Optimizing Geothermal Energy Extraction in CO2 Plume Geothermal Systems †

Abstract

:1. Introduction

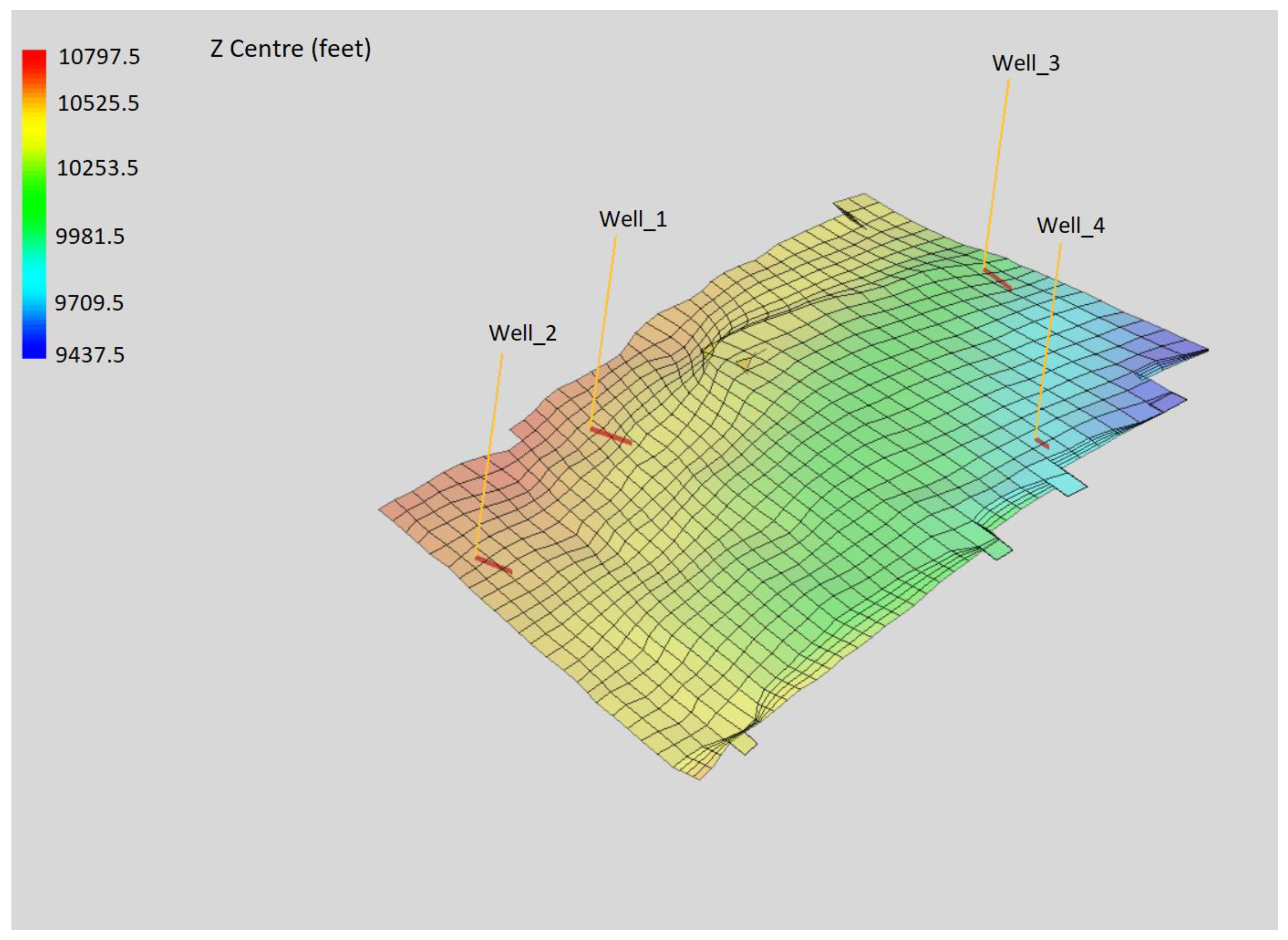

2. Model Description

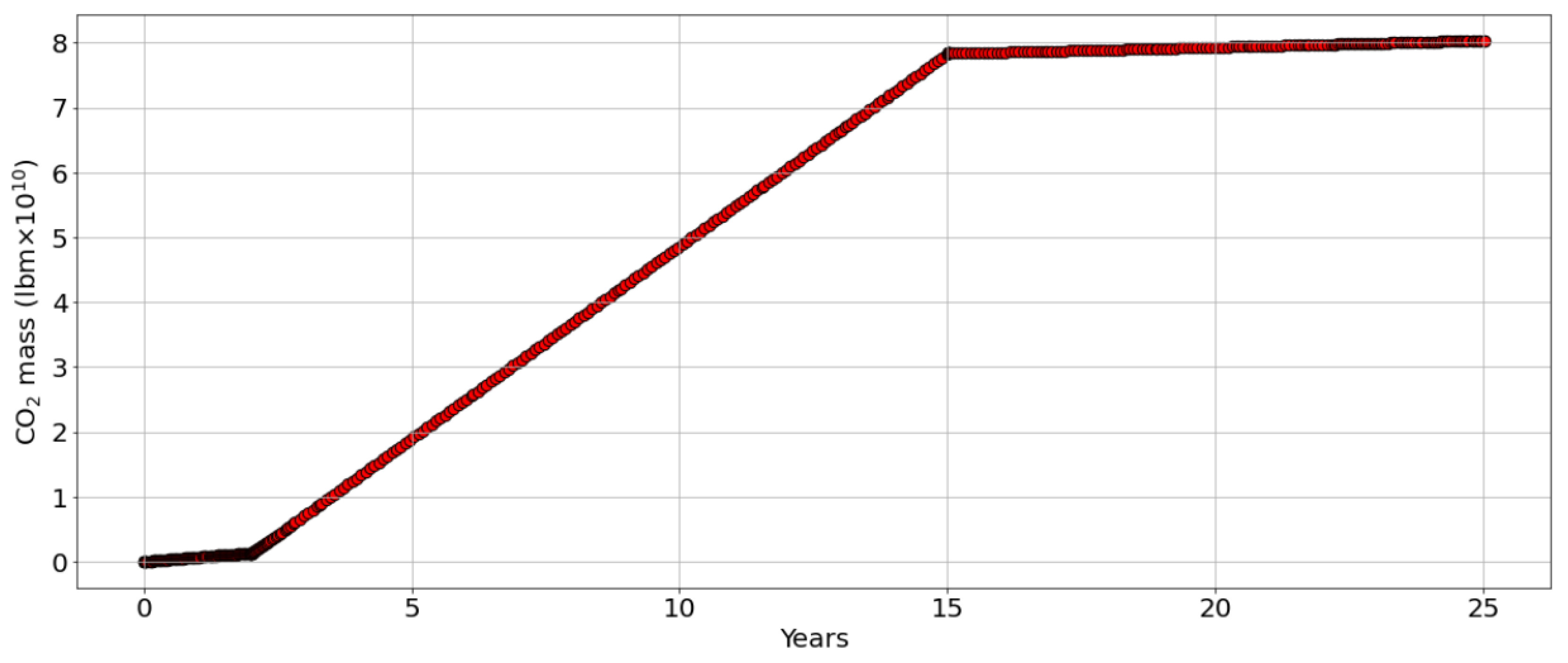

3. Schedule

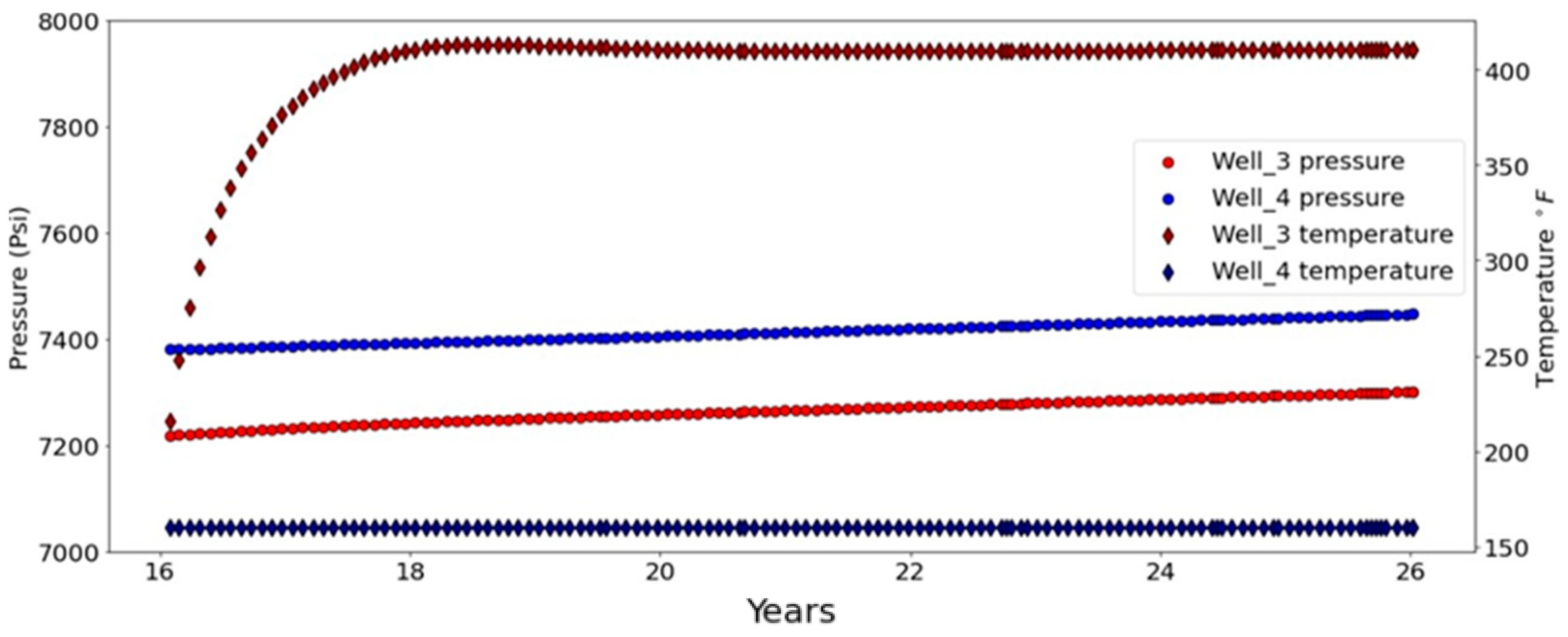

4. Discussion/Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DiPippo, R. Geothermal Power Plants: Principles, Applications, Case Studies and Environmental Impact; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Fytikas, M. Updating of the geological and geothermal research on Milos island. Geothermics 1989, 18, 485–496. [Google Scholar] [CrossRef]

- Mendrinos, D.; Choropanitis, I.; Polyzou, O.; Karytsas, C. Exploring for geothermal resources in Greece. Geothermics 2010, 39, 124–137. [Google Scholar] [CrossRef]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A systematic review of enhanced (or engineered) geothermal systems: Past, present and future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef]

- Brown, D.W. A hot dry rock geothermal energy concept utilizing supercritical CO2 instead of water. In Proceedings of the Twenty-Fifth Workshop on Geothermal Reservoir Engineering, Stanford University, Stanford, CA, USA, 24–26 January 2000; pp. 233–238. [Google Scholar]

- Randolph, J.B.; Saar, M.O. Combining geothermal energy capture with geologic carbon dioxide sequestration. Geophys. Res. Lett. 2011, 38. [Google Scholar] [CrossRef]

- Randolph, J.B.; Saar, M.O. Coupling carbon dioxide sequestration with geothermal energy capture in naturally permeable, porous geologic formations: Implications for CO2 sequestration. Energy Procedia 2011, 4, 2206–2213. [Google Scholar] [CrossRef]

- Adams, B.M.; Kuehn, T.H.; Bielicki, J.M.; Randolph, J.B.; Saar, M.O. A comparison of electric power output of CO2 Plume Geothermal (CPG) and brine geothermal systems for varying reservoir conditions. Appl. Energy 2015, 140, 365–377. [Google Scholar] [CrossRef]

- Langenfeld, J.K.; Bielicki, J.M. Assessment of sites for CO2 storage and CO2 capture, utilization, and storage systems in geothermal reservoirs. Energy Procedia 2017, 114, 7009–7017. [Google Scholar] [CrossRef]

- Freifeld, B.; Zakim, S.; Pan, L.; Cutright, B.; Sheu, M.; Doughty, C.; Held, T. Geothermal energy production coupled with CCS: A field demonstration at the SECARB Cranfield Site, Cranfield, Mississippi, USA. Energy Procedia 2013, 37, 6595–6603. [Google Scholar] [CrossRef]

- Miranda-Barbosa, E.; Sigfússon, B.; Carlsson, J.; Tzimas, E. Advantages from combining CCS with geothermal energy. Energy Procedia 2017, 114, 6666–6676. [Google Scholar] [CrossRef]

- Global CCS Institute. Global CCS Institute 2022 Status Report. 2022. Available online: https://status22.globalccsinstitute.com/2022-status-report/introduction/ (accessed on 14 June 2023).

- Lau, H.C.; Ramakrishna, S.; Zhang, K.; Radhamani, A.V. The role of carbon capture and storage in the energy transition. Energy Fuels 2021, 35, 7364–7386. [Google Scholar] [CrossRef]

- Gravanis, E.; Sarris, E. A working model for estimating CO2-induced uplift of cap rocks under different flow regimes in CO2 sequestration. Geomech. Energy Environ. 2023, 33, 100433. [Google Scholar] [CrossRef]

- Sarris, E.; Gravanis, E. Flow regime analysis of the pressure build-up during CO2 injection in saturated porous rock formations. Energies 2019, 12, 2972. [Google Scholar] [CrossRef]

- Ernestos, S.; Elias, G.; Panos, P. Investigation of self-similar interface evolution in carbon dioxide sequestration in saline aquifers. Transp. Porous Media 2014, 103, 341–359. [Google Scholar] [CrossRef]

- Petroleum Experts. IPM Suite, Version 13, [Software]; PE Limited: Edinburgh, UK, 2022. Available online: https://www.petex.com/products (accessed on 14 June 2023).

- Bell, I.H.; Wronski, J.; Quoilin, S.; Lemort, V. Pure and Pseudo-pure Fluid Thermophysical Property Evaluation and the Open Source Thermophysical Property Library CoolProp. Ind. Eng. Chem. Res. 2014, 53, 2498–2508. [Google Scholar] [CrossRef] [PubMed]

| Property | Name | Symbol | SI Conversion |

|---|---|---|---|

| pressure | pounds per square inch | Psi | 6894.76 Pa |

| temperature | Fahrenheit | °F | (K − 273.15) · 9/5 |

| depth | feet | ft | 0.348 m |

| permeability | milliDarcy | mD | 10−15 m2 |

| CO2 volume | (standard) cubic feet | (s)cf | 0.028 m3 |

| liquid volume | stock tank barrel | STB | 0.16 m3 |

| mass | pounds | lbm | 0.45 kg |

| specific enthalpy | British thermal unit per pound mass | BTU/lbm | 2326 J/kg |

| mass flow rate | pound mass per minute | 0.0076 kg/s | |

| energy | British thermal unit | BTU | 1055 J |

| one thousand | M | ||

| one million | MM | ||

| one billion | MMM |

| Parameter | Value | Units |

|---|---|---|

| Average Pressure (P) | 3800 | Psi |

| Temperature (T) | 500 | °F |

| Porosity (ϕ) | 0.2 | |

| Average depth (D) | 10, 180 | ft |

| Permeability (k) | 300 | mD |

| Bulk Volume (V) | 3.5 · 1011 | cf |

| Water in place | 1.1 · 1010 | STB |

| Thickness | 41.6 | ft |

| Well | Phase A | Phase B | Phase C |

|---|---|---|---|

| Well_1 | (P) 5000 STB/day | - | - |

| Well_2 | (P) 5000 STB/day | - | - |

| Well_3 | (I) 8 MMscf/day | (I) 70 MMscf/day | (P) 125 MMscf/day |

| Well_4 | (I) 8 MMscf/day | (I) 70 MMscf/day | (I) 130 MMscf/day |

| Well | Phase A | Phase B | Phase C |

|---|---|---|---|

| Well_1 | (P) 290 Mtonnes/year | - | - |

| Well_2 | (P) 290 Mtonnes/year | - | - |

| Well_3 | (I) 154 Mtonnes/year | (I) 1.3 MMtonnes/year | (P) 2.4 MMtonnes/year |

| Well_4 | (I) 154 Mtonnes/year | (I) 1.3 MMtonnes/year | (I) 2.5 MMtonnes/year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fotias, S.P.; Bellas, S.; Gaganis, V. Optimizing Geothermal Energy Extraction in CO2 Plume Geothermal Systems. Mater. Proc. 2023, 15, 52. https://doi.org/10.3390/materproc2023015052

Fotias SP, Bellas S, Gaganis V. Optimizing Geothermal Energy Extraction in CO2 Plume Geothermal Systems. Materials Proceedings. 2023; 15(1):52. https://doi.org/10.3390/materproc2023015052

Chicago/Turabian StyleFotias, Sofianos Panagiotis, Spyridon Bellas, and Vassilis Gaganis. 2023. "Optimizing Geothermal Energy Extraction in CO2 Plume Geothermal Systems" Materials Proceedings 15, no. 1: 52. https://doi.org/10.3390/materproc2023015052

APA StyleFotias, S. P., Bellas, S., & Gaganis, V. (2023). Optimizing Geothermal Energy Extraction in CO2 Plume Geothermal Systems. Materials Proceedings, 15(1), 52. https://doi.org/10.3390/materproc2023015052