Numerical Modelling of Void Closure Diffusion Model †

Abstract

1. Introduction

2. Material and Methods

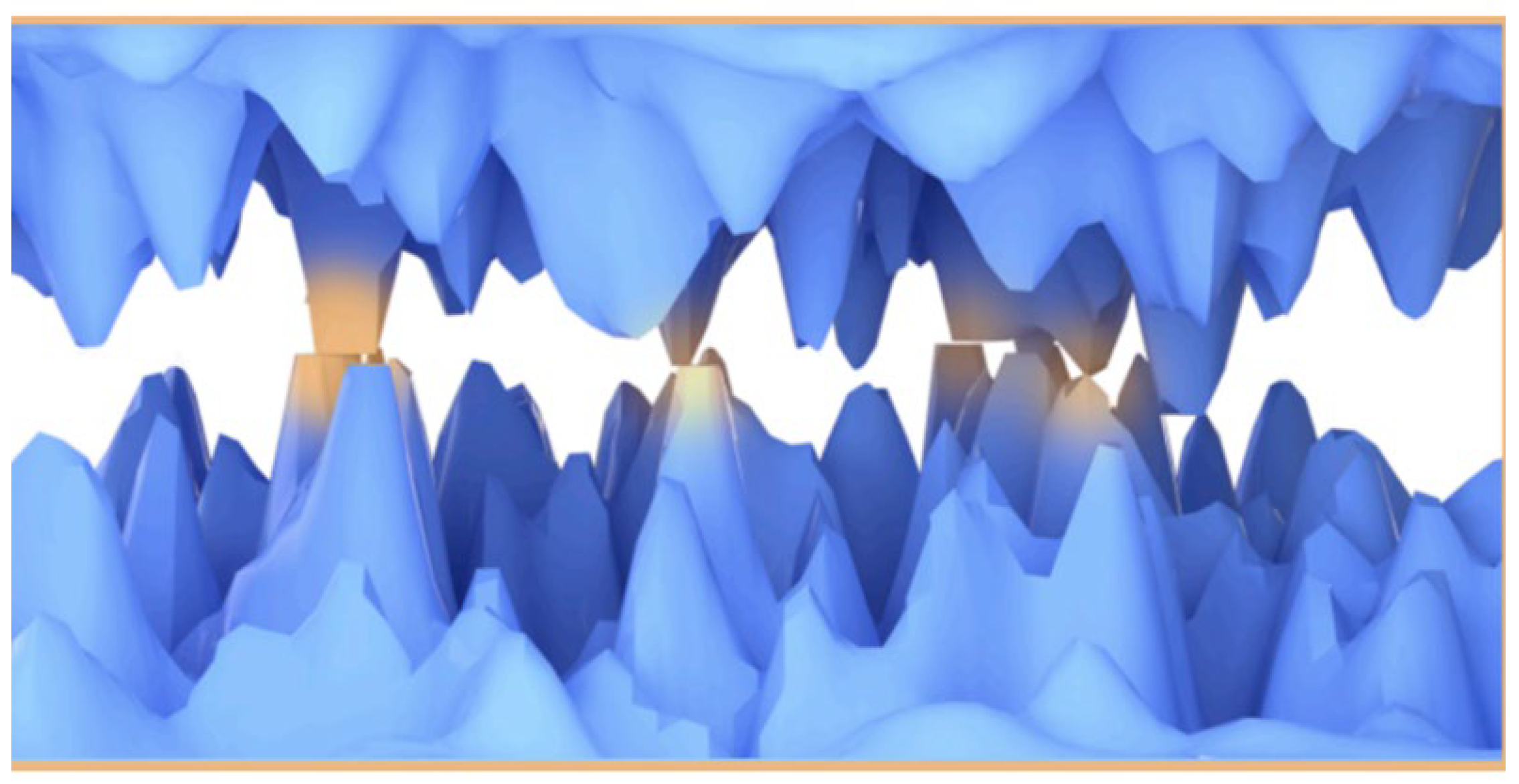

2.1. Geometric Modeling

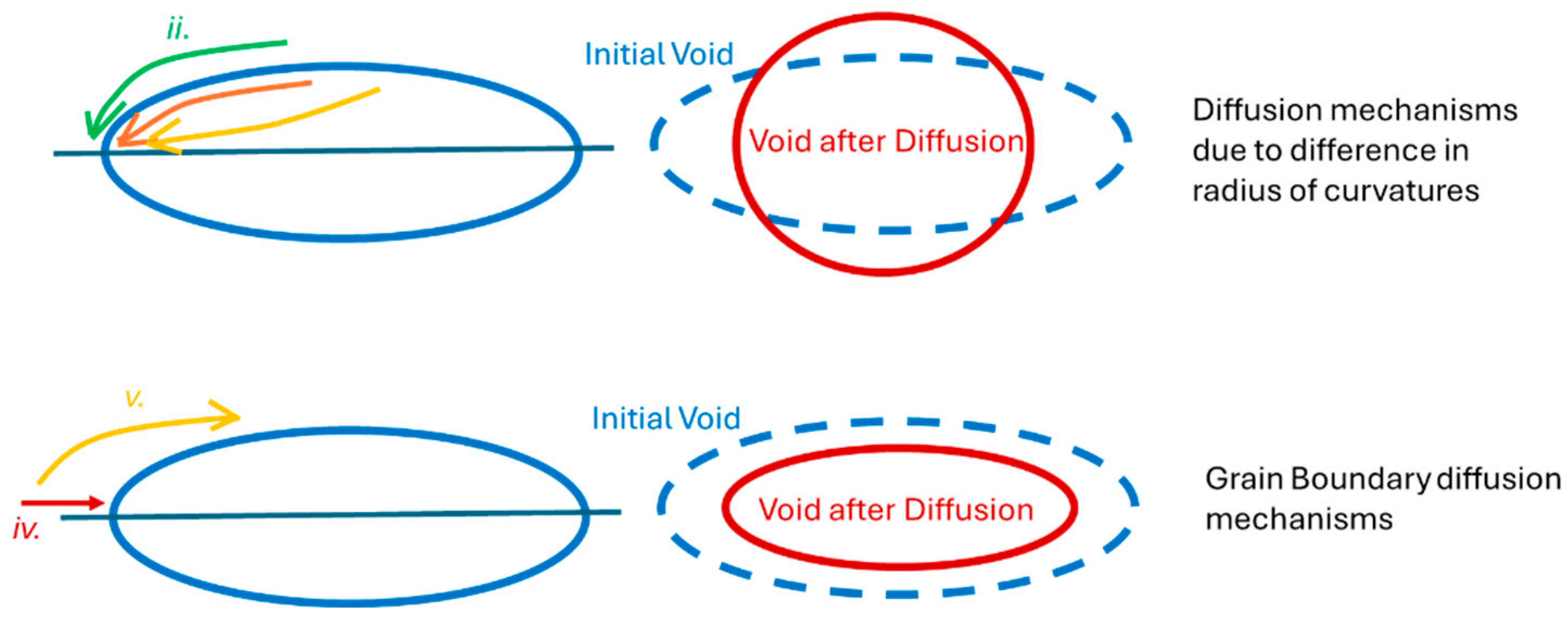

2.2. Mathematical Modeling

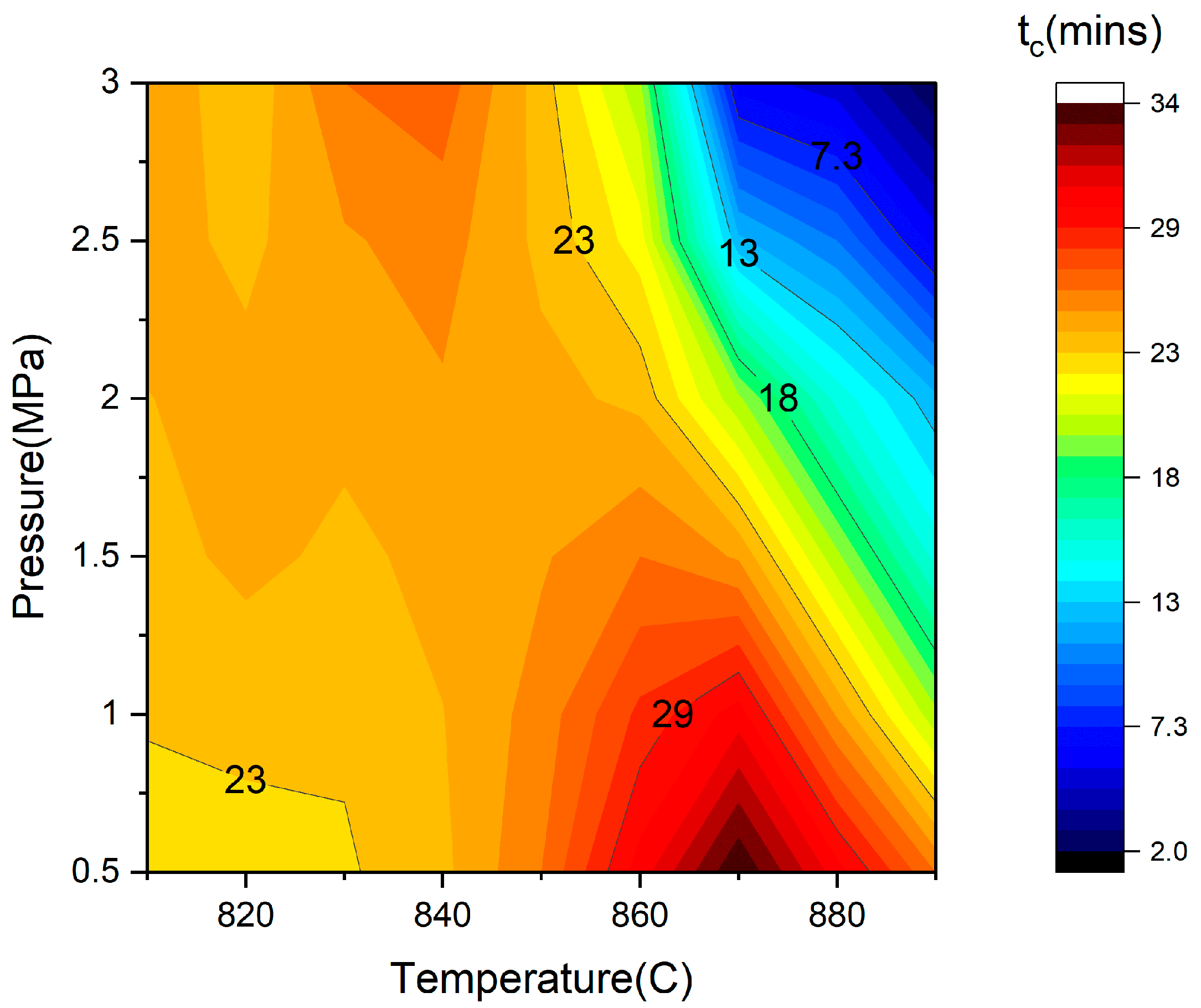

- Diffusion coefficients that determine the rate of void closure.

- Pressure–temperature interactions that dictate the bonding process.

- Temporal variations in the closure dynamics which highlight the process efficiency.

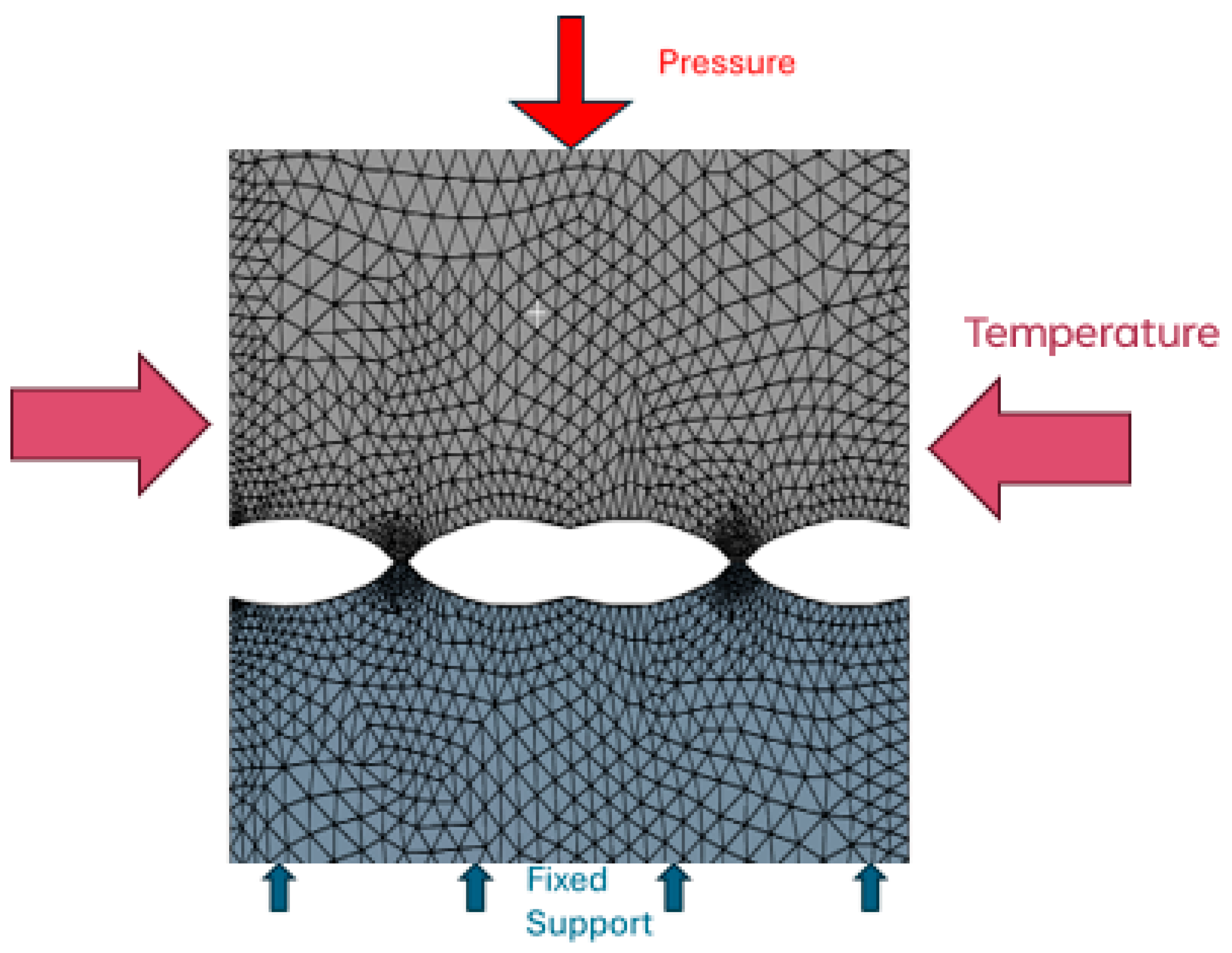

2.3. Meshing and Boundary Conditions

2.4. Simulation Parameters

3. Results and Discussion

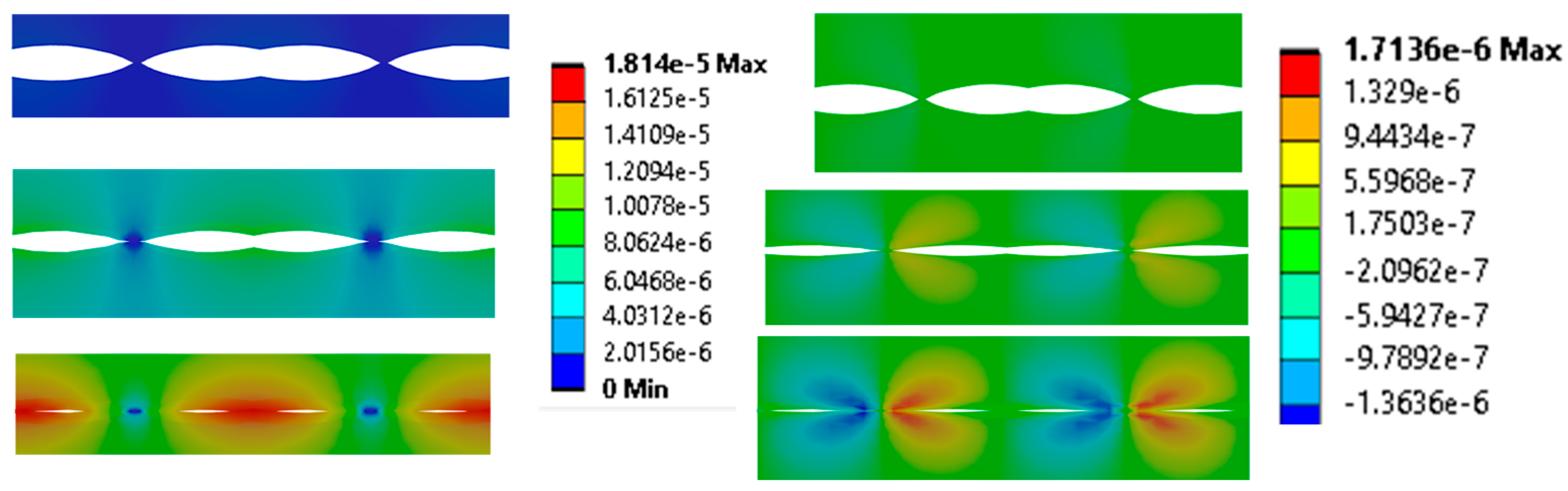

3.1. Contours

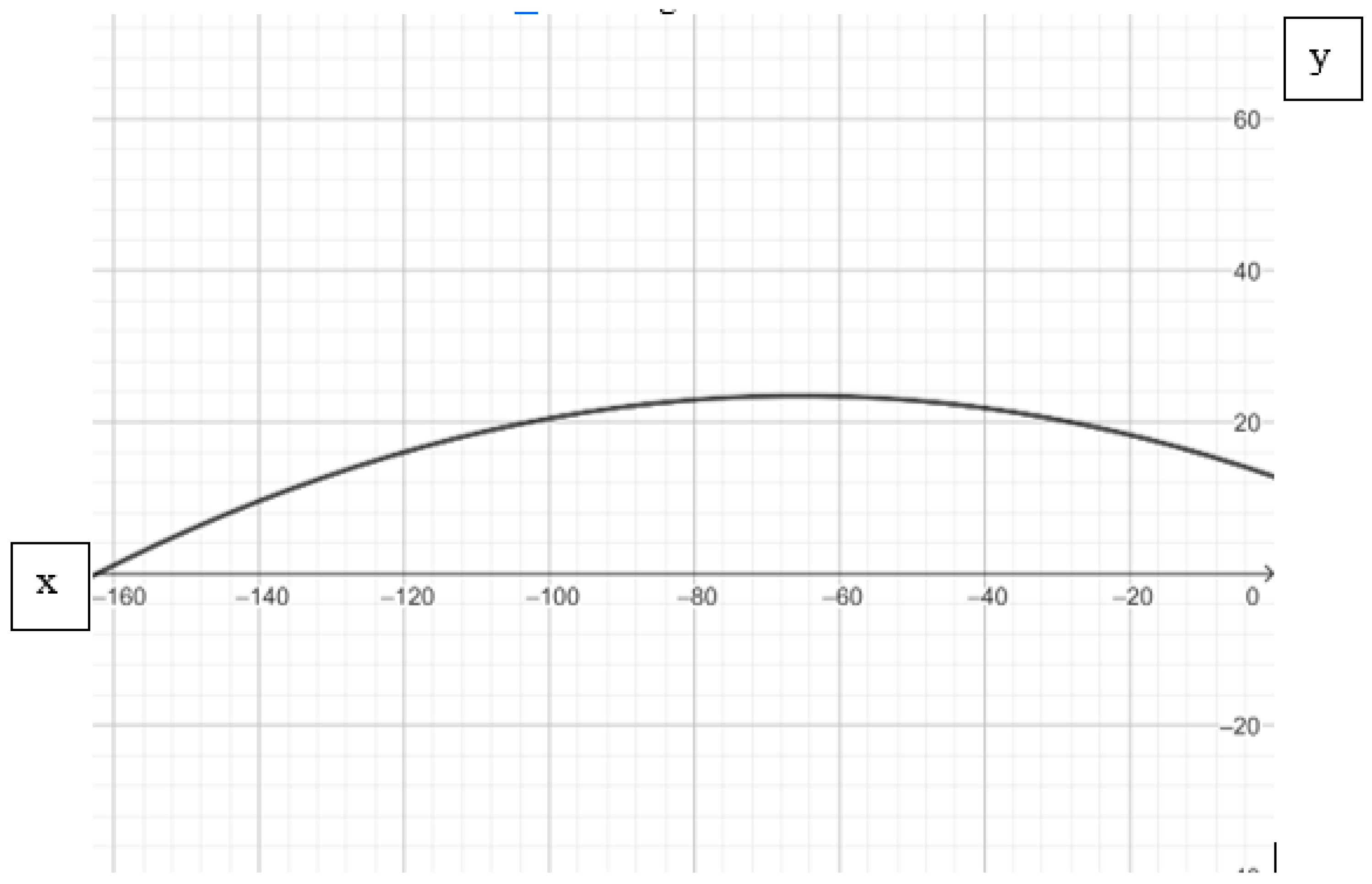

3.2. Numerical Derivatives

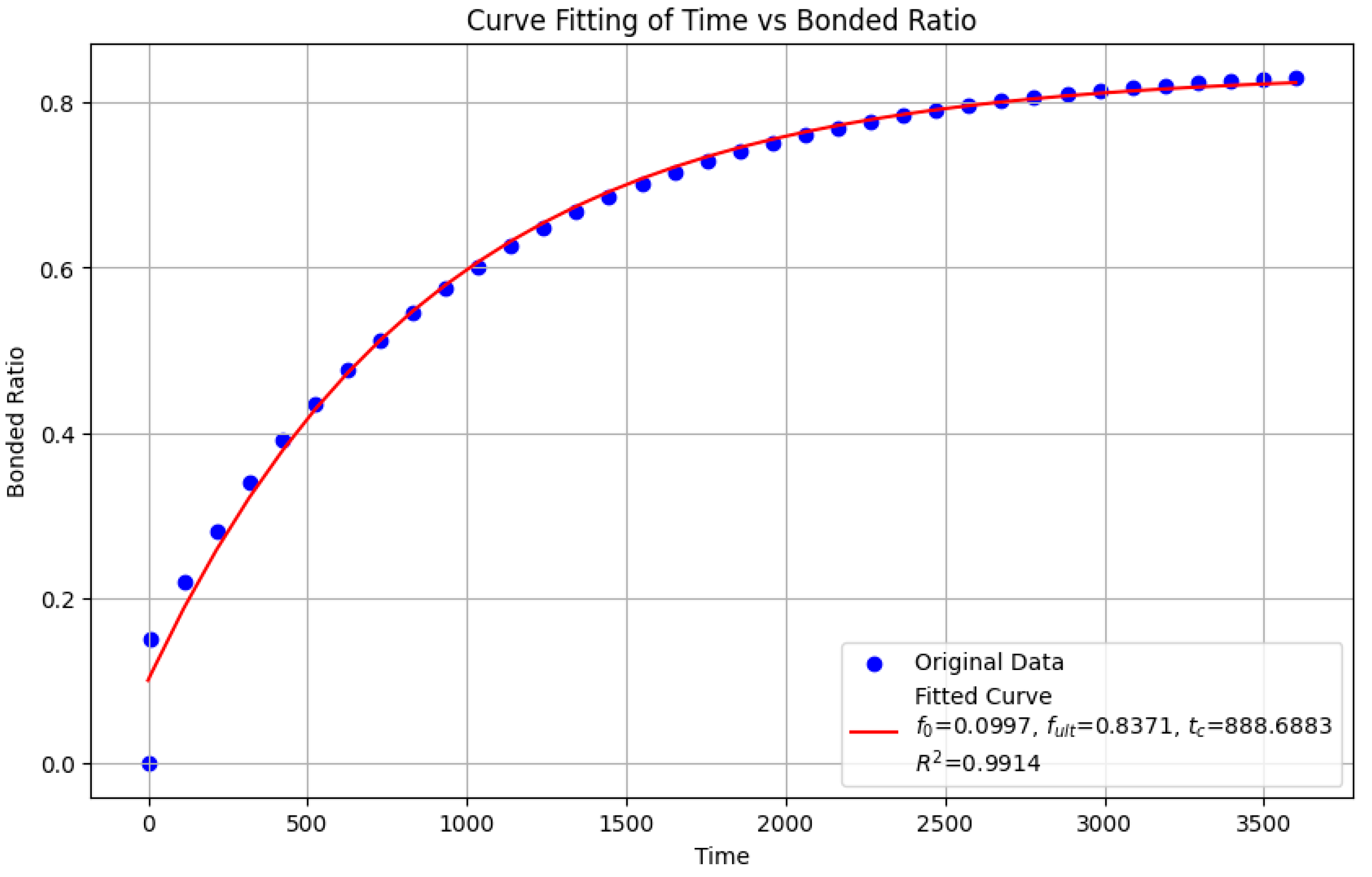

3.3. Curve-Fitting Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, D.; Feng, Z.; Wang, C.; Wang, W.; Liu, Z.; Niu, W. Comparison of microstructures and mechanical properties of Inconel 718 alloy processed by selective laser melting and casting. Mater. Sci. Eng. A 2018, 724, 357–367. [Google Scholar] [CrossRef]

- Dziuba, O.; Cempura, G.; Wusatowska-Sarnek, A.; Kruk, A. Influence of Isothermal Holding on the Microstructure and Mechanical Properties of Electron Beam Welded Dissimilar Inconel 718/ATI 718Plus® Joint. J. Mater. Eng. Perform. 2020, 29, 1515–1521. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Proces. Technol. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Walker, L.; Fink, C.; Hilla, C.; Lu, Y.; Zhang, W. Peculiar roles of nickel diffusion in intermetallic compound formation at the dissimilar metal interface of magnesium to steel spot welds. Mater. Des. 2023, 230, 111980. [Google Scholar] [CrossRef]

- Chatterjee, S.; Abinandanan, T.A.; Reddy, G.M.; Chattopadhyay, K. Microstructure Formation in Dissimilar Metal Welds: Electron Beam Welding of Ti/Ni. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 769–776. [Google Scholar] [CrossRef]

- Shojaei Zoeram, A.; Akbari Mousavi, S.A.A. Effect of interlayer thickness on microstructure and mechanical properties of as welded Ti6Al4V/Cu/NiTi joints. Mater. Lett. 2014, 133, 5–8. [Google Scholar] [CrossRef]

- Cline, C.L. An analytical and experimental study of diffusion bonding. Weld. J. 1966, 45, 481s–489s. [Google Scholar]

- Hamilton, C.H. Titanium Science and Technology; Plenum Press: New York, NY, USA, 1973; Volume 1, p. 625. [Google Scholar]

- Garmong, G.; Paton, N.E.; Argon, A.S. Attainment of full interfacial contact during diffusion bonding. Metall. Trans. A 1975, 6, 1269–1279. [Google Scholar] [CrossRef]

- Derby, B.; Wallach, E.R. Theoretical model for diffusion bonding. Met. Sci. 1982, 16, 49–56. [Google Scholar] [CrossRef]

- Pilling, J.; Livesey, D.W.; Hawkyard, J.B.; Ridley, N. Solid state bonding in superplastic Ti-6Al-4V. Met. Sci. 1984, 18, 117–122. [Google Scholar] [CrossRef]

- Hill, A.; Wallach, E.R. Modelling solid-state diffusion bonding. Acta Metall. 1989, 37, 2425–2437. [Google Scholar] [CrossRef]

- Li, S.-X.; Tu, S.-T.; Xuan, F.-Z. A probabilistic model for prediction of bonding time in diffusion bonding. Mater. Sci. Eng. A 2005, 407, 250–255. [Google Scholar] [CrossRef]

- Wu, H.; Yang, W.; Peng, H.; Li, X.; Chen, J. Diffusion bonding criterion based on real surface asperities: Modeling and validation. J. Manuf. Process 2020, 57, 477–487. [Google Scholar] [CrossRef]

- Yuan, L.; Xiong, J.; Peng, Y.; Li, Z.; Li, J. Modeling void closure in solid-state diffusion bonding of TC4 alloy. Vacuum 2020, 173, 109120. [Google Scholar] [CrossRef]

- Xydou, A.; Parviainen, S.; Djurabekova, F. Diffusion bonding of Cu atoms with molecular dynamics simulations. Results Phys. 2020, 16, 102890. [Google Scholar] [CrossRef]

- Li, W.; Liang, Y.; Bai, Y.; Lin, T.; Li, B.; Feng, J. Cu–Cu low-temperature diffusion bonding by spark plasma sintering: Void closure mechanism and mechanical properties. J. Mater. Sci. Technol. 2023, 139, 210–223. [Google Scholar] [CrossRef]

- Takahashi, Y.; Student, G.; Nishiguch, K. Modeling of Viscoplastic Adhering Process by a Finite Element Technique. 1993. Available online: http://www.asme.org/about-asme/terms-of-use.

- Takahashi, Y.; Inoue, K. Recent void shrinkage models and their applicability to diffusion bonding. Mater. Sci. Technol. 1992, 8, 953–964. [Google Scholar] [CrossRef]

- Alegria, J.; Miranda, R.M.; De Salazar, J.M.G.; Fernandes, A.A. Modelling of voids closure in the diffusion bonding process. In Materials Science Forum; Trans Tech Publications Ltd.: Wollerau, Switzerland, 2008; pp. 731–735. [Google Scholar] [CrossRef]

- Wang, S.B. Numerical Analysis on Interface Behavior in Initial Physical Contact Stage of Solid State Diffusion Bonding. PhD Thesis, Chang’an University, Xi’an, China, 2020. [Google Scholar]

- Peng, Y.; Li, Z.X.; Guo, W.; Xiong, J.T.; Li, J.L. Modeling of interfacial void closure and prediction of bonding time in solid-state diffusion bonding. J. Mater. Process. Technol. 2024, 324, 118267. [Google Scholar] [CrossRef]

- Shrestha, T.; Basirat, M.; Charit, I.; Potirniche, G.P.; Rink, K.K.; Sahaym, U. Creep deformation mechanisms in modified 9Cr–1Mo steel. J. Nucl. Mater. 2012, 423, 110–119. [Google Scholar] [CrossRef]

- Otto, F.; Viswanathan, G.B.; Payton, E.J.; Frenzel, J.; Eggeler, G. On the effect of grain boundary segregation on creep and creep rupture. Acta Mater. 2012, 60, 2982–2998. [Google Scholar] [CrossRef]

- Rajakumar, S.; Balasubramanian, V. Diffusion bonding of titanium and AA 7075 aluminum alloy dissimilar joints—Process modeling and optimization using desirability approach. Int. J. Adv. Manuf. Technol. 2016, 86, 1095–1112. [Google Scholar] [CrossRef]

- Negemiya, A.A.; Shankar, A.N.; Guruprasad, B.; Prakash, B.; Dineshkumar, S.; Batu, A.; Rajakumar, S. Investigation on Processing Maps of Diffusion Bonding Process Parameters for Ti-6Al-4 V/AISI304 Dissimilar Joints. Adv. Mater. Sci. Eng. 2021, 2021, 5601970. [Google Scholar] [CrossRef]

- Peng, Y.; Li, J.; Li, Z.; Guo, Z.; Guo, W.; Xiong, J. Modeling of bonding pressure based on the plastic deformation mechanism of interfacial voids closure in solid-state diffusion bonding. Mater. Des. 2024, 245, 113239. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akif, M.; Junaid, M.; Shehbaz, T.; Khan, F.N. Numerical Modelling of Void Closure Diffusion Model. Mater. Proc. 2025, 23, 11. https://doi.org/10.3390/materproc2025023011

Akif M, Junaid M, Shehbaz T, Khan FN. Numerical Modelling of Void Closure Diffusion Model. Materials Proceedings. 2025; 23(1):11. https://doi.org/10.3390/materproc2025023011

Chicago/Turabian StyleAkif, Muhammad, Massab Junaid, Tauheed Shehbaz, and Fahd Nawaz Khan. 2025. "Numerical Modelling of Void Closure Diffusion Model" Materials Proceedings 23, no. 1: 11. https://doi.org/10.3390/materproc2025023011

APA StyleAkif, M., Junaid, M., Shehbaz, T., & Khan, F. N. (2025). Numerical Modelling of Void Closure Diffusion Model. Materials Proceedings, 23(1), 11. https://doi.org/10.3390/materproc2025023011