Abstract

Approximately 40% and 36% of total energy consumption and CO2 emissions, respectively, in the EU are due to buildings. A large percentage of this energy consumption and its associated CO2 emissions are due to conventional heating, ventilation, and air conditioning (HVAC) systems. Solar desiccant cooling (SDEC) systems present a high energy saving potential to replace conventional HVAC systems. However, SDEC systems could generate a high environmental impact during their manufacturing stage, which may even exceed the benefit in the use phase. Therefore, the aim of this work is to focus on studying feasible ecodesign strategies for a SDEC system composed mainly of an indirect evaporative cooler, a desiccant wheel and a solar thermal system. More specifically, the strategies considered were: (a) selection of environmentally friendly materials, such as biocomposites based on natural fibers; (b) weight optimization; and (c) reuse of components at the end of the life phase. The results showed that the proposed strategies to the SDEC system could significantly improve the environmental impact throughout its entire life cycle. Combining all the proposed improvements, the environmental impact was reduced between 45% and 60% for all the indicators.

1. Introduction

The global energy consumption of buildings has increased sharply in recent years, which has generated problems owing to its associated environmental impacts [1]. Solar desiccant cooling (SDEC) systems could help to reduce energy consumption in buildings, due to the use of renewable energies and its high energy efficiency [2]. However, during the manufacturing and end-of-life stages, these system also consume raw materials and energy from non-renewable sources, hence generating high environmental impacts [3]. Therefore, to properly assess the real benefits of the SDEC system, it is necessary to determine its environmental impact throughout its entire life cycle [4]. Life cycle assessment (LCA) is an appropriate methodology to scientifically evaluate any type of system or process in terms of environmental impact [5].

Considering that the environmental impact generated by SDEC systems is mainly owing to their manufacturing and end-of-life phases [6], reuse or recyclability can be especially advantageous in terms of circular economy and sustainability. Thereby, the aim of this work was to analyze some improvements of the SDEC systems in term of environmental impact. Specifically, some eco-design strategies were evaluated, material changes and reuse of materials at the end-of-life of the system.

2. Material and Methods

The experimental SDEC system studied was located in Andaltec (Martos, southern Spain) and was designed to supply air conditioned to a research laboratory. LCA was applied to analyse the influence on the environmental impact of the ecodesign strategies considered. Different case studies were analysed: (a) the base system (DW1), (b) the base system with improvements in the manufacturing phase (DW2), (c) the base system with improvements in the end-of-life phase (DW3); and, finally, (d) the two types of previous improvements (DW2 and DW3) applied together (DW4). Concerning DW2, the specific modifications in terms of ecodesign were the replacement of the aluminum in the structure of the solar collector with steel; and the replacement of the steel in the structure of the desiccant cooling systems with natural fiber-based biocomposites (NFB), achieving a reduction of 50% in weight. Regarding DW3, an improvement of the end-of-life phase was studied in which 50% of total mass of the components were reuse.

For this work, Eco-Indicador99 method [7] was selected because it allows easy comparison of the results. This method assesses the life cycle based on the three impact categories:

- Impacts on natural resources: this category is represented by the Land Used Potential (LUP) indicator.

- Impacts on quality of ecosystems: this category is represented by Mineral Depletion (MND) and Fossil Fuel Depletion (FFD) indicators.

- Impacts on human health: this category is represented by Carcinogenic Effect Potential (CEP), Respiratory Effects Potential (RPEP), Climate Change Potential (CHP), Radiation Effect Potential (RDEP), Ozone Layer Depletion (OLD), Ecotoxicity Potential (ETP) and Acidification Potential (AP) indicators.

All of the impact categories described above can be summed up in a single parameter, called the “single score parameter” (SCP).

3. Results

3.1. SCP on Manufacturing Phase

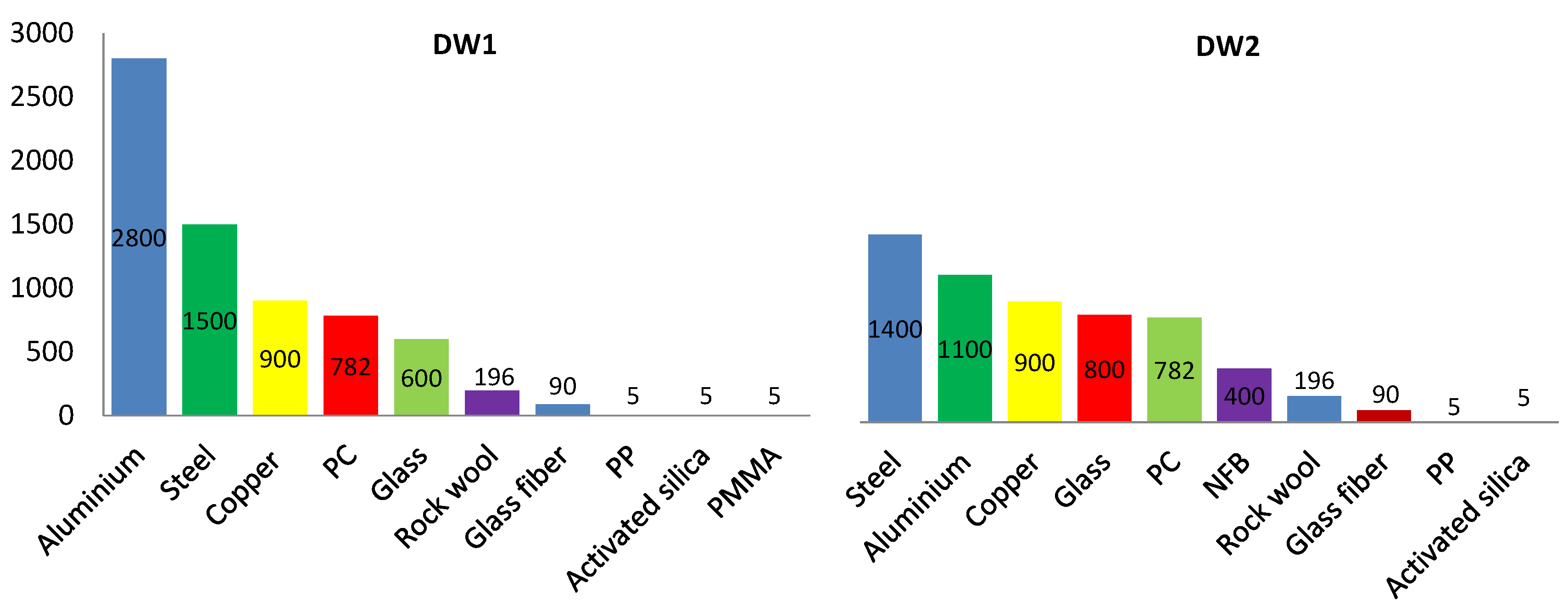

The contribution of the manufacture phase to the SCP in DW1 and DW2, respectively, is shown in Figure 1. It can be observed that the maximum SCP value for DW2 was for steel, this result being half of the maximum value of DW1, for aluminium. This was due to the amount of aluminum involved in DW2 was less than half that of DW1 as a consequence of replacing some aluminum with NFB and weight optimization.

Figure 1.

SCP in the manufacturing phase of the DW1 and DW2 prototypes.

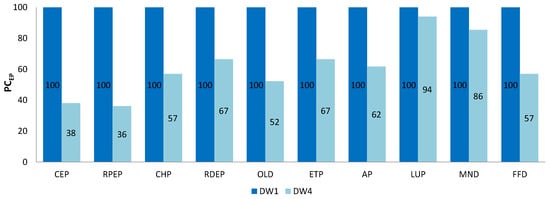

3.2. Impact Indicators

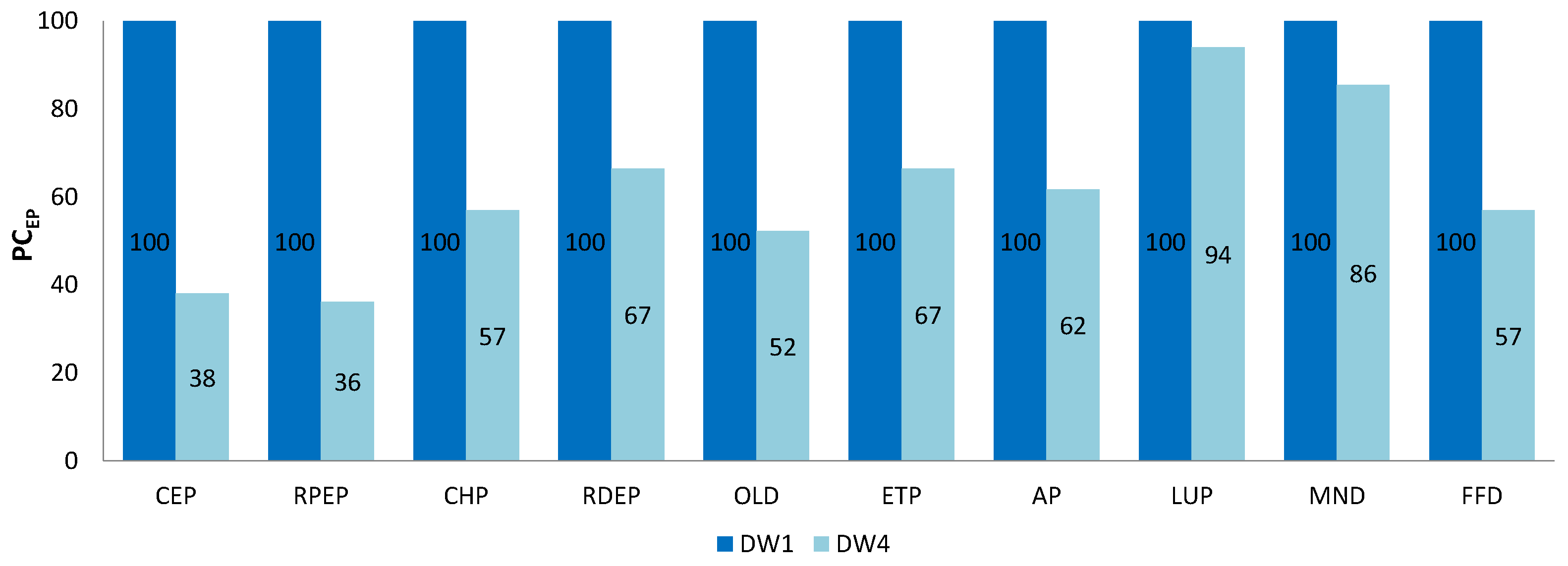

The percentage change in environmental performance (PCEP) for all impact indicators in DW4 and DW1 is shown in Figure 2. The lowest PCEP values are presented in DW4 owing to the reduction in material consumption during the manufacturing phase and due to the material reuse at the end-of-life phase. The lowest indicators in DW4 were CEP, REP, CHP, RDEP, OLD, ETP, AP and FFD. However, LUP and MND were barely modified due to their low influence on electricity consumption. The main differences of PCEP between DW4 and DW1 came from the great reduction of the electricity consumption from the grid necessary for the manufacture of the aluminum. The CHP result is noteworthy, since it is an indicator highly regarded nowadays and a reduction of 60% was achieved with DW4.

Figure 2.

Impact indicator results for DW1 vs DW4.

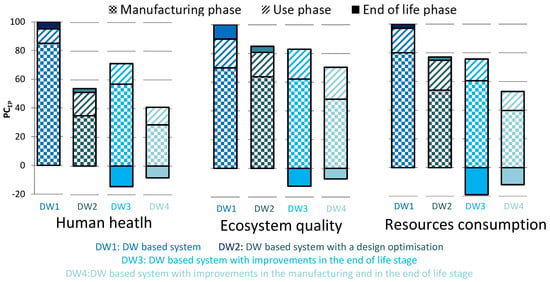

3.3. Results for the Different Impact Categories

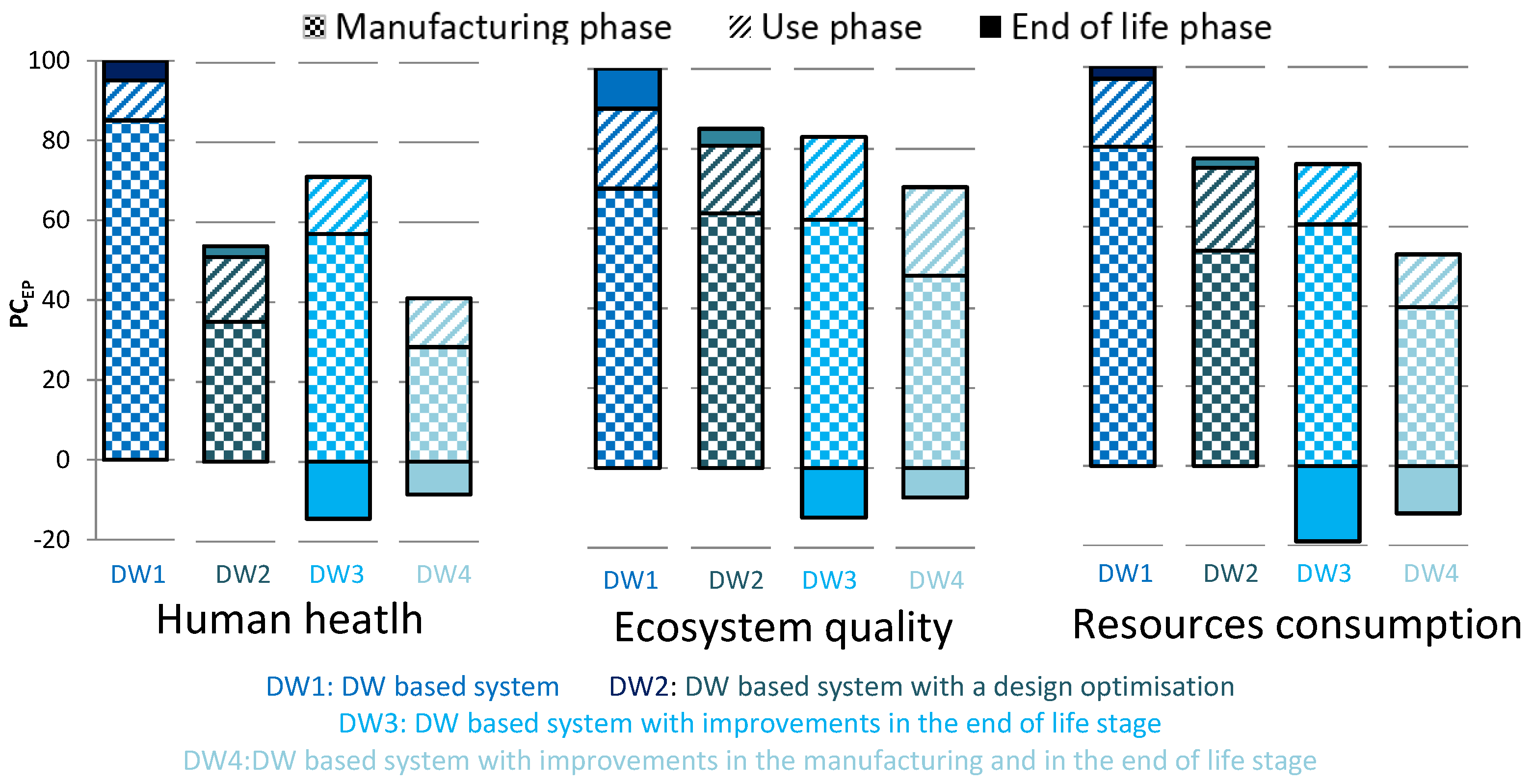

The results of the impact categories for all the case studies analysed are shown in Figure 3. The weight optimization strategy and the use of more environmentally friendly materials (DW2) led to a reduction of 50%, 18% and 22% in the impact categories of human health, ecosystem quality and resource consumption, respectively. In addition, DW3 results show that the reuse of materials used for manufacturing led to a reduction between 20% and 25% in the three impact categories studied. Finally, combining both strategies, DW2 and DW3, weight optimization and material reuse, a synergistic effect was perceived which led to a significant reduction in the impact associated with the different categories: up to 60% in human health, 25% in ecosystem quality and 45% in resource consumption.

Figure 3.

Evolution of the impact categories for all cases.

4. Conclusions

A Life cycle Assessment (LCA) for a solar desiccant cooling (SDEC) system was carried out. In this work, environmentally friendly and light materials, such as natural fiber-based biocomposites (NFB), were selected with the aim of reducing the environmental impact of the SDEC system. The results showed significant impact reductions, between 25% and 60%, for all impact categories analyzed. This improvement was due to the manufacturing phase (the stage with the greatest impact) and to the reuse of the material at the end of its life, reducing the global environmental impact. In terms of Land Used Potential (LUP) and Mineral Depletion (MND), with the proposed changes no improvements were obtained. This was due to the environmental benefit of reducing the use of steel and aluminum and, consequently, the reduction in energy consumption during the manufacturing phase. It is highly remarkable that these results can be extrapolated to other, similar SDEC systems; this is considering that, in all of them, manufacturing is the stage with the greatest environmental impact, as reported by the literature.

Author Contributions

F.C. and M.R.d.A. performed the energy consumption analyses necessary for conducting the LCA; J.C.-G. and F.J.N.-M. carry out the LCA and analyzed data; J.C.-G. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by DIPUTACIÓN PROVINCIAL DE JAÉN grant number [2020/3336] and by European Union’s Horizon 2020 grant number [H2020-WIDESPREAD2018-03-857801]. The APC was funded by Centro Tecnológico del Plástico Andaltec.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The present work has been conducted as a part of the CLIMASEE project funded by DIPUTACIÓN PROVINCIAL DE JAÉN. The authors also acknowledge the financial support received by the European Regional Development Fund and the Andalusian Economy, Knowledge, Enterprise and University Council, Spain, through the research project HICOOL, reference 1263034, and by European Union’s Horizon 2020 research and innovation program, through the research project WEDISTRICT, reference H2020-WIDESPREAD2018-03-857801.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Jing, Y.Y.; Bai, H.; Wang, J.J.; Liu, L. Life cycle assessment of a solar combined cooling heating and power system in different operation strategies. Appl. Energy 2013, 92, 843–853. [Google Scholar] [CrossRef]

- Castillo-González, J.; Comino, F.; Navas-Martos, F.J.; de Adana, M.R. Life cycle assessment of an experimental solar HVAC system and a conventional HVAC system. Energy Build. 2022, 256, 111697. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Finocchiaro, P.; Guarino, F.; Longo, S.; Nocke, B. Life cycle performance assessment of small solar thermal cooling systems and conventional plants assisted with photovoltaics. Sol. Energy 2014, 104, 93–102. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Longo, S.; Nocke, B.; Finocchiaro, P. LCA of a solar heating and cooling system equipped with a small water-ammonia absorption chiller. Sol. Energy 2012, 86, 1491–1503. [Google Scholar] [CrossRef]

- Heikkilä, K. Environmental impact assessment using a weighting method for alternative air-conditioning systems. Build. Environ. 2004, 39, 1133–1140. [Google Scholar] [CrossRef]

- Longo, S.; Palomba, V.; Beccali, M.; Cellura, M.; Vasta, S. Energy balance and life cycle assessment of small size residential solar heating and cooling systems equipped with adsorption chillers. Sol. Energy 2017, 158, 543–558. [Google Scholar] [CrossRef]

- European Commission. ILCD Handbook. Analysis of Existing Enviromental Impact Assessment Methodologies for Use in Life Cycle Assessment; European Commission: Brussels, Belgium, 2010. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).