Published: 11 November 2020

1. Introduction

In the last decade, nanocomposite materials based on such transparent matrices as TiO

2, ZnO, and Al-doped ZnO with noble nanoparticles (NPs) have become particularly attractive in the emerging fields of photonics [

1], catalysis [

2,

3], and security applications [

4]. These materials have unique spectral characteristics because of the surface plasmon resonance that influences them.

A number of applications require a local change in optical properties, and for this purpose, laser irradiation is a good candidate. A laser beam forms a local heat source on the surface of the material, which can be used to carry out local annealing to achieve desired optical properties. However, the effect of laser irradiation parameters on the annealing result is still not fully understood.

In this work, we study the process of local annealing by CW UV laser irradiation of thin Ag-TiO2 films. The square fields of interest were obtained by a constant speed line-by-line scanning and different laser intensities for each one. The change in the spectral characteristics depending on the regimes of laser processing was analyzed, and the structures of the modified areas investigated. A model describing a heat source formed by the laser beam is proposed, and estimates of the values of temperatures and duration of annealing depending on the regimes of laser irradiation are given.

2. Materials and Methods

The mesoporous amorphous titania films used in this study were produced with titanium tetraisopropoxide by the sol–gel technique as previously described in [

5]. The thickness of the film deposited on a glass substrate was 180 ± 10 nm. Silver ions are introduced within the mesopority by soaking in an aqueous ammoniacal silver nitrate solution (5 M) for 90 min with prior thermal treatment of the sample. After rinsing and drying, the sample is exposed to UV light for 10 min to initiate a growth of a high density of Ag NPs which leads to the optical absorption of the strurture in range from 400 to 480 nm.

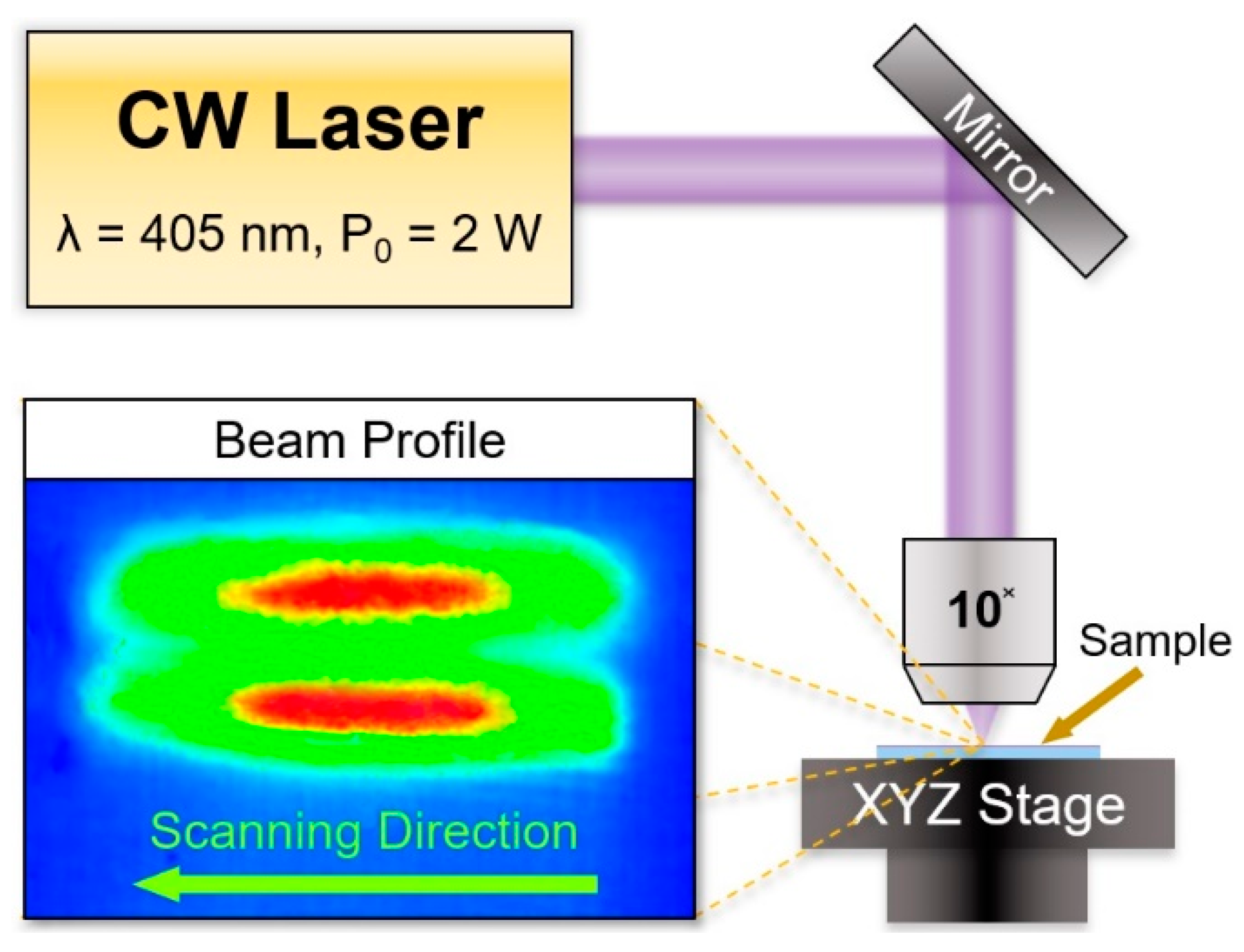

A CW UV semiconductor laser with a wavelength at 405 nm was used for laser annealing of Ag-TiO

2 samples. Double-mode irradiation of the laser was focused with the optical system to reach two elliptical spots in the beam with dimensions of 23 µm by 10 µm located at a distance 11.5 µm (

Figure 1). The structure modification was carried out by scanning with the laser beam along a major semi-axis with the speed at 100 µm/s using a Thorlabs MTS50/M-Z8 motorized three-coordinate table.

A visual analysis of the sample was applied using an optical microscope Carl Zeiss Axio Imager A1M (Germany). The microscope is equipped with objectives ranging up to 160×. Spectral characteristics in the range of 300–900 nm after laser treatment were measured in circular areas of about 200 µm in diameter using an MSFU-K microscope spectrophotometer (LOMO). To investigate the resulting structures on the nanoscale, a scanning electron microscope (SEM) of CrossBeam workstation Zeiss AURIGA was used.

3. Results

The laser processing of the samples was accomplished by line-by-line scanning covering the squares with area of 700 × 700 µm2. The distance between two lines was 20 µm, providing an overlap of laser tracks of 50 lines/mm. The intensity of laser irradiation was in range from 35 to 85 kW/cm2.

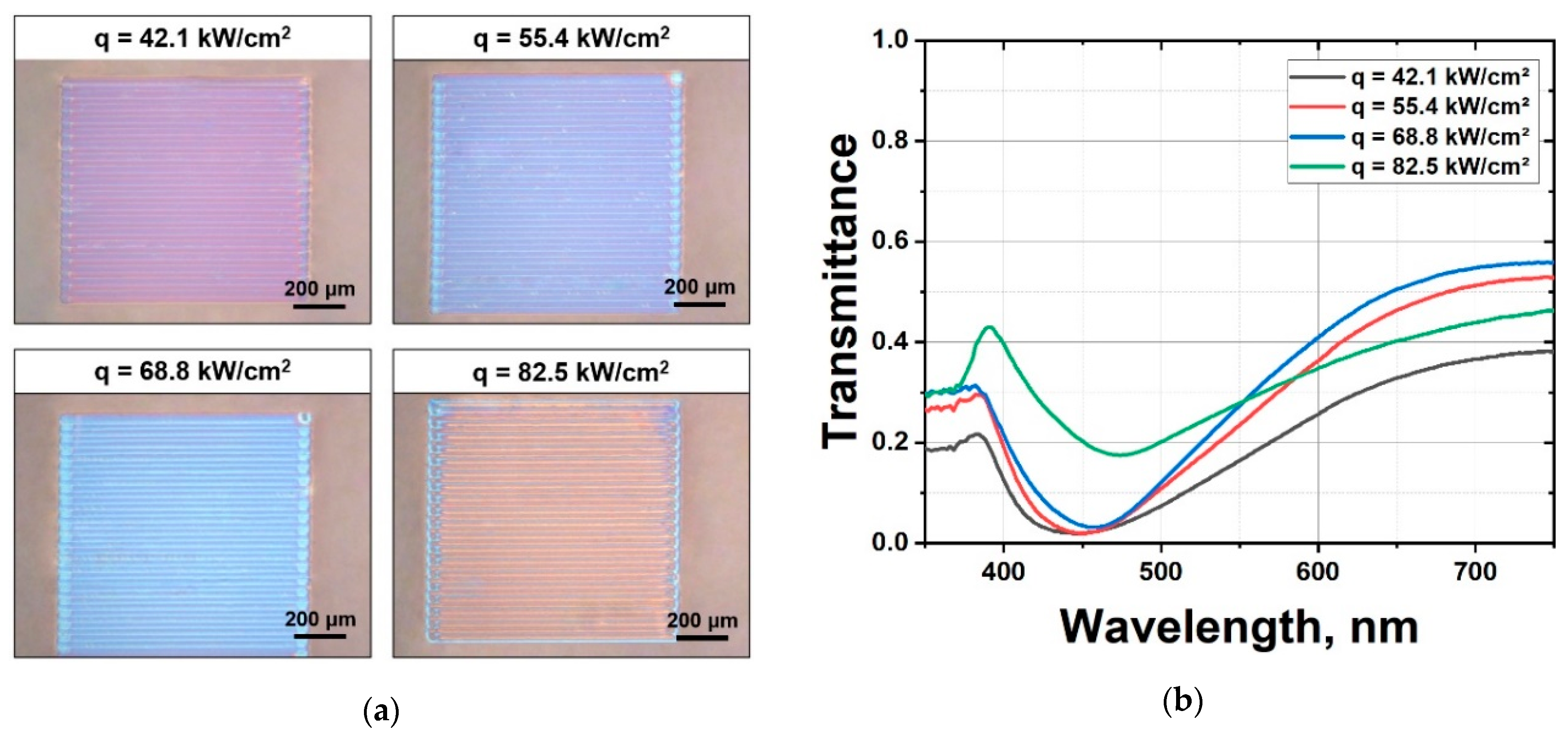

Figure 2a demonstrates the microphotographs of the squares obtained at four different intensities. One can see the change in color with the change of intensity. In particular, at the intensity of 42.1 kW/cm

2, the color of the square visibly seems pink, and at 55.4 kW/cm

2, the obtained square turns to blue. The further increase of intensity up to 68.8 kW/cm

2 leads to formation of the square with stronger and brighter blue, and at the highest intensity of 82.5 kW/cm

2, the square seems more like the initial film.

To better understand the change of optical properties, the transmittance spectra were measured for considered squares.

Figure 2b shows the presence of the minimum and its redshift from 435 to 475 nm. It should be noted that the intensity in the minimum is slightly increased with an increase in intensity up to 68.8 kW/cm

2, but reaching the value of 82.5 kW/cm

2 leads to a distinguishable increase in the minimum intensity from 0.02 to 0.17.

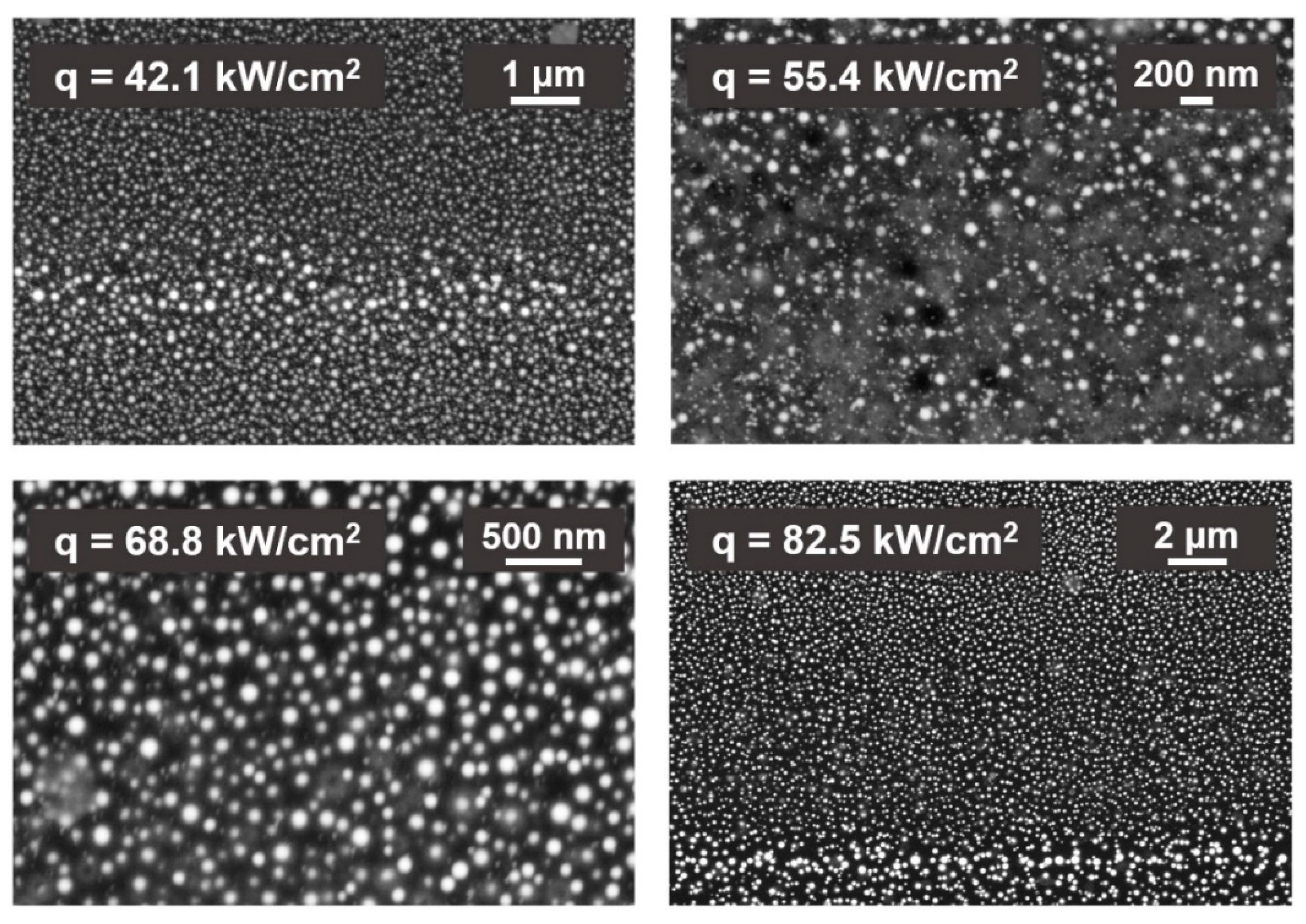

The presence of a minimum in transmittance spectra of Ag-TiO

2 films in the 400–500 nm range is due to the plasmon properties of Ag NPs. In our experiments, the laser annealing of the films activated NPs formation, which is demonstrated in the SEM images (

Figure 3). The concentration and size of NPs affect the spectral characteristics. In particular, the more NPs there are, the more redshifted the peak is, and the higher the concentration is, the lower the intensity is [

6]. Hence, we conclude that the size of NPs was decreased accompanying the concentration decrease as the intensity increased.

As a result of exposure to laser irradiation, the surface of the material changes. Laser annealing causes compaction of Ag-TiO

2 films, which reduces its thickness by 10–20% compared to the thickness of the original film [

4,

7], which indicates structural changes in the matrix. Thus, local modification occurs not only due to the formation of NPs but also due to a change in the structure of the film.

4. Discussion

The change in optical characteristics is associated with both the formation of NPs and the change in TiO2 structure. Both of these processes occur when exposed to laser irradiation, which forms a heat source on the material surface. The characteristics of this source, in turn, are determined by the scanning speed and intensity of laser radiation.

To better understand the influence of the parameters of a heat source on optical characteristics, we proposed considering a model of a volume heat source moving at constant speed. The temperature for such a source formed by double-mode beam is determined as follows:

where

t =

R−1(2

axrr/

υ)

0.5 is the effective time of film heating,

δ is the distance between two spots, and

Q(z) is the absorbed energy source from a single laser spot. To calculate

Q(

z), we assumed that the absorptivity of the film consisted of the absorption of the matrix and plasmon resonance from silver NPs, which disappears at a certain intensity or temperature. Calculations of temperatures along the axes were carried out using Miamoto equations [

8] that were extended for the case of a double-mode beam. Within the framework of this work, we present only the formula for calculating temperatures:

where

υ = 100 µm/s is the scanning velocity,

τ is the time-dependent variable,

zr = lf /(r2lf)1/3 is the coefficient of heat source size on the

Z coordinate,

r is the average radius,

xr and

yr are the proportionality coefficients for the X and Y coordinates, and

lf is the film half-thickness. The thermal diffusivity

a takes into account heat outflow from the irradiated regions into air and substrate.

Results of the temperature calculations are presented on

Figure 4. One can see that the temperature for intensity of 42.1 kW/cm

2 is in range from 200 to 400 °C along the X and Y axes. Upon reaching these temperatures, crystallization of amorphous titanium dioxide into brookite occurs [

9], and the process of formation of NPs is activated. Above 55.4 kW/cm

2, a temperature of 400 °C is reached, which leads to the formation of anatase from brookite [

9]. NP formation continues due to diffuse growth that results in a shift in transmission peaks and an increase in their intensity. It should be noted that as the intensity of the temperature distribution increases, it becomes more complex due to the complication of the absorptivity when higher temperatures are reached.

Another important parameter that characterizes laser annealing is the duration time of annealing. This parameter can be calculated for certain temperature as the ratio of the heating source size and the laser scanning speed. For example, we cross the temperature distribution for the X axis at 200 °C and find the cross-section size. At the intensity of 42.1 kW/cm2, the size is around 48 µm. The ratio of the size to the scanning speed (υ = 100 µm/s) is 48 ms, which is the desired duration time of annealing. For 200 °C the annealing time increases from 48 to 81.5 ms in the intensity range 42.1–82.5 kW/cm2, respectively. The temperature does not reach 400 °C at 42.1 kW/cm2, so the duration time changes from 0 up to 32 ms at 400 °C.

5. Conclusions

As a result of the work, the process of local annealing of Ag-TiO2 thin films by CW UV laser radiation has been considered.

The result of the structure modification was a change in the optical characteristics of the material, which manifested itself in the appearance and change of color. Squares with a size of 700 × 700 µm2 were recorded by line-by-line scanning, which changed their optical properties depending on the intensity of the laser irradiation. As a result, it was shown that an increase in the intensity from 45.1 to 82.5 kW/cm2 led to a change in the spectral transmittance in the region of the plasmon resonance peak from 435 to 475 nm. It was shown that a change in the optical characteristics in the plasmon peak region is associated with a change in the size and concentration of NPs in the film as well as with structural changes in the material.

To describe a heat source formed by laser radiation, a thermophysical model of a volume source moving at a constant velocity was proposed. The range of temperatures and duration of annealing were estimated taking into account the intensity of laser irradiation and scanning speed. As a result of the simulation, it was shown that when the intensity was increased from 45.1 to 82.5 kW/cm2, the maximum temperature in the irradiated zone changed from 390 to 600 °C. The thermal annealing time at 400 °C in this temperature range varies up to 32 ms.

Author Contributions

Conceptualization, M.M.S. and T.E.I.; methodology, M.M.S.; software, V.R.G. and Y.M.A.; validation, P.V.V., M.M.S. and Y.M.A.; formal analysis, V.R.G.; investigation, P.V.V. and M.M.S.; resources, F.V. and A.S.L.; data curation, P.V.V. and V.R.G.; writing—original draft preparation, P.V.V. and M.M.S.; writing—review and editing, T.E.I.; visualization, P.V.V.; supervision, T.E.I.; project administration, P.V.V.; funding acquisition, M.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the grant of Russian Science Foundation (project No. 19-79-10208).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

SEM measurements were done on the base of Interdisciplinary Resource Centre for Nanotechnology, Research Park, St. Petersburg State University.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Avayu, O.; Almeida, E.; Prior, Y.; Ellenbogen, T. Composite functional metasurfaces for multispectral achromatic optics. Nat. Commun. 2017, 8, 14992. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yan, C.; Li, C.; Lu, Z.; Ma, C.; Yan, Y.; Zhang, Y. Charge Transfer Tuned by the Surrounding Dielectrics in TiO2-Ag Composite Arrays. Nanomaterials 2018, 8, 1019. [Google Scholar] [CrossRef] [PubMed]

- Chibac-Scutaru, A.L.; Podasca, V.; Timpu, D.; Melinte, V. Comparative Study on the Influence of Noble Metal Nanoparticles (Ag, Au, Pd) on the Photocatalytic Activity of ZnO NPs Embedded in Renewable Castor Oil Polymer Matrices. Materials 2020, 13, 3468. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Vangheluwe, M.; Vocanson, F.; Cazier, A.; Bugnet, M.; Reynaud, S.; Vermeulin, A.; Destouches, N. Laser-driven plasmonic gratings for hiding multiple images. Mater. Horizons 2019, 6, 978–983. [Google Scholar] [CrossRef]

- Nadar, L.; Sayah, R.; Vocanson, F.; Crespo-Monteiro, N.; Boukenter, A.; Joao, S.S.; Destouches, N. Influence of reduction processes on the colour and photochromism of amorphous mesoporous TiO2 thin films loaded with a silver salt. Photochem. Photobiol. Sci. 2011, 10, 1810. [Google Scholar] [CrossRef] [PubMed]

- Garcia, M.A. Surface plasmons in metallic nanoparticles: Fundamentals and applications. J. Phys. D Appl. Phys. 2011, 44, 283001. [Google Scholar] [CrossRef]

- Liu, Z.; Siegel, J.; Garcia-Lechuga, M.; Epicier, T.; Lefkir, Y.; Reynaud, S.; Bugnet, M.; Vocanson, F.; Solis, J.; Vitrant, G.; et al. Three-Dimensional Self-Organization in Nanocomposite Layered Systems by Ultrafast Laser Pulses. ACS Nano 2017, 11, 5031–5040. [Google Scholar] [CrossRef] [PubMed]

- Miyamoto, I. Local Melting of Glass Material and Its Application to Direct Fusion Welding by Ps-laser Pulses. J. Laser Micro/Nanoeng. 2007, 2, 7–14. [Google Scholar] [CrossRef]

- Shul’Ga, Y.M.; Kabachkov, E.N.; Matyushenko, D.V.; Kurkin, E.N.; Domashnev, I.A. Thermally stimulated transformations in brookite-containing TiO2 nanopowders produced by the hydrolysis of TiCl4. Tech. Phys. 2011, 56, 97–101. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).