Abstract

Electric vehicles have recently gained greater attention across all countries for transportation purposes in on-road and off-road forms due to their supreme performance and clean eco-friendliness status. Lithium-ferrous phosphate batteries are the primary energy storage devices in electric vehicles due to their higher energy density, longer lifespan, and lower self-discharge rate. They also possess several technical advantages, including a wider range of applications, economic affordability, an environmentally friendly nature, and, most importantly, superior electrochemical performance, which makes them a strong competitor to lead acid batteries. In the present study, a performance and health assessment of a lithium ferrous phosphate battery (LFP) pack consisting of 23 cells connected in series balancing mode with a 7360 Wh maximum energy storage capacity has been carried out at various current ranges of operation such as 3 A, 5 A, and 8 A in a typically developed battery management system to estimate their optimized performance and overall health conditions. Further study has been conducted to investigate the characteristics of LFP packs under various power-mode conditions, ranging from 20 W to 750 W. This experimental study revealed that the LFP battery pack exhibits a remarkable state-of-charge capability, achieving 58% charging in a 3.3-h runtime period. A similar decreasing trend was also observed during power-mode operations. Furthermore, the LFP battery pack was fully charged after achieving a 50% State of Charge (SOC) under every current-mode condition, providing reliable outputs under the loading conditions. It is also stated that the state of health of the lithium ferrous phosphate is significantly higher at 92% during the entire investigation, which reflects the good thermal stability of the LFP battery pack for temperature variations from 26 °C to 31 °C. Finally, it is concluded that the LFP could be one of the most favourable energy storage systems due to its longer lifespan and its great affordability in automotive applications.

1. Introduction

The focus on environmental sustainability has increased globally, and the need to reduce carbon footprints has driven the demand for clean energy solutions. Conventional energy sources based on fossil fuels remarkably contribute to climate change and pollution, making it vitally important to explore replacements. Due to this transition, the battery management system (BMS) emerged as a technology that ensures the efficiency and safety of battery usage in numerous applications, ranging from electric vehicles to energy storage systems [1]. Research on this topic originated in the 1970s, with significant progress in development during the 1980s. The first lithium-ion battery was introduced in 1991, thanks to the efforts of the eminent scientist Akira Yoshino, who was later recognized as the “father of the lithium-ion battery” [2]. Retaining high energy density, long life, and the ability to be quickly recharged, Li-ion batteries have dominated industrial markets. Used in electric vehicles, DSLR cameras, smartwatches, pacemakers, and numerous other applications, the Li-ion battery has become an indispensable component in various industries. Although it was a remarkable development in the field of battery technology, it still lacked certain aspects, such as a limited lifespan, high cost, and temperature sensitivity, which can be effectively mitigated through the implementation of a robust battery management system. With the increased use of batteries in clean energy solutions, there has been a corresponding rise in the need to develop more sophisticated systems that can also adapt to future needs. This led to significant advancements in battery management system (BMS) technology, as it plays a crucial role in the health and performance of batteries.

A survey of the literature on battery management systems opens the door to multifaceted possibilities in the development of technology that can help humanity enhance its livelihood while taking essential care of the environment. The BMS plays a crucial role in addressing the fundamental and improved characteristics of a battery, such as state-of-charge (SOC), state-of-health (SOH), voltage, and current monitoring, as well as the overall security of the battery and its user [3]. Initially, the BMS centred its focus on SOC and SOH estimation using simple circuits. However, as the years progressed, scientists developed more advanced algorithms, such as Kalman filters and machine learning techniques, which enhanced accuracy [4]. The integration of thermal management systems and fault detection algorithms has deliberately improved issues related to overcharging and component damage, which are exacerbated by the increasing adoption of electric vehicles and the integration of renewable energy sources, such as wind and solar power. In essence, battery management systems are crucial in enhancing battery efficiency and their overall usefulness, which opens up new opportunities for green and innovative energy sources. Among all the batteries used in various applications, the lithium ferrous phosphate (LFP) battery plays a significant role in several electric vehicle sectors, especially in the automotive industry, due to its superior performance, longer lifespan, and higher power density [5]. With the widespread adoption of these LFPs at a faster rate among the public at affordable prices, these batteries are becoming more reliable energy storage devices in various industry sectors around the world. Highly effective battery management is crucial for enhancing the long-distance driving experience through power monitoring assessment, extended life duration, and reliable safety usage [4]. The mismanagement of LFP batteries, such as excessive charging and discharging, as well as other activities, can lead to a reduction in their lifespan and cause severe explosions. Therefore, a practical health assessment is highly desirable for EV-based batteries because of their unexpected and unreliable characteristics. According to Liu et al. [6], a lithium iron phosphate (LiFePO4) battery’s surface temperature rising over 150 °C increases the danger of thermal runaway. It causes a significant volume of flammable gas to be released. At high ambient temperatures, the battery experiences a more severe thermal runaway (TR) because the gas burns when exposed to an open flame [7].

In this study, the performance characteristics of the lithium ferrous phosphate battery were investigated using a newly developed battery management system (BMS). Various battery management techniques, such as state of charge (SOC) and state of health (SOH), have been experimentally studied under different current-mode and power-mode conditions. Further investigation has been conducted into the cooling conditions of each cell of the lithium ferrous phosphate battery during the health assessment process.

2. Experimental Setup

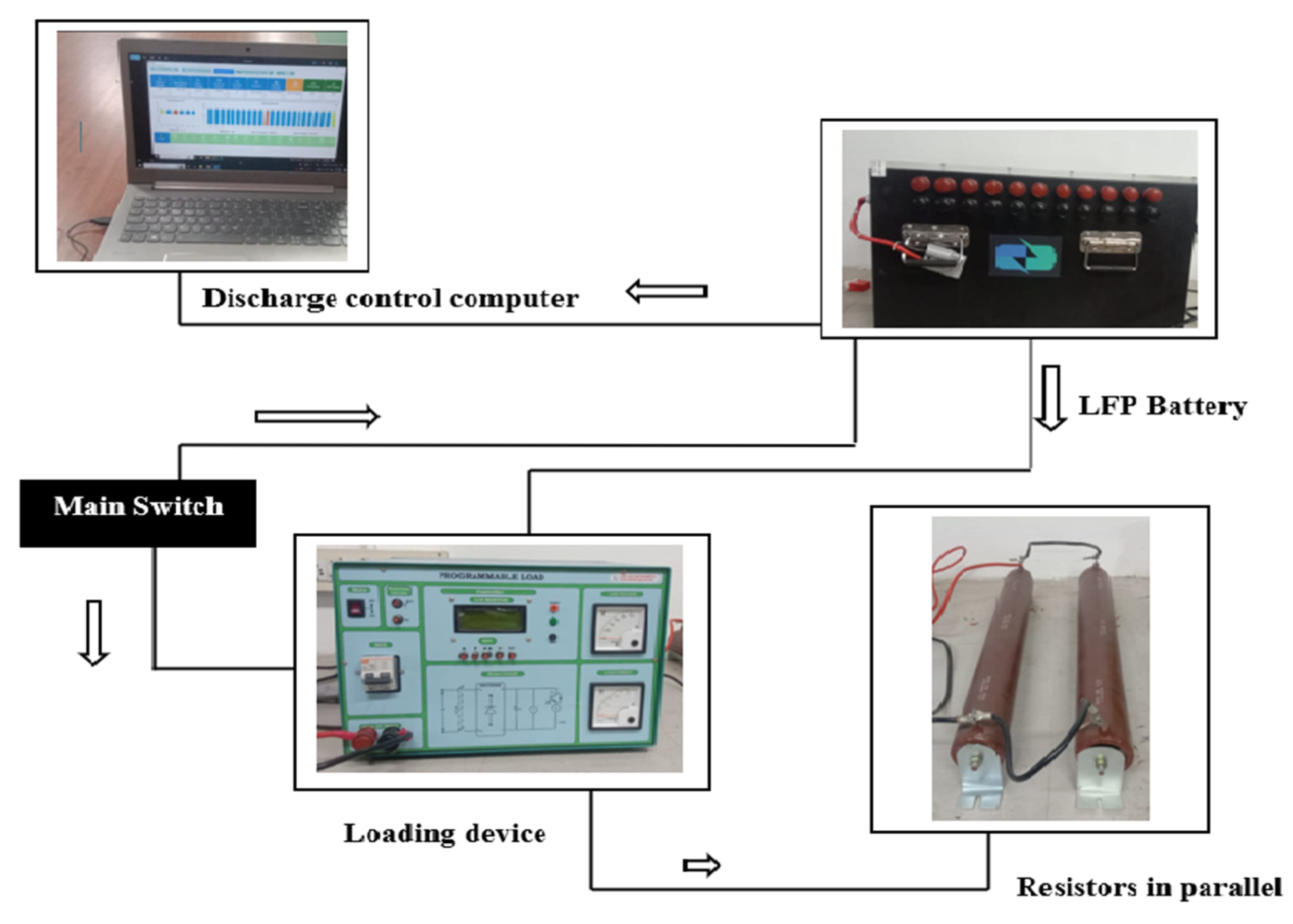

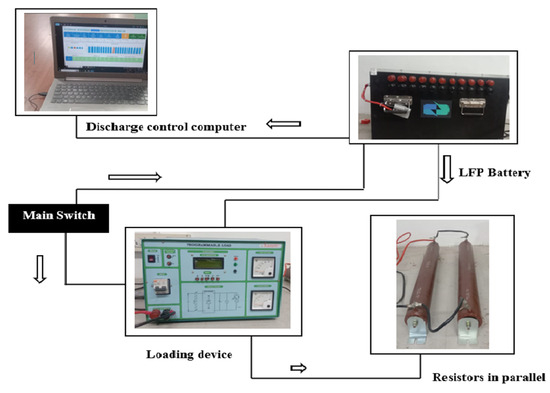

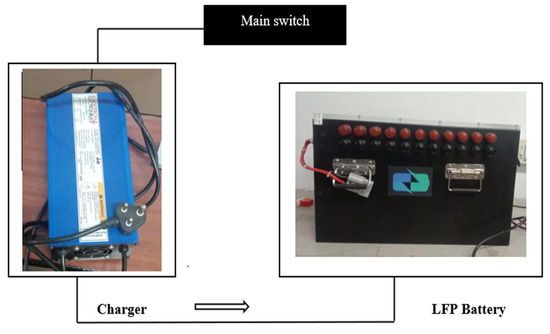

A typical battery management system has been developed by JSK Systems in Chennai, consisting of a lithium iron test cell, a loading device, and a data monitoring system. In this test setup, 23 cells of LFP batteries, each with a 3 V range, have been arranged in series balancing mode, with a total capacity of 100 Ah. A schematic representation of the newly developed Battery Management System (BMS) is shown in Figure 1. Various battery management assessment techniques for LFP, such as SOC, SOH, energy, power, and life assessments, can be performed using the BMS through discharge testing. The technical details of the LFP used in this investigation are presented in Table 1. Experiments were conducted at various current modes of operation of 3 A, 5 A, and 8 A, and further estimations were also made in different power-mode conditions. The battery performance was estimated by a constant current discharge method, which is the standard approach for analysis. It provides support for interpreting functions under specific conditions and can be used to accurately determine the battery’s capacity. Similarly, SOC and SOH were also assessed under different power modes of operation from 20 W to 750 W. The entire LFP battery pack was recharged after achieving a state of charge (SOC) of 50% under every current mode of operation. The linear relationship between time, SOC, and remaining capacity in the graph emphasizes the stability of the discharge process under various current modes. In this BMS system, 23 LFP cells are connected; therefore, it becomes very complex to estimate the performance behavior of the LFP battery pack. To account for the time variation and non-linear pattern of all 23 battery cells, the entire battery pack’s health assessment was conducted using a cell calculation-based technique.

Figure 1.

Experimental setup with LFP battery cells, loading device, resistors, and DAQ systems (discharging process).

Table 1.

Technical specifications of lithium ferrous phosphate battery.

3. Results and Discussion

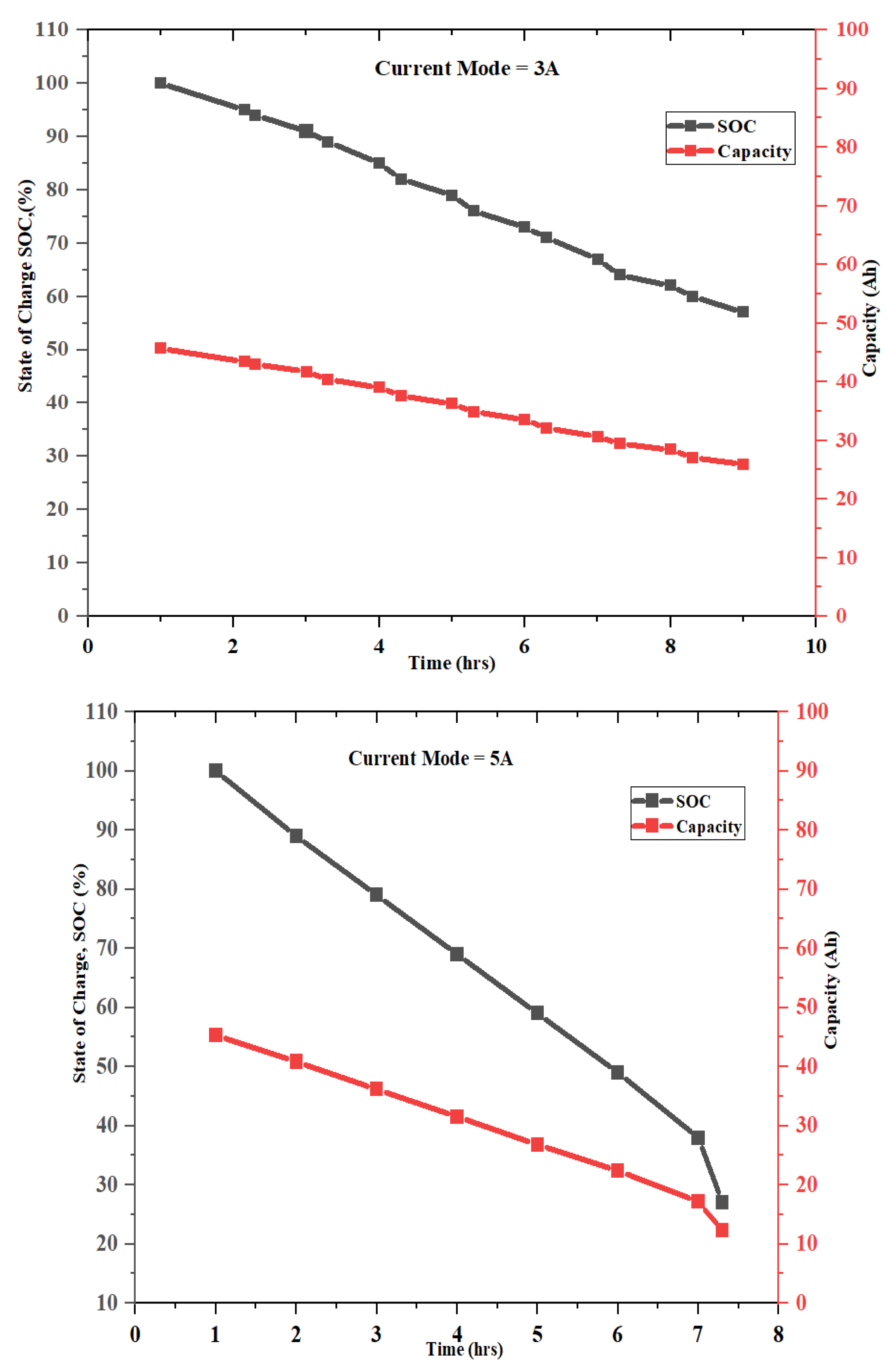

3.1. State-of-Charge Assessment

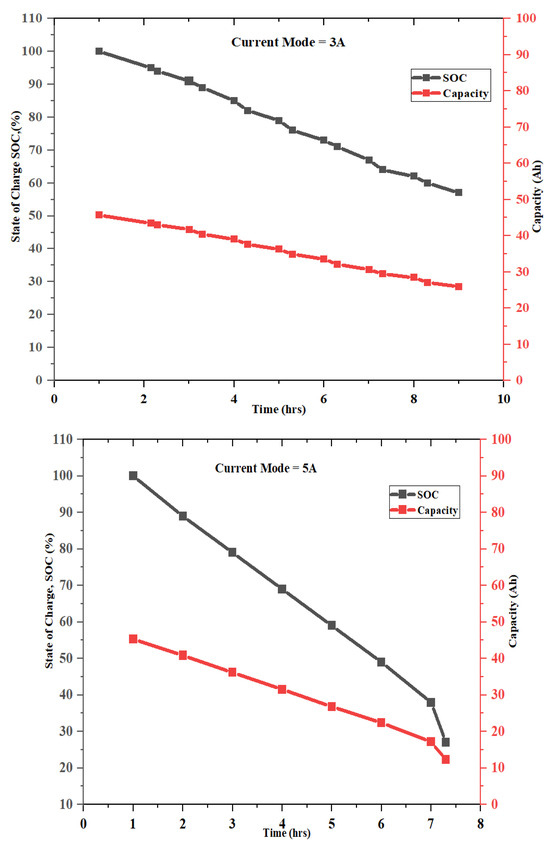

The state of charge (SOC) is one of the primary factors for estimating battery reliability from a safety perspective. All forms of batteries used in general applications should ensure a prompt response during charging, which provides smooth battery functioning. It provides a critical assessment of battery operation in electric vehicle (EV) applications. In general, the SOC, or State of Charge, is the percentage of a battery’s remaining charge relative to its full capacity. It indicates the amount of energy remaining in the battery. Figure 2 shows the effect of time duration on LFP’s SOC under various current modes of 3 A, 5 A, and 8 A operations. Capacity refers to the total amount of energy a battery can store, typically measured in ampere-hours (Ah) or watt-hours (Wh). It represents the maximum charge the battery can hold before it needs to be recharged. The SOC decreases linearly as time progresses, from approximately 100% to nearly 60% by the end of the 9-h time duration. As the state of charging is the ratio of current charge per total capacity, a higher SOC is a reflection of more energy being available relative to the battery’s total capacity. Figure 2 shows that a constant current of 3 A is drawn steadily from the battery throughout the entire discharging process. The capacity degrades with time (but much slower than the SOC). This means that the battery loses the ability to store energy as it discharges, which is attributed to the battery’s aging.

Figure 2.

Experimental setup with LFP battery cells and EV battery charger (charging process).

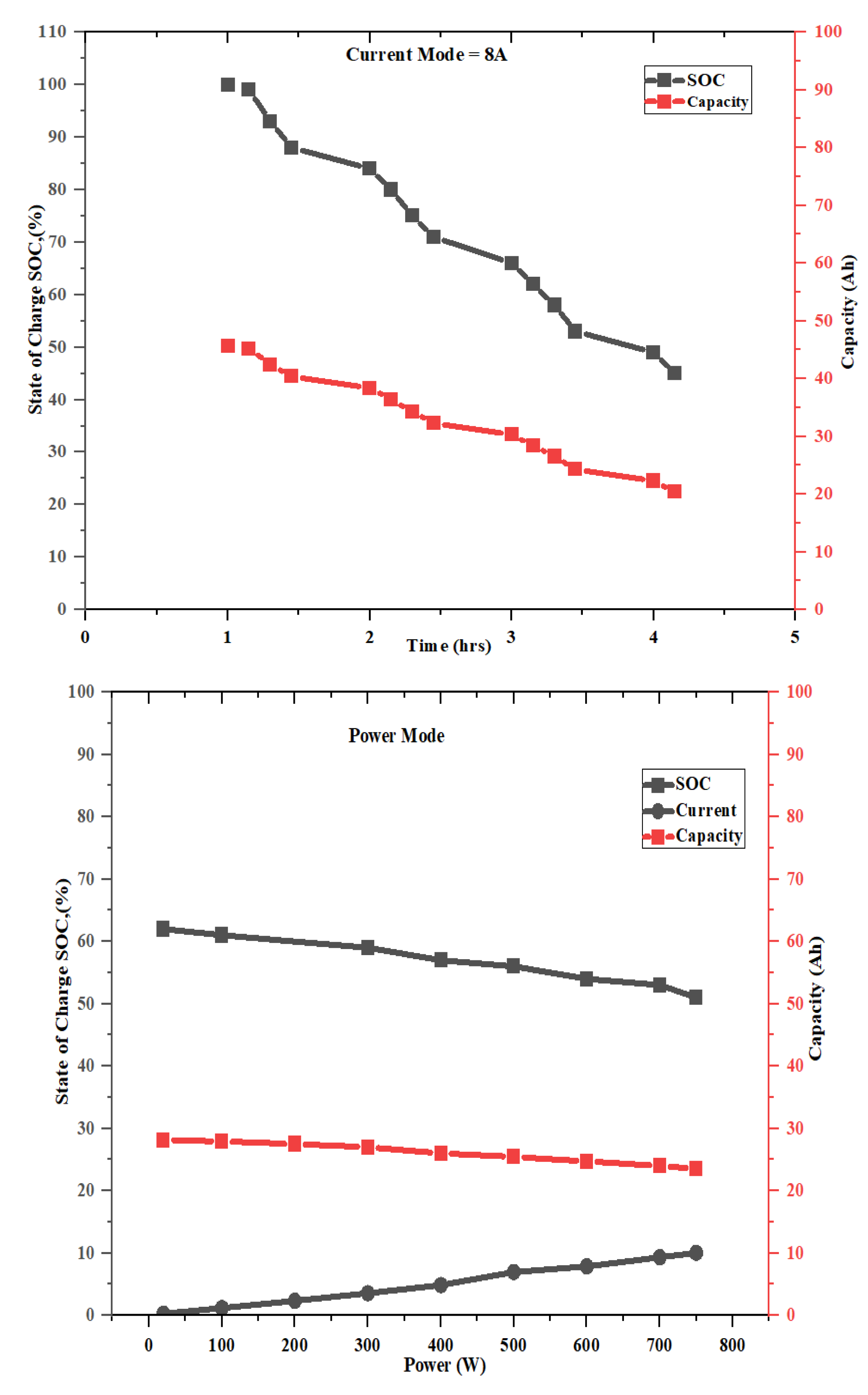

As time goes on, the SOC decreases linearly, reflecting a steady and uniform discharge process. This operation is expected under a constant current load, where the battery’s energy utilization is consistent. Similarly, as shown in Figure 2, the remaining capacity follows the same linear trend, demonstrating a direct relationship between the State of Charge (SOC) and the amount of energy left in the battery. Under controlled current discharge, the battery’s operation is consistently declining. Initially, when the experiment began, the SOC was at 100 per cent, and the capacity was measured to be 46 Ah. It is noted that the time duration for the SOC declined from full charging (100%) to 60% at 3 A, 5 A, and 8 A at 8.3 h, 5.0 h, and 3.3 h. The overall trend illustrates how an increase in time under a constant current of 3 A, 5 A, and 8 A affects the state of charge (SOC) and capacitance, which decrease as time elapses. Similarly, the state of charge of the LFP battery pack has been analysed under various power input conditions, as depicted in Figure 3. Interestingly, when the power input of the LFP battery pack is varied from 20 W to 750 W, the state of charge follows a decreasing trend, corresponding to an increase in power consumption. At a power input of 20 W, the SOC is 62%, whereas the SOC reaches 51% at maximum power consumption, and it maintains this level for 5 min under each power input. This is a similar trend to the current mode of operation.

Figure 3.

Effect of power input on state of charge.

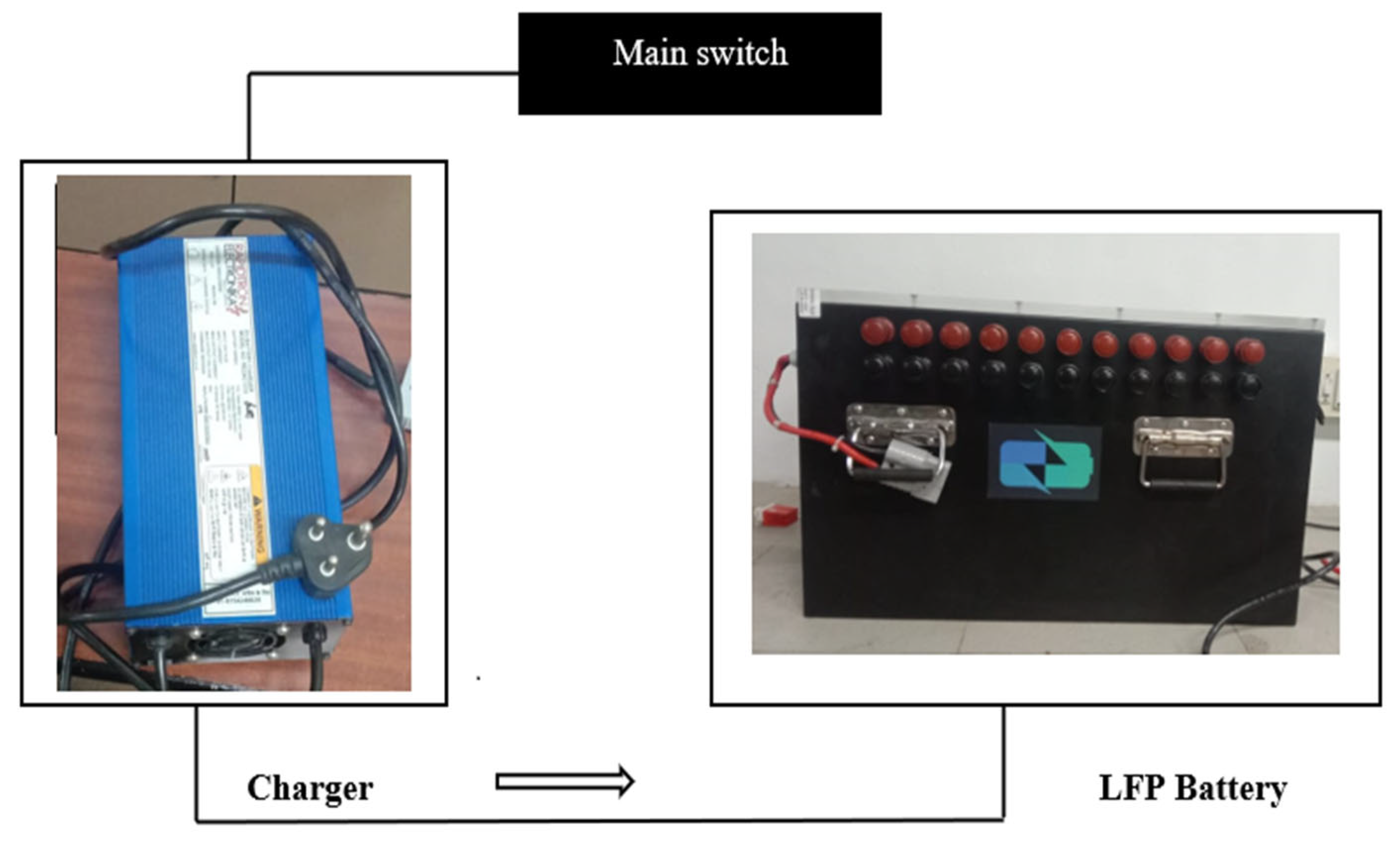

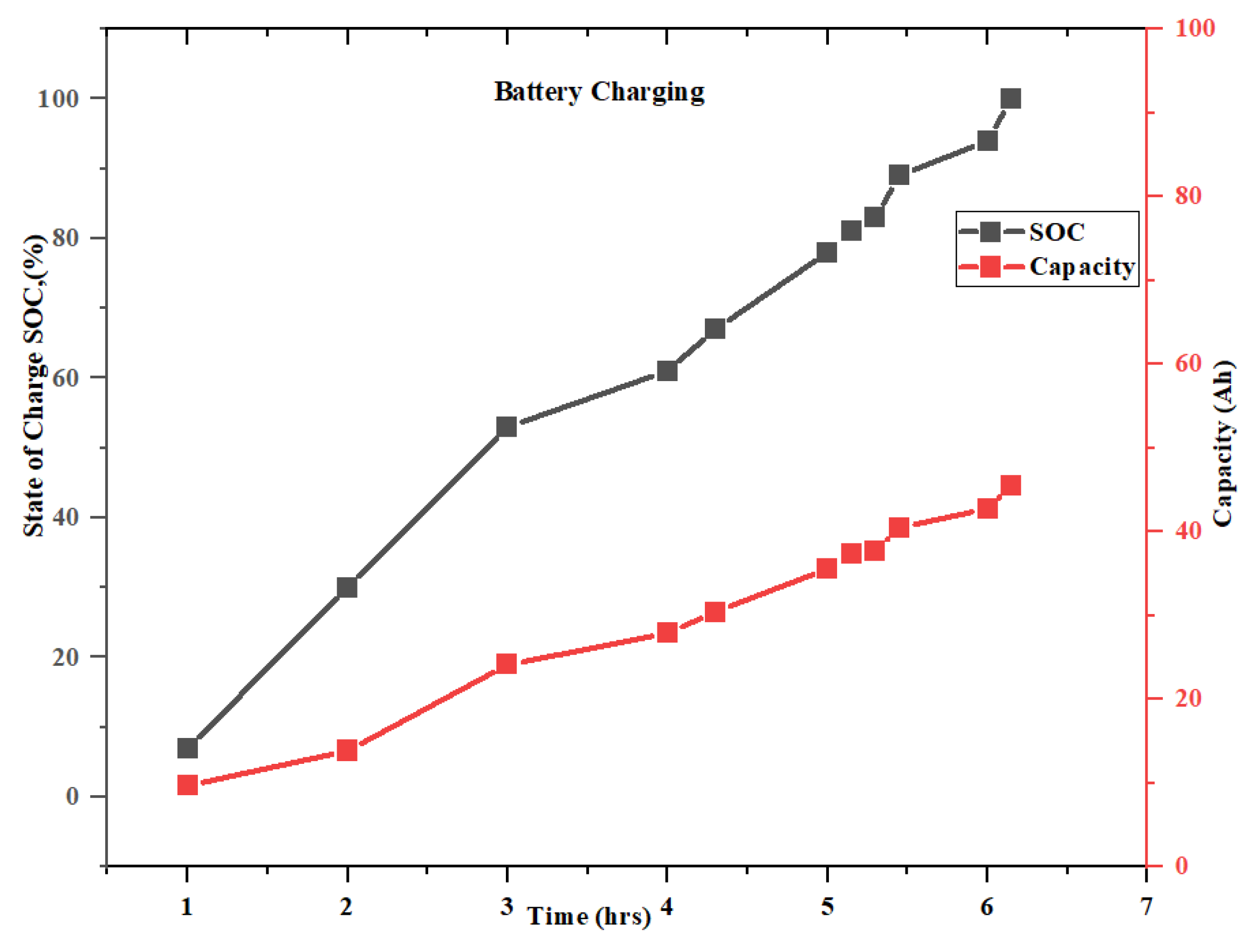

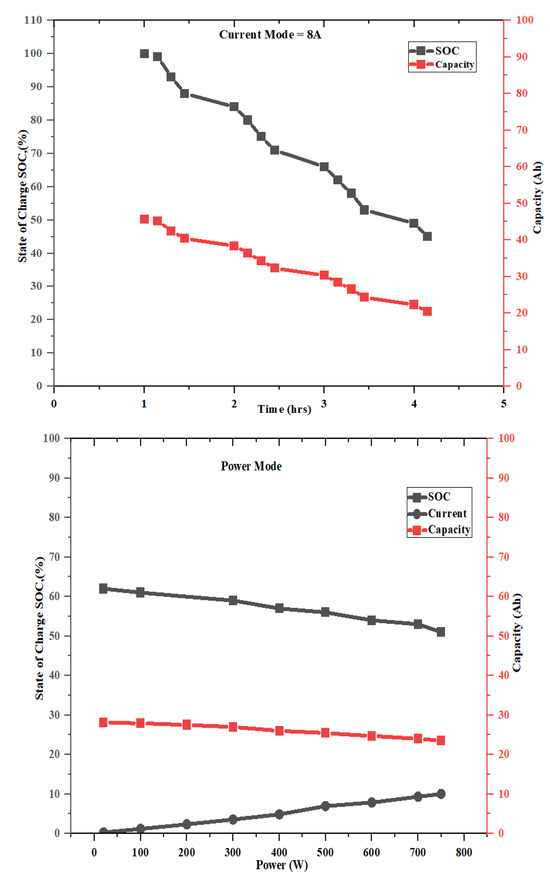

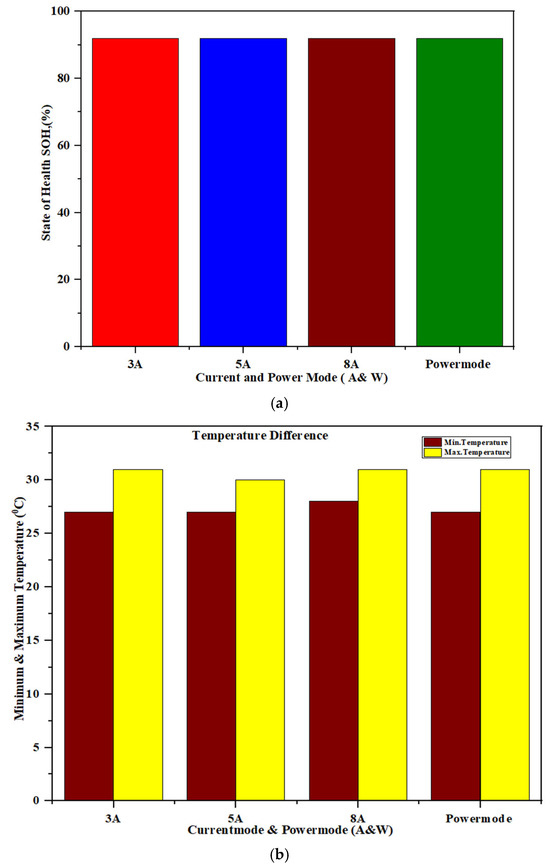

3.2. LFP Battery Charging

During the experimental investigation, the LFP battery pack was charged after every discharging process under various current-mode and power-mode conditions. As the minimum SOC for every current mode was maintained at 50% SOC, the LFP battery pack was recharged to a 100% level, and the status is presented in Figure 4. As noted in Figure 4, the time consumed to charge the 23 cells of the LFP battery back up to 100% is 6.15 h. As stated by other researchers [6,7], the battery charging time needs to be analysed to ensure smooth outcomes for the battery under all desirable operations, taking into consideration the degradation of the LFP battery due to fatigue discharging and overcharging conditions. As stated earlier, the LFP battery exhibited remarkable and stable performance throughout the entire investigation.

Figure 4.

Charging period of LFP battery pack.

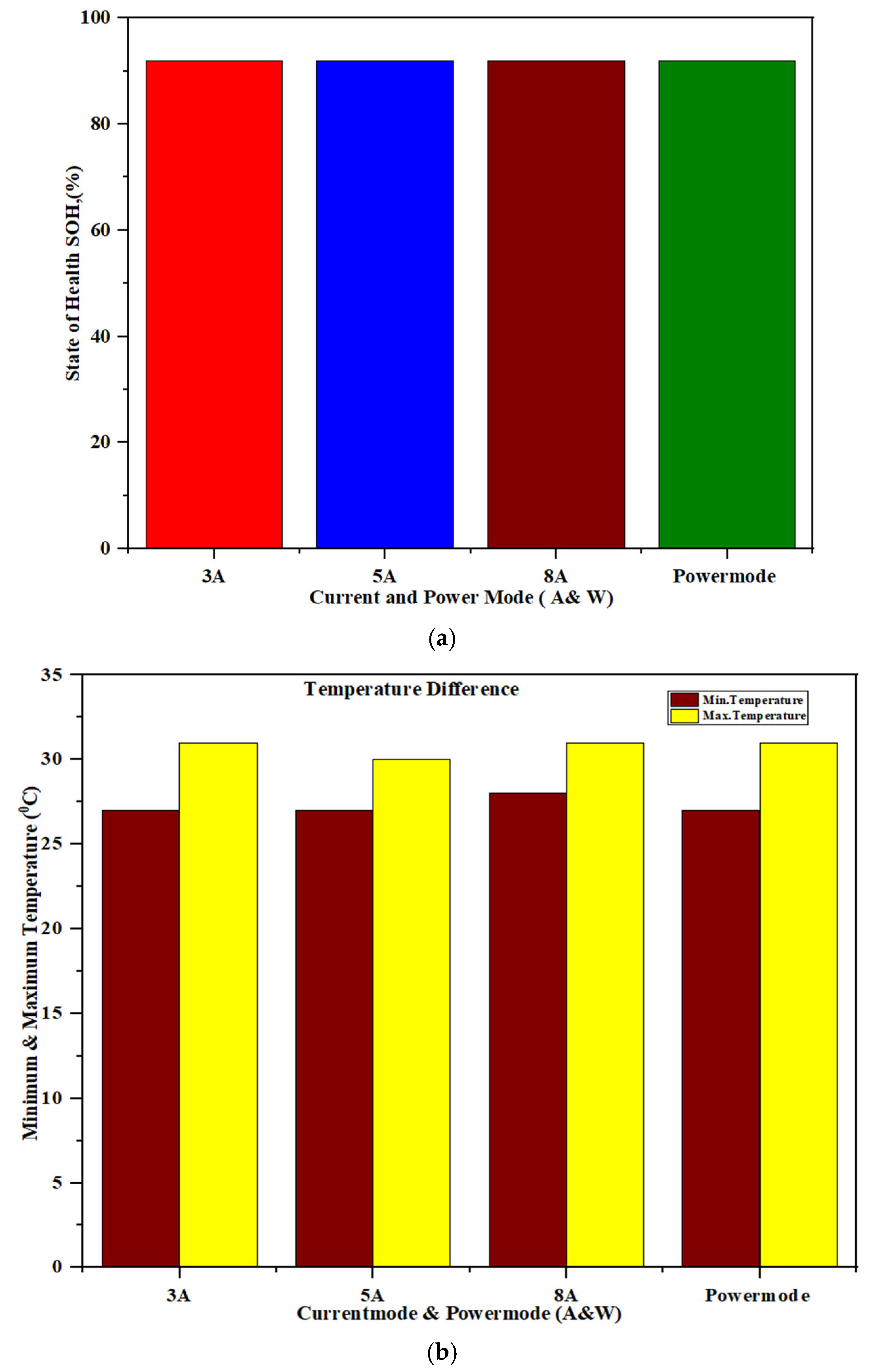

3.3. State-of-Health Assessment

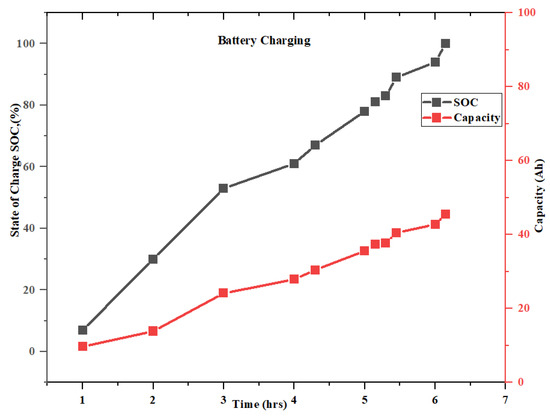

The state of health (SOH) is another type of battery health assessment parameter that distinguishes between the current health condition of a battery and its remaining useful life. Based on the manufacturer’s recommendation, the number of cycles a typical battery can withstand for its application is determined within the designated construction. The SOH is always used to compare the performance of a used battery with that of a newly developed one. Technically, it is estimated as the variation in the battery’s actual capacity relative to its nominal capacity, expressed as a percentage of the nominal capacity. In the present study, it is observed that the state of health (SOH) of the lithium ferrous phosphate battery pack is consistently maintained at 92% under all forms of current-mode and power-mode operations (Figure 5a). As the operating temperature remains constant during the investigation, based on ambient conditions of 26 °C to 31 °C, it does not significantly influence the SOH, as shown in Figure 5a,b. Suppose there is little temperature change in a battery despite altering the current. In that case, it is likely due to low internal resistance within the battery, meaning that even when current flows, minimal heat is generated because of the minimal resistance to this current flow; essentially, the battery is very efficient at converting electrical energy to usable power, with minimal energy loss as heat. As per the literature [8], the state of health can be estimated as the ratio of the measured battery capacity to the nominal battery capacity of the LFP battery. However, the SOH is greatly influenced by the manufacturing properties of LFP and other internal resistance factors, etc. As a new battery pack has been considered for investigation, the state of health remains constant in all the modes of operation. As the battery is further utilised in a device, its health, including its capacity and other useful parameters, will deteriorate until it reaches the end of its life.

Figure 5.

(a,b) State-of-Health Assessment and Thermal Management of LFP Battery Pack.

4. Conclusions

This experimental investigation into the performance and health management of a lithium-ferrous-phosphate battery pack was conducted using various current and power modes to assess the reliability of the LFP battery pack. The conclusions outlined below were drawn from this study. The state-of-charge assessment of the LFP battery pack yielded reliable and stable outputs, particularly with increased current-mode and power-mode operations.

- The state of charge is 58% for a period of 3.3 h when the current operating condition is 8 A. However, a lower current mode of 3 A, as an operating condition, resulted in an SOC of 57% after 9 h of reliable operation.

- The state of health of the LFP battery pack is consistently maintained at 92% throughout the experiment, and the temperature of the LFP battery pack is maintained at 25 °C to 31 °C.

Thus, with desirable advances, battery management technology will play a key role in energy storage and electric vehicle applications in the future.

Author Contributions

Conceptualization, N.K. and J.R.; methodology, V.M.; validation, T.W. and N.B.M.; formal analysis, S.M.; investigation, P.P. (Pranavya Punnakkattuparambil); resources, N.K., J.R.; data curation, S.M.; writing—original draft preparation, N.B.M., S.M. and P.P. (Pranavya Punnakkattuparambil); writing—review and editing, J.R. and P.P. (Preetha Punnakkattuparambil); supervision, V.M.; project administration, N.K., J.R.; funding acquisition, T.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Goin Global Industry-Academia Partnership Grant 2022 by the British Council, UK, under No IND/CONT/G/23-24/A1 (G/22-23/19).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sugumaran, G. An efficient buck-boost converter for fast active balancing of lithium-ion battery packs in electric vehicle applications. Comput. Electr. Eng. 2024, 118, 109429. [Google Scholar]

- Haraz, A.; Abualsaud, K.; Massoud, A. State-of-Health and State-of-Charge Estimation in Electric Vehicles Batteries: A Survey on Machine Learning Approaches. IEEE Access 2024, 12, 158110–158139. [Google Scholar] [CrossRef]

- Zhou, C.; Zhou, X.; Wang, Y.; Xiao, Y.; Liu, Y. Applicability assessment of equivalent circuit-thermal coupling models on LiFePO4 batteries operated under wide-temperature and high-rate pulse discharge conditions. Energy 2024, 313, 133709. [Google Scholar] [CrossRef]

- Vijaychandra, J.; Knypiński, Ł. A Comprehensive Review on Challenges and Possible Solutions of Battery Management Systems in Electric Vehicles. In Proceedings of the 2024 Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 24–28 June 2024; pp. 1–6. [Google Scholar]

- Dini, P.; Colicelli, A.; Saponara, S. Review on modeling and soc/soh estimation of batteries for automotive applications. Batteries 2024, 10, 34. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304. [Google Scholar] [CrossRef]

- Jindal, P.; Bhattacharya, J. Review—Understanding the thermal runaway behavior of Li-ion batteries through experimental techniques. J. Electrochem. Soc. 2019, 166, A2165. [Google Scholar] [CrossRef]

- Azis, N.A.; Joelianto, E.; Widyotriatmo, A. State of charge (SoC) and state of health (SoH) estimation of lithium-ion battery using dual extended kalman filter based on polynomial battery model. In Proceedings of the 2019 6th International Conference on Instrumentation, Control, and Automation (ICA), Bandung, Indonesia, 31 July 2019; pp. 88–93. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).