1. Introduction

Productivity in operating mines is reducing due to several factors such as the decreasing ore grades [

1]. Innovations needed for the establishment of effective selective mining methods could increase productivity. Because the main driver for innovation in the mining industry is the cost reduction of the processes rather than the diversification of the final product [

2], finding funding for research and development is difficult. To compensate, companies are collaborating with universities to innovate. Prototypes like in the case of automated hauling [

3] were initially developed by organisations and pilot tests were carried out without interrupting the operation of the mine.

In situ and on-site rock characterisation during mining for ore discrimination could boost selective mining. On the one hand, this can be achieved by using portable instruments such as portable laser-induced breakdown spectroscopy (pLIBS) and portable X-ray fluorescence (pXRF). The LIBS and XRF techniques are well established for ex situ analyses of processed samples in the laboratory. Moreover, handheld instruments are widely used in the field of geological exploration [

4,

5], where ore or pathfinder phases have been discriminated in situ. The main challenge for this operation of these portable instruments regards the signal interpretation of the unprocessed in situ samples due to matrix and other effects of natural rocks. Such effects can occur from the material’s properties such as the surface roughness, porosity, and water content, both for pXRF [

4] and pLIBS [

6].

On the other hand, ore discrimination could be achieved by estimating the mineralogical composition using multispectral or hyperspectral images. In this case, the difficulty concerns the need for verification of the relationship between the ore grade and the spectral features of the minerals of the ore [

7].

On-site analysis takes place during or after the exploration or the production phase of the deposit. As advanced exploration methods, various robotic scanners [

6] for automated analysis of the extracted core exist. Elemental analysis during drilling has not been achieved; however, there are some experimental and pre-commercial products for open hole logging using XRF [

8], hyperspectral imaging, and LIBS techniques [

9].

Regarding the excavation phase, only hyperspectral imaging has been conducted in underground environments for stand-off mineralogical analysis of the rock [

10,

11], without applications in operating mines. Notably, LIBS and XRF technologies are very promising because the LIBS signal can be detected from large distances [

12], while XRF technology provides a safer option for short (cm) to very short distances (mm), making it suitable for bucket sensing [

13]. To develop operational solutions, further research is needed to overcome the challenges of whole-rock sampling.

Testing these innovative systems necessitates disruptions of mining workflows, leading to substantial financial losses. The scope of this study is to investigate the possibility of substituting natural rocks with artificial equivalents to test stand-off rock inspection prototypes. For this purpose, analogue rocks are fabricated and scanned with contactless techniques (

Figure 1a,b) to show how the different properties of the material will affect the signal of each instrument. In particular, this study’s novelty lies in the development of a custom pLIBS scanner that ensures precise instrument movement and the use of commercially available solutions to accurately measure rock properties.

2. Materials and Methods

To simulate rocks in a laterite mine, three composite blocks were created, and their properties were measured with SciAps Z-903 pLIBS (Woburn, MA, USA) and Olympus Vanta pXRF (Tokyo, Japan) mounted on 3-axis robotic motion systems (

Figure 1a,b). Additionally, measurements were acquired with Geotek’s BoxScan (Daventry, UK) using a laser profilometer and a magnetic susceptibility sensor.

The duration of a measurement with pXRF was 2 min to achieve adequate accuracy for the elements. An approximation of the volume of the measured sample can be assumed from the penetration of X-rays, which usually is up to a depth of mm in common rocks and minerals [

4], while the laser beam spot size diameter is about 500 μm. In contrast, the pLIBS can measure a large number of elements in one location within 3 s or less but the penetration depth is only about 20–50 μm and the laser beam spot size diameter is about 50 μm.

For the rock analogues, three small artificial blocks were cast and cured in room conditions from (A) fine-grained lateritic ore (Lat) and (B) limestone waste aggregates (Lim0.38, Lim2), while white cement was used as binding material. For the Lat specimen, a 4 × 4 × 16 cm3 mould was used, while for Lim0.38 and Lim2, 5 × 5 × 5 cm3 moulds were used.

In

Figure 2a, the particle size distribution is depicted, while in

Figure 2b the cement to aggregates (C/A) and water to cement (W/C) ratios are presented. The main constituents of the laterite, derived from XRD analysis, were quartz, clinochlore, hematite, goethite, and calcite. The main constituents of the limestone were calcite, dolomite, and quartz. A typical composition of the major elements of white cement is CaO (67%), SiO

2 (22%), and Al

2O

3 (4%).

Additionally, aluminium powder was added in the second and the third mixtures. Aluminium powder reacts with the Ca(OH)2 formed in the hydration of cement, and produces hydrogen gas. The gas accumulates, forming voids in the mortar, resulting in the creation of porosity within the specimen. To simulate different amounts of surface roughness, the top side of each specimen was treated with sandpaper, and, lastly, distilled water was added after curation to increase the moisture content. The final density of the laterite analogue was 2.11 g/cm3, while the limestone analogues with aluminium powder concentrations of 0.38% and 2% (cement-based) resulted in a density of 1.88 g/cm3 and 1.54 g/cm3, respectively, indicating an increased porosity in the last case.

The two sides of each specimen were scanned with the laser profilometer and the magnetic susceptibility was measured on each side. Data from portable instruments were acquired when the specimens were dry and wet, as well as on their rough and flat sides. Because of the small inspected mass and the fast acquisition of the pLIBS, consecutive measurements were acquired on a grid (100 μm step) inside an area of 500 × 500 μm2. In contrast, the XRF technique has a larger inspected mass and slow acquisition; thus, only three measurements were carried out in one location on each side.

3. Results

The maximum average depth measured with the laser profilometer for the Lim2 specimen was approximately 4 mm. This average includes not only the small-scale variations (e.g., roughness) but also large-scale variations (e.g., inclination of the surface). An improved indicator for the surface roughness is the kurtosis of the distribution along the depth profile. Rougher surfaces have kurtosis > 3, while flat surfaces have kurtosis < 3 [

14]. For the Lim2 specimen, the kurtosis values were 4.2 and 2.2 for the rough and flat surfaces, respectively.

The magnetic susceptibility values of the laterite under dry conditions were 800–1100 × 10−5 SI and under wet conditions 400–600 × 10−5 SI on both sides. The magnetic susceptibility values of the Lim0.38 specimen were slightly positive from 2 to 10 × 10−5 SI and those of the Lim2 were from −8 to −12 × 10−5 SI under dry or wet conditions.

The elemental composition was derived automatically from the internal software of the pXRF. In

Figure 3, the concentration (%) of silicon and calcium are presented for all measured specimens under different conditions (wet or dry specimens and flat or rough exposed surface). The results indicate that there was an increased apparent percentage of silicon in laterite, while in limestone the concentration of calcium was high.

The impact of the specimens’ water content on the recorded signal is obvious from the observed calcium concentrations (

Figure 3) in Lim0.38 and Lim2 specimens. The apparent concentration is reduced from 34% to 26% in Lim2 on the flat side, while in Lim0.38 it is reduced from 32% to 26% on the rough side. The impact of specimen water content on measured silicon concentration is similar.

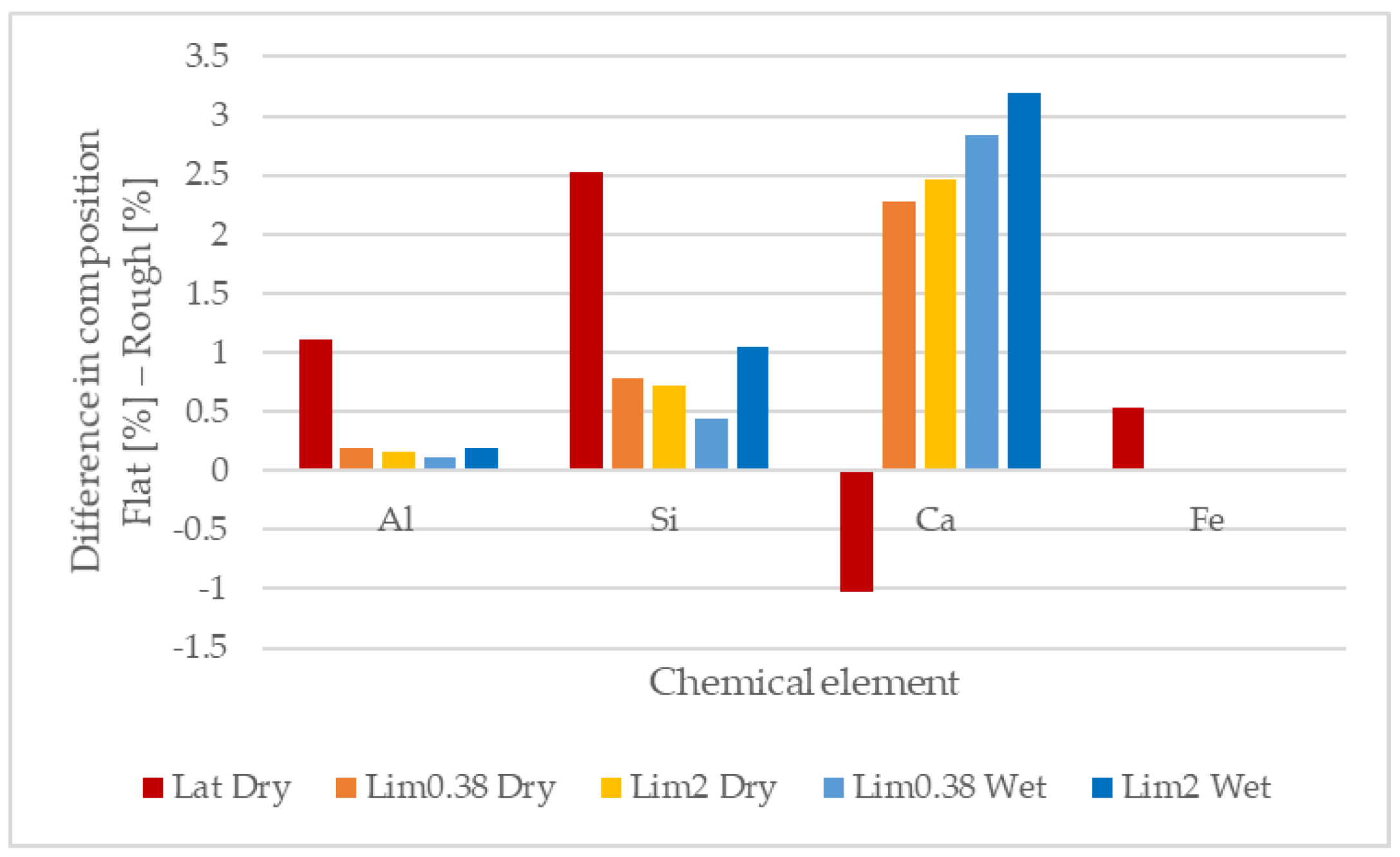

The effect of the surface roughness on the pXRF measurements is depicted in

Figure 4, where the difference in the composition of some chemical elements between the flat and rough sides are depicted. The observed calcium concentration in limestone analogues was slightly higher on the flat side. In particular, the difference in the concentrations from the flat to the rough side were, for the dry specimens, from 34% to 32% (Lim0.38) and from 33% to 30% (Lim2), while for the wet specimens they were from 29% to 26% (Lim0.38) and from 26% to 23% (Lim2). In the laterite analogue, silicon concentration was measured as 8% on the flat side and 5.5% on the rough side. In general, the rougher the surface was, the less intense the signal was for both the dry and wet specimens. An exception was the case of calcium in the laterite analogue.

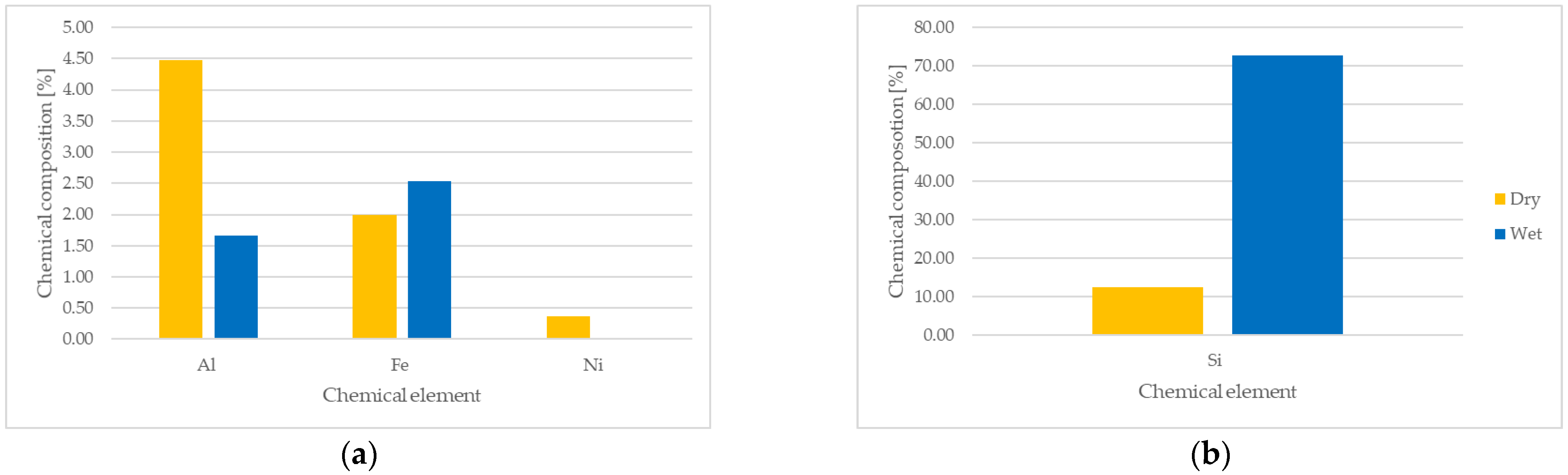

Comparing differences in the chemical composition between dry and wet conditions in the laterite specimens, acquired with the pLIBS, it is found that the increased percentage of water had a severe impact on silicon, aluminium, and nickel, while for iron the difference was not significant (

Figure 5a,b). In particular, the nickel content was under the detection limit in the wet specimen according to the interpretation software of the pLIBS instrument.

4. Discussion

In the examined specimens, the variation in their properties had a significant impact on the signal response of the majority of the used sensors. Specifically, when considering magnetic susceptibility, differences were found between the artificial laterite and limestone specimens, as well as between different artificial limestone specimens.

The results of the pXRF indicate that specimens with higher water content, higher porosity, and rougher surfaces displayed a generally lower detected concentration of calcium. Calcium can be correlated to the calcite, portlandite, calcium silicate hydrate, and calcium aluminate hydrate phases in the cured specimens.

This behaviour can be attributed to several factors, including the higher attenuation of X-rays and emitted fluorescence radiation in the presence of water and air within the material. Additionally, the scattering and diffusion of X-rays and emitted radiation on rough surfaces contribute to this outcome. Similarly, the recorded intensity in the pLIBS results was lower for the specimens with high water content due to the absorption of laser energy by water.

The diameter of the inspection spot (0.5 mm) is similar to the mean apparent diameter of the particles (

Figure 2a), for both the limestone and laterite aggregates. As a result, the inhomogeneity from the particle size distribution could affect the measurements. This effect is more significant on the measurements of the analogue laterite due to the different chemical composition of the coarser aggregates from the white cement. Additionally, the pLIBS method cannot penetrate as deep as pXRF inside the specimen; as a result, the pLIBS measurements will have larger variations. In this study, a portion of the very large difference in silicon in the laterite analogue between the dry and wet conditions (

Figure 5b) obtained with the pLIBS instrument could be attributed to local variations in the particle size distribution in the Lat specimen.

It is important to note that the acquired measurements were valuable for comparing different measuring conditions but not suitable for the accurate estimation of the elemental composition due to the lack of calibration curves for each condition. For instance, higher concentrations of calcium did not correspond to lower concentrations of other elements. This study focused on quantifying the signal response under different conditions (water saturation, porosity, and roughness) without providing precise quantification of each of these parameters. To our knowledge, no previous relative measurements have been acquired with pXRF and pLIBS scanners on analogue rocks.

5. Conclusions

In situ chemical analysis with handheld instruments is prone to matrix and other effects of the rock that emerge due to the lack of sample preparation. These characteristics make the upscaling of an innovation to industrial application difficult because extensive and costly trials are needed during the mining phase to determine the relationship between the real and the apparent values. High-precision novel motion systems were used to study this relationship, and it was found that analogue rocks with different properties could be created and used as a material for piloting contactless rock-sensing techniques. More specifically, despite the addition of the cement, specimens could retain their chemical and magnetic properties. These property differences between the ore and waste analogues remained observable. Furthermore, the calibration with laboratory techniques, the quantification of specimens’ properties, and the sampling on larger areas of the specimen could provide insights into the signal’s response, such as the usefulness of pLIBS and pXRF in mines where water is intermittently present.

Author Contributions

Conceptualisation, B.D. and M.G.; methodology, B.D. and D.V.; validation, F.M., D.V. and M.G.; formal analysis, B.D.; investigation, B.D. and D.V.; resources, D.V. and F.M.; data curation, B.D.; writing—original draft preparation, B.D.; writing—review and editing, D.V., F.M. and M.G.; visualisation, B.D. and F.M.; supervision, D.V., F.M. and M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the “Erasmus + Mobility Programme, Project Ref. number 2020-1EL01-KA103-077840” and the “Bilateral Exchange Programme between Greece & Hungary 2022, Decision Ref. number 119659/Z1 (GR), Scholarship Agreement number AK BE 2022-23/177342”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Dataset available on request from the authors.

Acknowledgments

The authors would like to thank Cornish Lithium, Geotek and their staff for providing the opportunity to take measurements with the BoxScan scanning platform.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sánchez, F.; Hartlieb, P. Innovation in the Mining Industry: Technological Trends and a Case Study of the Challenges of Disruptive Innovation. Min. Metall. Explor. 2020, 37, 1385–1399. [Google Scholar] [CrossRef]

- Calzada Olvera, B. Innovation in Mining: What Are the Challenges and Opportunities along the Value Chain for Latin American Suppliers? Miner. Econ. 2022, 35, 35–51. [Google Scholar] [CrossRef]

- Bircher, A.; Kamel, M.; Alexis, K.; Oleynikova, H.; Siegwart, R. Receding Horizon Path Planning for 3D Exploration and Surface Inspection. Auton. Robot. 2018, 42, 291–306. [Google Scholar] [CrossRef]

- Potts, P.J.; Sargent, M. In Situ Measurements Using Hand-Held XRF Spectrometers: A Tutorial Review. J. Anal. At. Spectrom. 2022, 37, 1928–1947. [Google Scholar] [CrossRef]

- Harmon, R.S.; Lawley, C.J.M.; Watts, J.; Harraden, C.L.; Somers, A.M.; Hark, R.R. Laser-Induced Breakdown Spectroscopy—An Emerging Analytical Tool for Mineral Exploration. Minerals 2019, 9, 718. [Google Scholar] [CrossRef]

- Shreeve, J.W. The Use of a Multi-Sensor Core Scanner Workflow as the Backbone of a Digital Core Repository. Geol. Soc. Lond. Spec. Publ. 2024, 527, SP527-2022-2065. [Google Scholar] [CrossRef]

- Choros, K.; Job, A.; Edgar, M.; Austin, K.; Mcaree, P. Can Hyperspectral Imaging and Neural Network Classification Be Used for Ore Grade Discrimination at the Point of Excavation? Sensors 2022, 22, 2687. [Google Scholar] [CrossRef] [PubMed]

- Hawke, P.J.; Bachmann, J. A New Blasthole XRF Probe for Mining Grade Control. ASEG Ext. Abstr. 2018, 2018, 1–5. [Google Scholar] [CrossRef]

- Jurado, M.J. The INNOLOG Project: Innovative Geophysical Logging Tools for Mineral Exploration; EIT RawMaterials: Berlin, Germany, 2020. [Google Scholar]

- Baik, H.; Son, Y.-S.; Kim, K.-E. A Tunnel Coaxial 3D Hyperspectral Scanning System for Underground Mine Investigation. Sci. Rep. 2023, 13, 10417. [Google Scholar] [CrossRef] [PubMed]

- Zajzon, N.; Topa, B.A.; Papp, R.Z.; Aaltonen, J.; Almeida, J.; Bodo, B.; Henley, S.; Pinto, M.; Zibret, G. Underwater Measurements with UX Robots; a New and Available Tool Developed by UNEXUP. Adv. Geosci. 2023, 62, 1–10. [Google Scholar] [CrossRef]

- Wan, X.; Li, C.; Wang, H.; Xu, W.; Jia, J.; Xin, Y.; Ma, H.; Fang, P.; Ling, Z. Design, Function, and Implementation of China’s First LIBS Instrument (MarSCoDe) on the Zhurong Mars Rover. At. Spectrosc. 2021, 42, 294–298. [Google Scholar] [CrossRef]

- Faraj, F.; Ortiz, J.M.; Arnal, J. Data Driven Approaches for Estimating Bulk Ore Sorting Value; Annual Report 2022; Predictive Geometallurgy and Geostatistics Lab: Kingston, ON, Canada, 2022; pp. 96–118. [Google Scholar]

- Pérez-Rey, I.; Ivars, D.M.; Alejano, L.R.; Arzúa, J. Experimental Observations and Variability Assessment of the Basic Friction Angle of Rock and Concrete Saw-Cut Surfaces under Different Testing Conditions. Arab. J. Geosci. 2022, 15, 248. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).