Effect of Battery Degradation on the Probabilistic Optimal Operation of Renewable-Based Microgrids

Abstract

:1. Introduction

- Meta-heuristic algorithms deal simultaneously with a set of feasible solutions; this allows different solutions to be found in the Pareto optimal front in just one execution of the algorithm. While in the mathematical programming approaches, a sequence of independent executions should be dealt with.

- Meta-heuristic algorithms are not sensitive to the continuity and formation of the Pareto front, which is one of the drawbacks of mathematical programming.

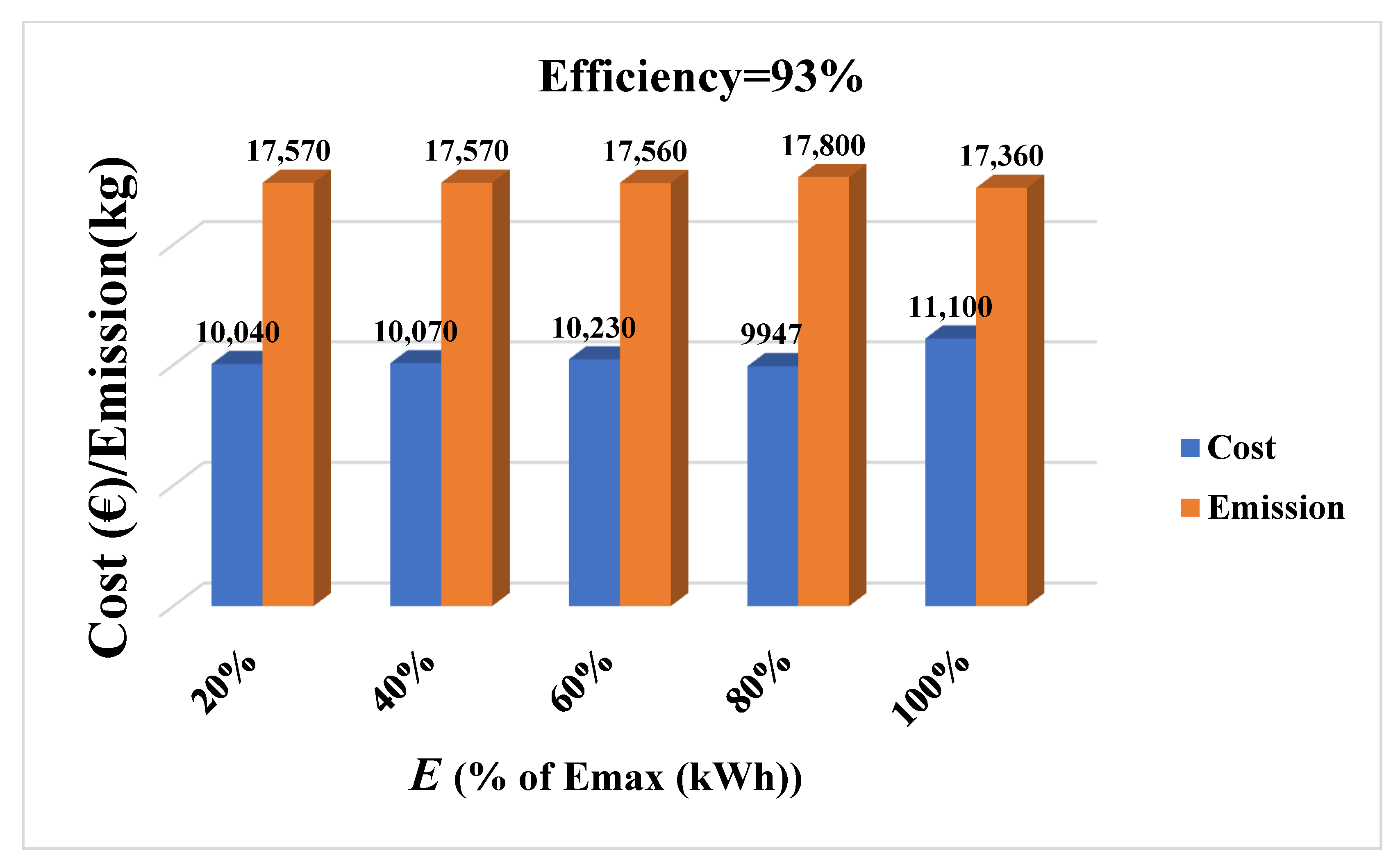

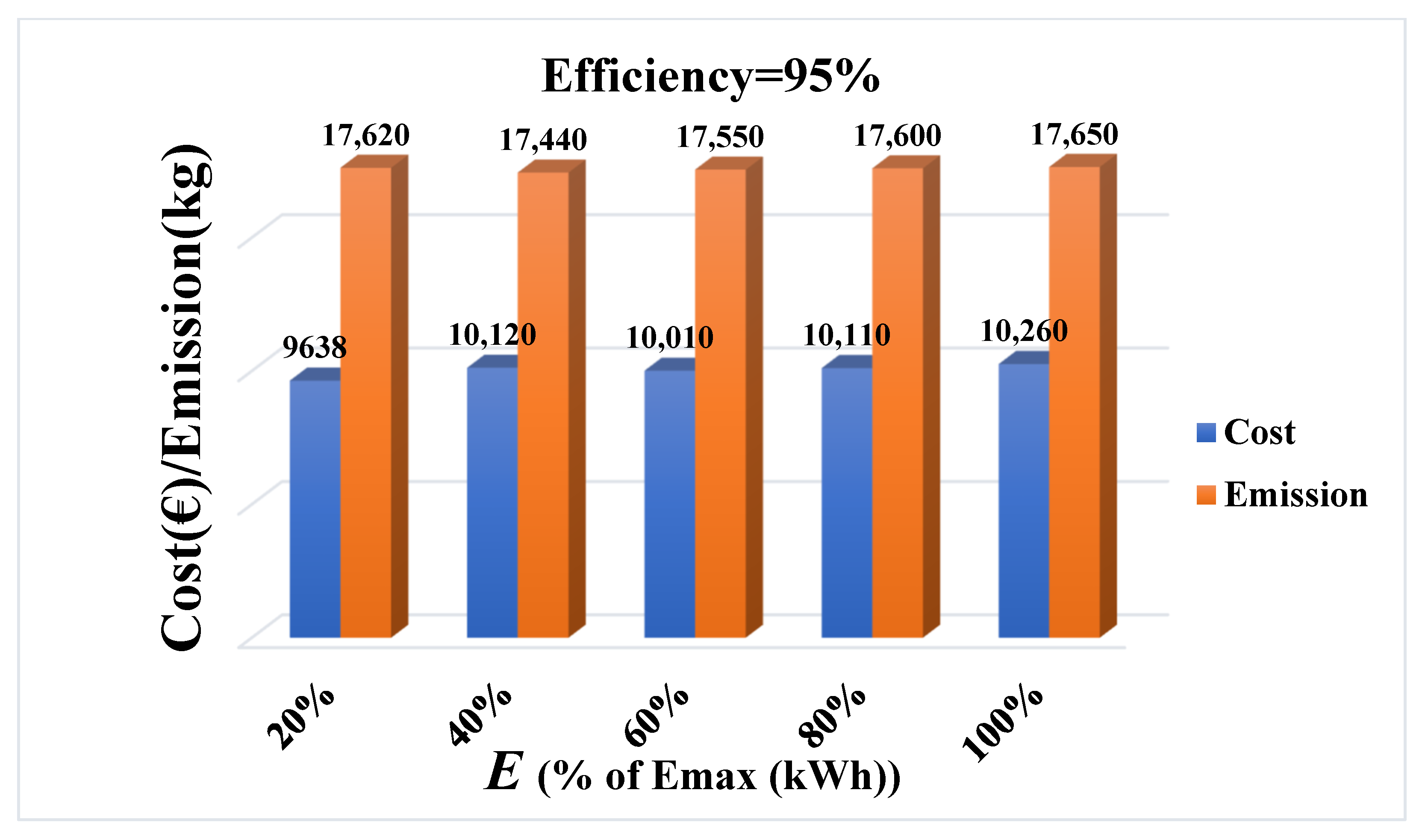

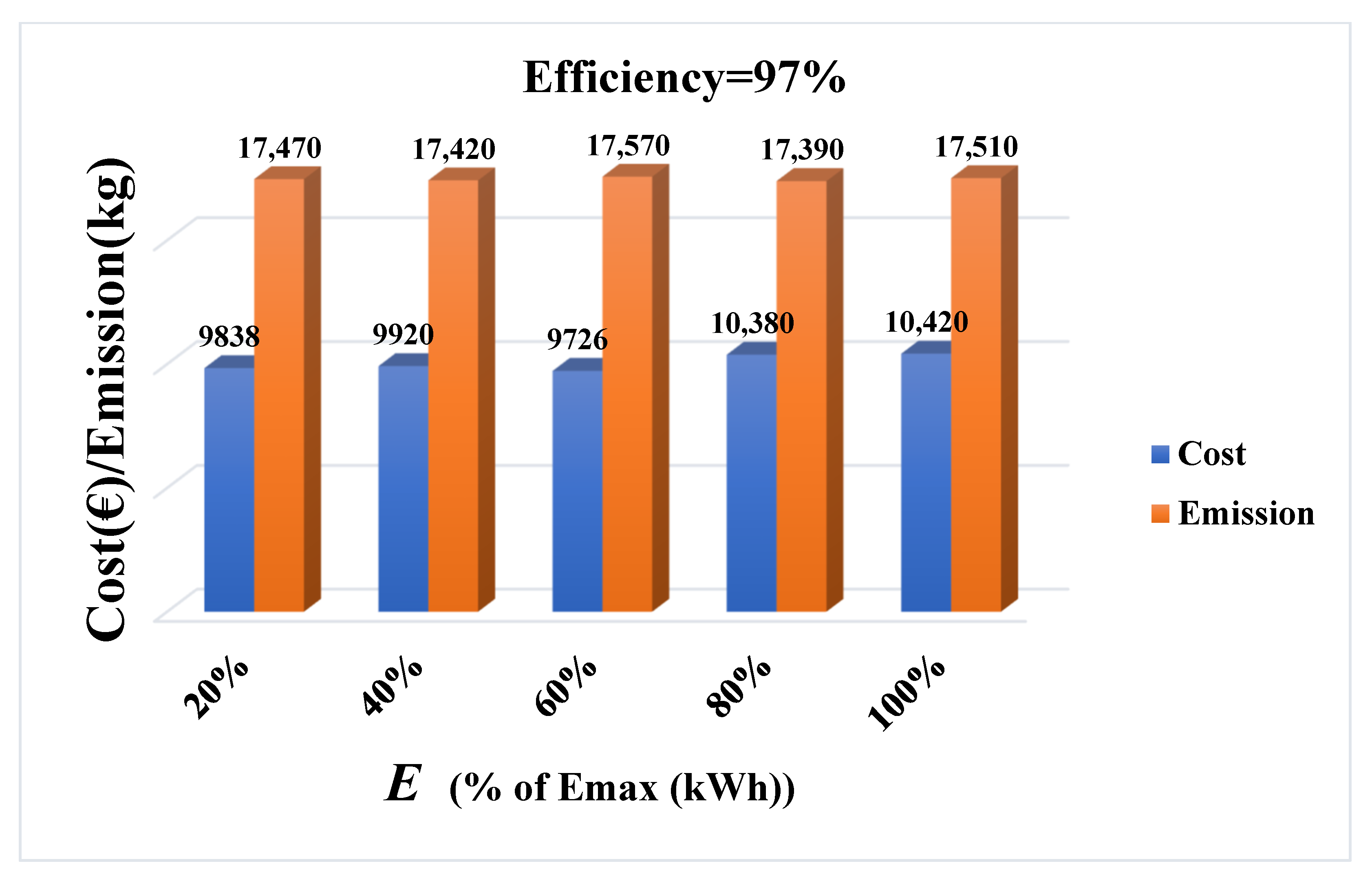

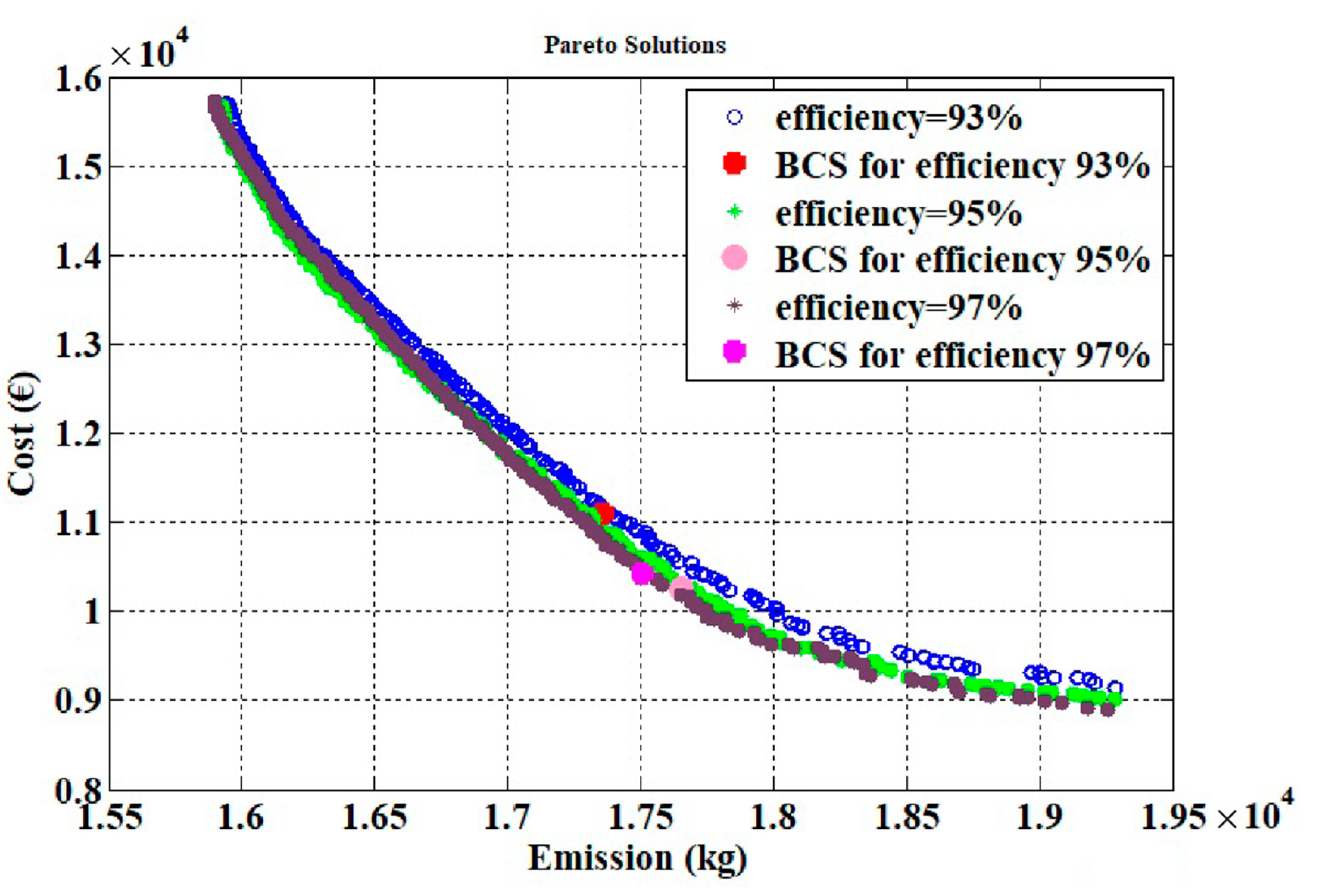

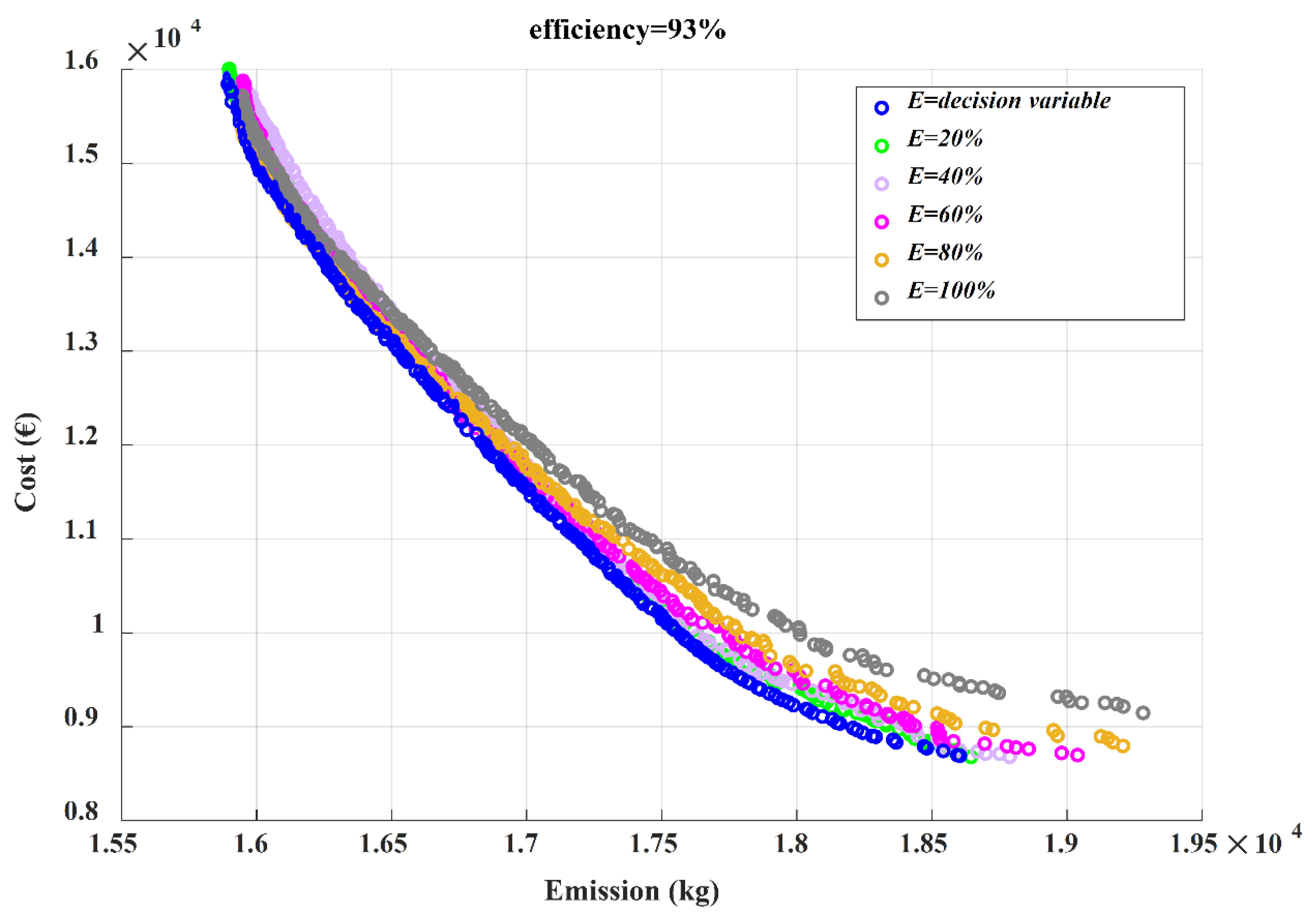

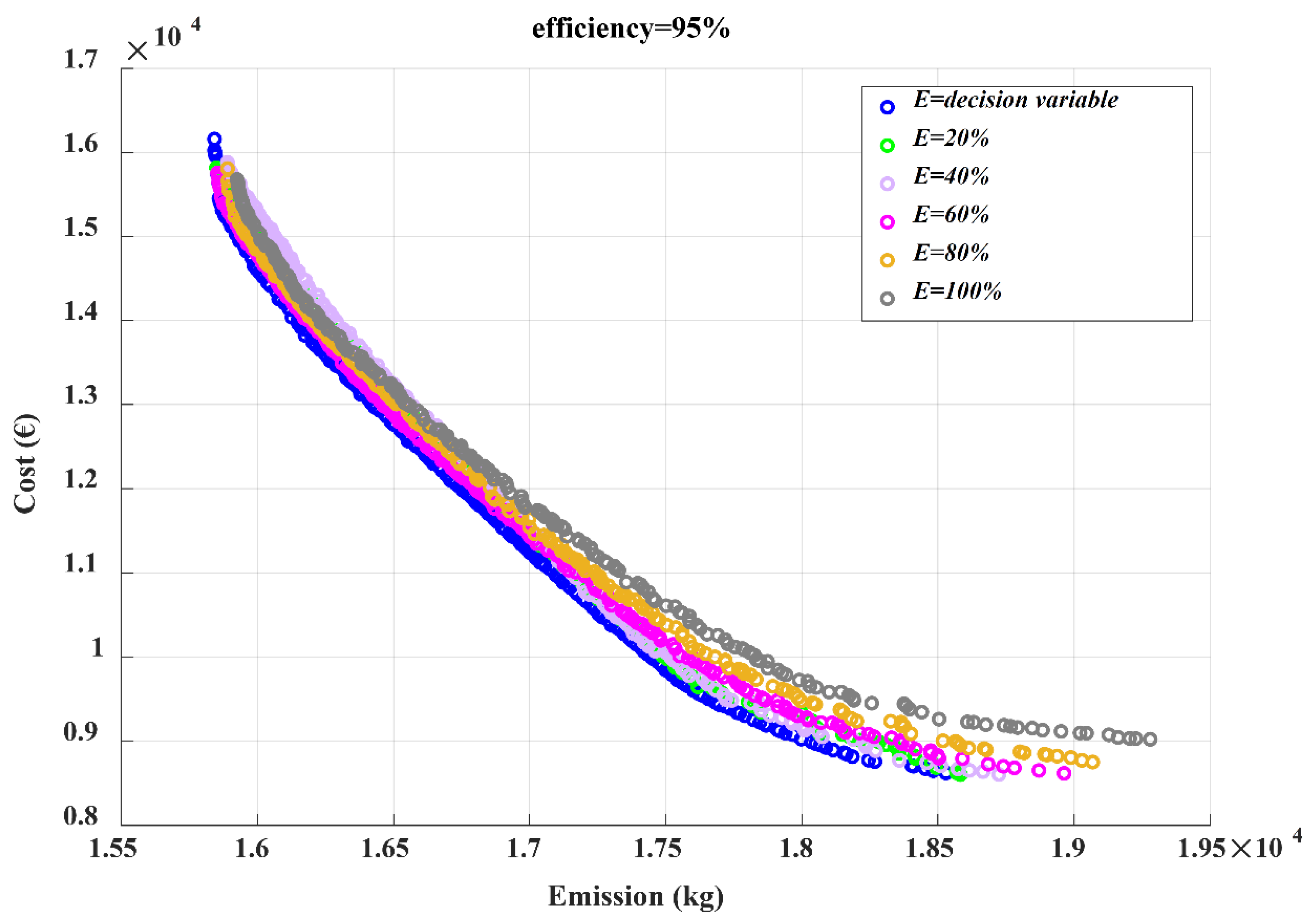

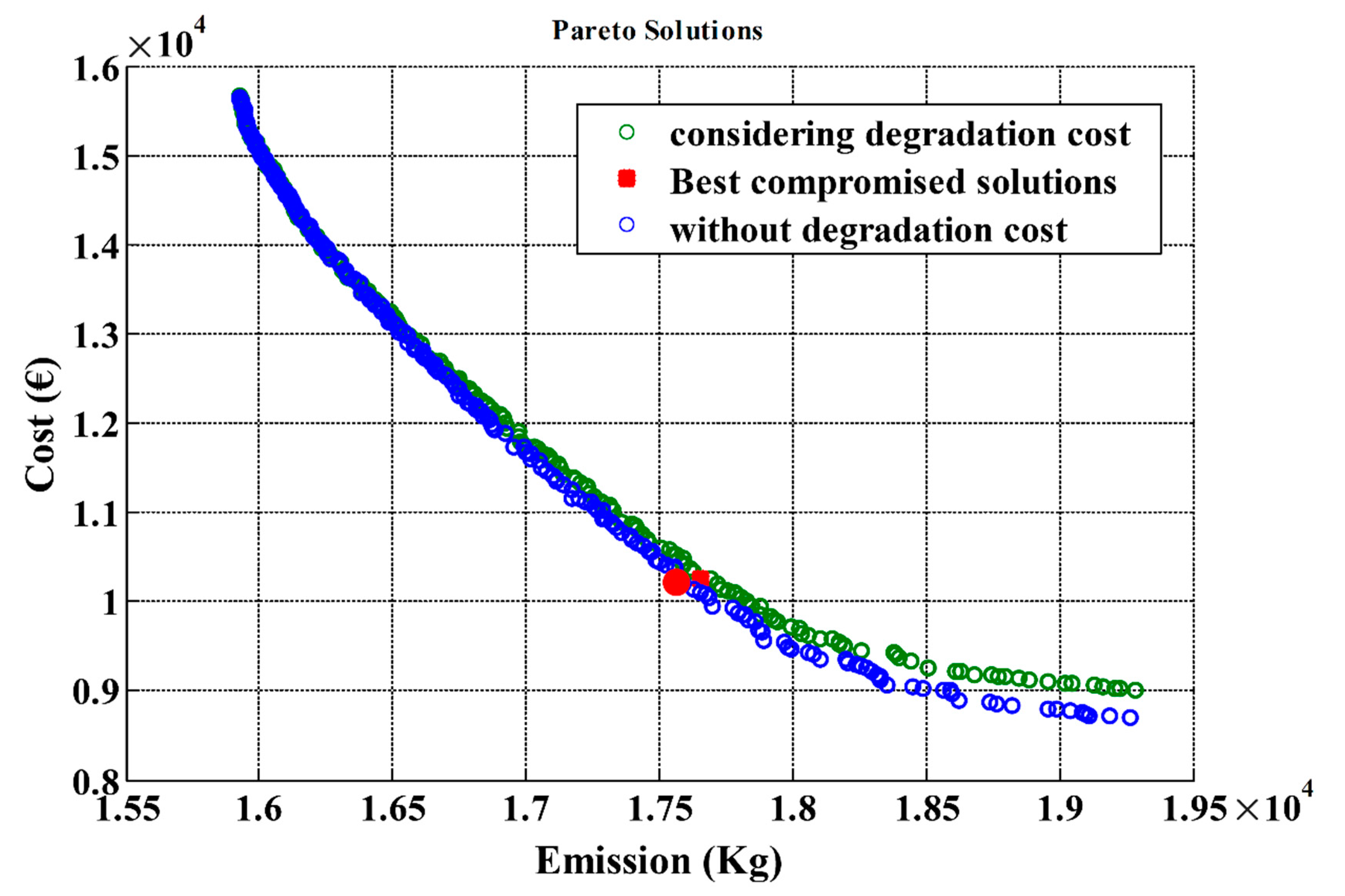

- The power constraints of the storage device (i.e., Li-ion battery in this study) as well as the degradation cost are considered in the MG’s MOOM problem. In order to consider different battery characteristics, including the battery efficiency, the battery’s initial charge, SOC, and different scenarios of the battery’s degradation cost are studied in the probabilistic MG’s MOOM problem.

- Modifications are added to the JAYA algorithm that make it more efficient in dealing with multi-objective problems. The efficiency of the suggested algorithm is examined by comparing its performance with some other well-known algorithms.

- The total cost of day-ahead market transactions and fuel costs, along with the emission of MG, are minimized through the introduced optimal scheduling approach. The suggested RUT-EMOJAYA reduces the MG’s dependency on the main grid and the electricity market, while maximizing the utilization of RESs in the studied region.

- The uncertainties related to the forecasted values of the load demand and market price, and the available outputs of RESs, as well as their correlations, are considered and dealt with efficiently using the suggested RUT-EMOJAYA.

2. Economic Model of Battery Storage Devices

3. Problem Formulation

3.1. Objective Functions

3.2. Constraints

3.2.1. Power Balance Constraint

3.2.2. Battery Limits

3.2.3. Real Power Constraints

4. Reduced Unscented Transformation (RUT)

5. Enhanced Multi-Objective JAYA Algorithm

5.1. A Brief Overview of the Original JAYA

5.2. Multi-Objective JAYA (MOJAYA)

| Algorithm 1. Pseudo code for controlling the size of repository. |

| 1: 2: for |

| 3: for |

| 4: distance = |

| 5: if distance < Epsilon |

| 6: |

| 7: end |

| 8: end |

| 9: end |

| 10: sort non-dominated solutions ascending according to |

| 11: save the first elements of the non-dominated solutions in the repository |

5.3. Enhanced MOJAYA (EMOJAYA)

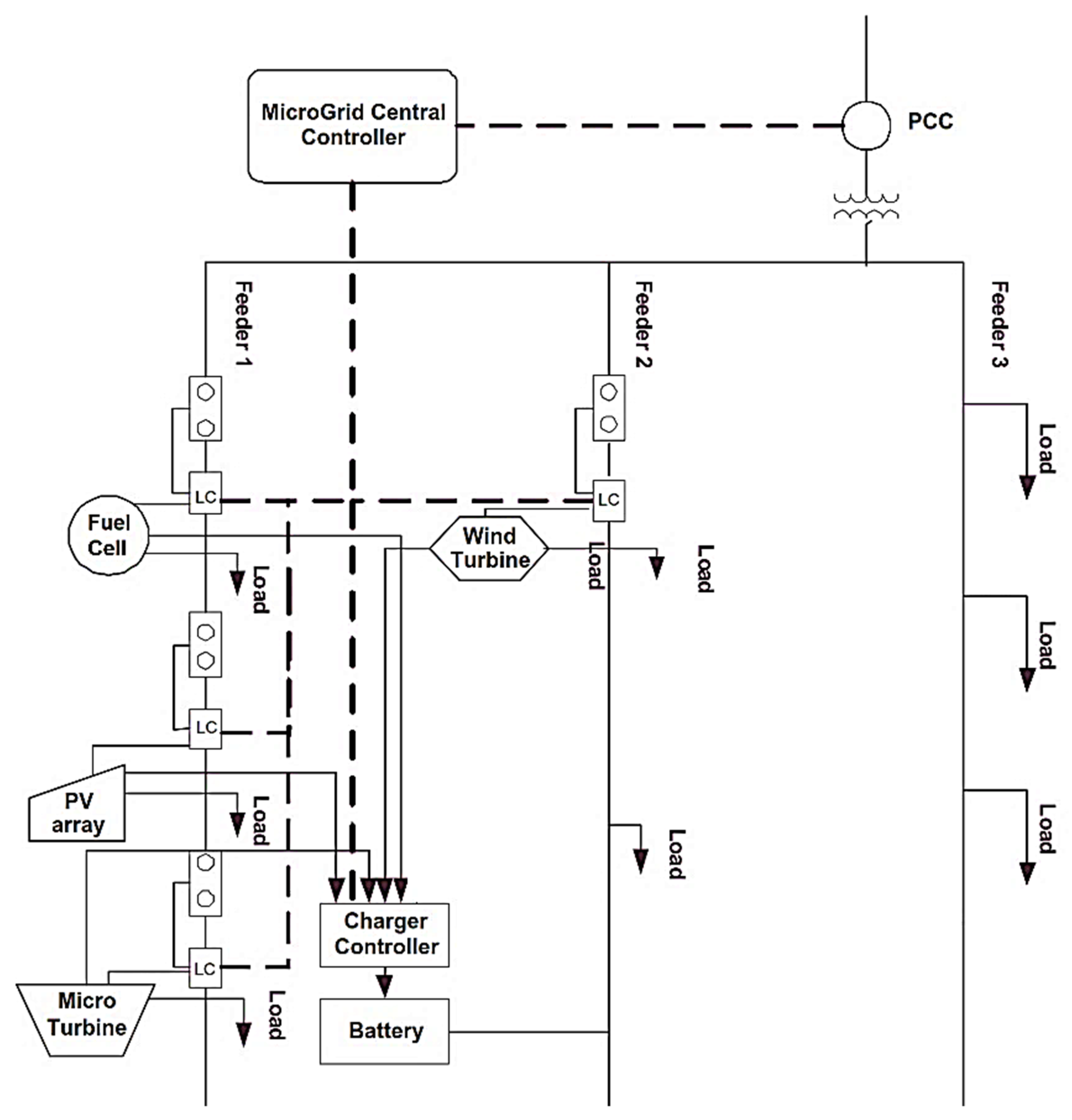

6. Application of the Suggested EMOJAYA Algorithm

7. Simulation Results

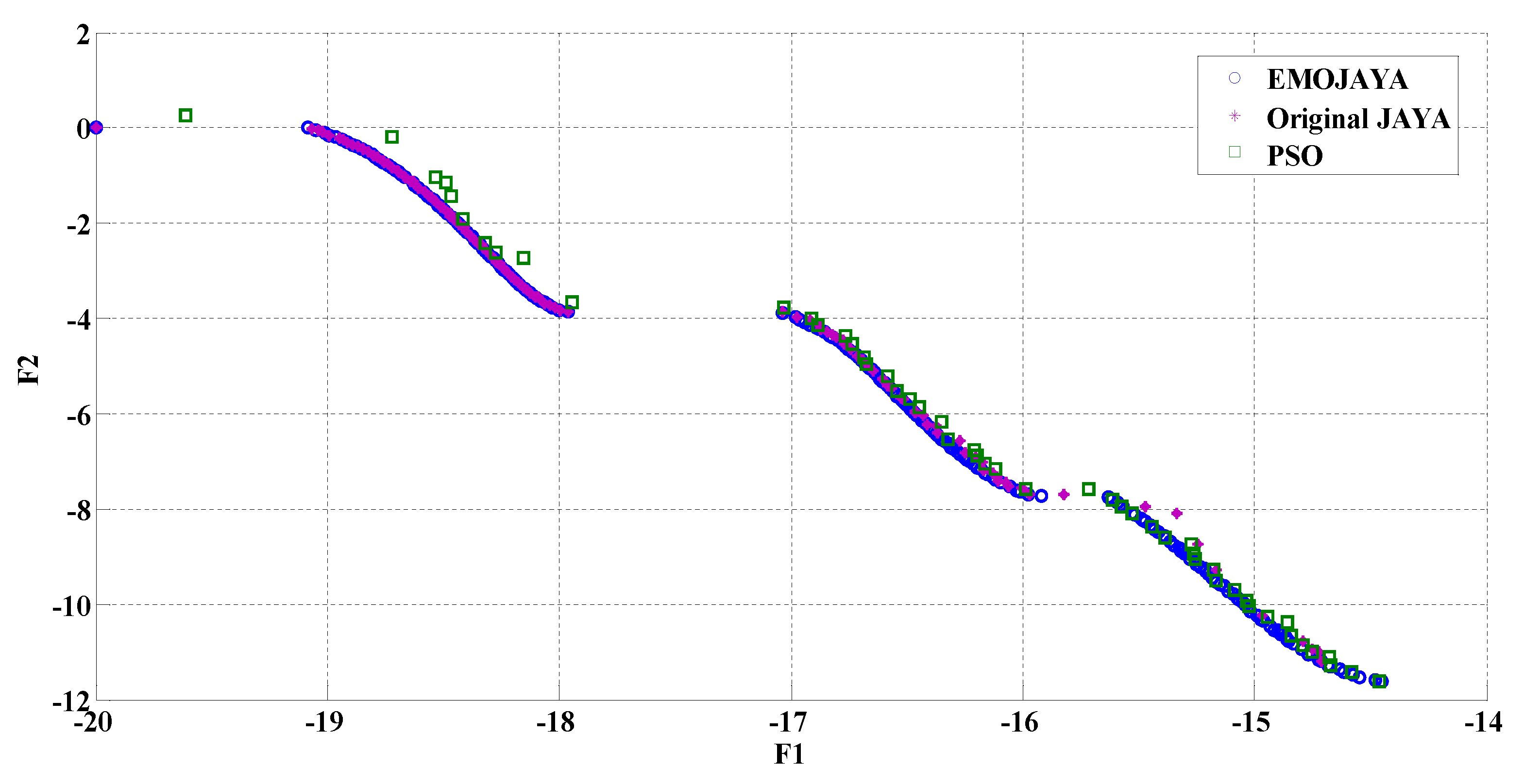

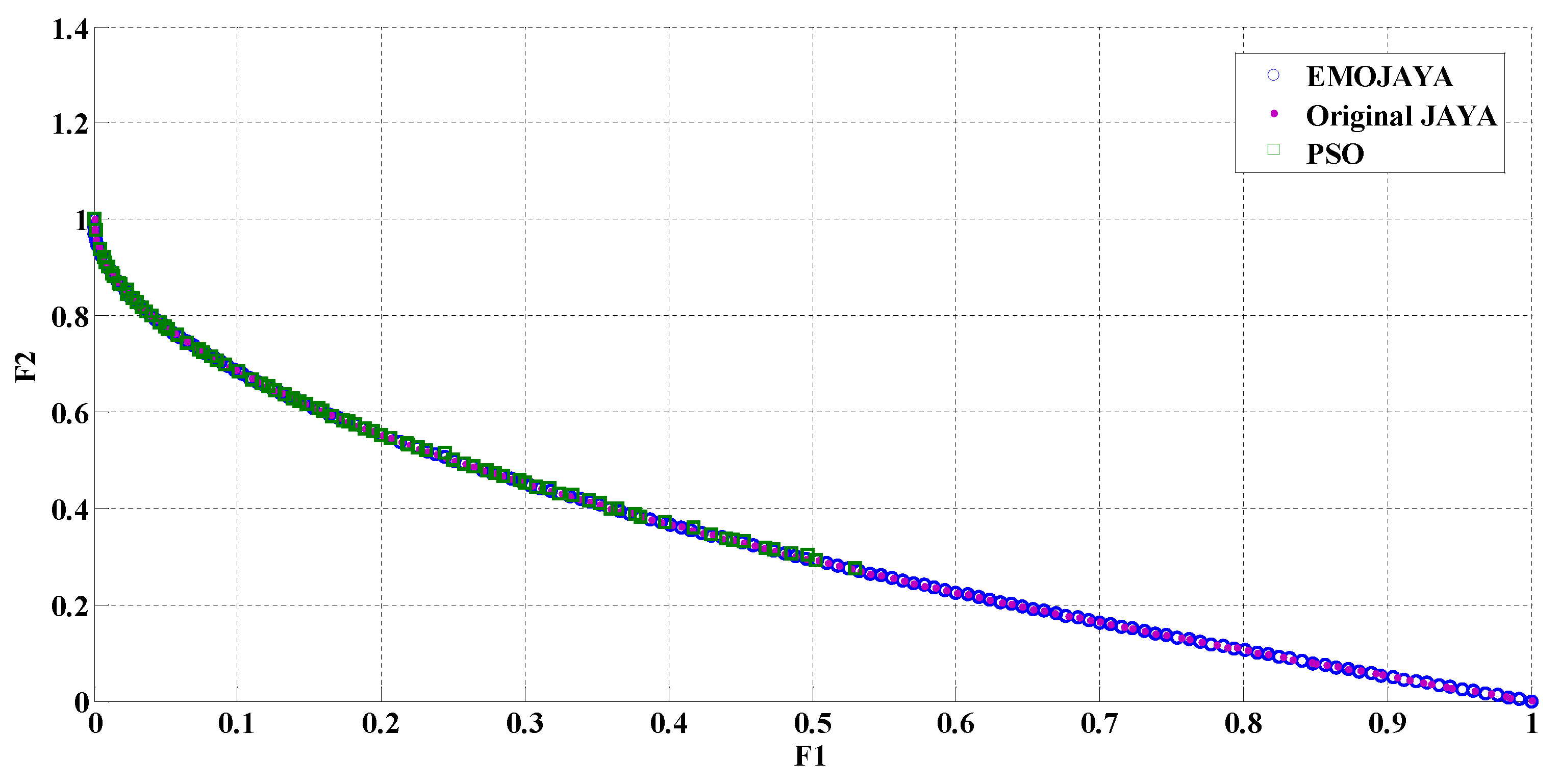

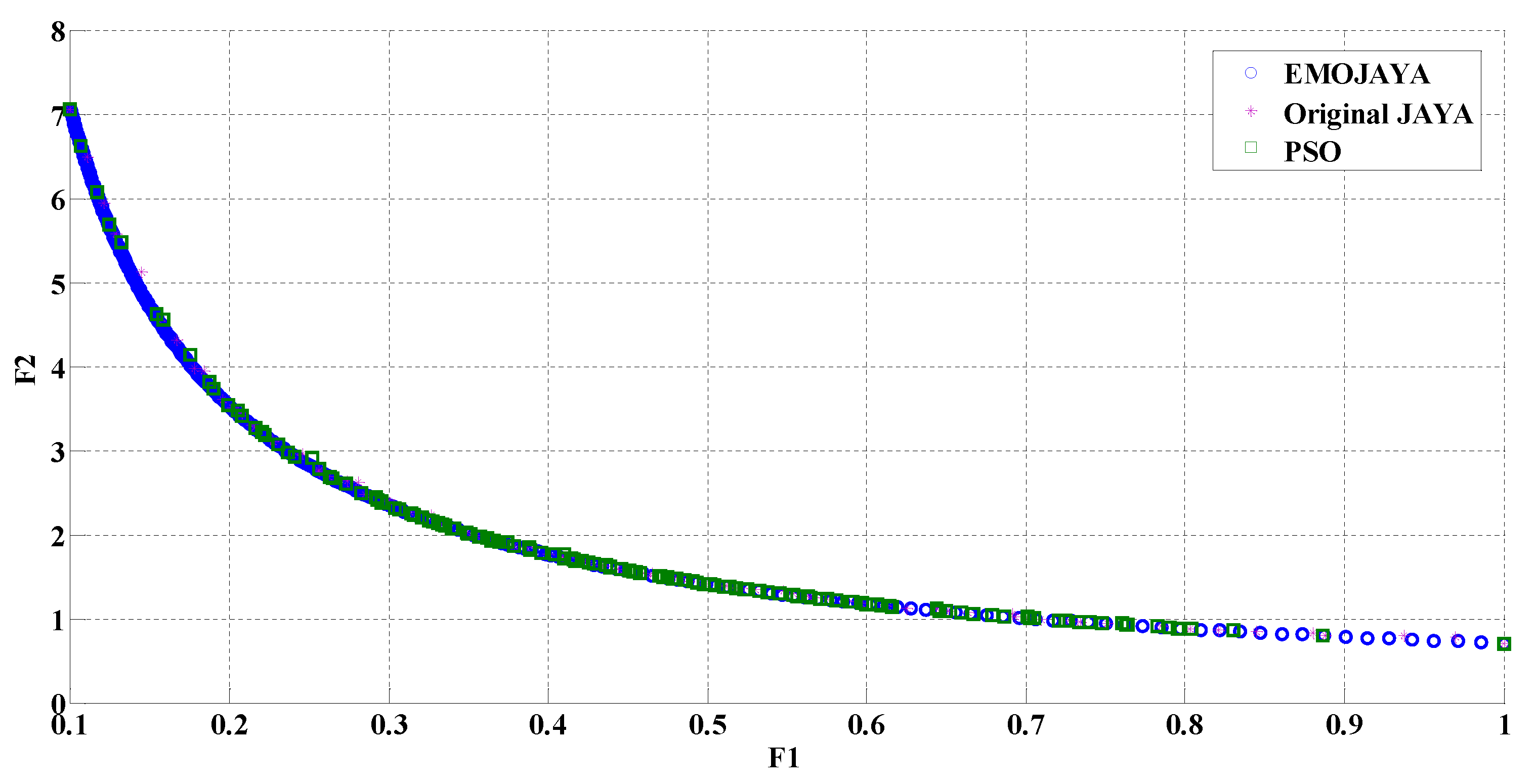

7.1. A Comparison between the Performance of Proposed EMOJAYA with Original JAYA and PSO Algorithms on Different Test Functions

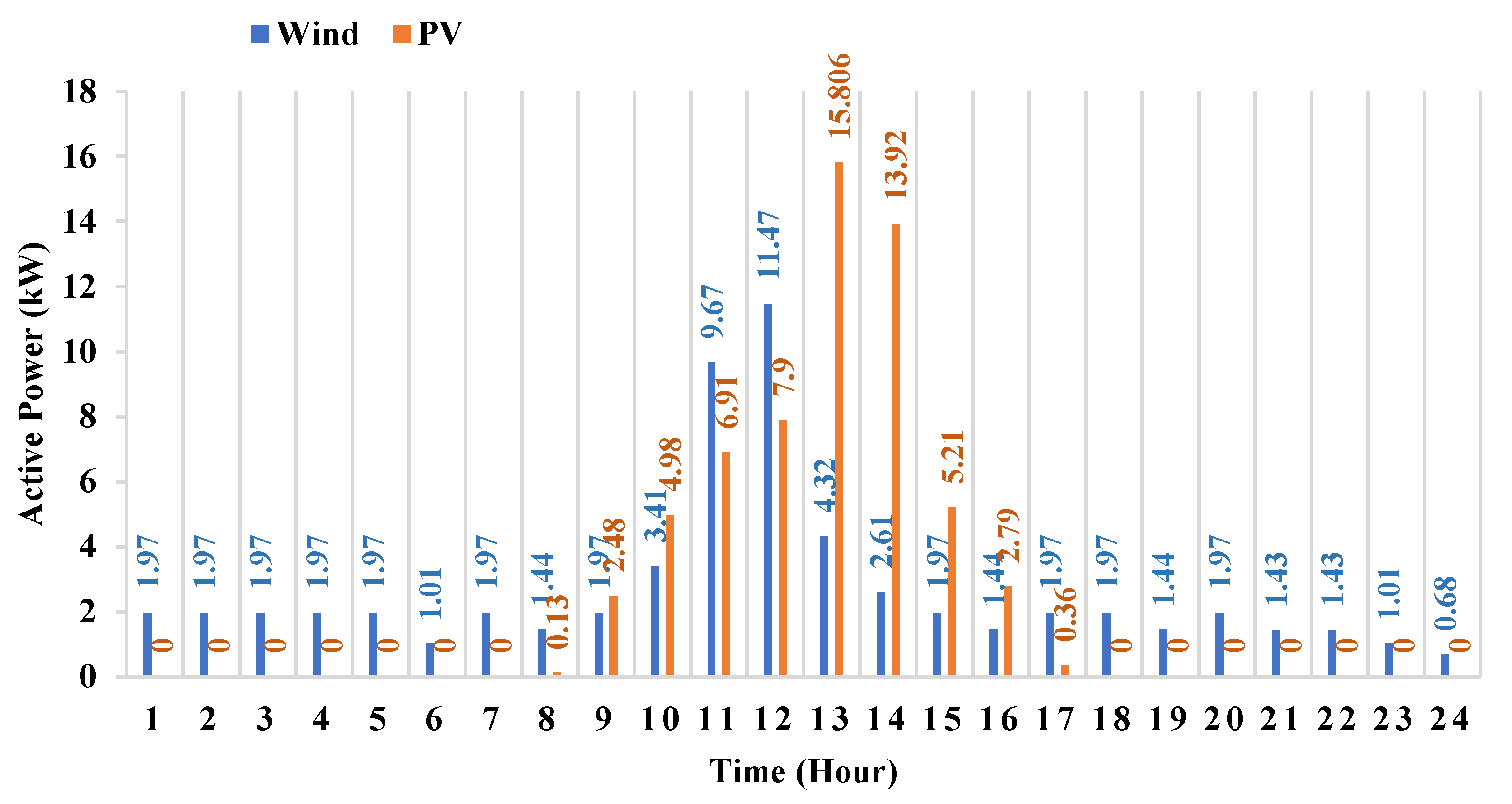

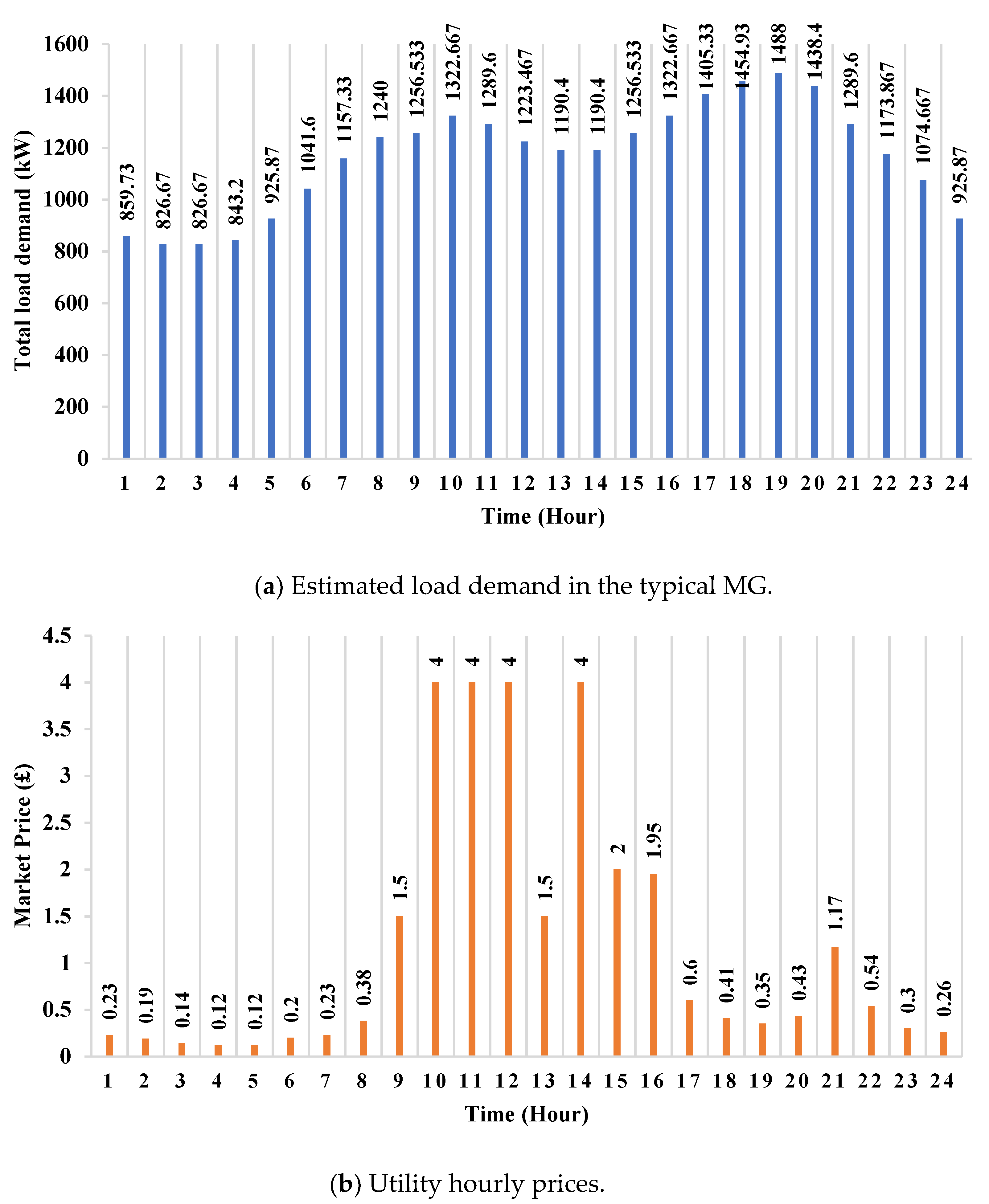

7.2. Solving the MG Energy Managemnet Problem

8. Conclusions

- i.

- Investigating elements of the future smart grids, including demand response and the influence of electric vehicles on the considered MG’s energy management problem.

- ii.

- Inspecting reliability as an objective function in the MG’s optimal operation management.

- iii.

- Comparing different energy storage devices, as well as a variety of battery technologies to decide on the most optimal economic design of the system.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| RES | renewable energy source |

| MG | microgrid |

| DER | distributed energy source |

| PSO | particle swarm optimization |

| ODED | optimal dynamic economic dispatch |

| WT | wind turbines |

| DG | distributed generator |

| MOOM | multi-objective optimal operation management |

| PCC | point of common coupling |

| LC | local controller |

| MGCC | micro grid central controller |

| EMOJAYA | enhanced multi-objective JAYA |

| RUT | reduced unscented transformation |

| SOC | state of charge |

| DoD | depth of discharge |

| FC | fuel cell |

| MT | micro-turbine |

| PV | photovoltaic |

| BCS | best-compromised solution |

| vector of decision variables | |

| N | number of decision variables |

| T | total number of hours |

| battery cycle life | |

| Qn | battery nominal capacity (kWh) |

| Q(t) | battery current capacity (kWh) |

| battery degradation cost (EUR) at hour t | |

| CBatt | battery investment cost (EUR/kWh) |

| NDG | total number of dispatchable generations |

| NBatt | total number of batteries |

| NRES | total number of RESs |

| Nd | total number of load levels |

| Costt | MG’s operation cost in hour t (EUR) |

| real output powers (kWh) of rth RES at hour t | |

| real output powers (kWh) of ith DG at hour t | |

| real output powers of sth storage at hour t | |

| active power bought (sold) from (to) the utility at hour t | |

| bids of RESs at hour t (EUR/kWh) | |

| bids of dispatchable DGs at hour t (EUR/kWh) | |

| bids of battery at hour t (EUR/kWh) | |

| bids of the utility grid at hour t (EUR/kWh) | |

| start-up cost for ith dispatchable DG | |

| shut down cost for ith dispatchable DG | |

| operational cost of dispatchable DGs | |

| operational cost of RESs | |

| operational cost of battery | |

| cost of power exchange between the MG and the utility grid (EUR) | |

| PLD | amount of dth load level |

| amount of pollutants emission for each generator at hour t (kg/MWh) | |

| amount of pollutants emission for storage device at hour t (kg/MWh) | |

| amount of pollutants emission for the utility grid at hour t (kg/MWh) | |

| amounts of energy stored inside the battery at hour t | |

| Pch (Pdisch) | permitted rate of charge (discharge) of the battery |

| ηc (ηd) | efficiency of the battery during charge (discharge) process |

| lower limit of amounts of energy storage inside the battery | |

| upper limit of amounts of energy storage inside the battery | |

| maximum rate of battery charge (discharge) during each time interval ∆t | |

| minimum active power of the ith DG | |

| maximum active power of the ith DG | |

| minimum active power of the bth storage | |

| maximum active power of the bth storage | |

| minimum active power of the utility at hour t. | |

| maximum active power of the utility at hour t. | |

| load demand |

References

- Ali, S.; Zheng, Z.; Aillerie, M.; Sawicki, J.P.; Péra, M.C.; Hissel, D. A Review of DC Microgrid Energy Management Systems Dedicated to Residential Applications. Energies 2021, 14, 4308. [Google Scholar] [CrossRef]

- Javidsharifi, M.; Pourroshanfekr, H.; Kerekes, T.; Sera, D.; Spataru, S.; Guerrero, J.M. Optimum Sizing of Photovoltaic and Energy Storage Systems for Powering Green Base Stations in Cellular Networks. Energies 2021, 14, 1895. [Google Scholar] [CrossRef]

- Linden, D.; Reddy, T. Handbook of Batteries, 3rd ed.; McGraw-Hill Professional: New York, NY, USA, 2001. [Google Scholar]

- González, A.; Goikolea, E.; Barrena, J.A.; Mysyk, R. Review on Supercapacitors: Technologies and Materials. Renew. Sustain. Energy Rev. 2016, 58, 1189–1206. [Google Scholar] [CrossRef]

- Javidsharifi, M.; Niknam, T.; Aghaei, J.; Mokryani, G. Multi-objective short-term scheduling of a renewable-based microgrid in the presence of tidal resources and storage devices. Appl. Energy 2018, 216, 367–381. [Google Scholar] [CrossRef] [Green Version]

- Rezvani, A.; Gandomkar, M.; Izadbakhsh, M.; Ahmadi, A. Environmental/economic scheduling of a micro-grid with renewable energy resources. J. Clean. Prod. 2015, 87, 216–226. [Google Scholar] [CrossRef]

- Modiri-Delshad, M.; Kaboli, S.H.A.; Taslimi-Renani, E.; Abd Rahim, N. Backtracking search algorithm for solving economic dispatch problems with valve-point effects and multiple fuel options. Energy 2016, 116, 637–649. [Google Scholar] [CrossRef]

- Hemmati, R.; Saboori, H.; Jirdehi, M.A. Stochastic planning and scheduling of energy storage systems for congestion management in electric power systems including renewable energy resources. Energy 2017, 133, 380–387. [Google Scholar] [CrossRef]

- Soares, J.; Silva, M.; Sousa, T.; Vale, Z.; Morais, H. Distributed energy resource short-term scheduling using Signaled Particle Swarm Optimization. Energy 2012, 42, 466–476. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Wu, Y.; Guo, Y.; Wang, B.; Wang, H.; Liu, H. A hybrid harmony search algorithm with differential evolution for day-ahead scheduling problem of a microgrid with consideration of power flow constraints. Appl. Energy 2016, 183, 791–804. [Google Scholar] [CrossRef]

- Gupta, R.A.; Gupta, N.K. A robust optimization based approach for microgrid operation in deregulated environment. Energy Convers. Manag. 2015, 93, 121–131. [Google Scholar] [CrossRef]

- Elsied, M.; Oukaour, A.; Gualous, H.; Brutto, O.A.L. Optimal economic and environment operation of micro-grid power systems. Energy Convers. Manag. 2016, 122, 182–194. [Google Scholar] [CrossRef]

- Elsied, M.; Oukaour, A.; Youssef, T.; Gualous, H.; Mohammed, O. An advanced real time energy management system for microgrids. Energy 2016, 114, 742–752. [Google Scholar] [CrossRef]

- Aghajani, G.R.; Shayanfar, H.A.; Shayeghi, H. Demand side management in a smart micro-grid in the presence of renewable generation and demand response. Energy 2017, 126, 622–637. [Google Scholar] [CrossRef]

- Marzband, M.; Azarinejadian, F.; Savaghebi, M.; Guerrero, J.M. An optimal energy management system for islanded microgrids based on multiperiod artificial bee colony combined with Markov chain. IEEE Syst. J. 2015, 11, 1712–1722. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Bhattacharjee, S.; Bhattacharya, A. Grey wolf optimisation for optimal sizing of battery energy storage device to minimise operation cost of microgrid. IET Gener. Transm. Distrib. 2016, 10, 625–637. [Google Scholar] [CrossRef]

- Marzband, M.; Ghadimi, M.; Sumper, A.; Domínguez-García, J.L. Experimental validation of a real-time energy management system using multi-period gravitational search algorithm for microgrids in islanded mode. Appl. Energy 2014, 128, 164–174. [Google Scholar] [CrossRef] [Green Version]

- Soares, J.; Ghazvini, M.A.F.; Vale, Z.; de Moura Oliveira, P.B. A multi-objective model for the day-ahead energy resource scheduling of a smart grid with high penetration of sensitive loads. Appl. Energy 2016, 162, 1074–1088. [Google Scholar] [CrossRef]

- Sachs, J.; Sawodny, O. Multi-objective three stage design optimization for island microgrids. Appl. Energy 2016, 165, 789–800. [Google Scholar] [CrossRef]

- Jin, X.; Mu, Y.; Jia, H.; Wu, J.; Jiang, T.; Yu, X. Dynamic economic dispatch of a hybrid energy microgrid considering building based virtual energy storage system. Appl. Energy 2017, 194, 386–398. [Google Scholar] [CrossRef]

- Liao, G.C. A novel evolutionary algorithm for dynamic economic dispatch with energy saving and emission reduction in power system integrated wind power. Energy 2011, 36, 1018–1029. [Google Scholar] [CrossRef]

- Guo, C.X.; Zhan, J.P.; Wu, Q.H. Dynamic economic emission dispatch based on group search optimizer with multiple producers. Electr. Power Syst. Res. 2012, 86, 8–16. [Google Scholar] [CrossRef]

- Azizipanah-Abarghooee, R.; Niknam, T.; Zare, M.; Gharibzadeh, M. Multi-objective short-term scheduling of thermoelectric power systems using a novel multi-objective θ-improved cuckoo optimisation algorithm. IET Gener. Transm. Distrib. 2014, 8, 873–894. [Google Scholar] [CrossRef]

- Sarshar, J.; Moosapour, S.S.; Joorabian, M. Multi-objective energy management of a micro-grid considering uncertainty in wind power forecasting. Energy 2017, 139, 680–693. [Google Scholar] [CrossRef]

- Javidsharifi, M.; Niknam, T.; Aghaei, J.; Mokryani, G.; Papadopoulos, P. Multi-objective day-ahead scheduling of microgrids using modified grey wolf optimizer algorithm. J. Intell. Fuzzy Syst. 2019, 36, 2857–2870. [Google Scholar] [CrossRef] [Green Version]

- Sharma, S.; Bhattacharjee, S.; Bhattacharya, A. Probabilistic operation cost minimization of Micro-Grid. Energy 2018, 148, 1116–1139. [Google Scholar] [CrossRef]

- Hossain, M.A.; Pota, H.R.; Squartini, S.; Abdou, A.F. Modified PSO algorithm for real-time energy management in grid-connected microgrids. Renew. Energy 2019, 136, 746–757. [Google Scholar] [CrossRef]

- Rao, R. Jaya: A simple and new optimization algorithm for solving constrained and unconstrained optimization problems. Int. J. Ind. Eng. Comput. 2016, 7, 19–34. [Google Scholar] [CrossRef]

- Javidsharifi, M.; Niknam, T.; Aghaei, J.; Shafie-khah, M.; Catalão, J.P. Probabilistic Model for Microgrids Optimal Energy Management Considering AC Network Constraints. IEEE Syst. J. 2019, 14, 2703–2712. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, F.A.; Koivo, H.N. Multiobjective optimization using Mesh Adaptive Direct Search for power dispatch problem of microgrid. Int. J. Electr. Power Energy Syst. 2012, 42, 728–735. [Google Scholar] [CrossRef]

- Zhou, C.; Qian, K.; Allan, M.; Zhou, W. Modeling of the cost of EV battery wear due to V2G application in power systems. IEEE Trans. Energy Convers. 2011, 26, 1041–1050. [Google Scholar] [CrossRef]

- Dallinger, D. Plug-in Electric Vehicles Integrating Fluctuating Renewable Electricity; Kassel University Press GmbH: Kassel, Germany, 2013; Volume 20. [Google Scholar]

- Chang, W.Y. The state of charge estimating methods for battery: A review. ISRN Appl. Math. 2013, 2013, 953792. [Google Scholar] [CrossRef]

- Deihimi, A.; Zahed, B.K.; Iravani, R. An interactive operation management of a micro-grid with multiple distributed generations using multi-objective uniform water cycle algorithm. Energy 2016, 106, 482–509. [Google Scholar] [CrossRef]

- Gazijahani, F.S.; Hosseinzadeh, H.; Tagizadeghan, N.; Salehi, J. A new point estimate method for stochastic optimal operation of smart distribution systems considering demand response programs. In Proceedings of the 2017 Conference on Electrical Power Distribution Networks Conference (EPDC), Semnan, Iran, 19–20 April 2017; IEEE: New York, NY, USA, 2017; pp. 39–44. [Google Scholar] [CrossRef]

- Rajasomashekar, S.; Aravindhababu, P. Biogeography based optimization technique for best compromised solution of economic emission dispatch. Swarm Evol. Comput. 2012, 7, 47–57. [Google Scholar] [CrossRef]

- Coello, C.C.; Dehuri, S.; Ghosh, S. (Eds.) Swarm Intelligence for Multi-Objective Problems in Data Mining; Springer: Berlin/Heidelberg, Germany, 2009; Volume 242. [Google Scholar]

- Fieldsend, J.E.; Singh, S. A Multi-Objective Algorithm Based upon Particle Swarm Optimisation, an Efficient Data Structure and Turbulence. 2002. Available online: http://hdl.handle.net/10871/11690 (accessed on 9 October 2019).

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Niknam, T.; Golestaneh, F.; Malekpour, A. Probabilistic energy and operation management of a microgrid containing wind/photovoltaic/fuel cell generation and energy storage devices based on point estimate method and self-adaptive gravitational search algorithm. Energy 2012, 43, 427–437. [Google Scholar] [CrossRef]

- Moghaddam, A.A.; Seifi, A.; Niknam, T.; Pahlavani MR, A. Multi-objective operation management of a renewable MG (micro-grid) with back-up micro-turbine/fuel cell/battery hybrid power source. Energy 2011, 36, 6490–6507. [Google Scholar] [CrossRef]

| Type | Min Power (kW) | Max Power (kW) | Bid (EUR /kWh) | Startup/ Shut Down Cost (EUR) | CO2 (kg/MWh) | SO2 (kg/MWh) | NOx (kg/MWh) |

|---|---|---|---|---|---|---|---|

| MT | 40 | 400 | 0.457 | 0.96 | 720 | 0.0036 | 0.1 |

| FC | 40 | 400 | 0.294 | 1.65 | 460 | 0.003 | 0.007 |

| PV | 0 | 300 | 2.584 | 0 | 0 | 0 | 0 |

| WT | 0 | 300 | 1.073 | 0 | 0 | 0 | 0 |

| Battery | 0 | 300 | 0.38 | 0 | 10 | 0.0002 | 0.001 |

| Utility | 0 | 1500 | - | - | 0.921 | 0.0036 | 0.0023 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Javidsharifi, M.; Pourroshanfekr Arabani, H.; Kerekes, T.; Sera, D.; Spataru, S.; Guerrero, J.M. Effect of Battery Degradation on the Probabilistic Optimal Operation of Renewable-Based Microgrids. Electricity 2022, 3, 53-74. https://doi.org/10.3390/electricity3010005

Javidsharifi M, Pourroshanfekr Arabani H, Kerekes T, Sera D, Spataru S, Guerrero JM. Effect of Battery Degradation on the Probabilistic Optimal Operation of Renewable-Based Microgrids. Electricity. 2022; 3(1):53-74. https://doi.org/10.3390/electricity3010005

Chicago/Turabian StyleJavidsharifi, Mahshid, Hamoun Pourroshanfekr Arabani, Tamas Kerekes, Dezso Sera, Sergiu Spataru, and Josep M. Guerrero. 2022. "Effect of Battery Degradation on the Probabilistic Optimal Operation of Renewable-Based Microgrids" Electricity 3, no. 1: 53-74. https://doi.org/10.3390/electricity3010005

APA StyleJavidsharifi, M., Pourroshanfekr Arabani, H., Kerekes, T., Sera, D., Spataru, S., & Guerrero, J. M. (2022). Effect of Battery Degradation on the Probabilistic Optimal Operation of Renewable-Based Microgrids. Electricity, 3(1), 53-74. https://doi.org/10.3390/electricity3010005