1. Introduction

Tailings storage facilities (TSFs) are crucial components of the mining industry, serving as repositories for waste materials generated during mineral extraction processes. However, the inherent risks associated with TSF structures and the devastating consequences of previous failures, such as the Stava disaster [

1] and the Brumadinho dam collapse [

2], have highlighted the urgent need for comprehensive safety measures. In response to these challenges, the SEC4TD project [

3] was initiated to leverage a model-based system engineering approach [

4,

5], enabling efficient and effective analysis to enhance TSF safety.

TSFs are recognized as high-risk structures due to their complex design and potential environmental and societal impact in the event of failure. The SEC4TD project was launched with the primary objective of increasing safety in TSFs to address these risks. This innovative project harnesses the power of model-based system engineering, which involves the data gathering, analysis, and creation of computational models to facilitate efficient and insightful analysis of TSF structures.

The SEC4TD project aims to develop a state-of-the-art system that integrates various data sources and computational models to enhance the understanding and management of TSFs. One key component of the project is the integration of in-field sensors, including the GNSS displacement sensor. This sensor plays a crucial role in monitoring TSF structures by continuously measuring any displacements or movements that may indicate potential instabilities or undesired events.

2. SEC4TD Project

The SEC4TD project is driven by the overarching goal of developing and validating an innovative solution to significantly enhance the safety of tailings storage facilities (TSFs). This solution is based on the integration of Internet of Things (IoT) low-power devices and the Model-Based System Engineering (MBSE) system. Together, these components enable the gathering, analysis, and utilization of data for informed decision-making processes, thereby improving overall TSF safety.

The project focuses on three primary areas: the development of IoT sensors, numerical modeling based on the Finite Element Method (FEM), and the integration of data and computational systems.

Notably, the solution developed within the SEC4TD project is designed to be adaptable and applicable to TSFs worldwide. Its flexibility allows seamless integration into existing TSFs, regardless of their geographical location or specific design. This global approach ensures that the developed solution has the potential to enhance TSF safety on a broad scale.

In addition to the technical aspects, the SEC4TD project also aims to develop a commercialization strategy for the solution. The project seeks to create a comprehensive strategy for the implementation and widespread adoption of the developed solution by considering factors such as market demand, stakeholder engagement, and scalability.

3. Model Based-System Engineering

In the field of tailings storage facilities (TSFs), ensuring safety, reliability, and efficiency is of paramount importance. The adoption of a model-based systems engineering (MBSE) approach [

6] has emerged as a valuable methodology for designing, analyzing, and managing complex TSFs throughout their lifecycle. This section explores the significance of the MBSE approach and its application [

7,

8] in enhancing the understanding, design, and operation of TSFs.

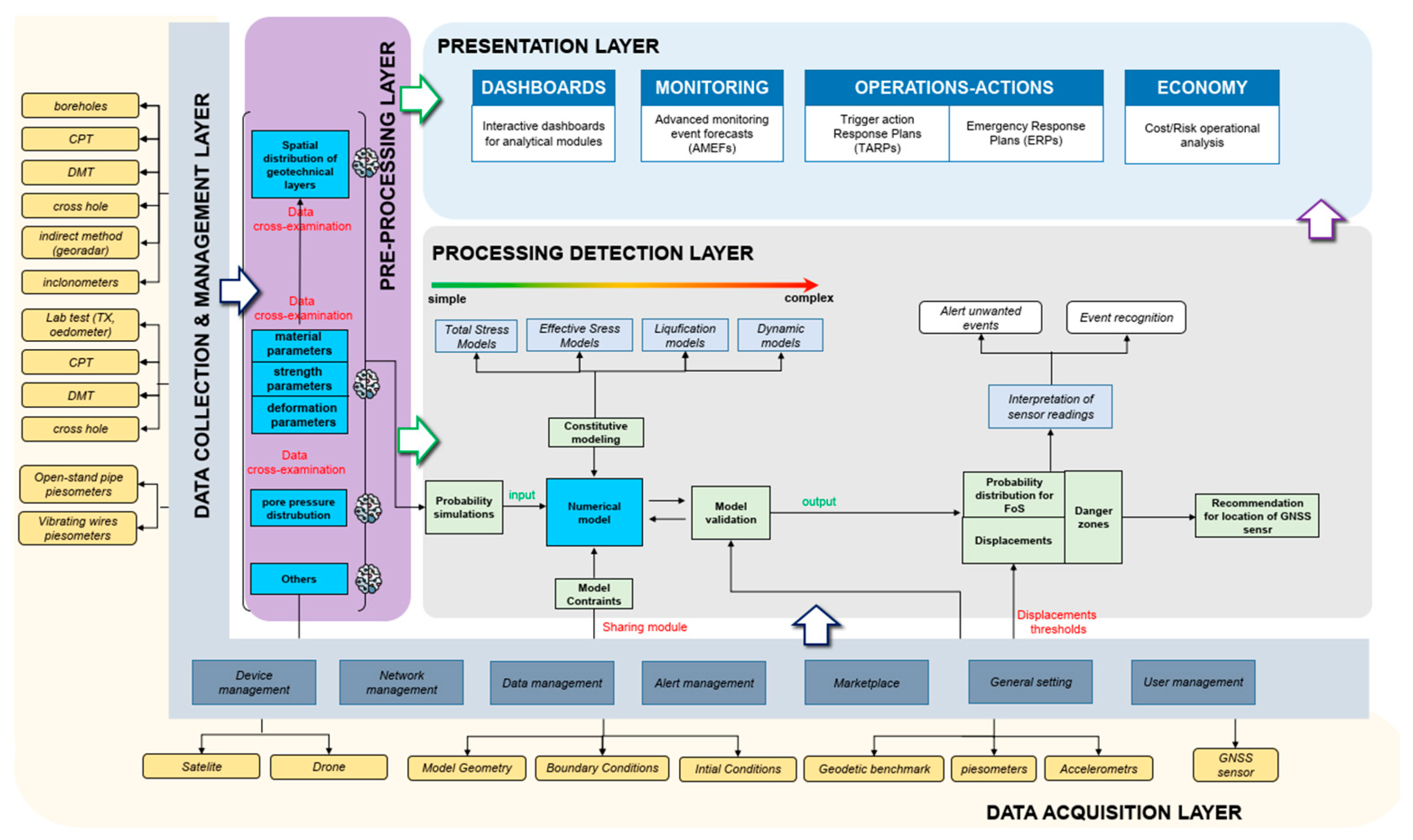

The MBSE approach emphasizes a holistic perspective of TSFs as integrated systems, considering their physical components, functional requirements, interactions, and behavior (see

Figure 1). By developing system models, engineers can capture the various aspects of a TSF, including its geometrical layout, hydraulic systems, structural components, and associated processes. This holistic view facilitates a comprehensive understanding of TSFs and ensures that all aspects are considered during the design and analysis phases.

TSFs have diverse requirements ranging from safety, environmental impact, regulatory compliance, and operational efficiency. MBSE provides a structured framework for managing these requirements throughout the lifecycle of a TSF. Requirements are captured in the system models, ensuring traceability, consistency, and the ability to assess their impact on the overall system, helping to make informed decisions and prioritizing design considerations to meet the specified requirements.

The MBSE approach encourages collaboration among multidisciplinary teams in TSF design and analysis. System models act as a common language that enables effective communication and cooperation between stakeholders, including engineers, geotechnical experts, environmental specialists, and regulatory bodies. By working together on a shared platform, the teams can seamlessly integrate their expertise, align their goals, and collectively address the complexities associated with TSFs.

4. System Architecture

The system architecture is designed to provide a comprehensive and integrated approach to enhancing the safety of tailings storage facilities. As shown in

Figure 2, it comprises several interconnected layers, each playing a vital role in ensuring the efficient and effective analysis, modeling, and presentation of TSF data.

At the foundation of the architecture lies the data acquisition layer, responsible for gathering data from various sensors deployed within the TSF. These sensors capture critical parameters, including ground movements, water levels, pore pressure, and environmental conditions. The collected data are then transmitted to the system for further analysis and processing.

In order to guarantee reliable transmission of data from remote areas, an IoT solution will be applied based on LoRA networks. IoT remote sensors will send signals to the wireless data loggers, and from there, data will be collected by gateways, which will then upload the sensor readings to the cloud.

Once the data is acquired, it enters the data preprocessing layer, in which the collected data undergoes preprocessing procedures to ensure its quality, accuracy, and reliability. Various methods, including standard techniques, machine learning approaches, and statistical methods, are used to analyze and process the data for further stages. This layer plays a crucial role in refining the data, making it suitable for meaningful analysis and modeling.

The computational layer forms the core of the system architecture. Here, numerical models are implemented using the Finite Element Method (FEM), allowing for the simulation of TSF behavior and stability. Different constitutive models, tailored to specific analysis requirements, are utilized to perform various computations. These include standard factors of safety calculations, as well as more advanced analyses such as liquefaction possibility. The computational layer enables comprehensive evaluations of TSF performance and risk scenarios.

The results from the computational layer are then passed on to the presentation layer. In this layer, data, analysis outputs, and computational results are visualized and presented in a user-friendly manner. Interactive dashboards, graphs, charts, and reports are generated to provide stakeholders with an intuitive understanding of the TSF’s behavior and safety. The presentation layer facilitates effective decision-making by presenting the information clearly and concisely, allowing for efficient communication among the project team, engineers, and other stakeholders involved.

Lastly, the system includes an alarming system that continuously monitors the data and analysis outputs in real time. Advanced algorithms are employed to detect unwanted events or abnormal patterns that may indicate potential risks or critical situations. The system triggers alarms to alert the relevant staff members when such events are detected. This timely alarming capability enables swift response and the implementation of appropriate risk mitigation measures.

The integration of these interconnected layers within the system architecture enables a comprehensive approach to TSF safety. It ensures efficient data acquisition, thorough data preprocessing, accurate computational modeling, effective data presentation, and timely alarming capabilities. By leveraging this architecture, the system facilitates proactive risk management, early detection of potential hazards, and efficient decision-making to ensure the stability and safety of tailings storage facilities.

So, to summarize, the system architecture seamlessly integrates data acquisition, preprocessing, computational modeling, presentation, and alarming layers. It enables efficient and effective analysis, modeling, and visualization of TSF data, thereby enhancing the safety and reliability of tailings storage facilities.

5. System Validation

It is crucial to conduct thorough validation on real-world tailings storage facilities (TSFs) to ensure the reliability and effectiveness of the developed system. The SEC4TD project will undergo verification via two distinct use cases: the Gradina Lake TSF in Bosnia and the Gilow TSF in Poland.

The Gradina Lake TSF is a valley fill-type facility located in Bosnia (see

Figure 3). It features containment provided by the natural topography and an engineered embankment known as the Medjedja Dam to the northeast. Designed in the early 1980s, construction of the facility took place between 1983 and 1986, with the first deposition of tailings occurring in 1985. The TSF spans approximately 80 hectares. In the Gradina Lake TSF, tailings were disposed of as a wet slurry with a low solid concentration. The slurry was pumped through pipelines and transported via gravity through an open channel toward the southwest corner of the TSF. Supernatant water was transferred under or through the embankment using an overflow system and directed via a steel pipeline within a concrete tunnel for discharge into the environment.

The second use case for system validation is the Gilow TSF located near Lubin in the Lower Silesian Voivodeship in southwestern Poland (see

Figure 4). The Gilow reservoir, an artificial reservoir built in 1968, was primarily used to store post-flotation waste from the nearby copper mine in Lubin. The reservoir was decommissioned in 1977, and afforestation efforts are currently underway. The Gilow TSF, covering an area of 620 hectares, reached its maximum level of 177.5 m above sea level (asl) in June 1980. Subsequently, a liquidation procedure was initiated. Approximately 60 million cubic meters of tailings were deposited within the TSF during its operational lifespan. Between 1982 and 1986, extensive reclamation work was carried out in the landfill area to facilitate biological land reclamation. Until May 1990, the Gilow TSF served as an emergency retention reservoir for Zelazny Most, with the collected water being redirected through an overflow tower for industrial purposes.

By validating the system on these real-world TSFs, the SEC4TD project aims to demonstrate the effectiveness, adaptability, and applicability of the developed solution. The validation process will involve the integration of the system with the existing infrastructure and sensors deployed in the Gradina Lake and Gilów TSFs. The system will collect real-time data, perform comprehensive analyses, and generate accurate computational models specific to each TSF’s characteristics. The validation results will provide valuable insights into the system’s performance, its ability to detect potential risks, and its contribution to enhancing TSF safety.

6. Conclusions

The SEC4TD project has focused on the development of an innovative system to enhance the safety and management of tailings storage facilities (TSFs). The designed SEC4TD system comprises three main components: IoT sensors, numerical modeling, and an engineering system. Throughout the project, extensive efforts have been made to ensure the system’s effectiveness, reliability, and applicability in real-world TSFs.

The SEC4TD system will be implemented and tested in two user cases, the Gradina Lake TSF in Bosnia and the Gilów TSF in Poland, to validate its effectiveness and applicability. The system’s performance and ability to enhance TSF safety will be demonstrated using these validation exercises, ensuring its reliability and practicality in real-world scenarios.

Furthermore, the SEC4TD project recognizes the importance of a well-defined commercialization strategy. Efforts will be directed at preparing a comprehensive commercialization strategy to maximize the impact of the developed system. This strategy will consider market demand, stakeholder engagement, scalability, and regulatory requirements to facilitate the widespread adoption and implementation of the SEC4TD system in the industry.