Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study †

Abstract

:1. Introduction

2. Methodology

- Design phase—The objective is to design the P&P façade by working on existing buildings in a less intrusive way so as not to affect users or daily activities while providing a deep retrofitting solution for the building envelope;

- Prototype phase—The objective is to manufacture the P&P façade to verify its feasibility and validate the prototypes;

- Testing phases—The objective is to validate the performances of the P&P façade system.

3. Results

3.1. Design Phase

- Opaque Unit—Curtain wall façade with customizable cladding system (fiber cement, cement board, wood panel, etc.) (Figure 1c);

- Window Unit—Curtain wall façade, which integrates the window frame unit and shading systems such as roller shutters or venetian blinds;

- Solar Thermal Collector Unit—Curtain wall façade with a water thermal solar collector, with water to be used for DHW to allow higher temperatures;

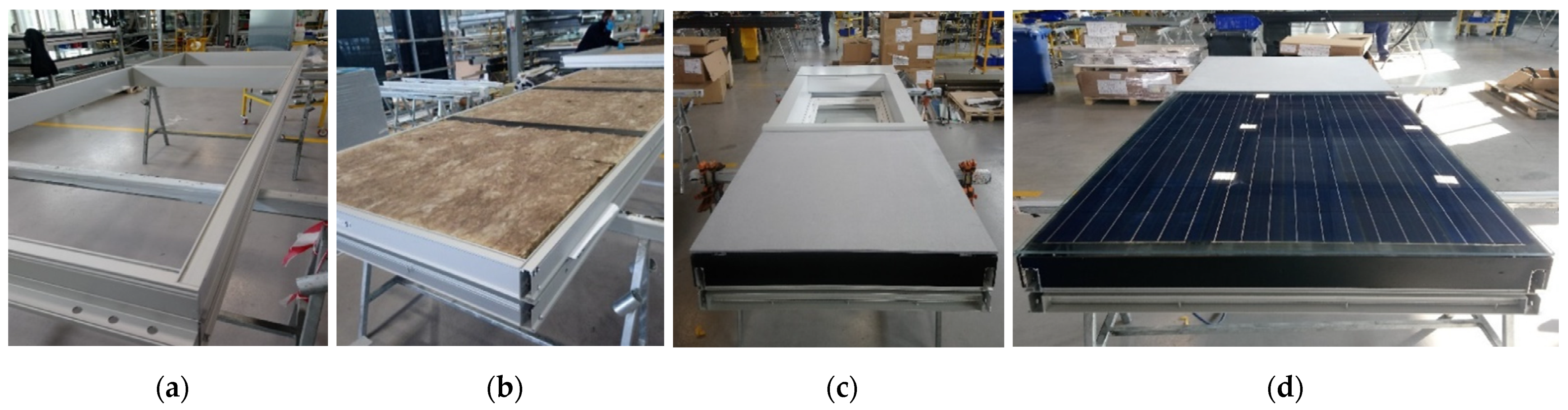

- PV Panel Unit—Curtain wall façade with a PV;

- Smart-IoT Unit—Curtain wall façade with sensors and actuators.

3.2. Prototyping Phase

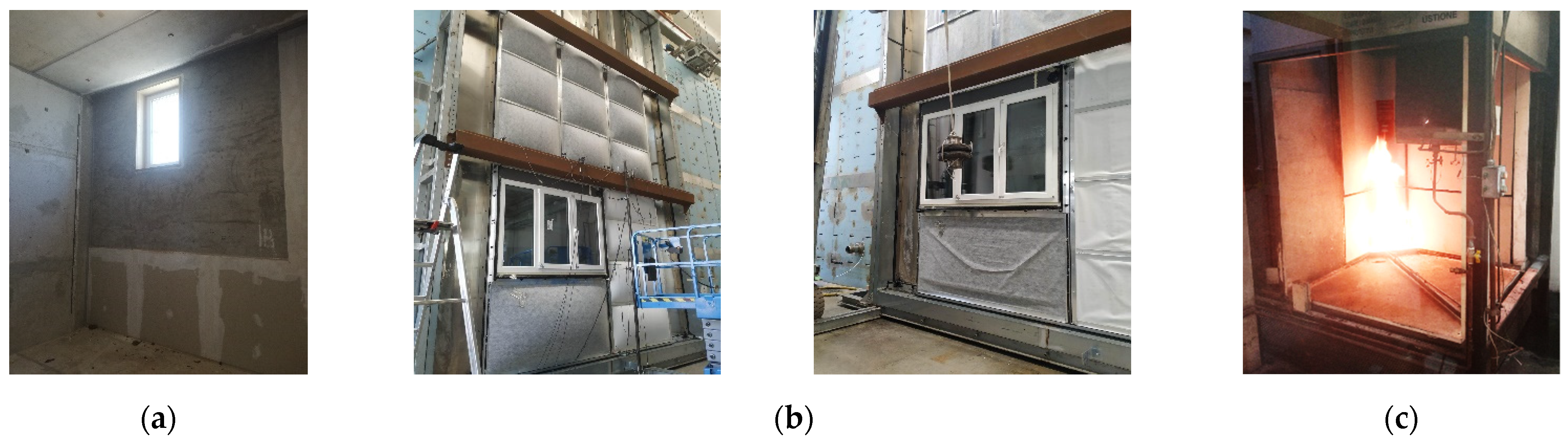

3.3. Testing Phase

- Real environment tests: The RenoZEB modular façade was installed, monitored, and tested in a controlled safe environment (KUBIK), namely a test facility owned by Tecnalia R&I (Figure 4). The aim was to validate the energy performance of the façade system by comparing the predicted and monitored results and to validate the installation procedure and generate video content for training activities.

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Anđelković, A.S.; Kljajić, M.; Macura, D.; Munćan, V.; Mujan, I.; Tomić, M.; Vlaović, Ž.; Stepanov, B. Building Energy Performance Certificate—A Relevant Indicator of Actual Energy Consumption and Savings? Energies 2021, 14, 3455. [Google Scholar] [CrossRef]

- RenoZEB. RenoZEB in a Nutshell. Available online: https://renozeb.eu/about/renozeb-in-a-nutshell.html (accessed on 16 November 2020).

- Pracucci, A.; Magnani, S.; Vandi, L.; Casadei, O.; Uriarte, A.; Bueno, B.; Vavallo, M. An Analytical Approach for the Selection of Technologies to Be Integrated in a Plug&play Façade Unit: The RenoZEB Case Study. Proceedings 2021, 65, 29. [Google Scholar] [CrossRef]

| Tests and Simulations | Test Conducted | Mock-Up |

|---|---|---|

| Thermal Behavior (EN13788) 1 | ISO EN 9869: 2014 standard EN 15026:2007 2 | Design and Kubik |

| Heat bridges and condensation risks | Design and Kubik | |

| Acoustic improvement of existing envelope | UNI EN ISO 16283-3:2016/EC 1-2016/EC 2-2016 and UNI EN ISO 717-1:2013 | Acoustic Mock-Up (AMU) |

| Watertightness of joints (protection against driving rain (EN12865:2002) | EN ISO 13830:2005 Curtain Wall façade—CE for façade | Performance Mock-Up (PMU) |

| Wind load resistance (ETAG 034—ER4—Safety in use) | EN ISO 13830:2005 Curtain Wall façade—CE for façade | Performance Mock-Up (PMU) |

| Reaction to fire (EN 13501-1) (Test under EN 13823, classification SBI) | EN 13501-1—Indication about Reaction to fire classification | Fire Mock-Up (FMU) |

| Fire resistance (EN1364-3 and EN 1364-4) | Not applicable in ventilated façade | -- |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pracucci, A.; Vandi, L.; Magnani, S.; Baietta, A.; Casadei, O.; Uriarte, A.; Vavallo, M. Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study. Environ. Sci. Proc. 2021, 11, 9. https://doi.org/10.3390/environsciproc2021011009

Pracucci A, Vandi L, Magnani S, Baietta A, Casadei O, Uriarte A, Vavallo M. Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study. Environmental Sciences Proceedings. 2021; 11(1):9. https://doi.org/10.3390/environsciproc2021011009

Chicago/Turabian StylePracucci, Alessandro, Laura Vandi, Sara Magnani, Alessia Baietta, Oscar Casadei, Amaia Uriarte, and Michele Vavallo. 2021. "Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study" Environmental Sciences Proceedings 11, no. 1: 9. https://doi.org/10.3390/environsciproc2021011009

APA StylePracucci, A., Vandi, L., Magnani, S., Baietta, A., Casadei, O., Uriarte, A., & Vavallo, M. (2021). Prefabricated Plug-and-Play Unitized Façade System for Deep Retrofitting: The RenoZEB Case Study. Environmental Sciences Proceedings, 11(1), 9. https://doi.org/10.3390/environsciproc2021011009