Selectivity Performance and Antifouling Properties of Modified Chitosan Composites †

Abstract

1. Introduction

2. Materials and Methods

3. Results

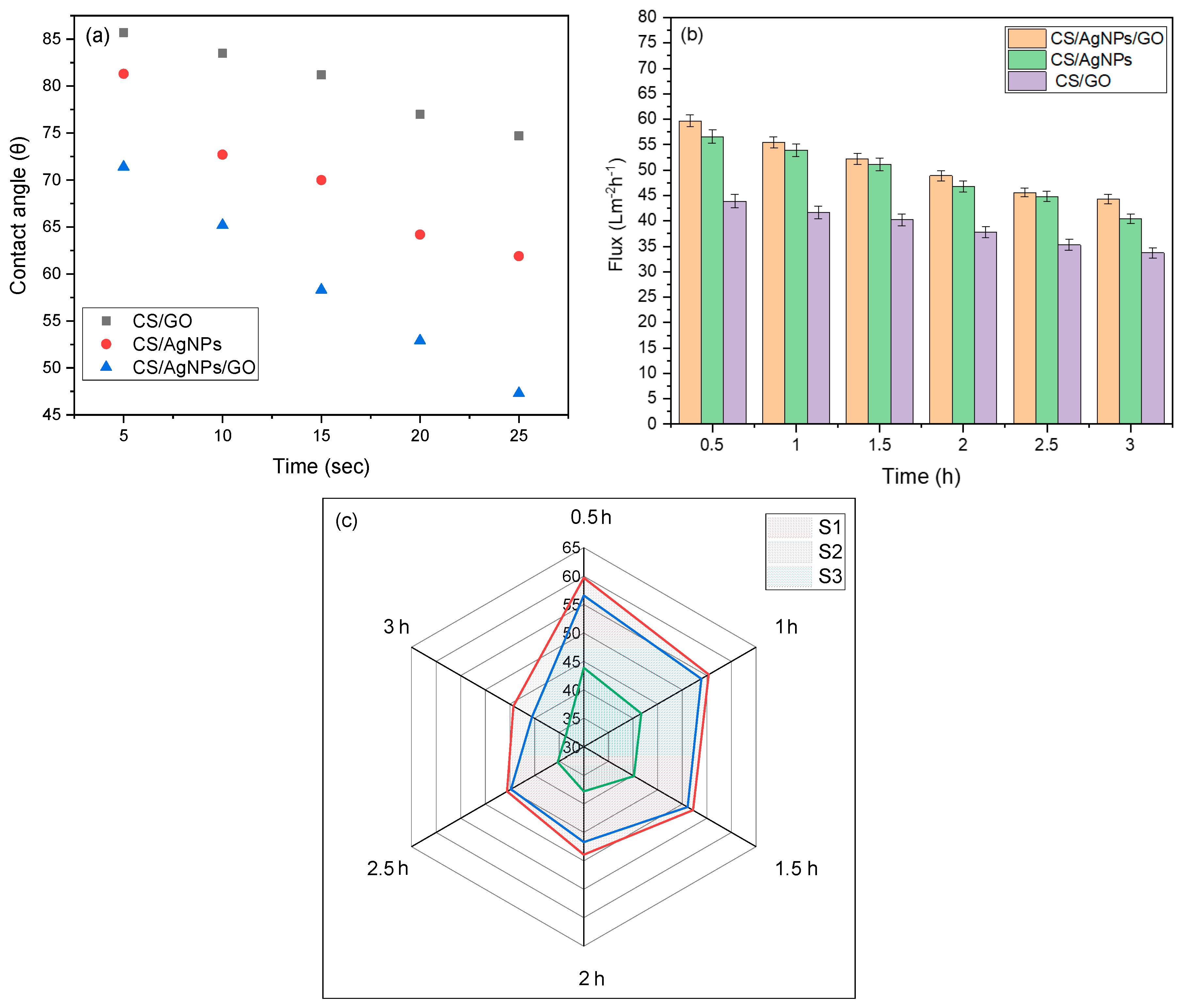

3.1. Membrane Surface Hydrophilicity

3.2. Characterization of Antifouling Performance

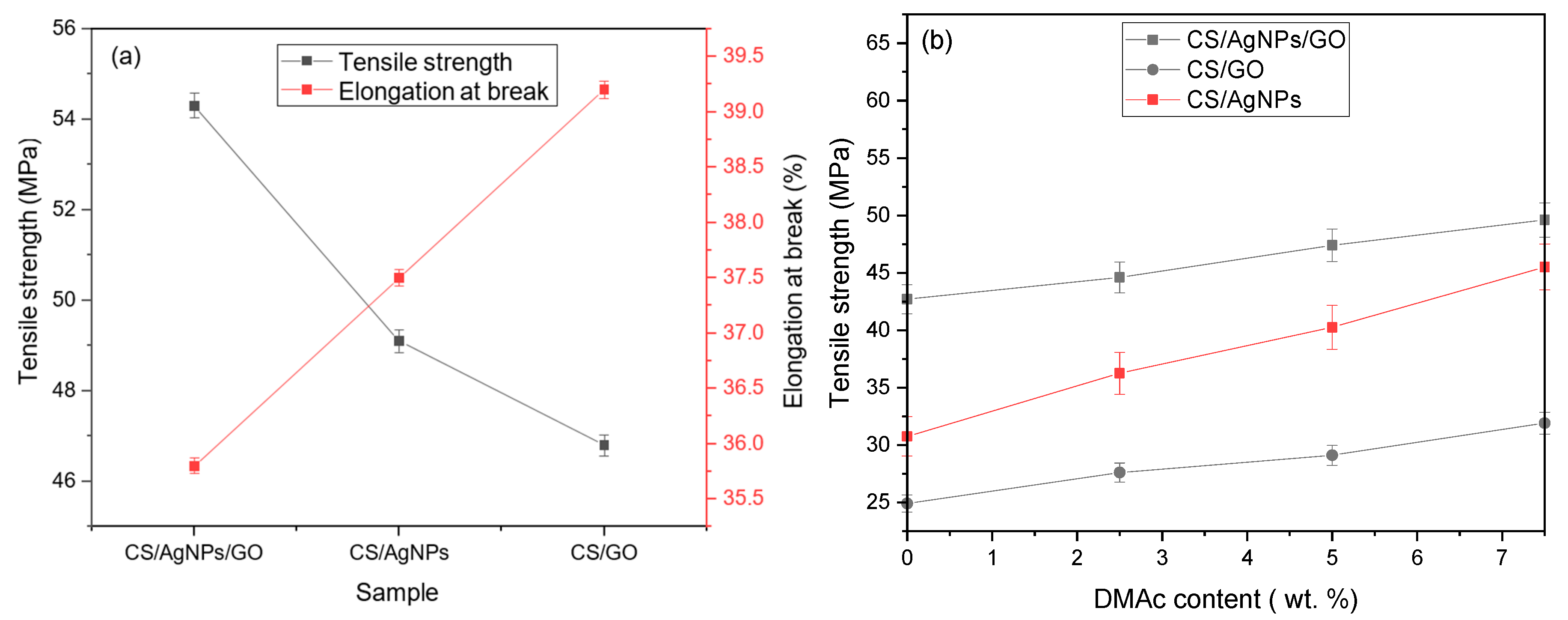

3.3. Mechanical Properties of the Composite Membrane

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cevallos-Mendoza, J.; Amorim, C.G.; Rodríguez-Díaz, J.M.; Montenegro, M.D.C.B. Removal of contaminants from water by membrane filtration: A review. Membranes 2022, 12, 570. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.A.; Amin, S.; Mohamed, A.A. Fouling in reverse osmosis membranes: Monitoring, characterization, mitigation strategies and future directions. Heliyon 2023, 9, e14908. [Google Scholar] [CrossRef] [PubMed]

- El-Araby, A.; Janati, W.; Ullah, R.; Ercisli, S.; Errachidi, F. Chitosan, chitosan derivatives, and chitosan-based nanocomposites: Eco-friendly materials for advanced applications (a review). Front. Chem. 2024, 11, 1327426. [Google Scholar]

- Peter, S.; Lyczko, N.; Gopakumar, D.; Maria, H.J.; Nzihou, A.; Thomas, S. Chitin and chitosan based composites for energy and environmental applications: A review. Waste Biomass. Valor. 2021, 12, 4777–4804. [Google Scholar] [CrossRef]

- Bustamante-Torres, M.; Arcentales-Vera, B.; Estrella-Nuñez, J.; Yánez-Vega, H.; Bucio, E. Antimicrobial activity of composites-based on biopolymers. Macromol 2022, 2, 258–283. [Google Scholar] [CrossRef]

- Ogazi, A.C.; Osifo, P.O. Inhibition of coliforms and Escherichia coli bacterial strains in water by 3D printed CS/GO/AgNP filtration membranes. J. Poly. Environ. 2023, 31, 4448–4467. [Google Scholar] [CrossRef]

- Li, J.; Zeng, H.; Wu, X.; Li, T.; Sun, Z.; Zhu, G.; Zhang, M.; Chen, L.; Pan, K.; Guo, X. Chitosan-based porous composites embedded with molybdenum disulfide nanosheets for removal of mercury from wastewater. Int. J. Biol. Macromol. 2025, 285, 138379. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Mai, Y.; Wang, Y.; Chen, S. Stretchable unidirectional liquid-transporting membrane with antibacterial and biocompatible features based on chitosan derivative and composite nanofibers. Carbohydr. Polym. 2022, 276, 118703. [Google Scholar] [CrossRef] [PubMed]

- Almanassra, I.W.; Jaber, L.; Backer, S.N.; Chatla, A.; Kochkodan, V.; Al-Ansari, T.; Shanableh, A.; Atieh, M.A. Oxidized carbide-derived carbon as a novel filler for improved antifouling characteristics and permeate flux of hybrid polyethersulfone ultrafiltration membranes. Chemosphere 2023, 313, 137425. [Google Scholar] [CrossRef] [PubMed]

| Sample | FRR (%) | Rt | Rir | Rr |

|---|---|---|---|---|

| S1 (CS/AgNPs/GO) | 77.52 ± 0.2 | 78.24 ± 0.31 | 10.31 ± 0.15 | 45.41 ± 0.43 |

| S2 (CS/AgNPs) | 68.21 ± 0.4 | 70.73 ± 0.34 | 9.82 ± 0.17 | 52.12 ± 0.51 |

| S3 (CS/GO) | 65.11 ± 0.5 | 66.51 ± 0.23 | 7.22 ± 0.11 | 58.71 ± 0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogazi, A.C. Selectivity Performance and Antifouling Properties of Modified Chitosan Composites. Mater. Proc. 2025, 25, 2. https://doi.org/10.3390/materproc2025025002

Ogazi AC. Selectivity Performance and Antifouling Properties of Modified Chitosan Composites. Materials Proceedings. 2025; 25(1):2. https://doi.org/10.3390/materproc2025025002

Chicago/Turabian StyleOgazi, Anthony C. 2025. "Selectivity Performance and Antifouling Properties of Modified Chitosan Composites" Materials Proceedings 25, no. 1: 2. https://doi.org/10.3390/materproc2025025002

APA StyleOgazi, A. C. (2025). Selectivity Performance and Antifouling Properties of Modified Chitosan Composites. Materials Proceedings, 25(1), 2. https://doi.org/10.3390/materproc2025025002