An Assessment of Hand-Held XRF Analyser Performance for the Characterisation of Aluminium Scrap †

Abstract

:1. Introduction

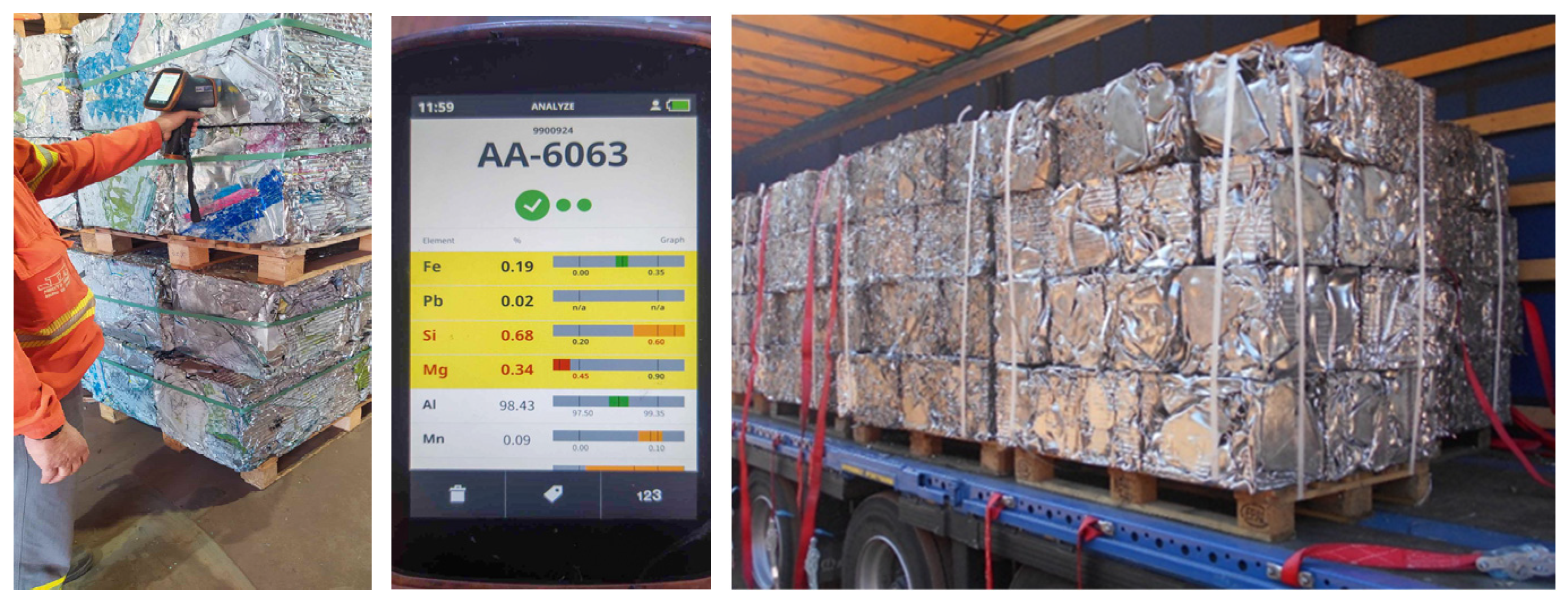

2. Materials and Methods

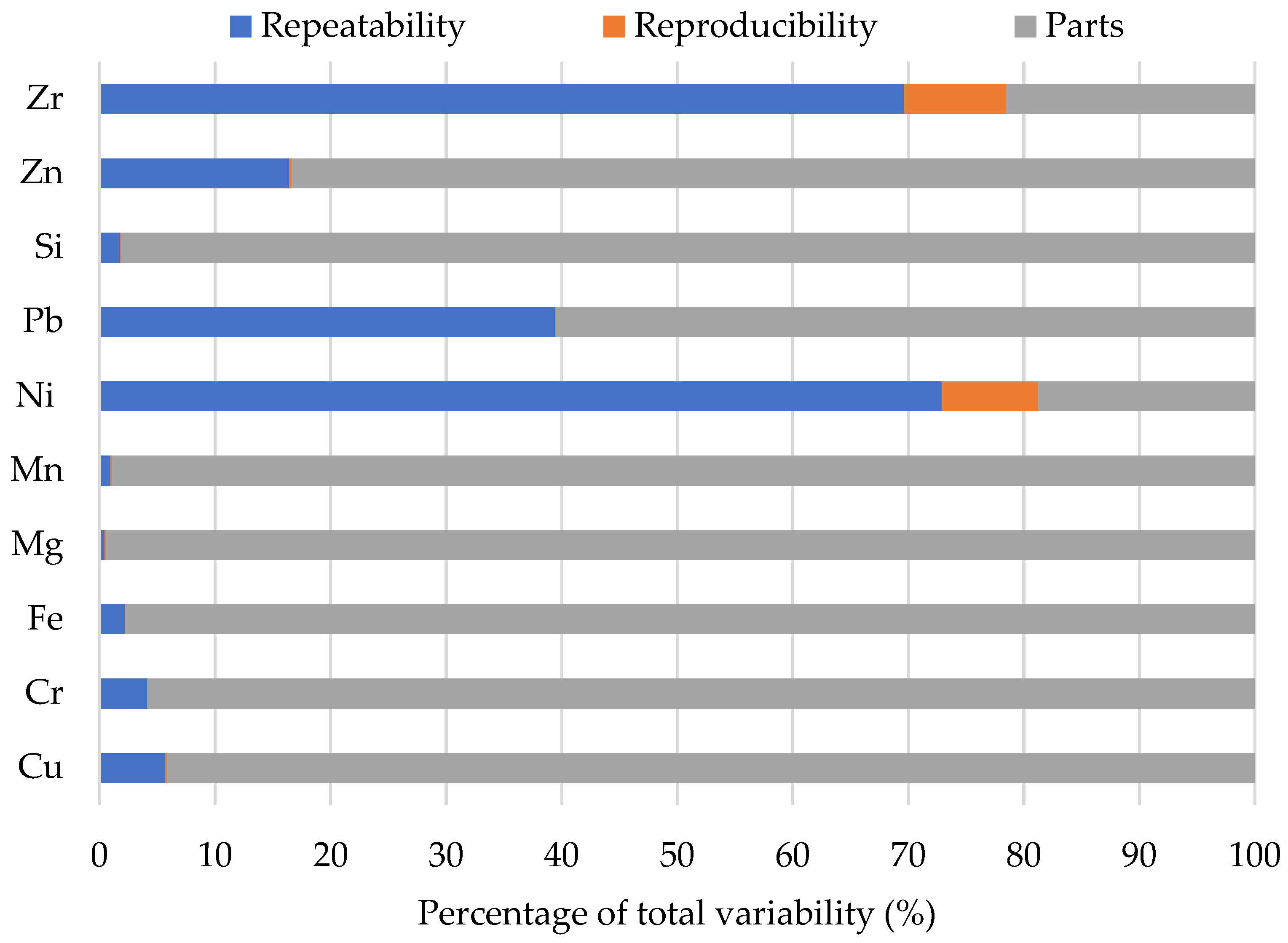

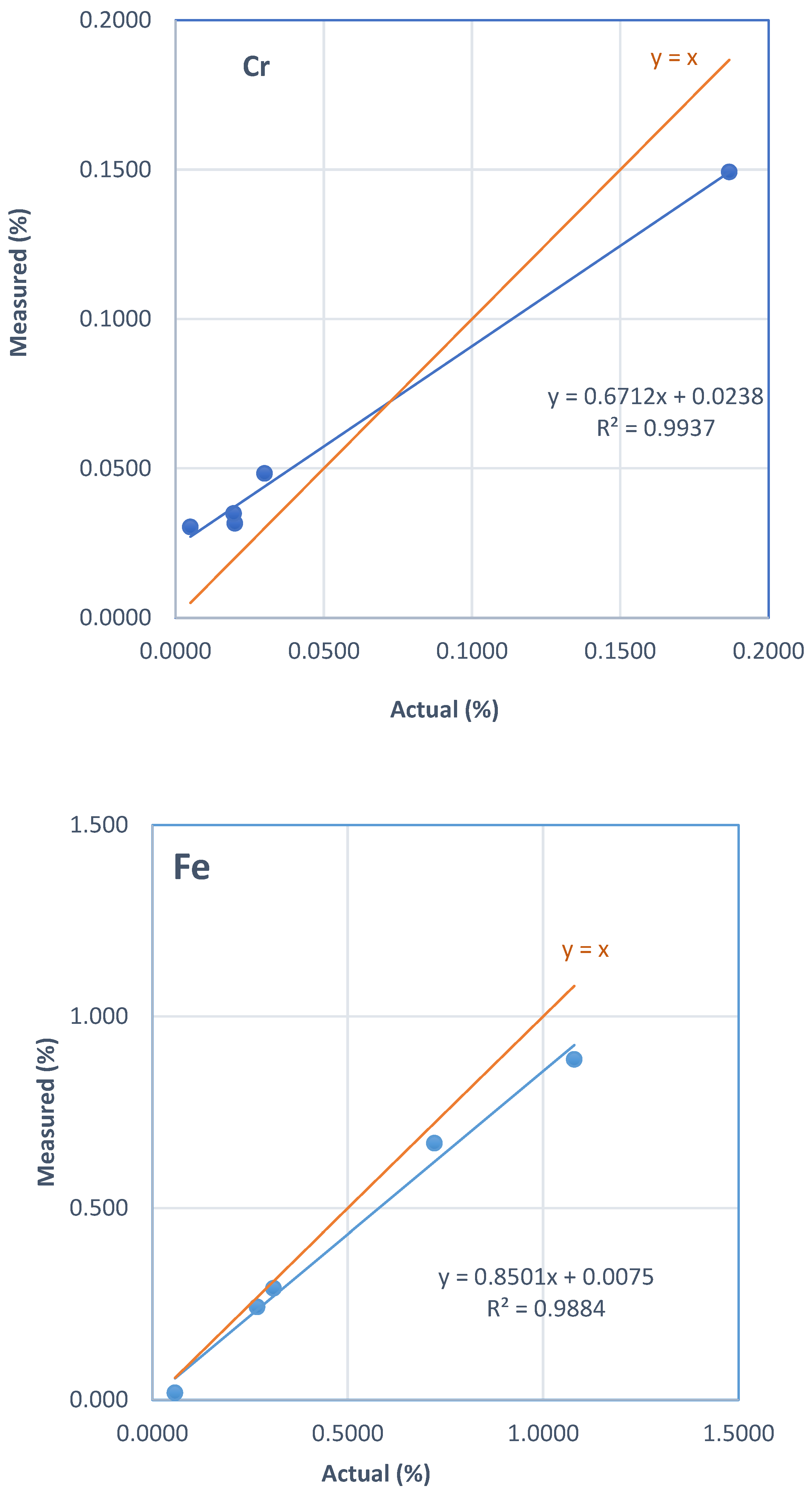

3. Results and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Capuzzi, S.; Timelli, G. Preparation and melting of scrap in aluminum recycling: A review. Metals 2018, 8, 249. [Google Scholar] [CrossRef]

- Chandra, M.J. Statistical Quality Control, 1st ed.; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Lemiere, B.A. Review of pXRF (field portable X-ray fluorescence) applications for applied geochemistry. J. Geochem. Explor. 2018, 188, 350–363. [Google Scholar] [CrossRef]

- Peruchi, R.; Balestrassi, P.; Paiva, A.; Ferreira, J.; Carmelossi, M. A new multivariate gage R&R method for correlated characteristics. Int. J. Prod. Econ. 2013, 144, 301–315. [Google Scholar]

- Hessing, T. Gage Repeatability and Reproducibility (R&R). 2016. Available online: https://sixsigmastudyguide.com (accessed on 10 June 2023).

- Hoffa, D.; Laux, C. Gauge R&R: An Effective Methodology for Determining the Adequacy of a New Measurement System for Micron-level Metrology. J. Ind. Technol. 2007, 23, 1–9. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ntourntoureka, A.; Galetakis, M.; Deligiorgis, V. An Assessment of Hand-Held XRF Analyser Performance for the Characterisation of Aluminium Scrap. Mater. Proc. 2023, 15, 25. https://doi.org/10.3390/materproc2023015025

Ntourntoureka A, Galetakis M, Deligiorgis V. An Assessment of Hand-Held XRF Analyser Performance for the Characterisation of Aluminium Scrap. Materials Proceedings. 2023; 15(1):25. https://doi.org/10.3390/materproc2023015025

Chicago/Turabian StyleNtourntoureka, Angeliki, Michail Galetakis, and Vasileios Deligiorgis. 2023. "An Assessment of Hand-Held XRF Analyser Performance for the Characterisation of Aluminium Scrap" Materials Proceedings 15, no. 1: 25. https://doi.org/10.3390/materproc2023015025

APA StyleNtourntoureka, A., Galetakis, M., & Deligiorgis, V. (2023). An Assessment of Hand-Held XRF Analyser Performance for the Characterisation of Aluminium Scrap. Materials Proceedings, 15(1), 25. https://doi.org/10.3390/materproc2023015025