1. Introduction

With the European Green Deal seeking to reduce energy consumption in order to reach net-zero emissions by 2050 [

1], the need to reduce consumption in all areas of the industrial sector has never been greater. Digital modelling and twinning are techniques which are becoming more widespread in the industrial sector. The objective of these models mainly relates to enhanced production planning and control (PPC), in addition to improved maintenance [

2]. At present, current literature shows the drive to reduce consumption and increase energy efficiency within manufacturing as a result of fostering other improvements such as increasing productivity and reducing costs [

3,

4,

5]. This research aims to primarily use a digital model to provide decision support with regards to energy consumption.

This paper details the initial work undertaken in developing a digital counterpart to the manufacturing process, with the goal of providing decision support with regards to energy consumption reduction. At present, it is estimated that the manufacturing process is digitalised to approximately 20% of the level required to support digital modelling. In order to create a digital model of this process, it is necessary to ensure the availability of more relevant and robust data. This study looks to identify and gather key performance data relating to a selected process and is centred on the development of a methodology to support this process.

2. Manufacturing Process

The selected manufacturing process consists of seven process steps from the beginning of production to when the produced unit is packaged and leaves the manufacturing facility.

These steps include:

Issue—A block of material is selected to undergo production;

Cut—This material is then cut into individual parts;

Machine—These parts are machined into the specified shape and size;

Clean line—Parts are sterilised and cleaned;

Label—Labels are printed and assigned to the parts;

Carton—Parts are packaged and sealed;

Ship—Parts leave the facility.

Each of the process steps were assessed based on the nature of the work involved. From this assessment, the process steps were categorised as either equipment intensive or rudimental. Equipment intensive steps were considered to rely on production equipment performance over the production operator’s contribution, which could result in significant energy use. In comparison, the work involved in rudimental process steps would not see much benefit in reduced energy consumption as this work majorly consisted of operator contribution. The energy intensive process steps were identified as steps 2, 3 and 4, (cut, machine and clean line), respectively. At the time of this study, it was found that only the clean line step (step 4) of the process had realtime energy logging sensors installed.

3. Methodology

3.1. HyDAPI

The HyDAPI methodology [

6] was adopted to assess the available data from the processes and to begin digitalisation. The methodology combines steps from improvement methodologies such as Lean Six Sigma with data mining modelling techniques, such as CRISP-DM, to effectively identify and apply digitalised process improvements, oriented towards a specified objective. In the case of this study, the objective was defined as the identification of process related data and assessing its availability.

In line with the ‘Define’ stage of the HyDAPI methodology, a project charter was created (

Section 3.2), providing an overview of the work. Following this, a data catalogue was collated (

Section 3.3) which consisted of identifying the relevant datapoint and assessing its level of digitalisation.

3.2. Project Charter

The project charter set the scope explored within the study and defined the successful outcome of the study, while also detailing the current and future state of the process, achievable benefits, potential risks and all of the involved stakeholders. The scope of the study was set at the predefined equipment intensive process steps. A successful outcome being the identification and understanding of the data that is currently readily available, the data that is not available and the means to make this data available.

Due to the varying natures of the work involved for each of the three process steps and the production equipment being utilised, the methodology would need to be applied to each step individually. The maximum energy rating of the selected assets showed that at installation, it was anticipated that the machining equipment (step 3) would require a higher power capacity than the cutting or clean line equipment (process steps 2 and 4, respectively). The power rating for the machining equipment was 85 kW, whereas for the cutting and cleanline equipment the ratings were 30 kW and 64 kW, respectively. Consequentially, the machining step was selected for initial assessment.

3.3. Data Catalogue

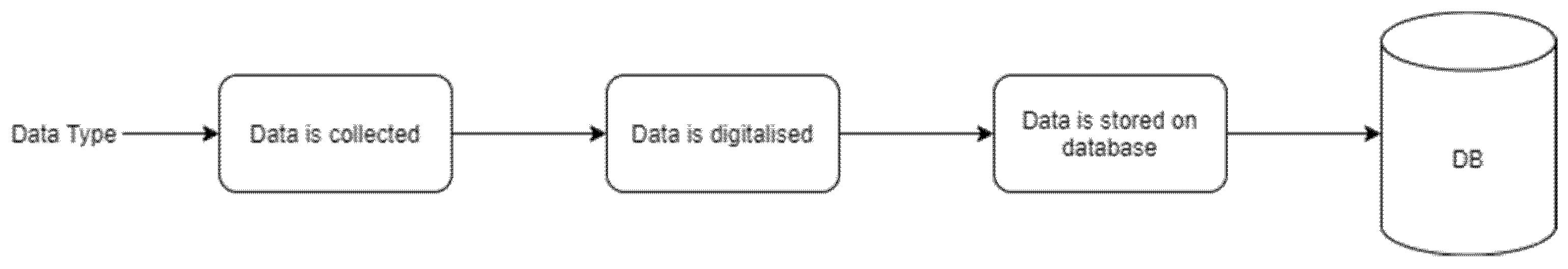

Understanding what data was available for the machining equipment was investigated in the data cataloguing stages (

Figure 1). When cataloguing the data, it was categorised into three types: energy, operational and maintenance. Any energy related data was identified as it would show the most relevance to the digital model. As previously mentioned, energy data was not commonly logged across the process, except for the clean line where energy data was collected every 15 min by the means of a wireless electricity monitor. Consequently, this meant that no energy data was available for the machining step.

Following this, the data being gathered during the machining step was examined, collected and categorized as either operational or maintenance. Operational datapoints, such as units produced, scrapped, process time etc., were all readily available as the production details are frequently updated on the operational software which feeds into a database. This data would be easily accessible in developing the digital model. Although maintenance data is available based on individual inspection, it was found that this data was not digitalised. With some data being unreliable and infrequent or available by manual assessment. This would not be sufficient for digital modelling without further digitalisation. Overall, it was found that only operational data was currently digitalized (

Table 1).

3.4. Energy Analysis

As no current energy data was available for the machining equipment, a temporary energy tracker was installed on the equipment over a 12 h production shift collecting energy data every 1 min. Over this shift, production operated as usual. Initial inspection of the energy data generated a cohesive energy profile from the production shift, which could be used in tandem with operational data from the same shift period.

Commonalities could be observed from the shape of the energy profile (

Figure 2). From analysis, three observations could be inferred.

The number of maximum peaks related to the number of units being produced during the shift, quantifying the energy consumption of the parts;

The time difference between the troughs of each of the two peaks denoted the amount of time taken to produce a part;

The time difference between the larger troughs of the two peaks denoted machine idling time, where it was left on standby without an operator present.

4. Conclusions

With the overlying goal of beginning a digital model of the process, the objective of applying this methodology was to uncover the level of digitalised data available. It was found that when considering the energy intensive machining step, and categorising the required data of the step into energy, the level of digitalisation varied for operational and maintenance data. Improvements in energy monitoring are required for this process step to develop the model, as no metering is currently installed. Operational data is readily available and adequately digitalised to contribute to the digital model. Maintenance data would not be included in its current state due to poor digitisation levels; however, using energy and operational data would result in a robust model. From the temporary energy tracker installed on the machining equipment, it was found that the production information could be validated from its energy profile, and this could feed into a knowledge-based model using the trends identified.

5. Future Work

Following the implementation of this methodology on the process, future work will involve integrating the model digitally. With digital models providing a static representation of the process, a digital shadow can view the digital representation updated in realtime with the physical equipment [

2]. Following this, a digital twin will see the digital model be fully synchronous with its physical counterpart and any changes on one will be instantly reflective on another [

2]. These proposed developments would see decision support being provided for issues at hand, potentially improving energy efficiency.