Optimization of a CHP Unit Operation on a University Campus for Carbon Dioxide Emission Minimization †

Abstract

:1. Introduction

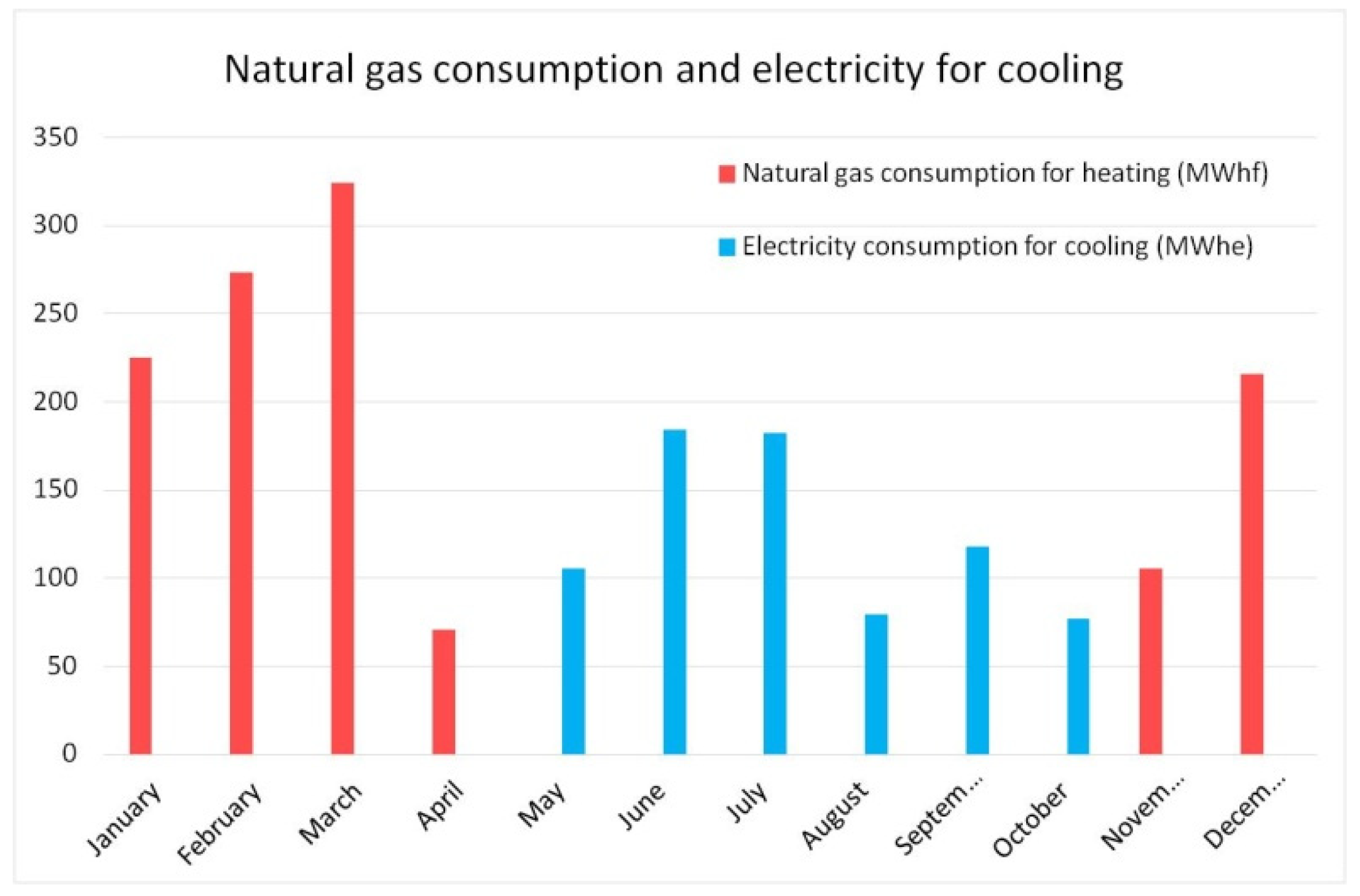

Energy Consumption Profile for the University of West Attica

2. CHP Methodology & Unit

2.1. Combined Heat and Power Methodology

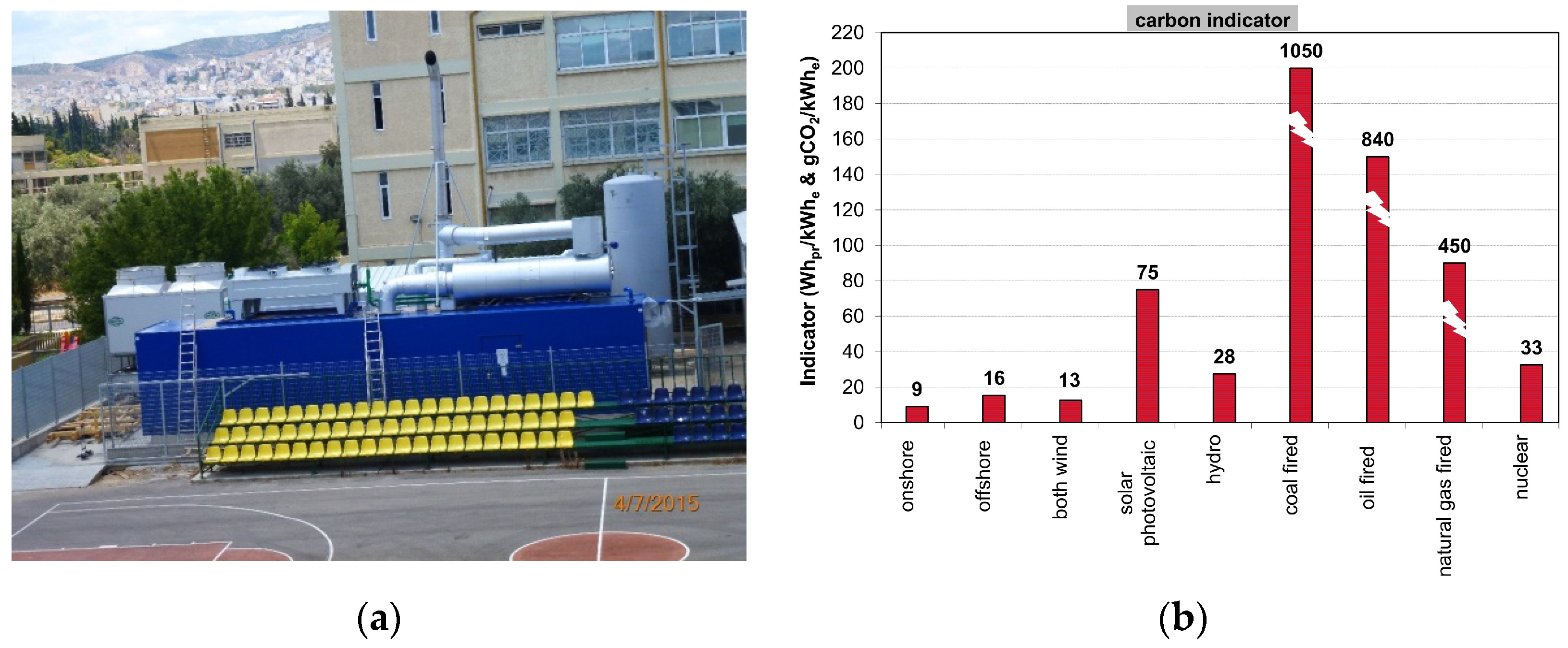

2.2. Combined Heat and Power Units of UNIWA

3. Carbon Dioxide Emissions Quantification

4. Problem Modeling

4.1. Conventional Demand Coverage

4.2. Modeling of Suggested Solution

4.3. The Model

5. Application, Results and Discussion

5.1. Application

5.2. Parametric Analysis of the Suggested Model

5.3. Results Discussion

6. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Darabadi, Z.A.; Khoshbakhti, S.R.; Mirmasoumi, S.; Bahlouli, K. Extensive thermodynamic and economic analysis of the cogeneration of heat and power system fueled by the blend of natural gas and biogas. Energy Convers. Manag. 2018, 164, 329–343. [Google Scholar]

- Rosen, M.A. Energy, environmental, health and cost benefits of cogeneration from fossil fuels and nuclear energy using the electrical utility facilities of a province. Energy Sustain. Dev. 2009, 13, 43–51. [Google Scholar] [CrossRef]

- Stavropoulos, G.G.; Skordas, G. Energy and Environmental Benefits from Natural Gas Cogeneration: A Case Study; OPET Network; European Commission: Brussels, Belgium, 2005.

- Gambini, M.; Vellini, M. High Efficiency Cogeneration: Electricity from Cogeneration in CHP Plants. Energy Procedia 2015, 81, 430–439. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Vlachos, G.T.; Paliatsos, A.G.; Kondili, E. Detailed Examination of Greek Electricity Sector Nitrogen Oxides Emissions for the Last Decade. J. Environ. Sci. Policy 2005, 8, 502–514. [Google Scholar]

- U.S. DoE (U.S. Department of Energy); EPA (United States Environmental Protection Agency). Combined Heat and Power. A Clean Energy Solution. 2012. Available online: https://www.energy.gov/sites/prod/files/2013/11/f4/chp_clean_energy_solution.pdf (accessed on 5 June 2023).

- Kaldellis, J.K.; Apostolou, G. Life cycle energy and carbon footprint of offshore wind energy. Comparison with onshore counterpart. Renew. Energy 2017, 108, 72–84. [Google Scholar] [CrossRef]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef]

- IPTO Greece, Market Statistics. Generation per Fuel. Available online: https://www.admie.gr/en/market/market-statistics/key-data/generation-per-fuel (accessed on 20 June 2023).

| Sel,grid | Sth,ng | Sel,chp | Operator | Criterion |

|---|---|---|---|---|

| 1 | 0 | 1 | = | Del |

| 0 | 1 | 1/c | ≥ | Dth |

| 0 | 0 | 1 | ≤ | CF * 8760 * Pel,chp |

| 0 | 1 | 0 | ≤ | Dth |

| 1 | 0 | 0 | ≥ | 0 |

| 0 | 1 | 0 | ≥ | 0 |

| 0 | 0 | 1 | ≥ | 0 |

| εgrid | εng | εchp | = | Min(Z) = e |

| Variables (Input) | Values | Units |

|---|---|---|

| Del | 3,000,000 | kWhe |

| Dth | 605,000 | kWhth |

| c | 0.85 | - |

| Pel,chpmax | 550 | kW |

| εgrid 1 | 0.9 | kgCO2/kWhe |

| εng | 0.25 | kgCO2/kWhth |

| εchp | 0.45 | kgCO2/kWhe |

| Variables (Output) | Values | Units |

|---|---|---|

| Sel,grid | 0 | kWhe |

| Sth,grid | 0 | kWhth |

| Sel,chp | 3,000,000 | kWhe |

| Sth,chp | 3,450,000 | kWhth |

| e′ (model) | 1,350,000 | kgCO2 |

| e (conventional) | 2,851,250 | kgCO2 |

| Δe (emissions reduction) | 53 | % |

| εgrid Values | CHP Optimal Operating Level |

|---|---|

| [0.90, 0.45) | Full electricity and heat production |

| [0.45, 0.15) | Electricity production needed for full heat production |

| [0.15, 0.10] | No production |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaldellis, K.; Kostopoulos, E.; Kaldellis, J.K. Optimization of a CHP Unit Operation on a University Campus for Carbon Dioxide Emission Minimization. Environ. Sci. Proc. 2023, 26, 210. https://doi.org/10.3390/environsciproc2023026210

Kaldellis K, Kostopoulos E, Kaldellis JK. Optimization of a CHP Unit Operation on a University Campus for Carbon Dioxide Emission Minimization. Environmental Sciences Proceedings. 2023; 26(1):210. https://doi.org/10.3390/environsciproc2023026210

Chicago/Turabian StyleKaldellis, Kleanthis, Emmanouil Kostopoulos, and John K. Kaldellis. 2023. "Optimization of a CHP Unit Operation on a University Campus for Carbon Dioxide Emission Minimization" Environmental Sciences Proceedings 26, no. 1: 210. https://doi.org/10.3390/environsciproc2023026210

APA StyleKaldellis, K., Kostopoulos, E., & Kaldellis, J. K. (2023). Optimization of a CHP Unit Operation on a University Campus for Carbon Dioxide Emission Minimization. Environmental Sciences Proceedings, 26(1), 210. https://doi.org/10.3390/environsciproc2023026210