Abstract

Incorrect vehicle tire pressure affects vehicle dynamics, fuel efficiency, and driver safety across different terrain conditions. The current central tire inflation system (CTIS) alleviates this issue by adjusting the tire pressure to a predetermined reference level. However, the existing CTIS only adjusts the pressure based on load conditions through manual input for terrain types and lacks advanced intelligence for optimal automation. Integrating the recognition result of terrain conditions enables real-time adjustments of tire pressure and enhances driving performance and efficiency. This study aims to integrate the terrain recognition component using a convolutional neural network (CNN) by reviewing previous terrain-detection models. The CTIS was enhanced to classify and detect terrain conditions and apply the correct tire pressure level. We employed a systematic literature review (SLR) to assess the development procedures for integrating the intelligent component with the basic CTIS. ResNet-18 was used as the most appropriate CNN model to classify the terrain conditions on a gathered local dataset. A single-wheel testbed using the enhanced CTIS is appropriate for laboratory testing and system integration tests.

1. Introduction

Vehicle tire pressure affects the tire lifespan, the fuel economy, carbon emissions, and vehicle safety and mobility. Inappropriate tire pressure is a common problem in vehicles but automatic car tire inflation systems can solve it easily [1]. An electromechanical system, the central tire inflation system (CTIS), is installed to automatically adjust tire pressure depending on input conditions such as the weight and speed of a vehicle [2]. With its automatic tire pressure adjustment function, the CTIS enhances the fuel economy by 2.8% and minimizes carbon dioxide (CO2) emissions by 58 kg per vehicle per year [3]. This system also improves vehicles’ performance on soft soil by increasing the maximum velocity by 20 to 36%, drawbar pull forces by 43 to 132%, and decreasing towed motion resistances by 18 to 11% [4]. In agricultural tractors (operating on paved roads and fields) and trucks (traversing on forest roads), the CTIS reduces the average fuel consumption by up to 8.9 and 1.7%, respectively [5].

Currently, the CTIS possesses high marketability with an expected growth forecast of 8.40% from 2021 to 2028 [6]. Its annual growth rate is 13%, expecting to reach USD 108 million in 2027 [7,8]. The market data suggest that a significant number of vehicles employ the CTIS. However, current CTIS technology is limited to manual operation, which is passive and does not consider the vehicle’s tire and terrain conditions. Improper tire pressure varies and directly affects the vehicle’s performance.

The CTIS has been improved to maintain the correct tire pressure without the need for human intervention. The existing CTIS adjusts tire pressure through button interfaces. The automated CTIS must maintain appropriate tire pressure according to the vehicle’s loading and speed [9,10].

We conducted a literature review to evaluate studies in which CTIS technology is improved by introducing an automatic terrain recognition feature that adjusts tire pressure accordingly. We also proposed a tire pressure management approach that integrates a terrain recognition device. We explored the use of convolutional neural network (CNN) models for real-time terrain detection and classification. The model’s accuracy reaches at least 90%, with an optimized design of an enhanced CTIS. Related studies on tire assemblies were also reviewed to ensure effective communication between system components, particularly control units and sensors. The results of this study provide a reference for integrating terrain recognition results into the CTIS.

2. Methodology

2.1. Research Design

We employed a systematic literature review (SLR) to examine and evaluate various models for terrain recognition. Features were extracted and analyzed from laboratory-based tire setups. In the SLR, the identification, selection, and synthesis of research findings were summarized and assessed for effectiveness and applicability (Figure 1) [11]. The results help to establish a solid foundation to develop an intelligent CTIS to adjust the tire inflation pressure based on terrain conditions.

Figure 1.

SLR research design.

2.2. Data Collection and Analysis Methods

Data collection is important in creating a CTIS prototype with a terrain-recognition function. We investigated the principles, variables, algorithms, components, and designs for the terrain-recognition component integrated into the CTIS. For the literature review, databases related to CTIS development were selected, focusing on its effectiveness and the integration of automatic terrain recognition using machine learning algorithms. For data analysis, inclusion and exclusion criteria were applied to assess the relevance of the studies. Relevant information included CTIS effectiveness, component designs, and machine learning algorithms for terrain recognition. The criteria enabled algorithms with high accuracy and short training times. The proposed methods were validated by assessing the feasibility of the experimental setup, machine learning models, and datasets for transfer learning.

3. Results

3.1. Effectiveness of CTIS

A total of 78% of European drivers travel with underinflated car tires [3]. Tire pressure impacts CO2 emissions and the fuel economy. We assessed the potential impact of the automated CTIS on vehicles. To measure the impact of the intelligent CTIS, three key effects were considered: (1) the difference in fuel efficiency caused by a change in tire pressure, (2) the difference in fuel efficiency caused by a change in the vehicle’s mass center at a reference tire pressure, and (3) the variation in fuel efficiency as a function of tire warm-up rolling time at the reference inflation and load condition.

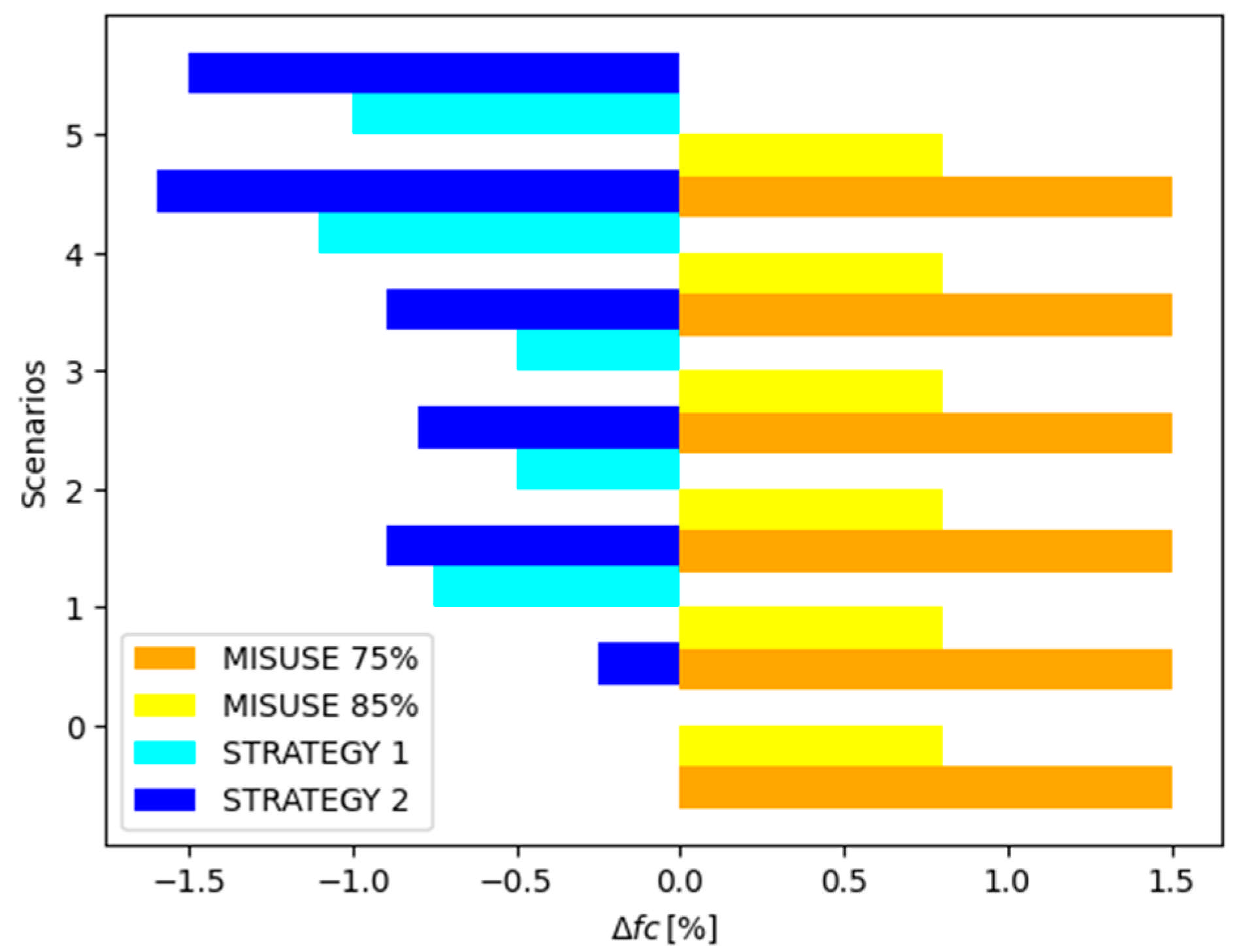

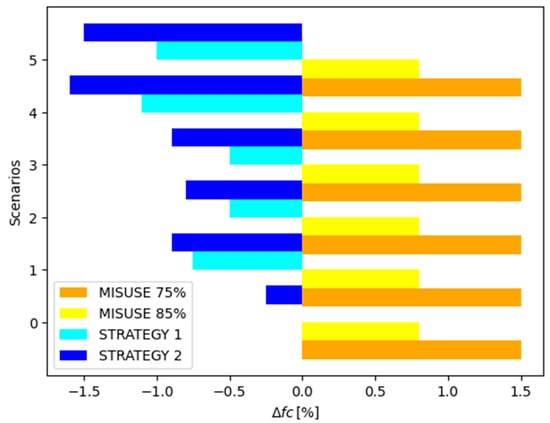

The results of the analysis for a single car are shown in Figure 2 as relative changes in fuel consumption in the formulated scenarios and strategies. The strategy of an autonomous on-board pressure control system was adjusted to load and temperature changes for the best fuel economy. An additional strategy was established considering increased tire pressure in the rural environment. Incorrect tire inflation (75% of the reference tire pressure) results in the worst fuel efficiency. Therefore, the intelligent CTIS improves the fuel economy and reduces CO2 emissions.

Figure 2.

Fuel consumption on scenarios, misuse, and strategies.

Regarding the fuel economy [12], continuous contact between the vehicle and the road enables the reduction in fuel consumption by up to 1.6–2.4%, depending on load. Considering a pressure change with time, the tire’s warm-up process needs to be managed effectively. When the engine starts, the pressure increases while the in-tire air mass gradually decreases as the tire temperature rises. Rolling resistance is negatively impacted by a low tire temperature. A sound management plan minimizes fuel use by about 0.5%.

The findings regarding the effect of tire pressure management on the fuel economy coincide with previous results [13]. As the tire pressure increases, the average fuel consumption of the vehicles decreases. In Ref. [9], the influence of an intelligent CTIS on vehicle lateral dynamics was studied. Understeering decreases at a constant tire inflation pressure as the vehicle mass increases. Additionally, for a load of 1350 kg, the understeering decreases as the tire inflation pressure increases. The vehicle’s lateral dynamic characteristics are affected by changes in the load, and the tire inflation pressure is related to understeering and oversteering. In conclusion, the CTIS must be built as an active control to improve lateral vehicle dynamics by automatically altering the tire pressure according to the vehicle operating parameters.

3.2. Terrain Recognition and Classification

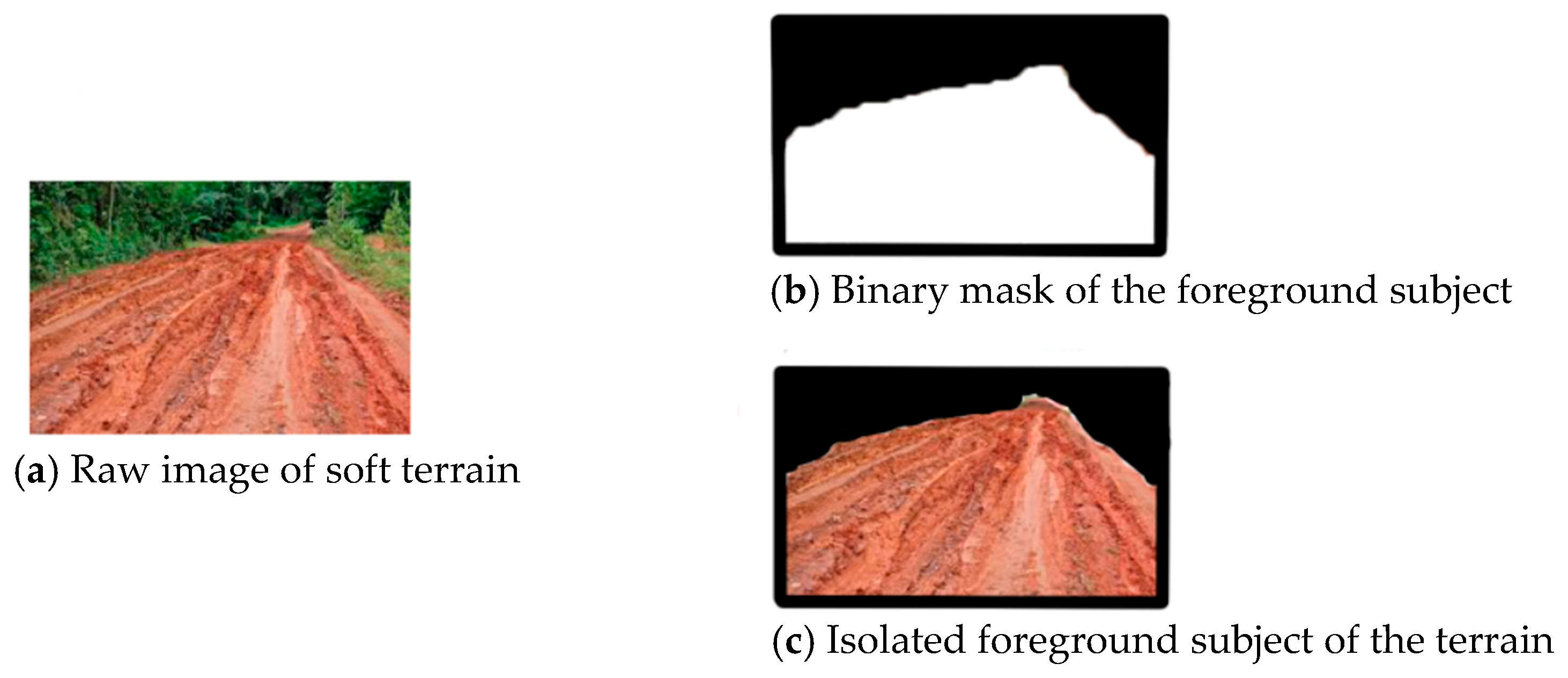

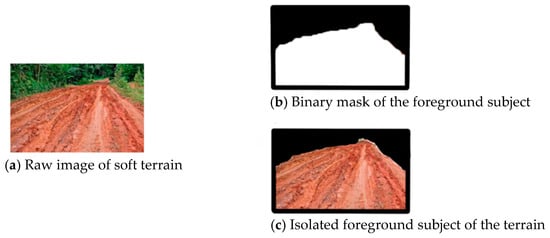

For terrain recognition algorithms, CNNs are used because they can extract features in identified patterns of input data. Several methods provide a vision for terrain recognition and can train the model with the gathered datasets. RGB, RGB-D, and infrared cameras are used to classify terrain conditions using collected infrared and depth data. Before training the neural network algorithm, images were preprocessed to remove the homogeneous background and tiling and to divide the high-resolution images into larger pixels, as shown in Figure 3 and Figure 4.

Figure 3.

Pre-processing of datasets.

Figure 4.

Tiling of terrain using 20 × 20 pixels.

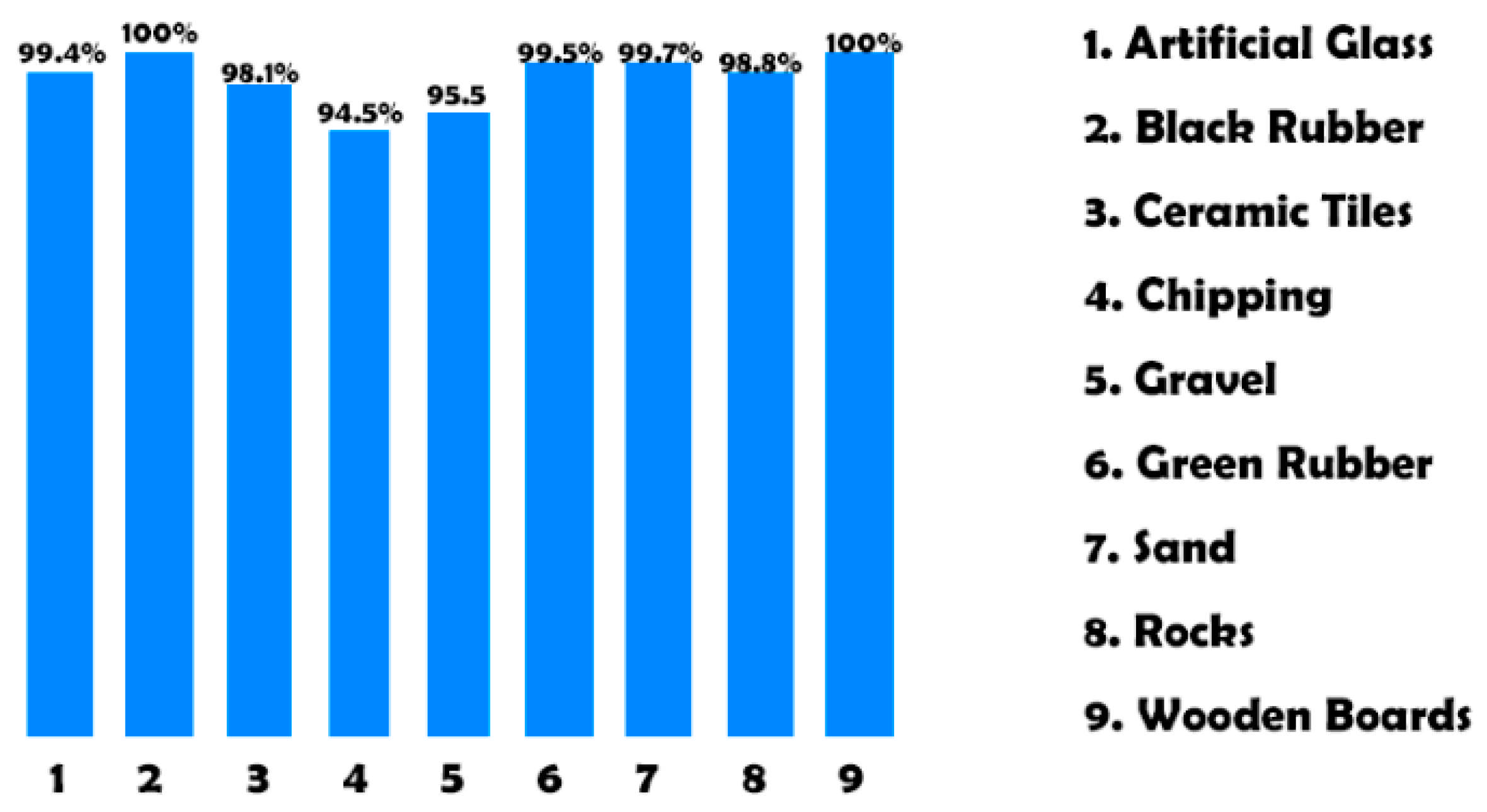

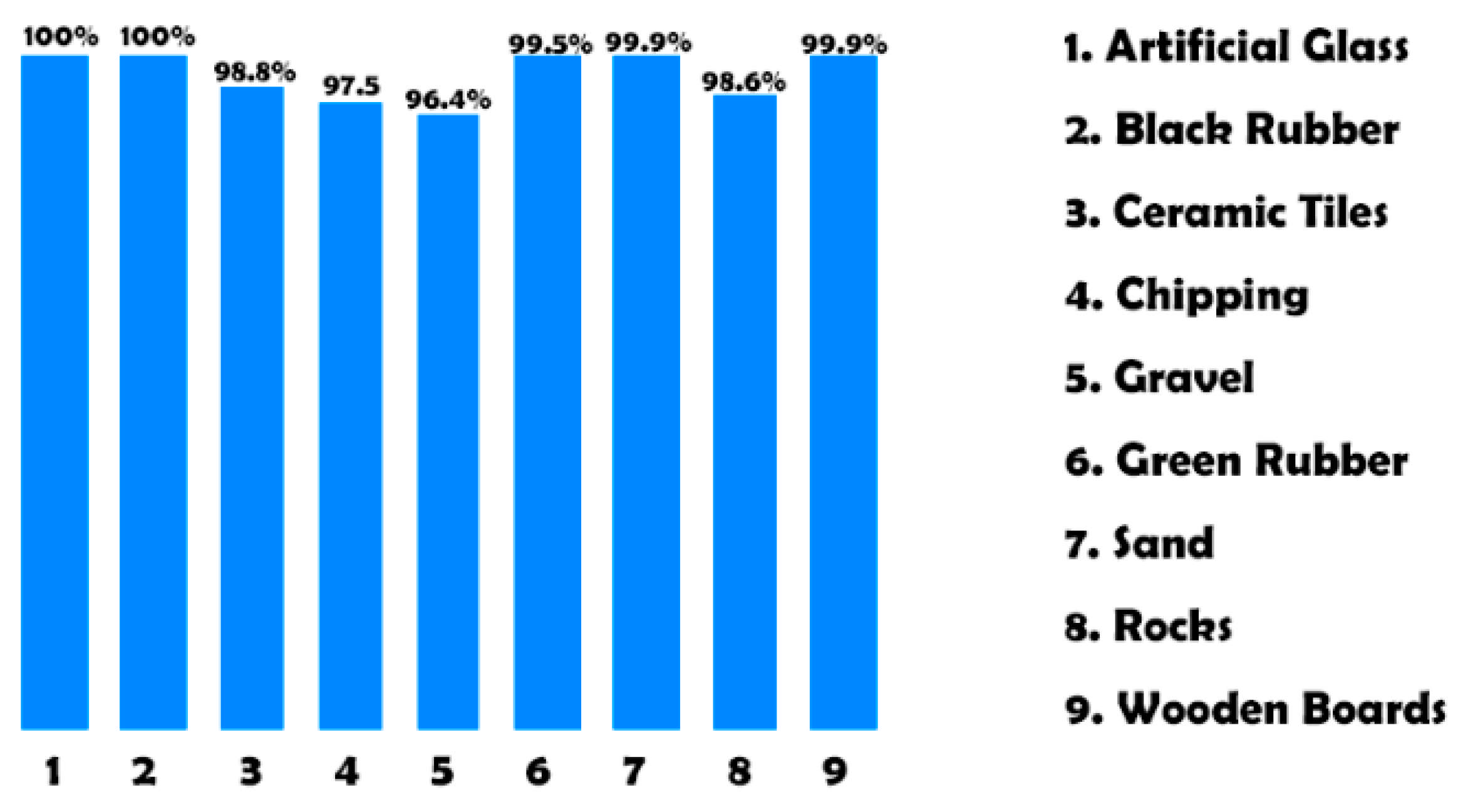

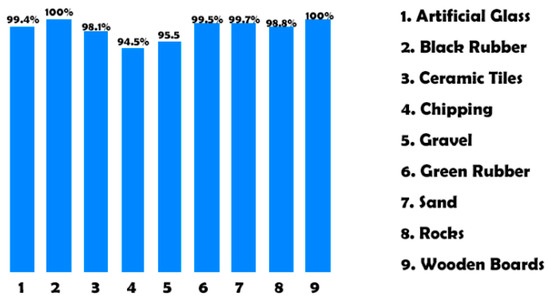

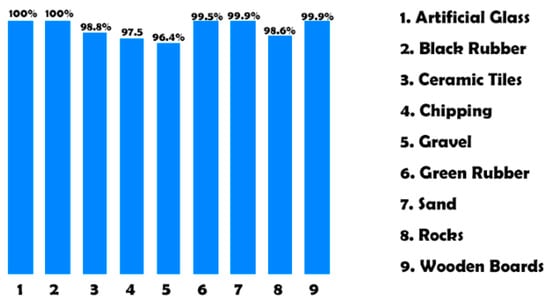

High accuracy was observed in the neural network for recognizing terrain classification from the provided nine terrain datasets [14]. The initial learning and algorithm testing involved RGB data and reached an accuracy of 98.41% (Figure 5). The accuracy rate was improved after infrared and depth data were introduced to the training and testing of datasets [14]. Thus, the average accuracy increased to 98.99% (Figure 6).

Figure 5.

Accuracy using RGB data.

Figure 6.

Accuracy using RGB, infrared, and depth data.

The terrain recognition algorithm was tested on heterogeneous image samples. The image was segmented to detect terrain conditions simultaneously. The results of the camera vision displayed terrain conditions in different colors and segmentation [14]. A larger field of view was used for aerial images taken by satellites and aerial balloons. The captured images were segmented according to their varying features, and terrain recognition was applied over a wide area to help vehicles adapt to classified terrain conditions [15,16].

The proposed architecture model adopted CNNs [17]. The local datasets contained three categories and around 1200 images per category of flat, soft, and uneven terrain conditions. The data were augmented to improve the dataset and increase the accuracy. Different pre-trained CNN models were trained with gathered datasets, and the accuracy, precision, recall, and f1-score results are shown in Table 1.

Table 1.

Comparison of CNN model performance.

Table 1 presents the different values of the accuracy of various trained models. The models were trained with different deep layers using ResNet and VGG. Each trained model achieved an accuracy of over 90% on the provided test data. The model performed successfully across different architectures. ResNet-18 demonstrated higher accuracy than the other models, showing better performance in learning the terrain images.

3.3. System Design and Framework, Developmental Procedures, and Test Results

The results of the SLR present the methodology, design, and procedure of the CTIS technology. In the designs, only one tire assembly was proposed in the experimental setup.

System integration tests were conducted to evaluate the feasibility of the utilized components in Ref. [18]. In the testing process, all system parts were connected, and the engineering design was assessed using computer-aided design (CAD) tools. The electronic and mechanical components operated effectively in testing. The theoretical inflation rate of the front and rear tires was calculated based on the ideal values in the system, including the performance of the engine and the air compressor, and the air capacity of the tires [19]. Theoretical calculations were performed for the inflation rate of the front tires (12 s per 2 psi) and the rear tires (21 s per 2 psi). In repetitive tests, the front tire needed 12 s to increase its pressure by 2 psi, and the rear tire needed 19.7 s. These results were similar to the values from the theoretical calculations. In Ref. [20], a design of an automatic tire inflation system was presented. The design of each component was examined and described, and the results indicated that the components in the system interacted well.

3.4. Tire Pressure and Terrain Relationships

As the CTIS regulates the tire inflation pressure, evaluating the relationship between the tire pressure and the terrain is necessary to determine the parameters of the intelligent CTIS to adapt to the vehicle’s terrain. The performance of off-road vehicles, particularly military ones, on soft terrain was heavily influenced by the terrain’s properties, with soil composition playing a crucial role [19]. As soil is mixed with weathered rocks air and water, it presents shear deformation and shear strength that affect vehicle mobility. Cohesive soils, such as damp clays, and frictional soils, such as dry sands, are challenging for off-road vehicles. The shear strength of soil, particularly in clay, decreases with moisture. It decreases by 24 to 29% as moisture reduces it by up to 70%, resulting in greater wheel slippage. This loss in traction increases motion resistance, directly affecting a vehicle’s fuel efficiency and maximum speed. Traction is constrained by the power system’s tractive capacity at any given speed [21].

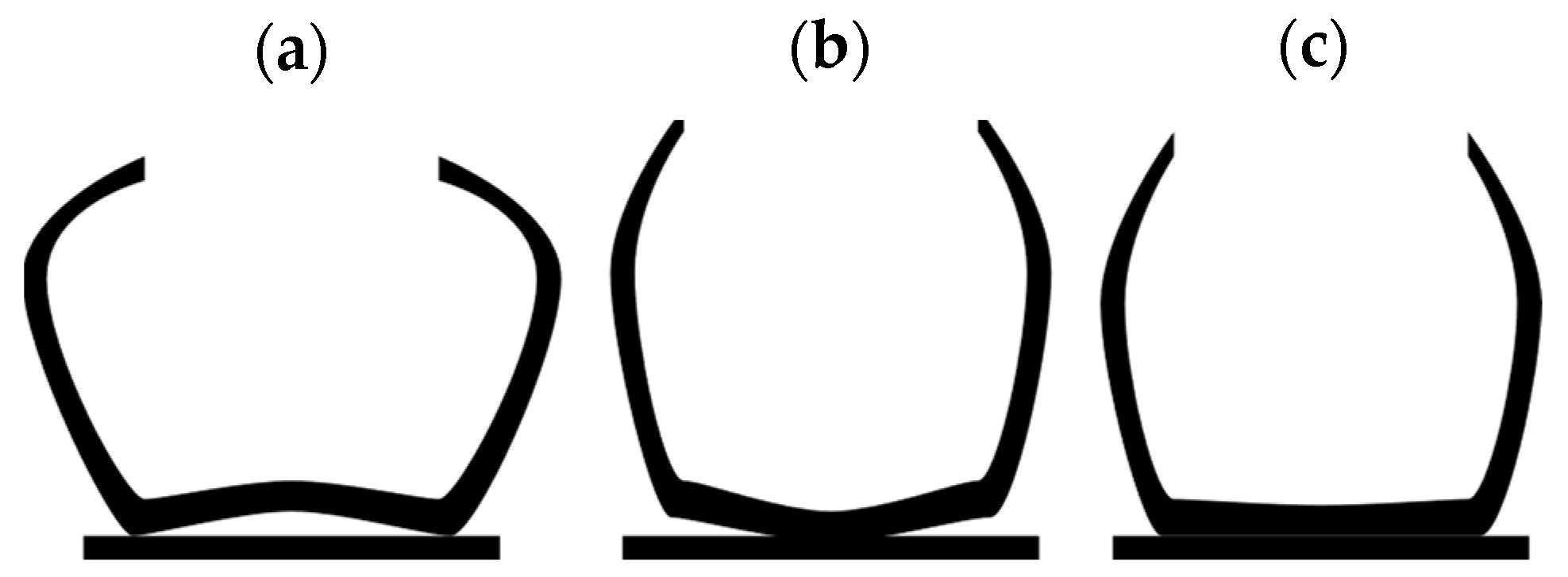

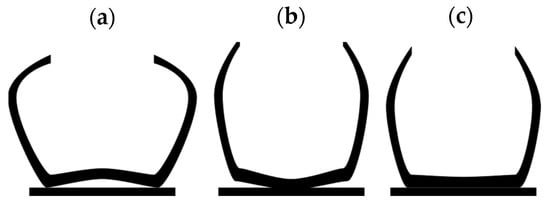

Tire pressure influences tire dynamics by altering the tire–road contact area and its ability to transfer forces [12]. Changes in tire pressure affect longitudinal slip stiffness, cornering stiffness, camber stiffness, and the tire’s deflection due to changes in vertical stiffness. Lowering the tire pressure expands the contact patch and improves traction, but when vehicles run on solid terrain at very low pressures, inward tread deformation reduces the tire’s force transfer efficiency and shortens its lifespan by deforming the sidewalls and tread. However, extreme under-inflation and reduced tire pressure increase rolling resistance and lower the contact pressure. The tire load is distributed effectively across the terrain. Various tire deformations are conceivable depending on the tire pressure level. Such deformations affect the stability of tires and cause uneven tread wear, as shown in Figure 7.

Figure 7.

Tire deformation in (a) low, (b) high, and (c) proper pressures.

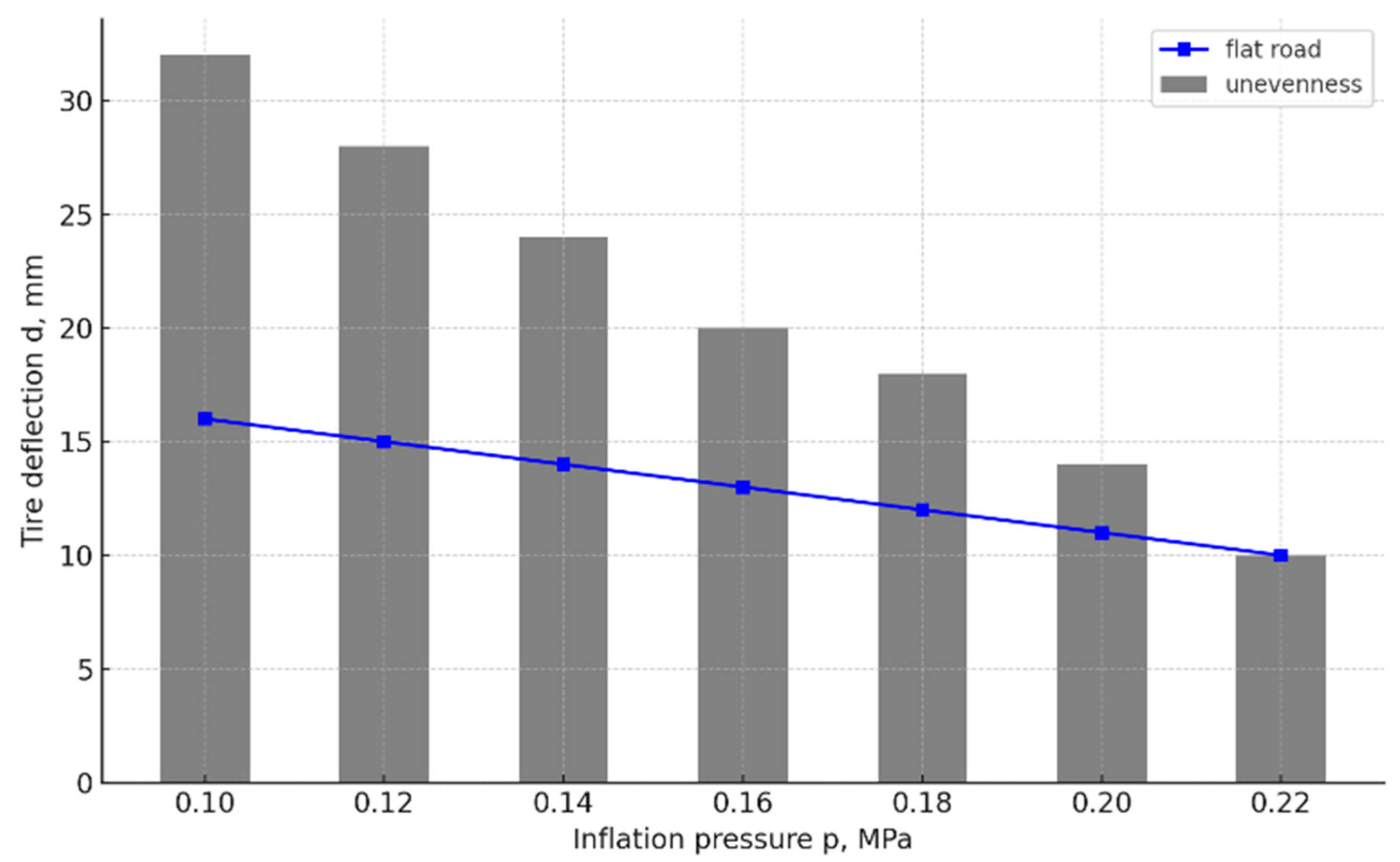

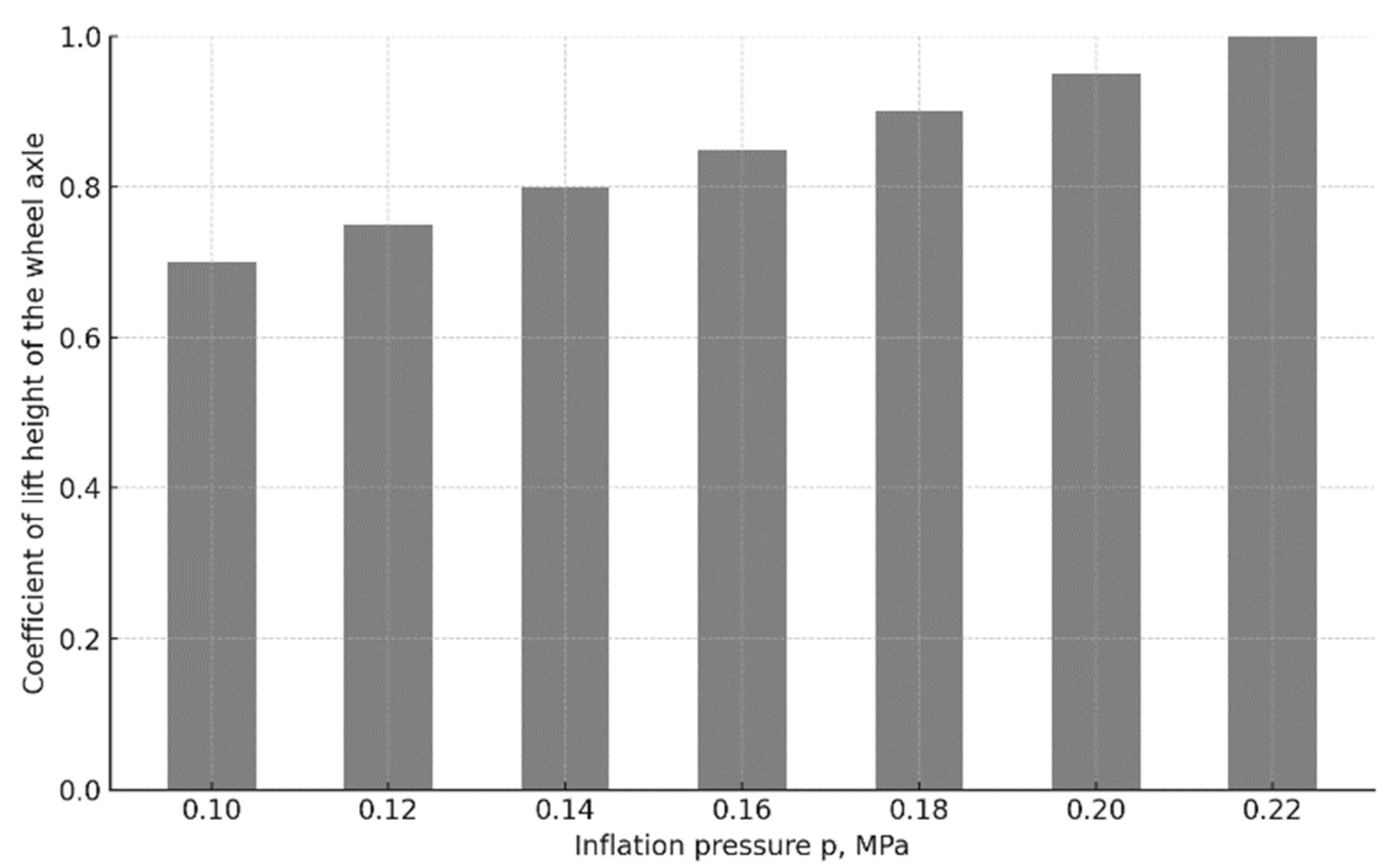

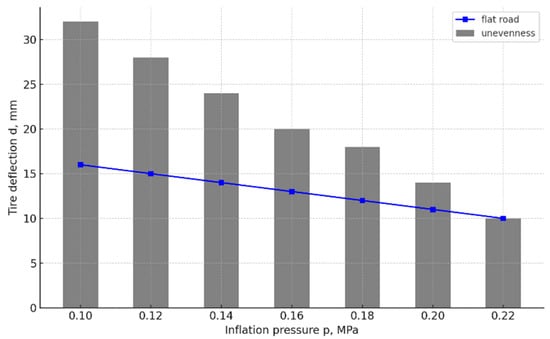

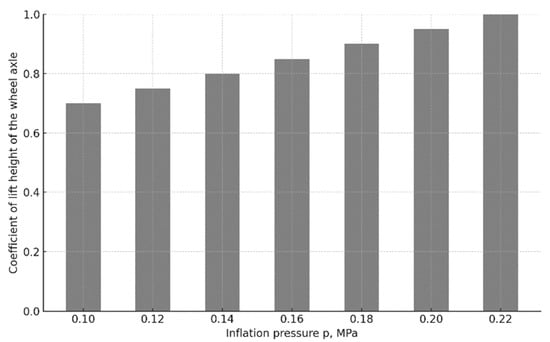

To overcome the unevenness of the road, a change in the load on the car’s tire is necessary [22]. When the load is changed, the suspension and tire deflection occur. The wheel load force and wheel axle movement, coupled with the vertical and longitudinal components of the wheel load force, are used to compute the direction of the force on the tire. The tire pressure influences the deflections in both the tire and wheel axle, as shown in Figure 8 and Figure 9.

Figure 8.

Tire deflection on uneven track with various pressures.

Figure 9.

Axle deflection on uneven track with various pressures.

4. Discussion

Maintaining the reference tire pressure with the automated CTIS improves fuel economy and vehicle dynamics, particularly on paved roads. The automated CTIS adapts to varying loads, but these findings are limited to on-road terrain. In off-road terrain conditions, including soil, sand, and uneven surfaces, lowered tire pressure below the reference level reduces fuel consumption. On deformable terrain conditions, such as soil and sand, lower pressures minimize wheel slippage, while on uneven terrain conditions, reduced tire pressure allows the suspension system to perform less work as tire deformation and axle deflection absorb the terrain’s height variations more effectively.

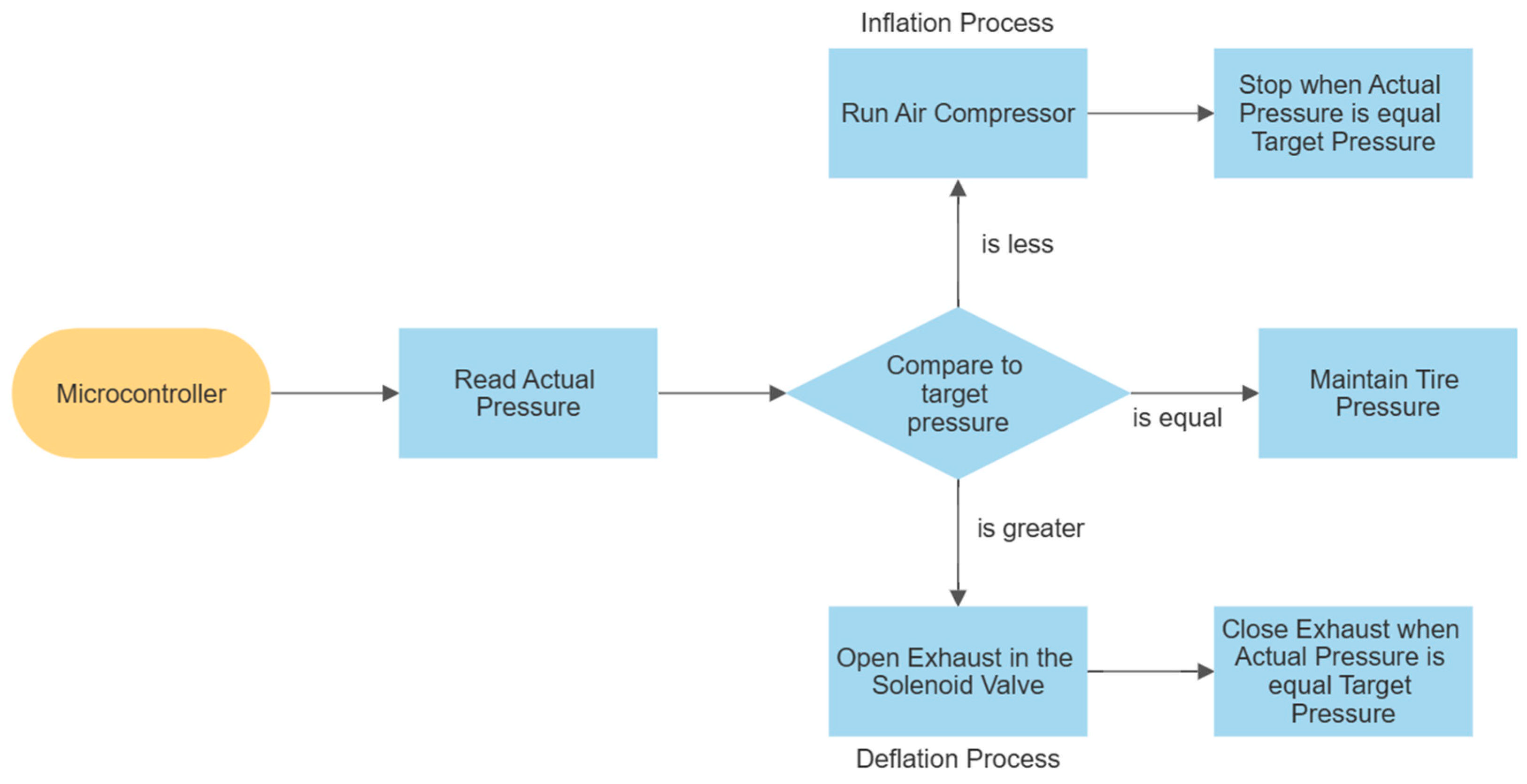

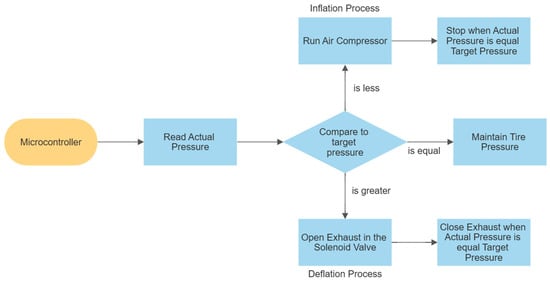

In assessing hardware designs, the basic components of the CTIS include microcontrollers, pressure sensors, solenoid valves, rotary joints, air compressors, batteries, voltage sensors, and relays. The designs of the inflation system and the connection of components are presented in Figure 10.

Figure 10.

Inflation and deflation process.

4.1. Benefits and Effectiveness of CTIS

The advanced CTIS in different road settings has benefits as an optimal tire pressure is maintained based on the vehicle’s load to improve fuel economy, vehicle dynamics, and the handling of oversteer and understeer. However, in off-road environments such as soft soils, decreased tire pressure enables better performance by increasing the tire’s contact area as the vehicle’s load is evenly distributed on the soft terrain. This minimizes soil compaction and enhances traction, reduces wheel slippage, and, consequently, improves fuel efficiency and mobility. Maintaining road-appropriate tire pressure on soft soils, by contrast, leads to less traction and increased energy waste due to slippage. Similar trends are observed on the sand as lowering tire pressure optimizes the tire–soil interaction by maximizing the contact patch area.

On uneven and rocky terrain conditions, reduced tire pressure enhances tire deformation, allowing the tire to conform to the terrain’s irregularities. This deformation reduces height variations at the wheel axle, decreasing the load on the suspension system for smoother driving.

In summary, tire pressure adjustment by the CTIS is conducted on different terrain types for optimal performance by lowering the tire pressure on deformable and uneven surfaces and maintaining the reference pressure for normal road conditions.

4.2. Terrain Recognition Model

For enhancing the automatic terrain recognition capabilities of the CTIS, CNNs are the most effective method. CNNs excel at identifying patterns and features and classifying terrain types by learning from self-gathered or existing databases. DeepLab, VeeGerTerramechanicsNet, and multi-class AdaBoost were also evaluated, and CNNs, particularly ResNet-18, demonstrated superior accuracy and faster training. ResNet-18’s performance is ideal for terrain recognition, and transfer learning is needed to maintain high accuracy.

4.3. Intelligent CTIS Operational Workflow and Design

The basic operation of the CTIS involves adjusting the tire pressure to optimal levels using key components such as microcontrollers, pressure sensors, solenoid valves, rotary joints, air compressors, and batteries. These components operate to continuously monitor tire pressure and adjust it as needed. When the tire pressure falls below or exceeds the desired range, the microcontroller activates the air compressor or solenoid valves to inflate or deflate the tires. All of the reviewed studies used similar setups with differences in individual components. The CTIS in the studies employs 3D CAD modeling for initial system design. Mechanical fabrication and system integration were evaluated for component interaction, and performance tests to measure tire inflation times.

Integration tests were conducted to ensure communication between the system’s components, while performance tests were performed to measure inflation times and verify the system’s ability to maintain the appropriate tire pressure. The tire pressure before and after CTIS installation was compared to evaluate its long-term effectiveness. Similar methods using integration and performance tests were evaluated using a terrain-recognition algorithm. In training and validating the algorithm, the accuracy and processing speed were measured. To assess the performance of the terrain-recognition component, the CTIS inflation performance test results confirmed the system’s functionality and ensured smooth integration of the new component.

Author Contributions

Conceptualization, C.L.C.L., C.J.I.T. and E.A.S.; methodology, C.J.I.T. and E.A.S.; software, C.L.C.L.; validation, C.L.C.L., C.J.I.T. and E.A.S.; formal analysis, E.A.S.; investigation, C.J.I.T.; resources, C.L.C.L.; data curation, C.L.C.L., C.J.I.T. and E.A.S.; writing—original draft preparation, C.J.I.T.; writing—review and editing, E.A.S.; visualization, C.L.C.L.; supervision, M.B.T., E.G.T.R. and J.P.T.C.; project administration, M.B.T., E.G.T.R. and J.P.T.C.; funding acquisition, M.B.T. and E.G.T.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research presentation was funded by Mapua Malayan Colleges Mindanao through the Office for Research, Development, and Innovation.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Datasets were downloaded from open access websites. Meanwhile, newly created datasets by authors may be requested by sending an email to any of the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Birkland, C. It’s in the Air: Managing and Maintaining Tires to Increase Service Life. Fleed Equipment. 14 December 2017. Available online: https://www.fleetequipmentmag.com/managing-maintaining-truck-tires-increase-service-life/ (accessed on 11 January 2023).

- Obringer, L.A. How Self-Inflating Tires Work. How Stuff Works. 9 February 2021. Available online: https://auto.howstuffworks.com/self-inflating-tire2.htm (accessed on 11 January 2023).

- d’Ambrosio, S.; Mameli, E.F.; Vitolo, R. Impact assessment of an intelligent central tire inflation system for passenger cars. In Proceedings of the 7th Transport Research Arena TRA 2018, Vienna, Austria, 16–19 April 2018; pp. 16–19. [Google Scholar]

- Kang, D.; Lee, M.C.; Cho, S.; Shin, Y. Experimental Study on Mobility of a Vehicle with CTIS in Soft Soil. Int. J. Automot. Technol. 2014, 15, 71–77. [Google Scholar] [CrossRef]

- Juselius, T.S. Investigation of the Energy Efficiency and Environmental Impact of Central Tire Inflation Systems for Commercial Vehicles Focusing on Agriculture and Forestry. 14 December 2020. Available online: https://aaltodoc.aalto.fi/handle/123456789/97528 (accessed on 11 January 2023).

- Fortune Business Insights. Central Tire Inflation Market Size, Share & Industry Analysis By Type (Central Tire Inflation System, Continuous Tire Inflation System), By Component (Rotary Union, Compressor, Pressure Sensor, Housing, Air Delivery System, ECU, Buffer Tank), By Vehicle (On-Highway Vehicle, Off-Highway Vehicle, Electric Vehicle) And Regional Forecast, 2025–2032. Fortune Business Insights. 2021. Available online: https://www.fortunebusinessinsights.com/central-tire-inflation-market-105604 (accessed on 11 January 2023).

- Markets and Markets. Automatic Tire Inflation System Market by Type (Central, Continuous), On-Highway Vehicle (LDV, HDV), Off-Highway (Agriculture, Construction), EV (BEV, PHEV, FCEV), Sales Channel (OEM, Aftermarket), Component & Region—Global Forecast to 2027. Markets and Markets. March 2020. Available online: https://www.marketsandmarkets.com/Market-Reports/automatic-tire-inflation-system-market-52126096.html (accessed on 11 January 2023).

- Cision PR Newswire. Automatic Tire Inflation System Market Is Expected to Display a Steady Growth by 2028|CAGR: 13%|UnivDatos Market Insights. Cision PR Newswire. 12 October 2022. Available online: https://www.prnewswire.com/news-releases/automatic-tire-inflation-system-market-is-expected-to-display-a-steady-growth-by-2028cagr-13-univdatos-market-insights-301647184.html (accessed on 11 January 2023).

- d’Ambrosio, S.; Mattei, E.D.; Vitolo, R.; Amati, N. Automatic adjustment of tire inflation pressure through an intelligent CTIS: Effects on the vehicle lateral dynamic behavior. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2021, 235, 3487–3508. [Google Scholar] [CrossRef]

- Diwakar, S. Automatic Tyre Pressure Inflation System. Int. J. Progress. Res. Sci. Eng. 2020, 1, 219–221. [Google Scholar]

- Dewey, A.; Drahota, A. Introduction to Systematic Reviews: Online Learning Module. Cochrane Training. 2016. Available online: https://training.cochrane.org/interactivelearning/module-1-introduction-conducting-systematic-reviews (accessed on 5 May 2023).

- d’Ambrosio, S.; Vitolo, R. Potential impact of active tire pressure management on fuel consumption reduction in passenger vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2018, 233, 961–975. [Google Scholar] [CrossRef]

- Szczucka-Lasota, B.; Kamińska, J.; Krzyżewska, I. Influence of tire pressure on fuel consumption in trucks with installed tire pressure monitoring system (TPMS). Sci. J. Silesian Univ. Technol. Ser. Transp. 2019, 103, 167–181. [Google Scholar] [CrossRef]

- Kozlowski, P.; Walas, K. Deep Neural Networks for Terrain Recognition Task. In Proceedings of the Baltic URSI Symposium, Poznan, Poland, Baltic. 15–17 May 2018. [Google Scholar]

- Lunsaeter, S.F.; Iwashita, Y.; Stoica, A.; Torreson, J. Terrain Classification from an Aerial Perspective. In Proceedings of the 2020 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Toronto, ON, Canada, 11–14 October 2020. [Google Scholar]

- Nguyen, N.-H.; Woo, D.-M.; Kim, S.; Park, M.-K. Terrain segmentation of high resolution satellite images using multi-class AdaBoost algorithm. In Proceedings of the International Conference on Natural Computation, Xiamen, China, 19–21 August 2014. [Google Scholar]

- Song, P.; Ma, X.; Li, X.; Li, Y. Deep Residual Texture Network for Terrain Recognition. IEEE Access 2019, 7, 90152–90161. [Google Scholar] [CrossRef]

- Dilwale, S.; Anvekar, O.; Daware, A.; Bhavad, V.; Bagal, S.; Shelar, P. Design and Development of Centralized Tyre Pressure System. Int. Res. J. Eng. Technol. 2018, 5, 2138–2146. [Google Scholar]

- Burase, I.; Kamble, S.; Patil, A.; Kharat, A. A Survey on Automatic Air Inflating System. Int. J. Innov. Res. Sci. 2016, 5, 18517–18523. [Google Scholar]

- Ghag, P. Automatic Tire Inflation System. Int. Res. J. Eng. Technol. 2022, 9, 107–111. [Google Scholar]

- Maclaurin, B. High Speed Off-Road Vehicles; Wiley Professional, Reference & Trade (Wiley K&L): Hoboken, NJ, USA, 2018. [Google Scholar]

- Parczewski, K. Impact of tire inflation pressure during overcoming of road unevenness. In Proceedings of the 21st International Scientific Conference Transport Means 2017, Juodkrantė, Lithuania, 20–22 September 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).