Abstract

To combat the detrimental impacts of climate change and meet the obligations outlined in the 2015 Paris Agreement, Carbon Capture, Utilization, and Storage (CCUS) has emerged as a crucial technology with significant potential for achieving climate targets. CCUS involves the capture, storage, and utilization of carbon dioxide (CO2) emissions from existing energy infrastructure, hard-to-abate industries, or directly from the atmosphere, presenting a promising solution for emission reduction. However, fully harnessing the benefits of carbon storage requires the development of technically robust, safe, and cost-effective well control strategies that align with fundamental subsurface policies. This study aims to offer a comprehensive reference guide for carbon storage applications by reviewing relevant research in the field and establishing key subsurface storage policies for carbon storage in saline aquifer formation along with their practical implementation in carbon storage development plans. Additionally, we explore the utilization of optimization techniques employed thus far in the development of effective well control strategies in saline aquifers, presenting mathematical tools utilized and the achieved results.

1. Introduction

The development of carbon capture, utilization, and storage technology has gained significant attention in recent years due to escalating concerns regarding CO2 emissions and the urgent imperative to address climate change while transitioning towards a carbon-neutral future [1]. Prominent organizations such as the International Energy Agency (IEA), International Renewable Energy Agency (IRENA), Intergovernmental Panel on Climate Change (IPCC), and Bloomberg New Energy Finance (BNEF) have underscored the pivotal role of extensive CCUS deployment in their long-term energy outlooks. They emphasize the indispensable need for widespread adoption of CCUS to restrict the global temperature rise to 1.5 °C [2,3,4,5].

CCUS applications encompass three primary stages: CO2 capture, transport, and utilization/storage. Various methods are employed for CO2 capture, including post-combustion, pre-combustion, and oxy-fuel combustion. Post-combustion technology involves the separation of CO2 from flue gas using chemical solvents subsequent to fuel combustion. Pre-combustion methods entail converting fuel into a mixture of hydrogen and CO2 gas prior to combustion, thereby enabling the utilization of the remaining hydrogen-rich mixture as fuel. Oxy-fuel technology entails the combustion of fuel with pure oxygen to generate CO2 and steam, followed by CO2 capture [6]. Retrofitting post-combustion and oxy-combustion equipment into existing facilities or incorporating them into new plants is considered feasible, while pre-combustion methods necessitate more extensive modifications and are better suited for new plants [7]. Additionally, the direct capture (DC) of CO2 from the atmosphere involves the extraction of CO2 using solid sorbents or liquid solvents. However, it is more energy-intensive and costly due to the lower concentration of CO2 in the atmosphere compared to flue gas [8].

Once CO2 is captured, it is compressed and transported through pipelines, ships, railways, or road tankers. It can be directly utilized, such as serving as heat transfer fluid, or indirectly through biological and chemical processes that convert it into valuable commodities and raw materials like fuels, chemicals, or building materials [9]. Alternatively, captured CO2 can be permanently stored in deep rock formations possessing suitable geological characteristics, effectively removing it from the atmosphere [10]. Geological storage options include storage in deep saline aquifers (CO2-Saline), storage with enhanced oil recovery (CO2-EOR/CO2-EOR+), storage with enhanced gas recovery (CO2-EGR) and storage in depleted oil or gas fields (CO2-depleted fields) that are no longer economically viable in terms of oil and gas production [11,12,13,14].

To fully utilize the extensive CO2 storage capacity offered by various storage options and achieve the ambitious objectives of CCUS technology, the implementation of a robust, safe, and cost-effective well control strategy is of utmost importance. This entails addressing three critical aspects. First, accurate site characterization and a comprehensive understanding of subsurface geology are essential prerequisites, enabling the effective use of numerical reservoir simulation and modeling techniques to evaluate the dynamic behavior of CO2 under various reservoir conditions and assess the impact of different injection strategies on storage performance [15].

The second aspect involves designing a well control strategy aligned with fundamental subsurface engineering policies. These policies should encompass managing primary risks and challenges encountered during carbon storage operations, ensuring a safe and effective storage process. For example, managing pressure build-up resulting from CO2 injection is a significant risk that requires careful consideration when designing the injection schedule for a storage site. Therefore, the development plan for the storage project, particularly the CO2 injection scheduling and well control strategy, should account for this aspect. Additionally, other policies may pertain to the long-term containment of injected CO2 and the technical feasibility of integrating carbon storage with enhanced recovery applications such as enhanced oil recovery (EOR) and enhanced gas recovery (EGR).

The third aspect involves utilizing optimization tools to strike a balance among the technical subsurface policies at the field scale maximizing storage capacity without compromising site integrity. This also involves integrating techno-economic trade-offs to ensure the commercial viability of CCUS projects. Implementing subsurface engineering policies can potentially limit the effective storage capacity of a storage site. For instance, injecting CO2 into saline aquifers already occupied by incompressible fluids (brine solution) can lead to rapid pressure build-up. If uncontrolled, this may result in high pressures that could fracture the caprock or reactivate faults [16]. Controlling factors in such cases are the injection rates or wellhead pressure decrease. Furthermore, integrating additional technical policies, such as enhancing long-term containment and security, can further reduce the effective storage capacity. Therefore, the application of optimization techniques becomes necessary to mitigate this challenge and optimize overall storage performance.

By effectively addressing these three critical aspects—accurate site characterization, adherence to fundamental subsurface engineering policies, and the utilization of optimization techniques—an effective well control strategy can be developed to ensure the safe, efficient, and economically viable operation of carbon storage projects. This approach maximizes storage capacity while mitigating risks, contributing to the successful implementation of CCUS technology in achieving emission reduction goals.

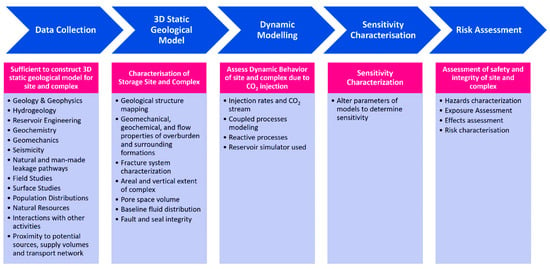

Existing studies and legal frameworks, such as the EU CCS Directive (2009/31/EC), have established robust processes for site characterization, encompassing a thorough assessment of subsurface geology, geomechanics, hydrogeology, and other pertinent factors (Figure 1). Additionally, numerical reservoir simulation and modeling techniques have demonstrated their maturity in accurately representing large-scale carbon storage reservoirs, capturing various mechanisms such as structural, dissolution, and residual trapping, as well as predicting the behavior and extent of the CO2 plume throughout different project phases, including injection, closure, and post-closure [17,18]. However, a clear definition of key technical policies for underground carbon storage operations is still lacking. To address this gap, this paper reviews carbon storage studies, with a specific focus on defining key technical policies for designing carbon storage operations, including well schedules and storage plans. It also explores computational optimization approaches used in designing carbon storage well strategies in saline aquifers, emphasizing the integration of technical policies into optimization techniques and showcasing results from designing in situ injection schedules. By bridging this gap and providing a comprehensive understanding of technical policies and optimization techniques in designing well control strategies, this research paper serves as a valuable resource for researchers, policymakers, and industry professionals, empowering them to make informed decisions and design effective carbon storage strategies.

Figure 1.

An overview of the characterization and assessment of the potential storage complex and surrounding area (reproduced, source: Guidance document 2, CCS Directive, EU 2009/31/EC).

2. Key Subsurface Policies in CO2 Geological Storage: Outline and Application

Various technical uncertainties, including storage capacity, site integrity, long-term containment, and the practical implementation of CO2 storage alongside enhanced oil and gas recovery, contribute to the shortfall in reaching required scale to achieve net zero emission. To address these challenges and uncertainties, it is crucial to establish robust technical policies and strategies for carbon storage in CCUS projects. This section focuses on discussing key technical policies related to the design and implementation of CCUS projects in saline aquifers, particularly focusing on injection and well control strategies.

2.1. Pressure Management: Controlling Pressure Build-Up and Geomechanical Complications

Geological storage capacity for CO2 is determined by the expansion of pore space in the rock formation, accompanied by the compression and decrease in volume of the originally contained fluids. Although the formation fluids can be displaced or withdrawn to accommodate additional CO2 volume, an increase in pressure within the host formation is still expected during large-scale carbon storage deployment. Therefore, the effective management of pressure build-up to avoid geomechanical complications is crucial during the injection of substantial quantities of carbon dioxide into underground structures. The response of the reservoir’s pressure primarily depends on the boundary conditions of the host formation, which can be categorized into three distinct systems: closed, semi-closed, and open.

- (1)

- Closed systems are characterized by impervious boundaries surrounding the storage formation and vertical obstruction by impermeable sealing units. These systems lack pressure bleed-off mechanisms and therefore experience a more significant impact from pressure build-up. While closed systems mitigate the risk of brine leakage during CO2 injection, it is essential to maintain pressure below the maximum threshold tolerated by the formation. This is necessary to ensure the mechanical integrity of the storage site, preventing failures in the caprock and reactivation of fractures and faults.

- (2)

- Semi-closed systems have lateral impervious boundaries and are partially sealed above and/or below by semi-permeable sealing units. These systems can effectively reduce reservoir pressurization through pressure bleed-off mechanisms. For example, brine migration into semi-sealing units and lateral displacement of brine help mitigate pressure. However, elevated pressure levels in semi-closed systems may result in brine displacement into freshwater aquifers through leaky faults and wells, posing environmental risks.

- (3)

- Open systems have lateral boundaries located at such a distance that they remain unaffected by pressure disturbances. They naturally experience less pressure build-up compared to closed and semi-closed systems [19].

Considering the pressure response of various systems, it becomes apparent that the effective storage capacity of a reservoir is determined not only by the pore volume of the formation rocks but also by the maximum allowable pressure build-up. Szulczewski et al. [20] have demonstrated that limited porosity may prevail in the long term; however, the storage system pressure constraint serves as the principal limiting factor for short-term CO2 storage. Therefore, it is crucial to effectively manage pressure build-up to mitigate geomechanical complications and ensure safe and efficient storage operations.

To comply with the pressure management policy and mitigate pressure build-up issues, researchers have proposed development schemes involving the extraction of brine from aquifers. This approach aims to increase the effective storage capacity of CO2 and control pressure build-up at saline aquifer storage sites. Studies by Court et al. [21] and Buscheck et al. [22] have demonstrated the significant advantages of brine production in controlling pressure without impacting the conformational shape of the CO2 plume. However, brine production comes with additional costs and logistical requirements. To address these challenges, Birkholzer et al. [23] have shown that it is possible to reduce the amount of brine produced during CO2 storage operations by optimizing well placement and rates. Cihan et al. [24] applied this technique to a realistic example in the Vedder Formation in California, USA, successfully optimizing the ratio of produced brine volume to the volume of injected CO2. In addition to the practical mitigation measure of brine production, researchers have also focused on optimizing well control strategies for CO2 injection schedules in saline aquifers. For example, Santibanez-Borda et al. [25] developed an optimization strategy to maximize CO2 storage while considering economic factors such as pre-tax revenues in the Cenozoic Sandstones of the Forties in the North Sea. The optimization considered the constraint that the caprock fracture pressure should not be reached at any time with results showing a 125% increase in the amount of CO2 that can be stored for a 1:1 ratio of CO2 injection to brine production.

2.2. Geological Storage Security: Improving Residual and Solubility Trapping

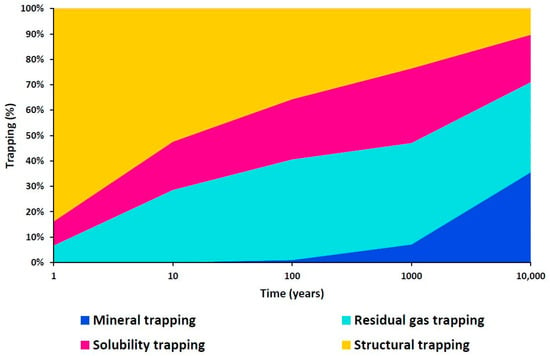

When considering the utilization of pore space for CO2 storage, the preferred state for injection is supercritical CO2 (scCO2). This is because scCO2 has a higher density compared to gaseous CO2 [26]. Meanwhile, when CO2 is injected underground, it encounters a combination of physical and chemical trapping mechanisms which are effective over different time intervals and scales (Figure 2) [26]. Most of the injected CO2 will reside in a mobile phase of CO2 known as structural trapping, resulting from the lateral free movement or vertical migration of CO2 towards the caprock. Other trapping mechanisms come into play to immobilize the CO2 afterwards within the reservoir, which are as follows [27]:

- (1)

- Residual gas trapping: encountered when formation water encroaches or invades the CO2 plume, leaving a portion of the CO2 trapped as residual gas within the pore spaces of the rock formation.

- (2)

- Solubility trapping: Achieved when CO2 partially dissolves into the aqueous phase present in the formation, leading to solubility trapping. This dissolved CO2 is unlikely to leave the solution unless there is a significant decrease in pressure.

- (3)

- Mineral trapping: Anticipated when CO2 reacts with native minerals in the rock formation, resulting in the precipitation of carbonate minerals. This process helps to immobilize CO2 in a more secure manner.

Since carbon storage’s primary purpose is to provide permanent and long-term underground CO2 storage, enhancing the long-term safety and security of underground CO2 storage necessitates a thorough evaluation of the effectiveness and security characteristics of in situ trapping mechanisms. Among these mechanisms, mineralization offers the highest level of security, albeit with a protracted timescale ranging from hundreds to thousands of years [27,28,29]. In contrast, solubility and residual trapping represent short-term and low-risk solutions for ensuring safe CO2 storage. Therefore, it is crucial to prioritize the storage of CO2 in soluble and residual forms as part of a comprehensive policy to ensure the long-term containment of injected CO2. By implementing effective management strategies, storage development plans and well control techniques that maximize the utilization of these trapping mechanisms, a significant portion of the injected CO2 can be immobilized, thereby reducing the risk of leakage from potential outlets in the formation (e.g., fractures, faults, and abandoned wells).

Figure 2.

Trapping mechanisms scale over time intervals (revised after [29]).

However, a major challenge in implementing this policy arises from the predominant upward buoyancy-driven displacement of CO2, which restricts the horizontal access of the CO2 plume to fresh brine, consequently diminishing the efficiency of solubility and residual trapping mechanisms. To address this challenge, several researchers have proposed various development plans and schemes. For instance, investigations conducted by Leonenko and Keith [30], as well as Hassanzadeh et al. [31], have explored the potential of brine injection to expedite the dissolution of CO2 in formation brines, resulting in significant improvements in storage security. These studies advocate for the application of reservoir engineering techniques, particularly optimization strategies, to enhance storage security. In turn, Shamshiri and Jafarpour [32] have applied optimization methods to the injection well control strategy, leading to improved sweep efficiency and enhanced contact between injected CO2 and in situ brine. Their findings demonstrate substantial enhancements in both residual and solubility trapping mechanisms.

3. The Optimization of Well Control Strategies for Effective CO2 Sequestration in Saline Aquifers

Optimizing the injection schedule of CO2 in deep saline aquifers poses significant engineering challenges due to multiple objectives, technical policies, and limited knowledge of geological characterization. To tackle these challenges, mathematical optimization tools are employed to guide injection planning and operations efficiently. These tools help minimize computational costs and explore a range of likely outcomes, especially in assessing long-term storage security by considering CO2 migration over hundreds of years post-operation. In this section, we review and analyze different modeling and optimization techniques employed in developing technical injection strategies for saline aquifers over the past 15 years.

Kumar [33] applied the conjugate gradient method to optimize CO2 injection strategies in a two-dimensional vertical cross-section of a heterogeneous saline aquifer. The objective function aimed to maximize residual trapped CO2 accounting for storage security engineering policy. The optimization routine led to a significant reduction in structurally trapped CO2, with a 16% reduction in CO2 saturation at the top of the aquifer compared to the base case scenario for a single well. For multiple wells, the optimized solution resulted in reduced free gas saturation and more residual trapping, highlighting the importance of optimizing both injection rates and the number of wells. Kumar also investigated the effects of the number of optimization time steps, capillary pressure, and heterogeneity, as well as the effects of the initial settings on the optimization results.

Nghiem et al. [34] explored the acceleration of residual gas and solubility trapping by injecting water above CO2 injectors. They optimized the water injector settings (depth, rate, and injection duration) maximizing an objective function that accounted for trapping efficiency index, which involved both residual and solubility trappings. Their findings showed that water injection at different depths favored different trapping mechanisms, with deeper injection favoring residual gas trapping in low-permeability aquifers and shallower injection favoring solubility trapping in high-permeability formations. In a later work, Ngheim et al. [35] conducted a study on the interaction between solubility and residual gas trapping mechanisms in CO2 injection and post-closure phases. They concluded that these mechanisms compete and occur simultaneously employing a bi-objective optimization approach and obtained Pareto-optimal solutions.

Shamshiri and Jafarpour [32] proposed a method to improve the efficiency of CO2 injection and enhance contact with in situ brine. They introduced pseudo-production wells to compute hypothetical breakthrough curves, aiming for uniform sweep efficiency. The objective function minimized differences in CO2 production rates among the pseudo-producers and delayed breakthrough time to achieve better sweep efficiency. They used the Broyden–Fletcher–Goldfarb–Shanno (BFGS) algorithm and technical policy constraints to maintain a technically sound injection schedule. The proposed method was tested on two models, demonstrating significant improvements in residual and solubility trapping. In a more recent work, the authors modified the objective function by eliminating the breakthrough term. They found that while a uniform sweep improves storage potential in the aquifer, directly maximizing stored CO2 is more effective. They observed that sweep efficiency optimization does not consider storage potential in different porosity zones, while maximizing stored gas utilizes available storage volume, regardless of sweep efficiency. Cameron and Durlofsky [36] conducted a study to minimize the long-term presence of mobile CO2 in a saline aquifer. They optimized the placement and schedule of multiple CO2 injection wells using a Hooke–Jeeves direct search (HJDS) method. The best solution achieved through the optimization showed improvements of 7% in dissolution and 5% in residual trapping. They also investigated the effect of brine cycling, finding that increasing the volume of injected brine decreased the optimized mobile CO2 fraction. Overall, their study demonstrated the effectiveness of optimizing CO2 injection to reduce mobile CO2 in a saline aquifer and highlighted the importance of considering brine cycling in CO2 storage strategies.

Zhang and Agarwal [37,38] employed a genetic algorithm-based optimizer with the TOUGH2 simulator to optimize the injection schedule for a water-alternating gas (WAG) system. Their goal was to enhance CO2 sequestration efficiency and minimize CO2 plume dispersion. They assessed WAG efficiency by measuring the reduction in CO2 plume migration relative to constant injection, normalized to the total water injection. The optimization was conducted for vertical and horizontal well configurations in hypothetical aquifer models. The optimized WAG operations achieved a 14% reduction in CO2 migration and lower gas saturation in the upper layer of the aquifer compared to constant injection. However, they acknowledged the potential risk of increased injection pressure in WAG, which could jeopardize formation integrity. To manage the elevated injection pressure, the authors extended their previous work on optimizing injection strategies for horizontal wells. They utilized the CO2 injection rate as the decision variable and the caprock pressure as a constraint. The optimization employed a modified well injectivity fitness function in conjunction with a Bezier curve to represent the time-dependent continuous function of CO2 injection rate.

Cihan et al. [24,39] developed a differential evolution algorithm to optimize well placement and brine production rates. The objective was to minimize the ratio of extracted fluid (brine) to injected fluid (CO2) while ensuring no CO2 breakthrough at production wells and avoiding pressure build-up beyond a threshold. The results showed that the gradient-free Constrained Differential Evolution (CDE) algorithm produced similar results to the gradient-based Sequential Quadratic Programming (SQP) algorithm. However, the CDE algorithm required a larger number of objective function evaluations compared to the SQP algorithm. Furthermore, coupling the CDE optimization algorithm with a numerically averaged heterogeneous aquifer model with a critically stressed fault near the injection zone demonstrated the successful estimation of optimal rates and locations for CO2 injection and brine production wells while meeting multiple pressure build-up constraints.

Tarrahi and Afra [40] extended the work of Shamshiri and Jafarpour by proposing a formulation to optimize CO2 sequestration through controlling the operating conditions of CO2 injection wells. They aimed to promote uniform CO2 dispersion in the aquifer formation. Instead of equalizing rates of pseudo-production wells, they focused on equalizing the CO2 dispersion and breakthrough time of equidistant pairs of cells from CO2 injection wells. The study showed that using a gradient-based optimization technique, the total CO2 stored in the aquifer increased by approximately 11% compared to the base case.

Babaei et al. [41] used an evolutionary optimization algorithm to determine the optimal distribution of CO2 injection rates among existing wells in heterogeneous storage complexes in the Forties and Nelson reservoirs in the North Sea. They considered both single and multiple objective functions, aiming to minimize the fraction of CO2 in a free gaseous state outside licensed regions and maximize the amount of dissolved and residual trapped CO2. The study tested different grid resolutions to find a balance between model accuracy and computation time. The results indicated that the optimization strategy using fine-scale models reduced mobile CO2 by 21% compared to the base case. In addition, coarser grid resolutions yielded acceptable errors in representing the optimal injection strategies.

Santibanez-Borda et al. [25] addressed computational challenges in optimizing CO2 storage system performance by using surrogate models instead of reservoir models. They aimed to maximize the utilization of CO2 storage capacity in the brine-saturated Forties and Nelson reservoirs in the North Sea. Different surrogate modeling techniques, including Linear Regression (LR), Regularized Linear Regression (RLR), and multivariate adaptive regression splines (MARS), were utilized. The optimization process involved the CO2 injection rates of eight injection wells and five brine production wells using the simplex method and the GRG (generalized reduced gradient) method. The results showed that LR and RLR surrogate models predicted optimal rates while meeting pressure constraints. The optimized approach increased the amount of CO2 that could be stored by 125% for a 1:1 ratio of CO2 injection to brine production, with five brine production wells producing up to 2.2 million tons/year of brine over a forty-year operating period.

4. Conclusions

The successful implementation of carbon storage operations demands a robust and cost-effective well control strategy. This involves precise site characterization, adherence to fundamental subsurface engineering policies, and the utilization of optimization techniques. While site characterization and numerical simulations are well-established, there remains a critical gap in defining technical policies for underground carbon storage. To bridge this divide, this paper proposes two essential technical policies for storage in saline aquifer formations: pressure management and storage security.

Furthermore, deep saline aquifers offer substantial CO2 storage potential, yet uncertainties surrounding capacity, containment, and policy implementation necessitate the application of optimization techniques. Given the intricacies of this challenge, traditional analytical approaches for resolving the injection schedule in the subsurface fall short. In response, a variety of methods have been explored in the literature to tackle this complexity, while upholding technical policies to arrive at a secure, technically sound, and economically viable injection schedule. This study delved into the application of optimization techniques, particularly focusing on modeling methods and their outcomes.

Our research reveals that both derivative and derivative-based optimization techniques have been deployed to address storage security concerns and long-term liability issues associated with large-scale CO2 storage in saline aquifers. It is evident that optimization techniques can enhance both residual and solubility trapping while conforming to the technical policy constraints of pressure control and geomechanical considerations. Nonetheless, there is a pressing need for further research to overcome the limitations of existing techniques and develop more robust and efficient optimization tools capable of effectively addressing uncertainties in subsurface parameters, particularly in optimizing CO2 injection schedules and well control strategies in saline aquifers.

Author Contributions

Conceptualization, I.I. and V.G.; methodology, I.I.; resources, I.I.; writing—original draft preparation, I.I.; writing—review and editing, I.I. and V.G.; visualization, I.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Hellenic Foundation for Research and Innovation (HFRI) under the 3rd Call for HFRI PhD Fellowships (fellowship number 61/513800).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained in the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jarvis, S.M.; Samsatli, S. Technologies and Infrastructures Underpinning Future CO2 Value Chains: A Comprehensive Review and Comparative Analysis. Renew. Sustain. Energy Rev. 2018, 85, 46–68. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2022; IEA: Paris, France, 2022. [Google Scholar]

- Intergovernmental Panel on Climate Change. Prepared by Working Group III. In Climate Change 2022, Mitigation of Climate Change; IPCC: Cambridge, UK, 2021. [Google Scholar]

- International Renewable Energy Agency. World Energy Transitions Outlook 2023: 1.5 °C Pathway; IRENA: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Bloomberg New Energy Finance. New Energy Outlook 2022; Bloomberg: New York, NY, USA, 2022. [Google Scholar]

- Madejski, P.; Chmiel, K.; Subramanian, N.; Kuś, T. Methods and Techniques for CO2 Capture: Review of Potential Solutions and Applications in Modern Energy Technologies. Energies 2022, 15, 887. [Google Scholar] [CrossRef]

- Kheirinik, M.; Ahmed, S.; Rahmanian, N. Comparative Techno-Economic Analysis of Carbon Capture Processes: Pre-Combustion, Post-Combustion, and Oxy-Fuel Combustion Operations. Sustainability 2021, 13, 13567. [Google Scholar] [CrossRef]

- Wang, X.; Song, C. Carbon Capture From Flue Gas and the Atmosphere: A Perspective. Front. Energy Res. 2020, 8, 560849. [Google Scholar] [CrossRef]

- Ghiat, I.; Al-Ansari, T. A Review of Carbon Capture and Utilisation as a CO2 Abatement Opportunity within the EWF Nexus. J. CO2 Util. 2021, 45, 101432. [Google Scholar] [CrossRef]

- Rackley, S.A. Introduction to Geological Storage. In Carbon Capture and Storage; Elsevier: Amsterdam, The Netherlands, 2017; pp. 285–304. [Google Scholar] [CrossRef]

- Ji, X.; Zhu, C. CO2 Storage in Deep Saline Aquifers. In Novel Materials for Carbon Dioxide Mitigation Technology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 299–332. [Google Scholar] [CrossRef]

- Mohammadian, E.; Mohamed Jan, B.; Azdarpour, A.; Hamidi, H.; Hidayati Binti Othman, N.; Dollah, A.; Nurliyana Binti Che Mohamed Hussein, S.; Azrina Binti Sazali, R. CO2—EOR/Sequestration: Current Trends and Future Horizons. In Enhanced Oil Recovery Processes—New Technologies; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Liu, S.-Y.; Ren, B.; Li, H.-Y.; Yang, Y.-Z.; Wang, Z.-Q.; Wang, B.; Xu, J.-C.; Agarwal, R. CO2 Storage with Enhanced Gas Recovery (CSEGR): A Review of Experimental and Numerical Studies. Pet. Sci. 2022, 19, 594–607. [Google Scholar] [CrossRef]

- Hannis, S.; Lu, J.; Chadwick, A.; Hovorka, S.; Kirk, K.; Romanak, K.; Pearce, J. CO2 Storage in Depleted or Depleting Oil and Gas Fields: What Can We Learn from Existing Projects? Energy Procedia 2017, 114, 5680–5690. [Google Scholar] [CrossRef]

- Nepveu, M.; Neele, F.; Delprat-Jannaud, F.; Akhurst, M.; Vincké, O.; Volpi, V.; Lothe, A.; Brunsting, S.; Pearce, J.; Battani, A.; et al. CO2 Storage Feasibility: A Workflow for Site Characterisation. Oil Gas Sci. Technol.—Rev. D’ifp Energ. Nouv. 2015, 70, 555–566. [Google Scholar] [CrossRef]

- Rutqvist, J.; Birkholzer, J.T.; Tsang, C.-F. Coupled Reservoir–Geomechanical Analysis of the Potential for Tensile and Shear Failure Associated with CO2 Injection in Multilayered Reservoir–Caprock Systems. Int. J. Rock Mech. Min. Sci. 2008, 45, 132–143. [Google Scholar] [CrossRef]

- Singh, V.; Cavanagh, A.; Hansen, H.; Nazarian, B.; Iding, M.; Ringrose, P. Reservoir Modeling of CO2 Plume Behavior Calibrated Against Monitoring Data From Sleipner, Norway. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- Dai, Z.; Xu, L.; Xiao, T.; McPherson, B.; Zhang, X.; Zheng, L.; Dong, S.; Yang, Z.; Soltanian, M.R.; Yang, C.; et al. Reactive Chemical Transport Simulations of Geologic Carbon Sequestration: Methods and Applications. Earth Sci. Rev. 2020, 208, 103265. [Google Scholar] [CrossRef]

- Zhou, Q.; Birkholzer, J.T.; Tsang, C.-F.; Rutqvist, J. A Method for Quick Assessment of CO2 Storage Capacity in Closed and Semi-Closed Saline Formations. Int. J. Greenh. Gas Control 2008, 2, 626–639. [Google Scholar] [CrossRef]

- Szulczewski, M.L.; MacMinn, C.W.; Juanes, R. How Pressure Buildup and CO2 Migration Can Both Constrain Storage Capacity in Deep Saline Aquifers. Energy Procedia 2011, 4, 4889–4896. [Google Scholar] [CrossRef]

- Court, B.; Bandilla, K.W.; Celia, M.A.; Buscheck, T.A.; Nordbotten, J.M.; Dobossy, M.; Janzen, A. Initial Evaluation of Advantageous Synergies Associated with Simultaneous Brine Production and CO2 Geological Sequestration. Int. J. Greenh. Gas Control. 2012, 8, 90–100. [Google Scholar] [CrossRef]

- Buscheck, T.A.; Sun, Y.; Hao, Y.; Wolery, T.J.; Bourcier, W.; Tompson, A.F.B.; Jones, E.D.; Julio Friedmann, S.; Aines, R.D. Combining Brine Extraction, Desalination, and Residual-Brine Reinjection with CO2 Storage in Saline Formations: Implications for Pressure Management, Capacity, and Risk Mitigation. Energy Procedia 2011, 4, 4283–4290. [Google Scholar] [CrossRef]

- Birkholzer, J.T.; Cihan, A.; Zhou, Q. Impact-Driven Pressure Management via Targeted Brine Extraction—Conceptual Studies of CO2 Storage in Saline Formations. Int. J. Greenh. Gas Control 2012, 7, 168–180. [Google Scholar] [CrossRef]

- Cihan, A.; Birkholzer, J.T.; Bianchi, M. Optimal Well Placement and Brine Extraction for Pressure Management during CO2 Sequestration. Int. J. Greenh. Gas Control 2015, 42, 175–187. [Google Scholar] [CrossRef]

- Santibanez-Borda, E.; Govindan, R.; Elahi, N.; Korre, A.; Durucan, S. Maximising the Dynamic CO2 Storage Capacity through the Optimisation of CO2 Injection and Brine Production Rates. Int. J. Greenh. Gas Control 2019, 80, 76–95. [Google Scholar] [CrossRef]

- Doughty, C.; Pruess, K. Modeling Supercritical Carbon Dioxide Injection in Heterogeneous Porous Media. Vadose Zone J. 2004, 3, 837–847. [Google Scholar] [CrossRef]

- Al Hameli, F.; Belhaj, H.; Al Dhuhoori, M. CO2 Sequestration Overview in Geological Formations: Trapping Mechanisms Matrix Assessment. Energies 2022, 15, 7805. [Google Scholar] [CrossRef]

- La Plante, E.C.; Mehdipour, I.; Shortt, I.; Yang, K.; Simonetti, D.; Bauchy, M.; Sant, G.N. Controls on CO2 Mineralization Using Natural and Industrial Alkaline Solids under Ambient Conditions. ACS Sustain. Chem. Eng. 2021, 9, 10727–10739. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Prepared by Working Group III. In Special Report on Carbon Dioxide Capture and Storage; IPCC; Working Group III: Cambridge, UK, 2005. [Google Scholar]

- Leonenko, Y.; Keith, D.W. Reservoir Engineering To Accelerate the Dissolution of CO2 Stored in Aquifers. Env. Sci. Technol. 2008, 42, 2742–2747. [Google Scholar] [CrossRef] [PubMed]

- Hassanzadeh, H.; Pooladi-Darvish, M.; Keith, D.W. Accelerating CO2 Dissolution in Saline Aquifers for Geological Storage—Mechanistic and Sensitivity Studies. Energy Fuels 2009, 23, 3328–3336. [Google Scholar] [CrossRef]

- Shamshiri, H.; Jafarpour, B. Optimization of Geologic CO2 Storage in Heterogeneous Aquifers Through Improved Sweep Efficiency. In Proceedings of the SPE International Conference on CO2 Capture, Storage, and Utilization, New Orleans, LA, USA, 10–12 November 2010. [Google Scholar] [CrossRef]

- Kumar, D. Optimization of Well Settings to Maximize Residually Trapped CO2 in Geologic Carbon Sequestration; Stanford University: Stanford, CA, USA, 2007. [Google Scholar]

- Nghiem, L.; Yang, C.; Shrivastava, V.; Kohse, B.; Hassam, M.; Chen, D.; Card, C. Optimization of Residual Gas and Solubility Trapping for CO2 Storage in Saline Aquifers. In Proceedings of the SPE Reservoir Simulation Symposium, The Woodlands, TX, USA, 2–4 February 2009. [Google Scholar] [CrossRef]

- Nghiem, L.; Shrivastava, V.; Kohse, B.; Hassam, M.; Yang, C. Simulation and Optimization of Trapping Processes for CO2 Storage in Saline Aquifers. J. Can. Pet. Technol. 2010, 49, 15–22. [Google Scholar] [CrossRef]

- Cameron, D.A.; Durlofsky, L.J. Optimization of Well Placement, CO2 Injection Rates, and Brine Cycling for Geological Carbon Sequestration. Int. J. Greenh. Gas Control. 2012, 10, 100–112. [Google Scholar] [CrossRef]

- Zhang, Z.; Agarwal, R.K. Numerical Simulation and Optimization of CO2 Sequestration in Saline Aquifers for Vertical and Horizontal Well Injection. Comput. Geosci. 2012, 16, 891–899. [Google Scholar] [CrossRef]

- Zhang, Z.; Agarwal, R. Numerical Simulation and Optimization of CO2 Sequestration in Saline Aquifers. Comput. Fluids 2013, 80, 79–87. [Google Scholar] [CrossRef]

- Cihan, A.; Birkholzer, J.; Bianchi, M. Targeted Pressure Management During CO2 Sequestration: Optimization of Well Placement and Brine Extraction. Energy Procedia 2014, 63, 5325–5332. [Google Scholar] [CrossRef]

- Tarrahi, M.; Afra, S. Optimization of Geological Carbon Sequestration in Heterogeneous Saline Aquifers through Managed Injection for Uniform CO2 Distribution. In Proceedings of the Carbon Management Technology Conference, Sugar Land, TX, USA, 17–19 November 2015. [Google Scholar] [CrossRef]

- Babaei, M.; Pan, I.; Korre, A.; Shi, J.-Q.; Govindan, R.; Durucan, S.; Quinn, M. CO2 Storage Well Rate Optimisation in the Forties Sandstone of the Forties and Nelson Reservoirs Using Evolutionary Algorithms and Upscaled Geological Models. Int. J. Greenh. Gas Control. 2016, 50, 1–13. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).