Numerical Modeling of Post-Tensioned Concrete Flat Slabs with Unbonded Tendons in Fire †

Abstract

1. Introduction

2. Numerical Modeling

2.1. Test Specimens

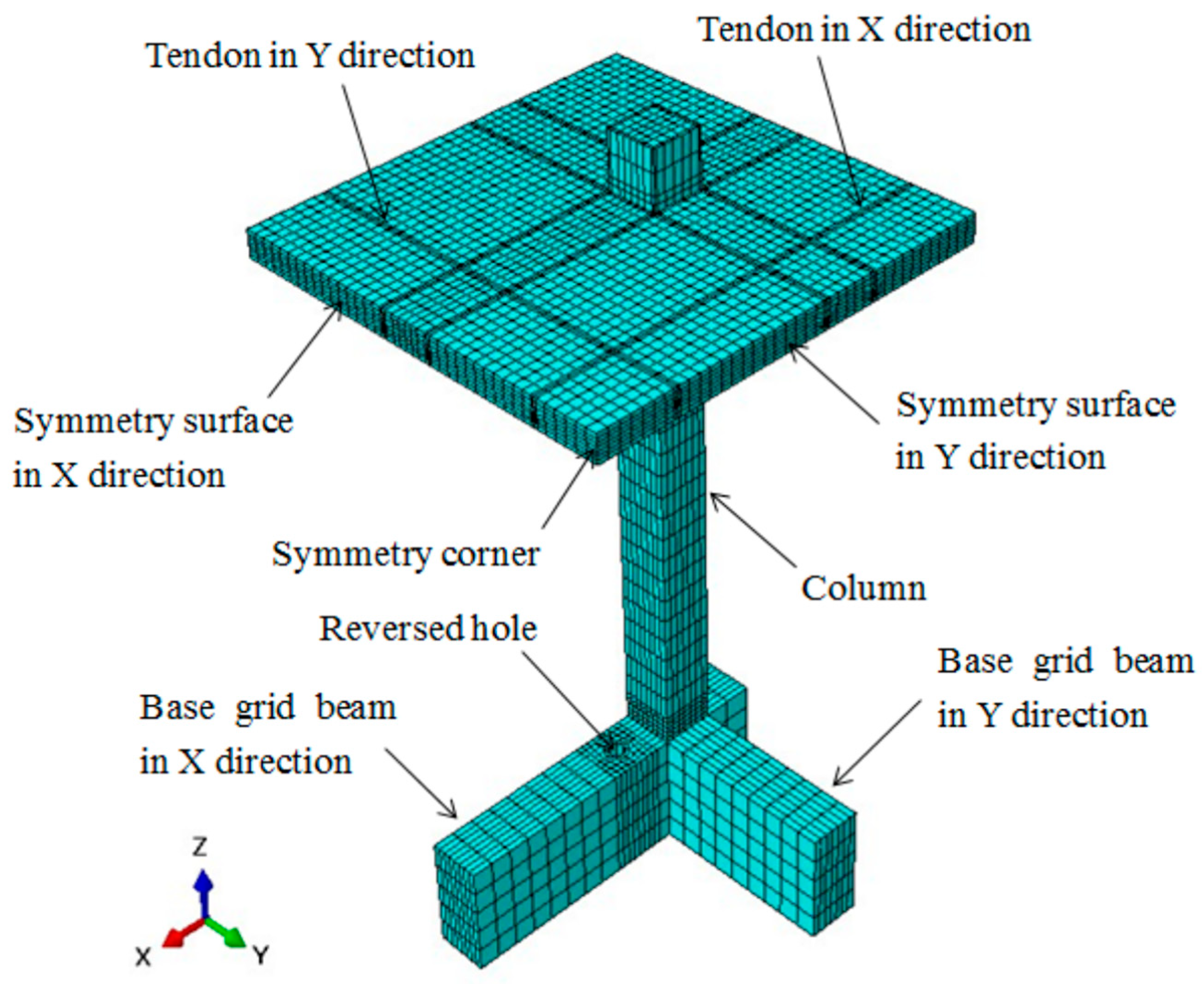

2.2. Numerical Model

3. Verification of FEM

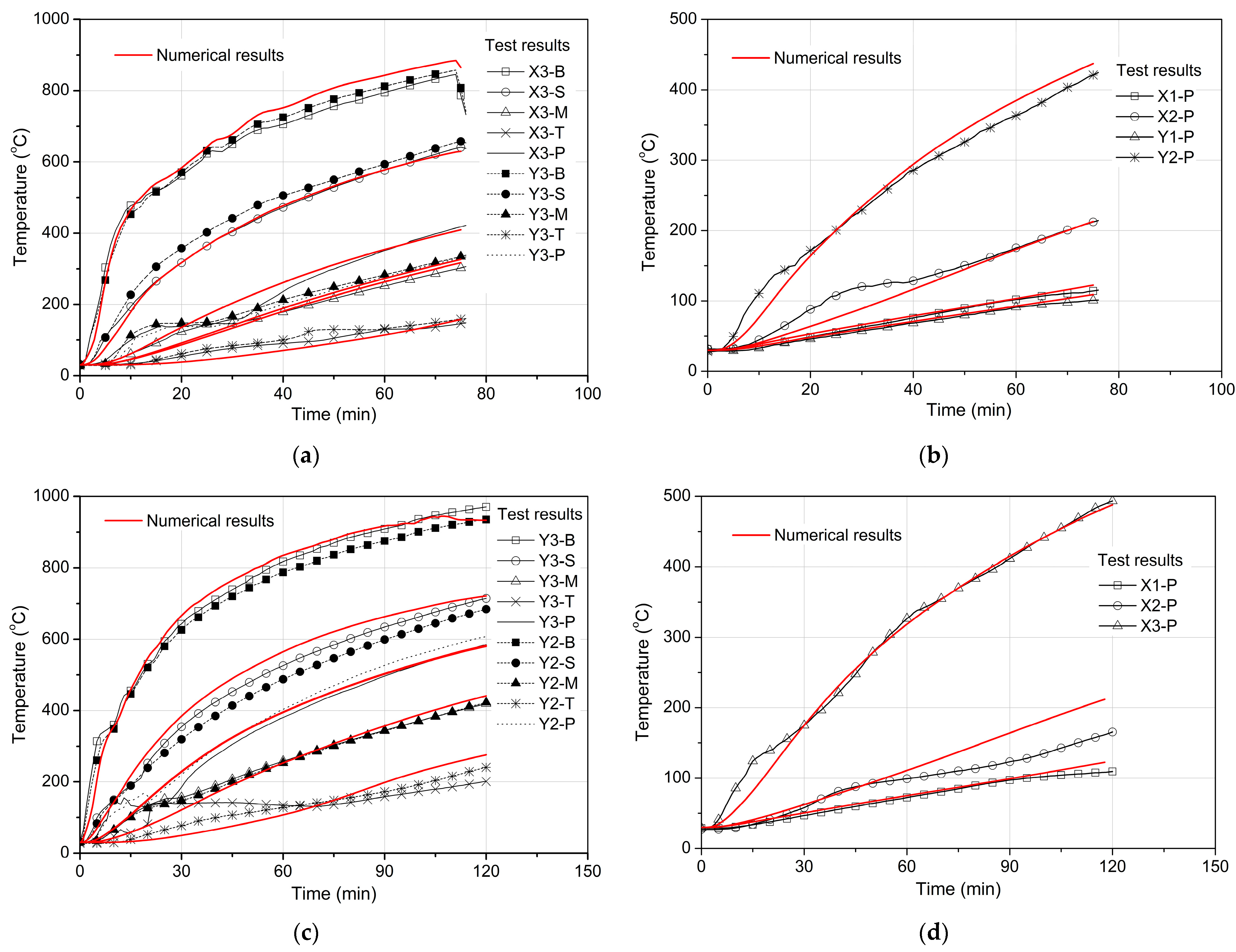

3.1. Temperature Field

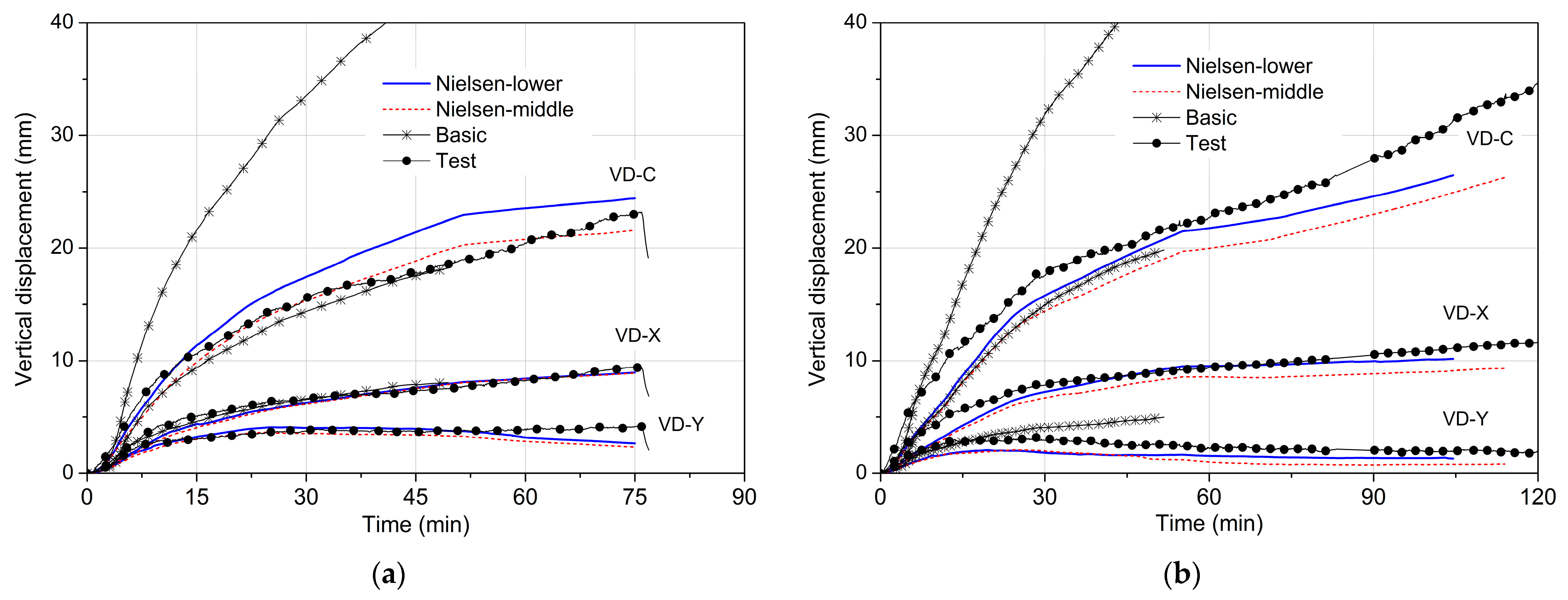

3.2. Structural Responses

4. Parametric Study Results and Discussions

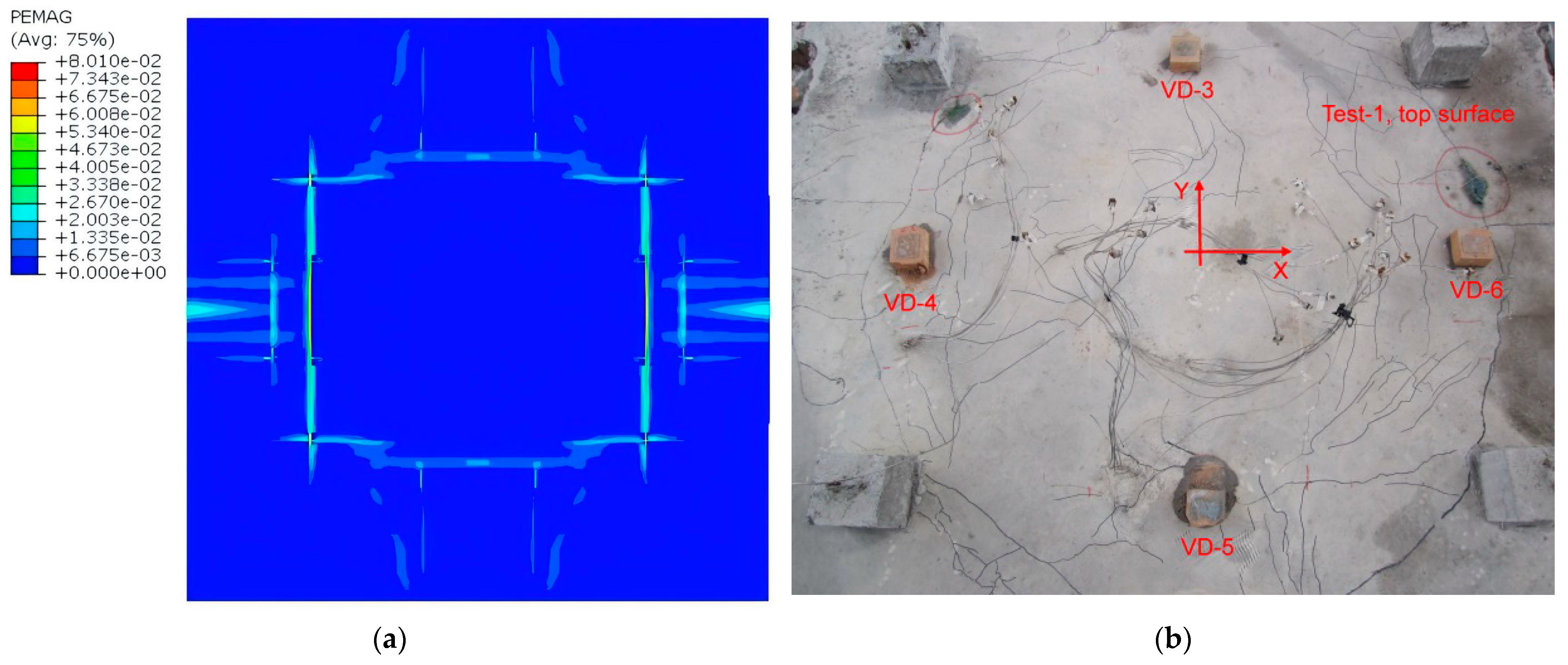

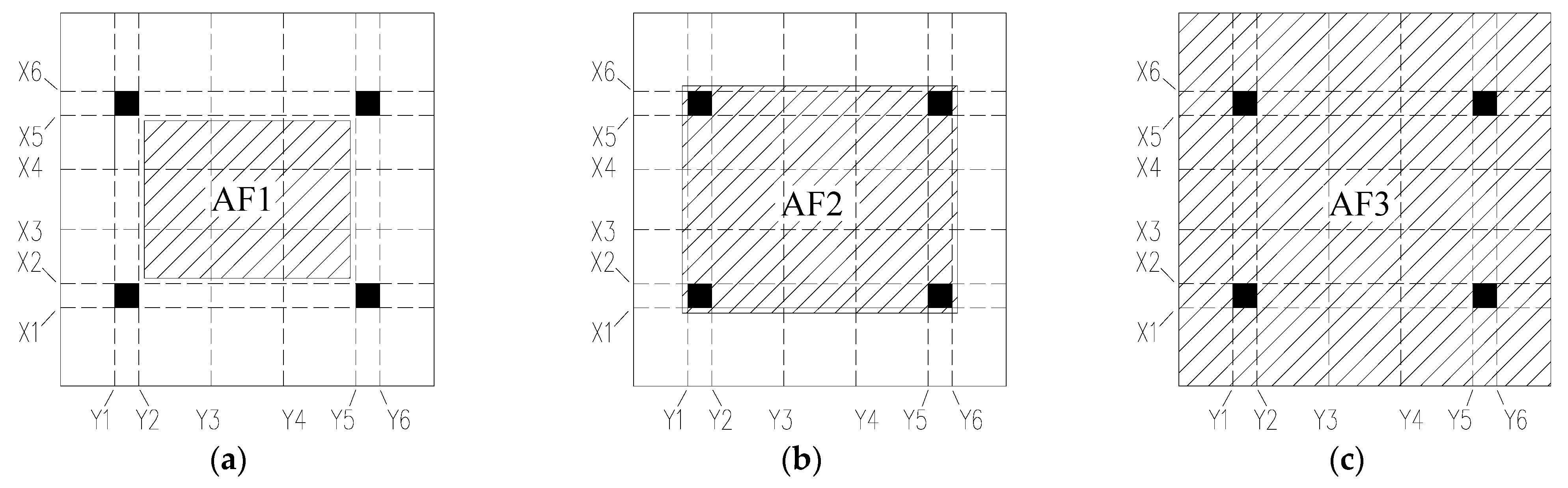

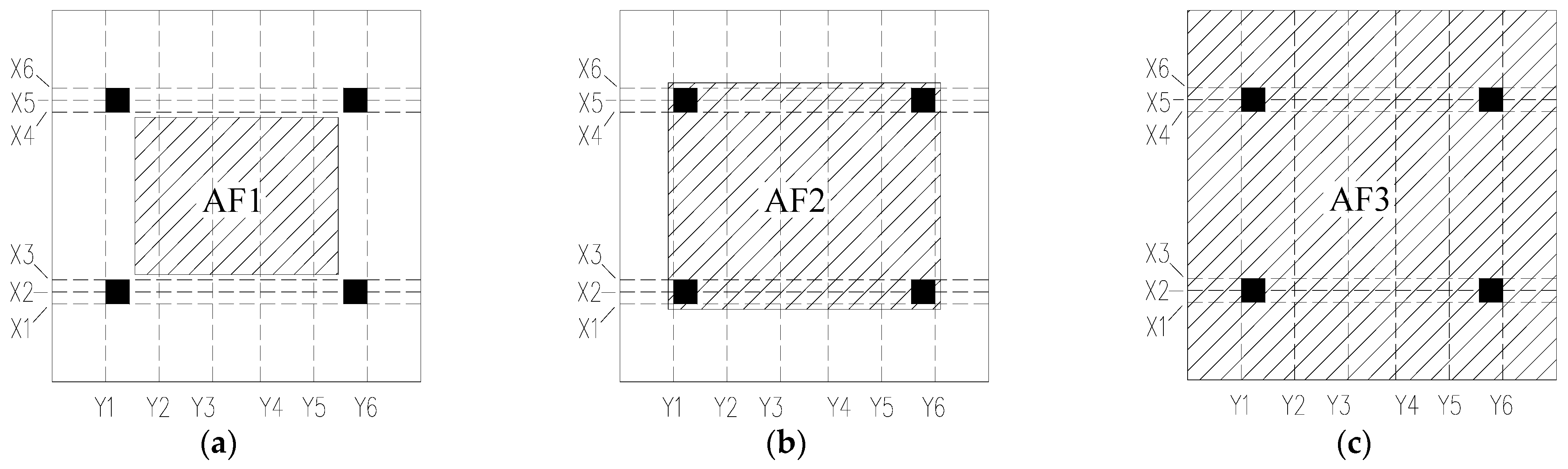

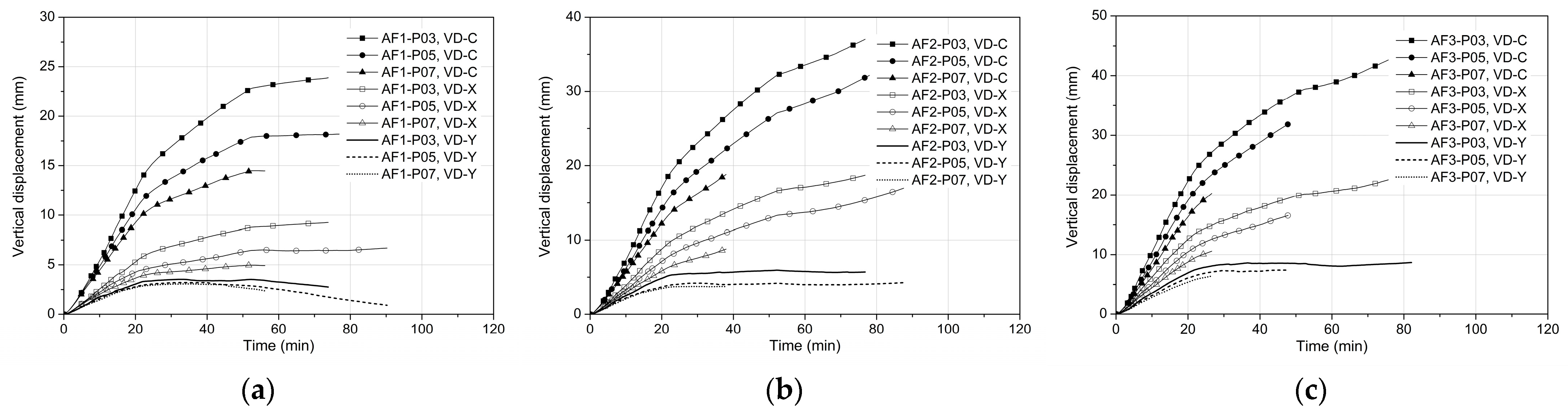

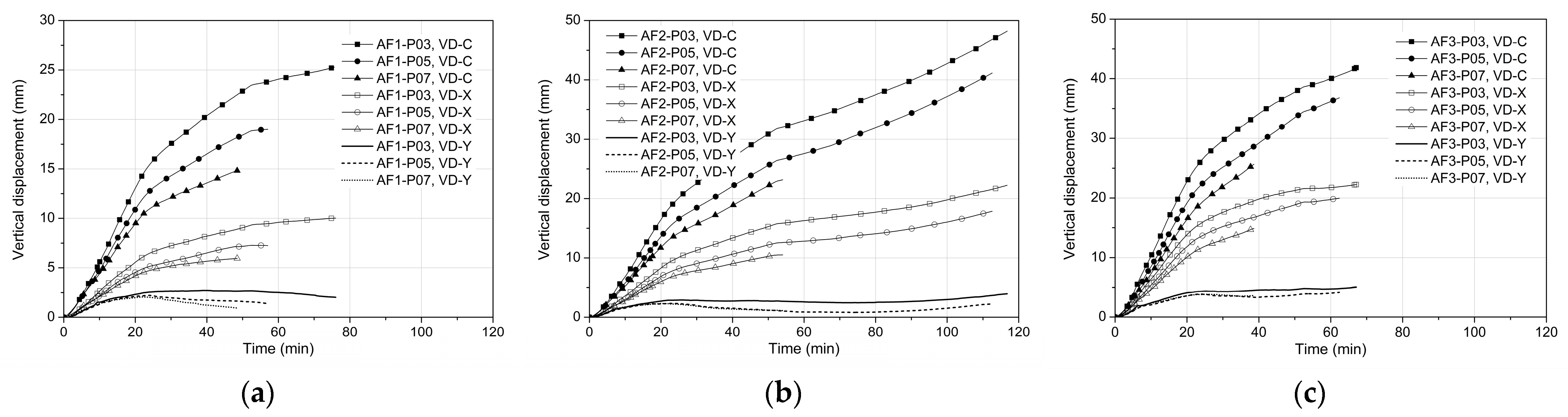

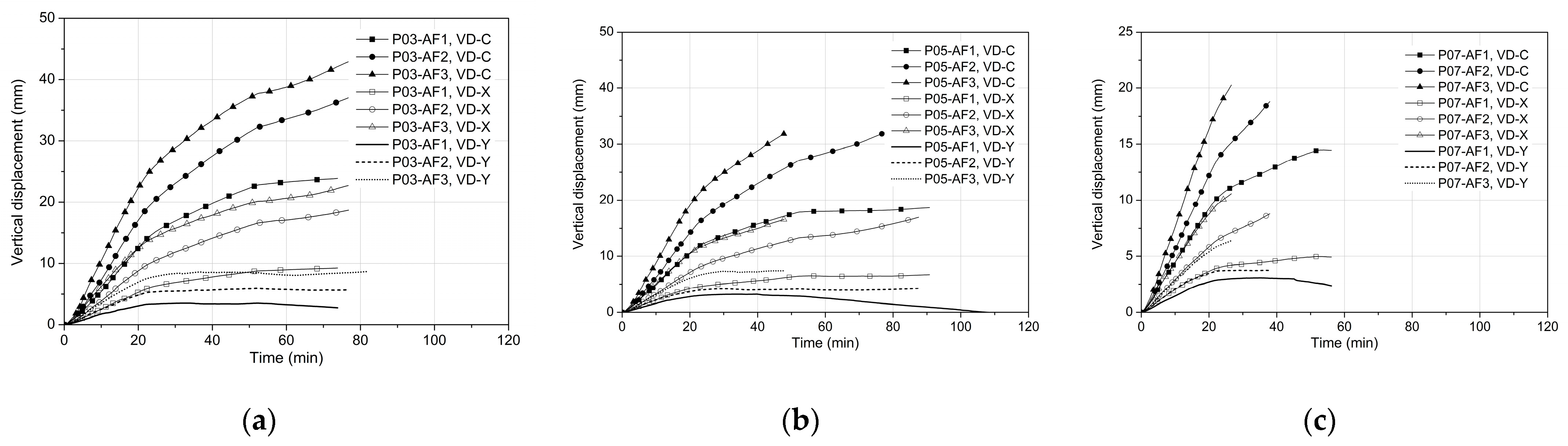

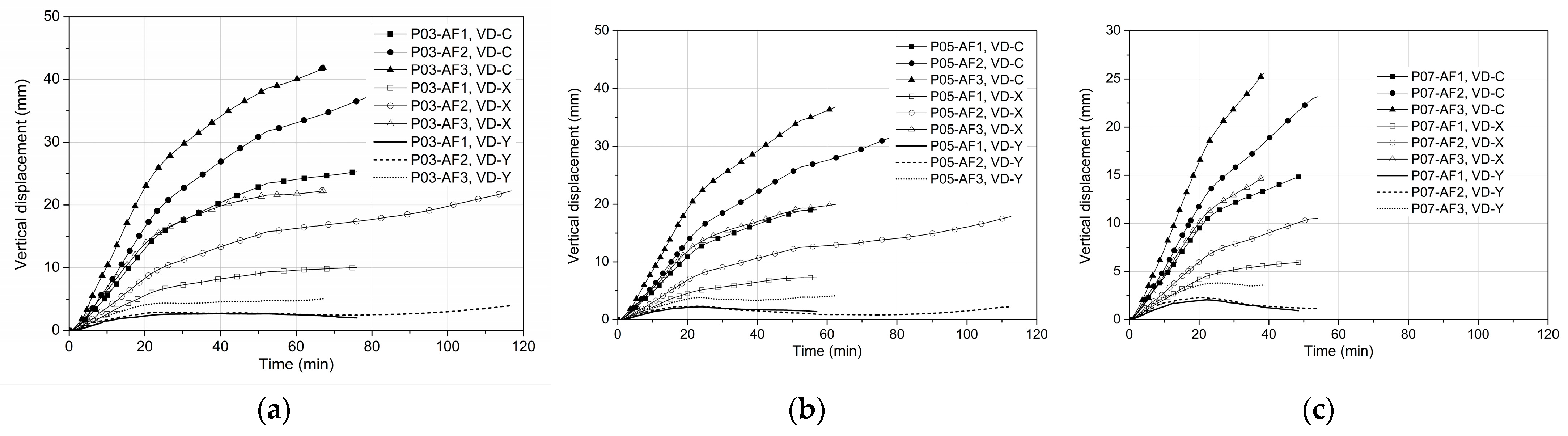

4.1. Effects of Tendon Distribution

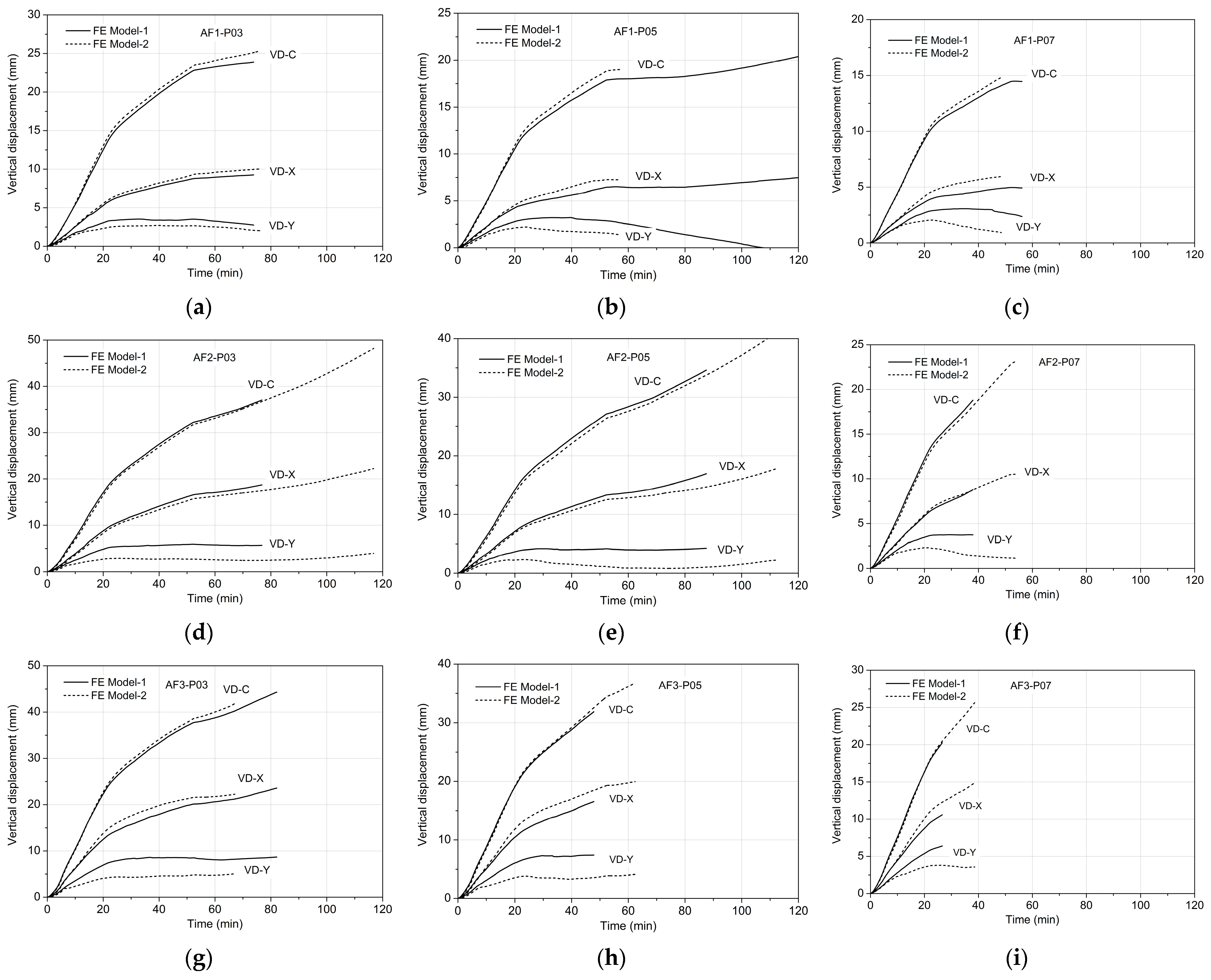

4.2. Effects of Level of Prestressing

4.3. Effects of Areas Exposed to Fire

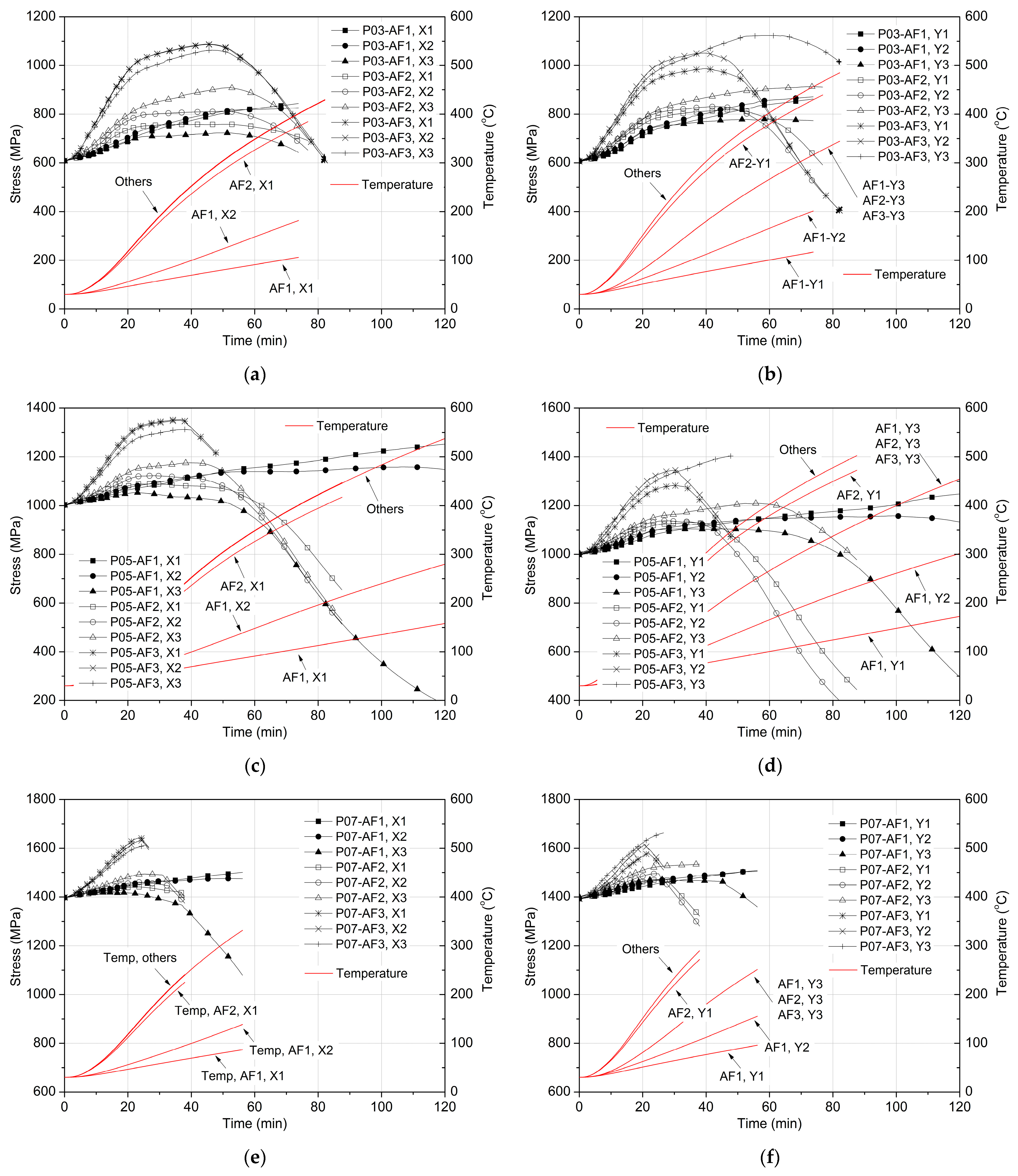

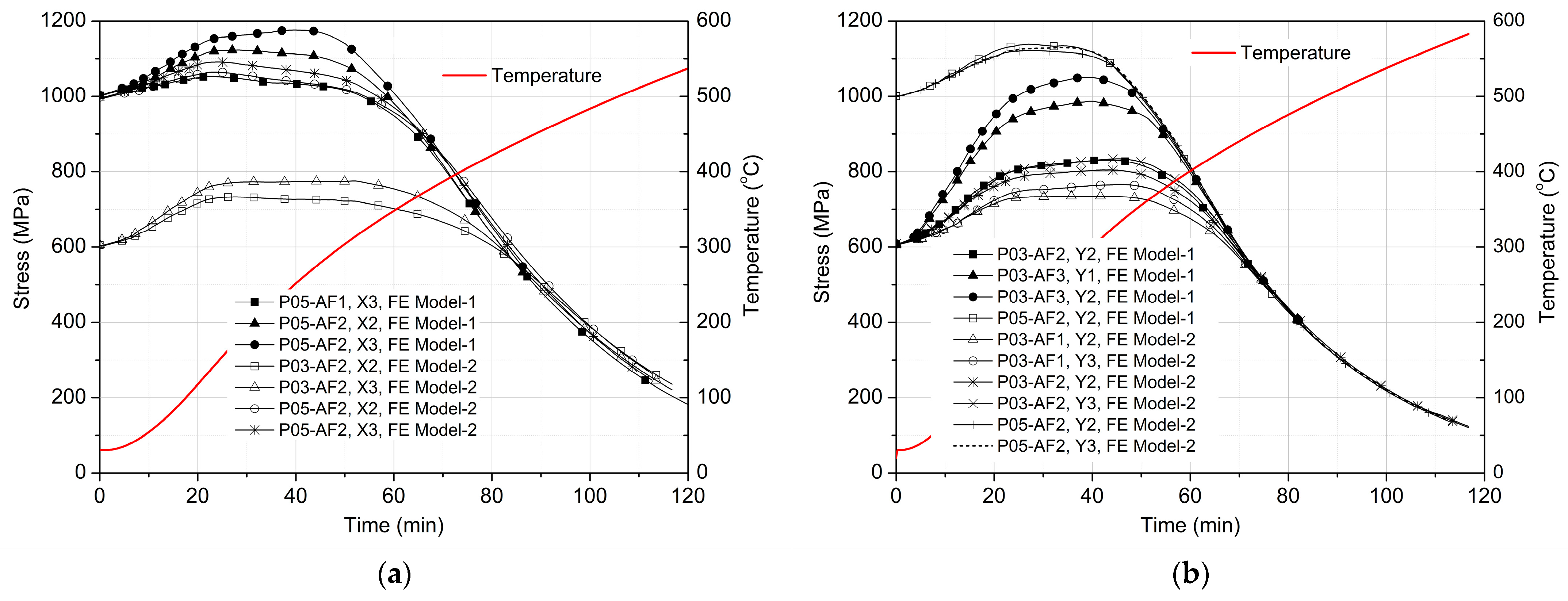

4.4. Variations in Stresses of Tendons in the Same Profile

5. Conclusions

- The considered tendon distributions slightly influence the mid-span column strip deflection due to the concrete transient creep strain under fire.

- The prestressing level has a significant effect on the vertical deflections of the slabs under fire. Increasing the level increases the transient creep strain of concrete and the balanced load provided by prestressing tendons, further resulting in a decrease in deflections.

- The fire-exposed area of the slab soffit strongly affects the vertical deflections. Enlarging this area loosens the surrounding panel restraints on the central panel flexural deformation, increasing deflections.

- High initial tendon stresses cause the tendon to yield early in the fire, leading to a sudden stress drop and lower fire resistance of the slabs.

- Tendon stresses start to decline gradually from 300 °C and drop faster as the temperature climbs. Similar temperature field stress–time curves tend to merge into a common one.

- The dropping-stage tendon stresses can be estimated using the common curve when the temperature field and initial stresses are known, without accounting for slab deformation interactions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wei, Y.; Au, F.T.K.; Li, J.; Tsang, N.M.C. Experimental and numerical investigation of post-tensioned concrete flat slabs in fire. J. Struct. Fire Eng. 2016, 7, 2–18. [Google Scholar] [CrossRef]

- ACI 318-08; Building Code Requirements for Structural Concrete and Commentary, ACI Standard. American Concrete Institute: Farmington Hills, MI, USA, 2008.

- BS EN 1992-1-2; Eurocode 2: Design of Concrete Structures—Part 1–2: General Rules—Structural Fire Design. British Standards Institution: London, UK, 2023.

- Gustaferro, A.H. Fire resistance of post-tensioned structures. J. Prestress. Concr. Inst. 1973, 18, 38–63. [Google Scholar] [CrossRef]

- Gales, J.; Bisby, L.A.; Gillie, M. Unbonded post tensioned concrete in fire: A review of data from furnace tests and real fires. Fire Saf. J. 2011, 46, 151–163. [Google Scholar] [CrossRef]

- Yuan, A.M.; Dong, Y.L.; Gao, L.T. Behavior of unbonded prestressed continuous concrete slabs with the middle and edge span subjected to fire in sequence. Fire Saf. J. 2013, 56, 20–29. [Google Scholar]

- Zheng, W.Z.; Hou, X.M.; Shi, D.S.; Xu, M.X. Experimental study on concrete spalling in prestressed slabs subjected to fire. Fire Saf. J. 2010, 45, 283–297. [Google Scholar] [CrossRef]

- Ellobody, E.; Bailey, C. Behaviour of Unbonded Post-Tensioned One-way Concrete Slabs. Adv. Struct. Eng. 2008, 11, 107–120. [Google Scholar] [CrossRef]

- Gillie, M.; Usmani, A.S.; Rotter, J.M. A structural analysis of the first Cardington test. J. Constr. Steel Res. 2001, 57, 581–601. [Google Scholar] [CrossRef]

- Gillie, M.; Usmani, A.S.; Rotter, J.M. A structural analysis of the Cardington British steel corner test. J. Constr. Steel Res. 2002, 58, 427–442. [Google Scholar] [CrossRef]

- Mirza, O.; Uy, B. Behaviour of headed stud shear connectors for composite steel-concrete beams at elevated temperatures. J. Constr. Steel Res. 2009, 65, 662–674. [Google Scholar] [CrossRef]

- Ellobody, E.; Bailey, C.G. Modeling of bonded post-tensioned concrete slabs in fire. Proc. Inst. Civ. Eng. Struct. Build. 2008, 161, 311–323. [Google Scholar] [CrossRef]

- Ellobody, E.; Bailey, C.G. Modeling of unbonded post-tensioned concrete slabs under fire conditions. Fire Saf. J. 2009, 44, 159–167. [Google Scholar] [CrossRef]

- Bailey, C.G.; Ellobody, E. Whole-building behaviour of bonded post-tensioned concrete floor plates exposed to fire. Eng. Struct. 2009, 31, 1800–1810. [Google Scholar] [CrossRef]

- Wei, Y.; Au, F.T.K.; Li, J.; Tsang, N.M.C. Effects of transient creep strain on post-tensioned concrete slabs in fire. Mag. Concr. Res. 2017, 69, 337–346. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, L.; Au, F.T.K.; Li, J.; Tsang, N.M.C. Thermal creep and relaxation of prestressing steel. Constr. Build. Mater. 2016, 128, 118–127. [Google Scholar] [CrossRef]

- Schneider, U.; Schneider, M. An advanced transient concrete model for the determination of restraint in concrete structures subjected to fire. J. Adv. Concr. Technol. 2009, 7, 403–413. [Google Scholar] [CrossRef]

- Terro, M.J. Numerical modeling of the behavior of concrete structures in fire. ACI Struct. J. 1998, 95, 183–193. [Google Scholar]

- Youssef, M.A.; Moftah, M. General stress-strain relationship for concrete at elevated temperatures. Eng. Struct. 2007, 29, 2618–2634. [Google Scholar] [CrossRef]

- Gawin, D.; Pesavento, F.; Schrefler, B.A. Modeling of deformations of high strength concrete at elevated temperatures. Mater. Struct. 2004, 37, 218–236. [Google Scholar] [CrossRef]

- Pearce, C.J.; Nielsen, C.V.; Bicanic, N. Gradient enhanced thermo-mechanical damage model for concrete at high temperatures including transient thermal creep. Int. J. Numer. Anal. Methods Geomech. 2004, 28, 715–735. [Google Scholar] [CrossRef]

- Khoury, G.A.; Grainger, B.N.; Sullivan, P.J.E. Transient thermal strain of concrete: Literature review, conditions within specimen and behaviour of individual constituent. Mag. Concr. Res. 1985, 37, 131–144. [Google Scholar] [CrossRef]

- Khoury, G.A.; Grainger, B.N.; Sullivan, P.J.E. Strain of concrete during first heating to 600 °C under load. Mag. Concr. Res. 1985, 37, 195–215. [Google Scholar] [CrossRef]

- Schneider, U. Concrete at high temperatures—A general review. Fire Saf. J. 1986, 13, 55–68. [Google Scholar] [CrossRef]

- Ožbolt, J.; Bošnjaka, J.; Periškic, G.; Sharma, A. 3D numerical analysis of reinforced concrete beams exposed to elevated temperature. Eng. Struct. 2014, 58, 166–174. [Google Scholar] [CrossRef]

- Cruz, C.R. Apparatus for measuring creep of concrete at high temperatures. J. PCA Res. Dev. Lab. 1968, 10, 36–42. [Google Scholar]

- BS EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1–2: General Actions—Actions on Structures Exposed to Fire. British Standards Institution: London, UK, 2002.

- Wei, Y.; Au, F.T.K. Numerical Modeling of Prestresssing Steel Tendons under Fire and Post-Fire Conditions. Adv. Struct. Eng. 2015, 18, 1703–1722. [Google Scholar] [CrossRef]

| Test Case | Tendon Distribution | Design Prestressing Level | Design Loading Ratio |

|---|---|---|---|

| Test-1 | Distributed–Distributed | 0.37 | 0.50 |

| Test-2 | Banded–Distributed | 0.50 | 0.35 |

| Test-3 | Distributed–Distributed | 0.50 | 0.50 |

| Test-4 | Banded–Distributed | 0.50 | 0.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Fan, D.; Au, F.T.K. Numerical Modeling of Post-Tensioned Concrete Flat Slabs with Unbonded Tendons in Fire. Eng. Proc. 2025, 98, 31. https://doi.org/10.3390/engproc2025098031

Wei Y, Fan D, Au FTK. Numerical Modeling of Post-Tensioned Concrete Flat Slabs with Unbonded Tendons in Fire. Engineering Proceedings. 2025; 98(1):31. https://doi.org/10.3390/engproc2025098031

Chicago/Turabian StyleWei, Ya, Daoan Fan, and Francis T. K. Au. 2025. "Numerical Modeling of Post-Tensioned Concrete Flat Slabs with Unbonded Tendons in Fire" Engineering Proceedings 98, no. 1: 31. https://doi.org/10.3390/engproc2025098031

APA StyleWei, Y., Fan, D., & Au, F. T. K. (2025). Numerical Modeling of Post-Tensioned Concrete Flat Slabs with Unbonded Tendons in Fire. Engineering Proceedings, 98(1), 31. https://doi.org/10.3390/engproc2025098031