Working Fluid Selection for Biogas-Powered Organic Rankine Cycle-Vapor Compression Cycle †

Abstract

1. Introduction

2. System Description

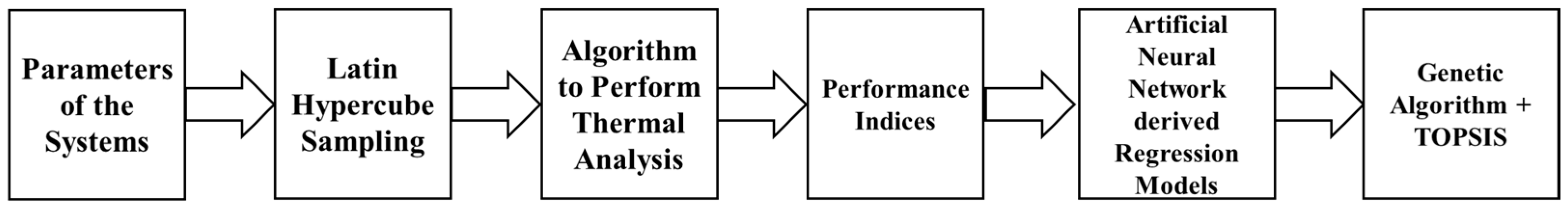

3. Mathematical Modeling

- The system operates in steady-state conditions [28].

- The standard ambient pressure and temperature are taken as 25 °C (298 K) and 101 kPa [30].

- The pump work of the HTF pump is ignored [30].

4. Methodology

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Specific Heat (kJ/kg·K) | |

| Exergy Destruction (kW) | |

| Enthalpy (kJ/kg) | |

| Mass Flow Rate (kg/s) | |

| Heat Transfer (kW) | |

| s | Entropy (kJ/kg·K) |

| T | Temperature (K) |

| Work (kW) | |

| UA | Heat Transfer Capacity (kW/K) |

| fg | Flue Gases |

| HTF | Heat Transfer Fluid |

| HTF,HX | Representing heat exchanger handling flue gases and heat transfer fluid |

References

- Nasir, M.T.; Ekwonu, M.C.; Park, Y.; Esfahani, J.A.; Kim, K.C. Assessment of a district trigeneration biomass powered double organic rankine cycle as primed mover and supported cooling. Energies 2021, 14, 1030. [Google Scholar] [CrossRef]

- Kelkar, M. Demise of fossil fuels part I: Supply and demand. Heliyon 2024, 10, e39200. [Google Scholar] [CrossRef]

- Inglesi-Lotz, R. The impact of renewable energy consumption to economic growth: A panel data application. Energy Econ. 2016, 53, 58–63. [Google Scholar] [CrossRef]

- Strzalka, R.; Schneider, D.; Eicker, U. Current status of bioenergy technologies in Germany. Renew. Sustain. Energy Rev. 2017, 72, 801–820. [Google Scholar] [CrossRef]

- Moriarty, P.; Honnery, D. What is the global potential for renewable energy? Renew. Sustain. Energy Rev. 2012, 16, 244–252. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J.; Cao, Y.; Zhong, J.; Liu, Y.; Kang, C.; Tan, Y. Interaction between urban microclimate and electric air-conditioning energy consumption during high temperature season. Appl. Energy 2014, 117, 149–156. [Google Scholar] [CrossRef]

- Chan, C.W.; Ling-Chin, J.; Roskilly, A.P. A review of chemical heat pumps, thermodynamic cycles and thermal energy storage technologies for low grade heat utilization. Appl. Therm. Eng. 2013, 50, 1257–1273. [Google Scholar] [CrossRef]

- Chua, K.J.; Chou, S.K.; Yang, W.M.; Yan, J. Achieving better energy-efficient air conditioning—A review of technologies and strategies. Appl. Energy 2013, 104, 87–104. [Google Scholar] [CrossRef]

- Brown, J.S.; Domanski, P.A. Review of alternative cooling technologies. Appl. Therm. Eng. 2014, 64, 252–262. [Google Scholar] [CrossRef]

- Zeyghami, M.; Goswami, D.Y.; Stefanakos, E. A review of solar thermo-mechanical refrigeration and cooling methods. Renew. Sustain. Energy Rev. 2015, 51, 1428–1445. [Google Scholar] [CrossRef]

- Nasir, M.T.; Ali, M.A.; Khan, T.S.; Al-Hajri, E.; Kadri, M.B.; Kim, K.C. Performance assessment and multi objective optimization of an Organic Rankine Cycle driven cooling air conditioning system. Energy Build. 2019, 191, 13–30. [Google Scholar] [CrossRef]

- Nasir, M.T.; Ekwonu, M.C.; Esfahani, J.A.; Kim, K.C. Integrated vapor compression chiller with bottoming organic rankine cycle and onsite low-grade renewable energy. Energies 2021, 14, 6401. [Google Scholar] [CrossRef]

- Prigmore, D.; Barber, R. Cooling with the sun’s heat Design considerations and test data for a Rankine Cycle prototype. Sol. Energy 1975, 17, 185–192. [Google Scholar] [CrossRef]

- Biancardi, F.R.; Sitler, J.W.; Melikian, G. Development and test of solar Rankine cycle heating and cooling systems. Int. J. Refrig. 1982, 5, 351–360. [Google Scholar] [CrossRef]

- Demierre, J.; Henchoz, S.; Favrat, D. Prototype of a thermally driven heat pump based on integrated Organic Rankine Cycles (ORC). Energy 2012, 41, 10–17. [Google Scholar] [CrossRef]

- Demierre, J.; Favrat, D.; Schiffmann, J.; Wegele, J. Experimental investigation of a Thermally Driven Heat Pump based on a double Organic Rankine Cycle and an oil-free Compressor-Turbine Unit. Int. J. Refrig. 2014, 44, 91–100. [Google Scholar] [CrossRef]

- Wang, H.; Peterson, R.; Harada, K.; Miller, E.; Ingram-Goble, R.; Fisher, L.; Yih, J.; Ward, C. Performance of a combined organic Rankine cycle and vapor compression cycle for heat activated cooling. Energy 2011, 36, 447–458. [Google Scholar] [CrossRef]

- Little, A.B.; Garimella, S. Comparative assessment of alternative cycles for waste heat recovery and upgrade. Energy 2011, 36, 4492–4504. [Google Scholar] [CrossRef]

- Cola, F.; Romagnoli, A.; Hey Heng Kiat, J. An evaluation of the technologies for heat recovery to meet onsite cooling demands. Energy Convers. Manag. 2016, 121, 174–185. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Aziz, F.; Mudasar, R.; Kim, M.H. Exergetic and heat load optimization of high temperature organic Rankine cycle. Energy Convers. Manag. 2018, 171, 48–58. [Google Scholar] [CrossRef]

- Inc, B. Waste Heat Recovery: Technology Opportunities in the US Industry. 2008; pp. 1–112. Available online: http://www1.eere.energy.gov/manufacturing/intensiveprocesses/pdfs/waste_heat_recovery.pdf (accessed on 10 March 2025).

- Lai, N.A.; Wendland, M.; Fischer, J. Working fluids for high-temperature organic Rankine cycles. Energy 2011, 36, 199–211. [Google Scholar] [CrossRef]

- Shu, G.; Li, X.; Tian, H.; Liang, X.; Wei, H.; Wang, X. Alkanes as working fluids for high-temperature exhaust heat recovery of diesel engine using organic Rankine cycle. Appl. Energy 2014, 119, 204–217. [Google Scholar] [CrossRef]

- Li, H.; Bu, X.; Wang, L.; Long, Z.; Lian, Y. Hydrocarbon working fluids for a Rankine cycle powered vapor compression refrigeration system using low-grade thermal energy. Energy Build. 2013, 65, 167–172. [Google Scholar] [CrossRef]

- Saleh, B. Parametric and working fluid analysis of a combined organic Rankine-vapor compression refrigeration system activated by low-grade thermal energy. J. Adv. Res. 2016, 7, 651–660. [Google Scholar] [CrossRef]

- Bu, X.; Wang, L.; Li, H. Performance analysis and working fluid selection for geothermal energy-powered organic Rankine-vapor compression air conditioning. Geotherm. Energy 2013, 1, 1–14. [Google Scholar] [CrossRef]

- Toffolo, A.; Lazzaretto, A.; Manente, G.; Paci, M. A multi-criteria approach for the optimal selection of working fluid and design parameters in Organic Rankine Cycle systems. Appl. Energy 2014, 121, 219–232. [Google Scholar] [CrossRef]

- Nasir, M.T.; Kim, K.C. Working fluids selection and parametric optimization of an Organic Rankine Cycle coupled Vapor Compression Cycle (ORC-VCC) for air conditioning using low grade heat. Energy Build. 2016, 129, 378–395. [Google Scholar] [CrossRef]

- Meng, N.; Li, T.; Wang, J.; Jia, Y.; Liu, Q.; Qin, H. Synergetic cascade-evaporation mechanism of a novel building distributed energy supply system with cogeneration and temperature and humidity independent control characteristics. Energy Convers. Manag. 2020, 209, 112620. [Google Scholar] [CrossRef]

- Moran, M.; Shapiro, H.; Boettner, D.; Bailey, M. Fundamentals of Engineering Thermodynamics, 9th ed.; Wiley & Sons Ltd.: Hoboken, NJ, USA, 2018. [Google Scholar]

- Çengel, Y.; Boles, M.A. Thermodynamics: An Engineering Approach, 5th ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

| Working Fluid | Critical Pressure (kPa) | Critical Temperature (°C) | ODP | GWP |

|---|---|---|---|---|

| M-Xylene | 3534.5 | 343.73 | 0 | Very low |

| Decane | 2103 | 344.55 | 0 | Very low |

| Propylcyclohexane | 2860 | 357.65 | 0 | Very low |

| Butane (R600) | 3790 | 152 | 0 | 20 |

| Isobutane (R600a) | 3640 | 135 | 0 | 20 |

| Parameter | Range |

|---|---|

| ORC Evaporator Temperature | 325 °C–335 °C |

| ORC Condenser Temperature | 50 °C–70 °C |

| ORC Condenser Sub-Cooling Temperature | 0 °C–14 °C |

| Isentropic Efficiency Expander | 0.7–0.9 |

| Isentropic Efficiency Pump | 0.75–0.9 |

| Pinch Point Temperature Evaporator ORC | 5 °C–15 °C |

| VCC Evaporator Temperature | −2 °C–5 °C |

| VCC Condenser Temperature | 50 °C–70 °C |

| Isentropic Efficiency Compressor | 0.7–0.9 |

| Pinch Point Temperature HTF HX | 5 °C–15 °C |

| Pinch Point Temperature Condenser ORC | 5 °C–15 °C |

| Pinch Point Temperature Condenser VCC | 3 °C–14 °C |

| Working Fluid Combination | ||

|---|---|---|

| Decane ORC-R600 VCC | 42.19 | 16.07 |

| Decane ORC-R600a VCC | 24.50 | 6.71 |

| M-Xylene ORC-R600 VCC | 21.04 | 13.96 |

| M-Xylene ORC-R600a VCC | 30.06 | 16.49 |

| C3CC6 ORC-R600 VCC | 14.55 | 19.87 |

| C3CC6 ORC-R600a VCC | 12.84 | 15.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talha, M.; Malik, N.M.; Nasir, M.T.; Khalid, W.; Safdar, M.; Iqbal, K.F. Working Fluid Selection for Biogas-Powered Organic Rankine Cycle-Vapor Compression Cycle. Mater. Proc. 2025, 23, 1. https://doi.org/10.3390/materproc2025023001

Talha M, Malik NM, Nasir MT, Khalid W, Safdar M, Iqbal KF. Working Fluid Selection for Biogas-Powered Organic Rankine Cycle-Vapor Compression Cycle. Materials Proceedings. 2025; 23(1):1. https://doi.org/10.3390/materproc2025023001

Chicago/Turabian StyleTalha, Muhammad, Nawaf Mehmood Malik, Muhammad Tauseef Nasir, Waqas Khalid, Muhammad Safdar, and Khawaja Fahad Iqbal. 2025. "Working Fluid Selection for Biogas-Powered Organic Rankine Cycle-Vapor Compression Cycle" Materials Proceedings 23, no. 1: 1. https://doi.org/10.3390/materproc2025023001

APA StyleTalha, M., Malik, N. M., Nasir, M. T., Khalid, W., Safdar, M., & Iqbal, K. F. (2025). Working Fluid Selection for Biogas-Powered Organic Rankine Cycle-Vapor Compression Cycle. Materials Proceedings, 23(1), 1. https://doi.org/10.3390/materproc2025023001