (kWt) | 350 | 315 |

| Thermal efficiency of the boiler (%) | 81% | 90% |

| Lower heating value (LHV) (kWh kg−1) | 3.11 | 11.86 |

| Water content (%) | 35.00% | |

| Average biomass/diesel consumption (Mg year−1) | 290.1 | 41.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sperandio, G.; Suardi, A.; Acampora, A.; Civitarese, V. Carbon Footprint of Thermal Energy Production from Poplar Short-Rotation Coppice Plantations. Environ. Sci. Proc. 2021, 3, 101. https://doi.org/10.3390/IECF2020-07908

Sperandio G, Suardi A, Acampora A, Civitarese V. Carbon Footprint of Thermal Energy Production from Poplar Short-Rotation Coppice Plantations. Environmental Sciences Proceedings. 2021; 3(1):101. https://doi.org/10.3390/IECF2020-07908

Chicago/Turabian StyleSperandio, Giulio, Alessandro Suardi, Andrea Acampora, and Vincenzo Civitarese. 2021. "Carbon Footprint of Thermal Energy Production from Poplar Short-Rotation Coppice Plantations" Environmental Sciences Proceedings 3, no. 1: 101. https://doi.org/10.3390/IECF2020-07908

APA StyleSperandio, G., Suardi, A., Acampora, A., & Civitarese, V. (2021). Carbon Footprint of Thermal Energy Production from Poplar Short-Rotation Coppice Plantations. Environmental Sciences Proceedings, 3(1), 101. https://doi.org/10.3390/IECF2020-07908