Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy †

Abstract

1. Introduction

2. Bibliographic Background

- Historical importance of the site;

- Commodity extracted;

- Availability of published scientific data;

- Accessibility of the site for field investigation.

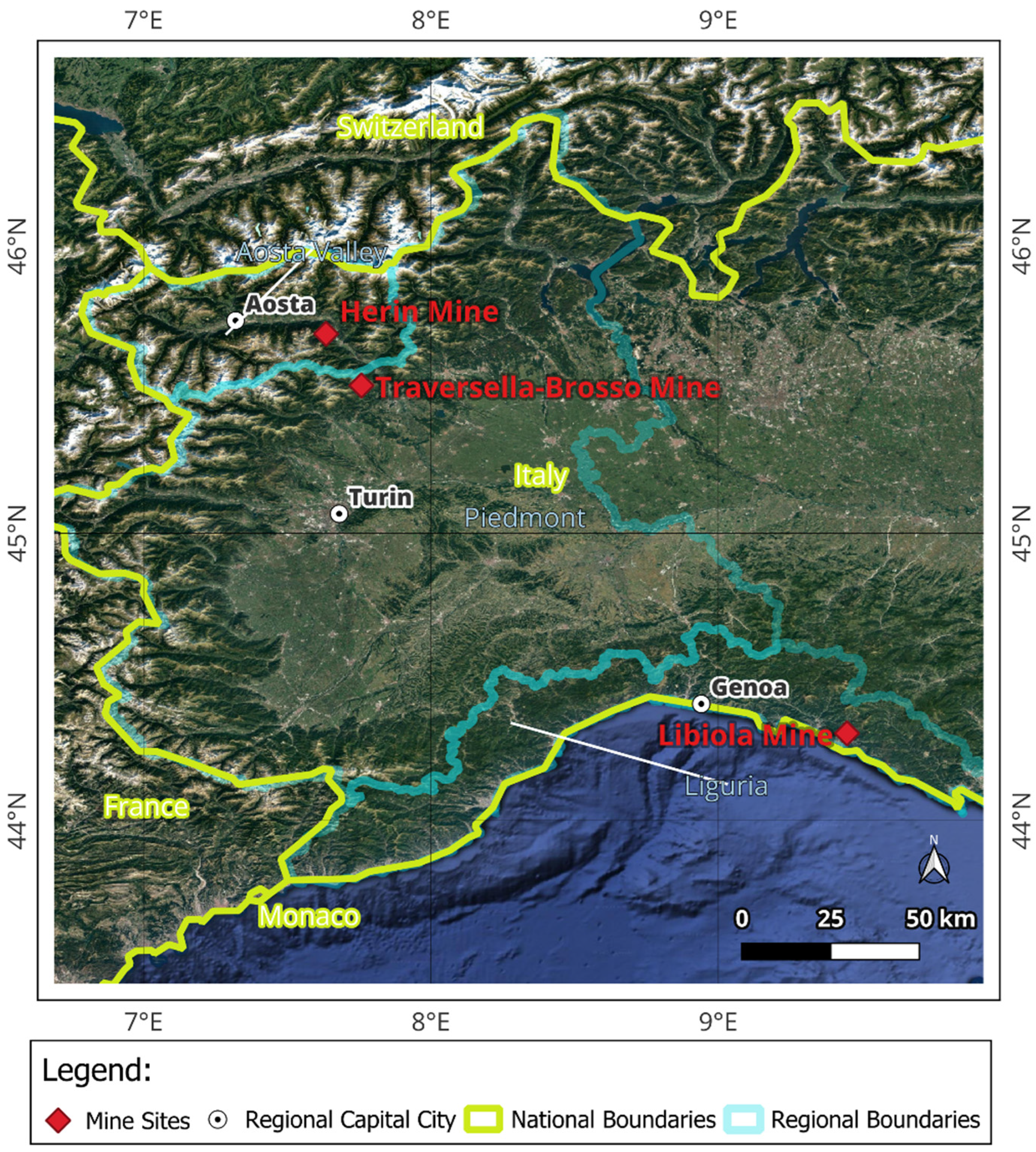

2.1. Traversella-Brosso Mine District, Piedmont

2.2. Libiola Mine, Liguria

2.3. Herin Mine, Aosta Valley

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; A Secure and Sustainable Supply of Critical Raw Materials in Support of the Twin Transition; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; A Green Deal Industrial Plan for the Net-Zero Age; European Commission: Brussels, Belgium, 2023. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions: The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Abdale, L.; Trimmer, L.M., III. The Mineral Industry of Italy. In 2017–2018 Minerals Yearbook ITALY; USGS: Reston, VA, USA, 2022; pp. 23.1–23.6. [Google Scholar]

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale. Inventario Nazionale Ai Sensi Dell’art. 20 Del D.Lgs.117/08. Available online: https://www.isprambiente.gov.it/it/banche-dati/strutture-di-deposito-di-tipo-a (accessed on 30 June 2023).

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale. d’Italia, D. per il S.G.; Research, H.I. for E.P. and Inventario nazionale delle Strutture di Deposito di Rifiuti Estrattivi, Chiuse o Abbandonate, di tipo A. Rapporto di Aggiornamento 2017. 2017. Available online: https://www.isprambiente.gov.it/files/miniere/Inventario_Aggiornamento_2017.pdf (accessed on 30 June 2023).

- ISPRA—Istituto Superiore per la Protezione e la Ricerca Ambientale; (SNPA), S.N. a Rete per la P. dell’Ambiente. Research, H.I. for E.P. and Inventario Nazionale delle Strutture di Deposito di Rifiuti Estrattivi, Chiuse o Abbandonate, di tipo A. Rapporto di Aggiornamento 2022. 2022. Available online: https://www.isprambiente.gov.it/files2023/pubblicazioni/rapporti/rapporto-inventario-strutture-deposito-rev-3782022.pdf (accessed on 30 June 2023).

- Turi, B.; Zucchetti, S. Indagine isotopica sui processi minerogenetici nel giacimento di Traversella (Torino). Geoing. Ambient. E Mineraria 1978, 15, 42–53. [Google Scholar]

- Costa, E.; Dino, G.A.; Benna, P.; Rossetti, P. The Traversella Mining Site as Piemonte Geosite. Geoheritage 2019, 11, 55–70. [Google Scholar] [CrossRef]

- Le Miniere Italiane dal 1870 al 2019. 1870–2019, I.M. Le Miniere di Ferro di Traversella e Brosso. Available online: https://sites.google.com/view/miniere-italia/regioni/piemonte/metalliferi/miniere-di-ferro-di-traversella-e-brosso (accessed on 30 June 2023).

- Matteucci, E. Tenori e distribuzione degli elementi del gruppo delle Terre rare nella Scheelite di Traversella. Symp. Internazionale Sui Giacimenti Minerari Delle Alpi 1966, 2, 689–704. [Google Scholar]

- Gruppo Mineralogico Valchiusella. La Scheelite di Traversella. 2004, Volume 1. Available online: https://drive.google.com/file/d/12BfddB_jgQJmxDyz7516QEqH-TZPlk6o/view (accessed on 30 June 2023).

- Marescotti, P.; Carbone, C.; De Capitani, L.; Grieco, G.; Lucchetti, G.; Servida, D. Mineralogical and Geochemical Characterisation of Open-Air Tailing and Waste-Rock Dumps from the Libiola Fe-Cu Sulphide Mine (Eastern Liguria, Italy). Environ. Geol. 2008, 53, 1613–1626. [Google Scholar] [CrossRef][Green Version]

- Buccheri, G.; Andras, P.; Vajda, E.; Midula, P.; Melichová, Z.; Dirner, V. Soil Contamination by Heavy Metals at Libiola Abandoned Copper Mine, Italy. Acta Montan. Slovaca 2018, 23, 337–345. [Google Scholar]

- Marini, L.; Saldi, G.; Cipolli, F.; Ottonello, G.; Vetuschi Zuccolini, M. Geochemistry of Water Discharges from the Libiola Mine, Italy. Geochem. J. 2003, 37, 199–216. [Google Scholar] [CrossRef]

- Marescotti, P.; Azzali, E.; Servida, D.; Carbone, C.; Grieco, G.; De Capitani, L.; Lucchetti, G. Mineralogical and Geochemical Spatial Analyses of a Waste-Rock Dump at the Libiola Fe–Cu Sulphide Mine (Eastern Liguria, Italy). Environ. Earth Sci. 2010, 61, 187–199. [Google Scholar] [CrossRef]

- Carbone, C.; Di Benedetto, F.; Marescotti, P.; Martinelli, A.; Sangregorio, C.; Cipriani, C.; Lucchetti, G.; Romanelli, M. Genetic Evolution of Nanocrystalline Fe Oxide and Oxyhydroxide Assemblages from the Libiola Mine (Eastern Liguria, Italy): Structural and Microstructural Investigations. Eur. J. Mineral. 2005, 17, 785–795. [Google Scholar] [CrossRef]

- Dinelli, E.; Lucchini, F.; Fabbri, M.; Cortecci, G. Metal Distribution and Environmental Problems Related to Sulfide Oxidation in the Libiola Copper Mine Area (Ligurian Apennines, Italy). J. Geochem. Explor. 2001, 74, 141–152. [Google Scholar] [CrossRef]

- Dinelli, E.; Tateo, F. Different Types of Fine-Grained Sediments Associated with Acid Mine Drainage in the Libiola Fe–Cu Mine Area (Ligurian Apennines, Italy). Appl. Geochem. 2002, 17, 1081–1092. [Google Scholar] [CrossRef]

- Fantone, I.; Grieco, G.; Strini, A.; Cavallo, A. The Effect of Alpine Metamorphism on an Oceanic Cu-Fe Sulfide Ore: The Herin Deposit, Western Alps, Italy. Period. Mineral. 2014, 83, 345–365. [Google Scholar] [CrossRef]

- Fantone, I.; Grieco, G.; Strini, A. Compositional Zoning in Pyrite as a Tool for Reconstructing the Ore Ore-Forming Processes: An example from the Abandoned Fe-Cu Sulfide Mine of Herin (Aosta Valley, Italy). Acta Mineral. Petrogr.—Abstr. Ser. 2014, 8, 29. [Google Scholar]

- Fantone, I.; Grieco, G.; Strini, A. La Miniera Di Herin: Uno Spaccato Storico E Geologico Nel Paesaggio Valdostano. 5° Convegno Geologia e Turismo; 2013. Available online: https://www.isprambiente.gov.it/public_files/geologia-e-turismo/1-FANTONE-GRIECO-poster.pdf (accessed on 30 June 2023).

- Binel, C. Appunti per una Storia della Miniera di Rame di Herin (Champdepraz, Valle d’Aosta). In Piemonte Minerario. Minerali, Storia, Ambiente del Territorio Piemontese e Valdostano; Politecnico di Torino: Torino, Italy, 1993; pp. 127–140. [Google Scholar]

| Site | Municipality, Province, Region | Reported Commodities | Information on Mining Dumps |

|---|---|---|---|

| Traversella-Brosso Mine | Traversella, Turin, Piedmont | Fe 1, W, Mo, U, REE 2 | ISPRA [6,7] |

| Brosso, Turin, Piedmont | Minor works [12] | ||

| Libiola Mine | Sestri Levante, Genoa, Liguria | Fe 3, Cu | ISPRA [6,7] |

| Marescotti et al. [13,16] | |||

| Buccheri et al. [14] | |||

| Herin Mine | Champdepraz, Aosta, Aosta Valley | Fe 3, Cu, Ni, Co | ISPRA [6] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baldassarre, G.; Fiorucci, A.; Marini, P. Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy. Mater. Proc. 2023, 15, 77. https://doi.org/10.3390/materproc2023015077

Baldassarre G, Fiorucci A, Marini P. Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy. Materials Proceedings. 2023; 15(1):77. https://doi.org/10.3390/materproc2023015077

Chicago/Turabian StyleBaldassarre, Gabriele, Adriano Fiorucci, and Paola Marini. 2023. "Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy" Materials Proceedings 15, no. 1: 77. https://doi.org/10.3390/materproc2023015077

APA StyleBaldassarre, G., Fiorucci, A., & Marini, P. (2023). Recovery of Critical Raw Materials from Abandoned Mine Wastes: Some Potential Case Studies in Northwest Italy. Materials Proceedings, 15(1), 77. https://doi.org/10.3390/materproc2023015077