Abstract

We incorporated a Peltier cooling system into vests for personal comfort and applications in various workplaces. We tested the Peltier cooling vest using temperature sensors and evaluated the vest’s performance. The developed Peltier cooling vest included thermoelectric cooler modules to improve cooling efficiency and comfort by using water’s heat transfer and thermal conductivity. Through testing and subjective assessments, the effectiveness of the wearable cooling system and its potential for widespread adoption were validated. Furthermore, an intelligent control algorithm was developed to maintain target temperatures. The built-in temperature sensor enabled temperature stability in the set temperature range. The average cooling response time of the Peltier cooling vest was 9.42 min. In a lower temperature range of 16 to 24 °C, the vest maintained a stable temperature. A correlation between temperature and power consumption was observed. To improve the performance, built-in Bluetooth and a graphic user interface need to be integrated. Then, the Peltier cooling vest and its technology can be used in medical and industrial settings.

1. Introduction

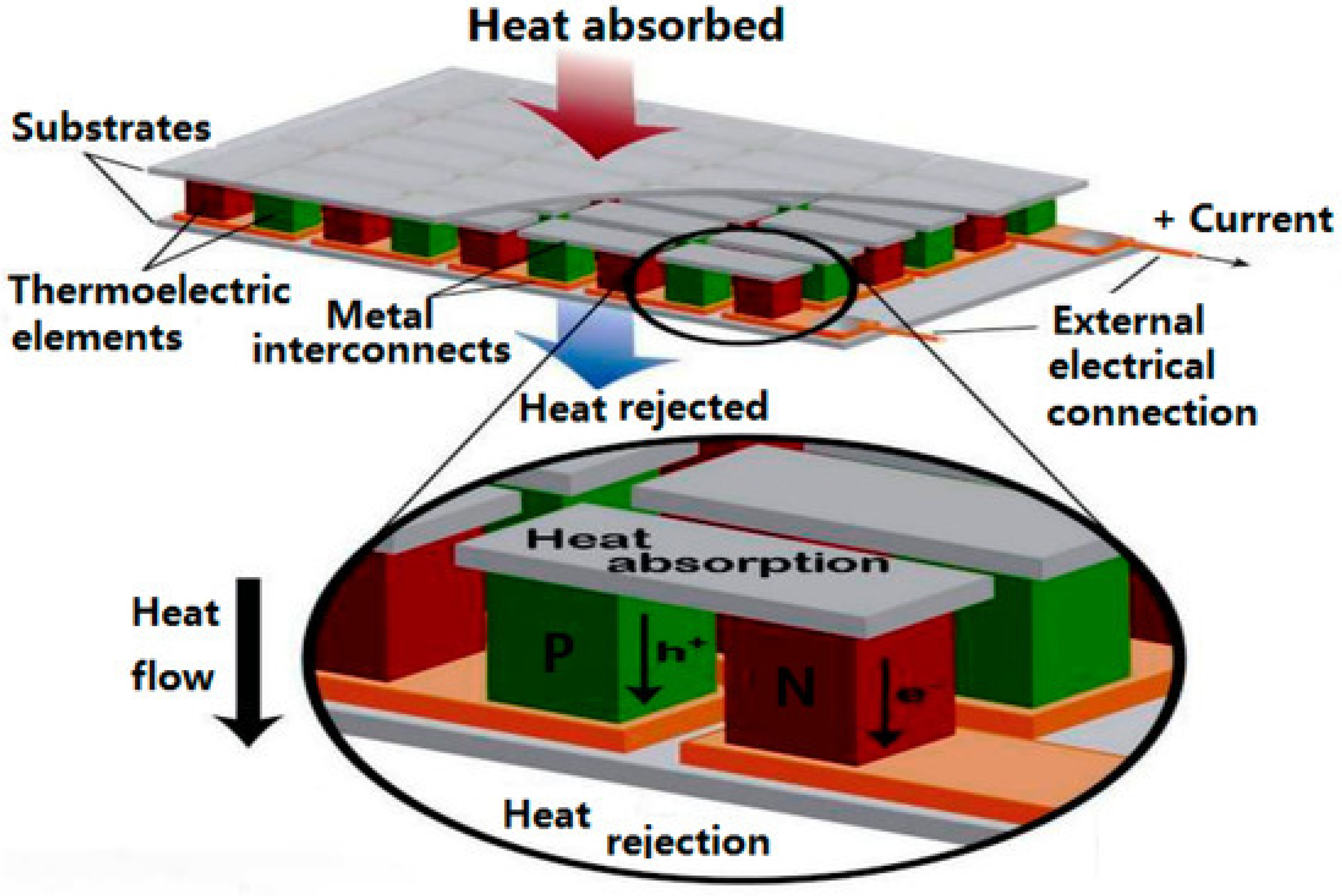

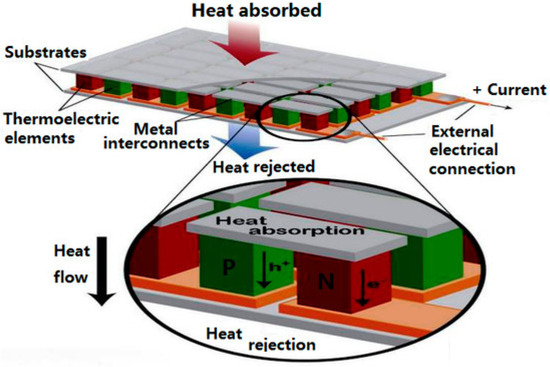

The advancement of wearable technologies has fueled innovation in many fields, most notably personal comfort and healthcare. Among these innovations, the incorporation of Peltier cooling systems into vests stands out as a promising way to effectively regulate body temperature. We researched how to improve the functionality and efficiency of the Peltier cooling vests. Peltier devices, also known as thermoelectric coolers, take advantage of the Peltier effect to provide efficient cooling [1]. By creating a temperature gradient of semiconductor materials, these devices transfer heat from one side to another, cooling one side, while generating heat on the other side, as shown in Figure 1.

Figure 1.

Peltier effect and principle [1].

Using wearable cooling technology, we designed a vest integrated with thermoelectric cooler modules and a temperature sensor array. Water’s high heat capacity and thermal conductivity were used to improve cooling efficiency and comfort. By circulating chilled water through specially designed channels within the vest, excess heat from the wearer’s body was dissipated, resulting in effective temperature regulation and increased comfort [2,3,4,5]. Wearable cooling systems provide personalized cooling directly to the user. Among various cooling methods, thermoelectric cooling modules have received attention due to their small size, light weight, and energy efficiency, making them ideal for wearables.

We integrated an array of temperature sensors into the vest, as temperature monitoring is critical for ensuring maximum comfort and preventing overheating or overchilling. By placing an array of sensors, temperature distribution was monitored for precise cooling system adjustments. By measuring the cooling time to the given temperature range, a consistent and comfortable temperature was maintained. The Peltier cooling system was controlled to control real-time temperature fluctuations. The vest’s power consumption was monitored to improve its performance. We evaluated the vest’s performance in terms of functionality with the smartphone application. User experience was assessed employing empirical testing, criteria, and subjective methods. Participants of different genders and ages participated in the assessment to validate the vest’s effectiveness and its potential for widespread use [6].

The integration of the Peltier cooling system with vests is a solution for effectively regulating body temperature [7]. According to the advancement of wearable cooling technology, user comfort and work efficiency can be improved in medical and industrial settings.

2. Methodology

2.1. System Process

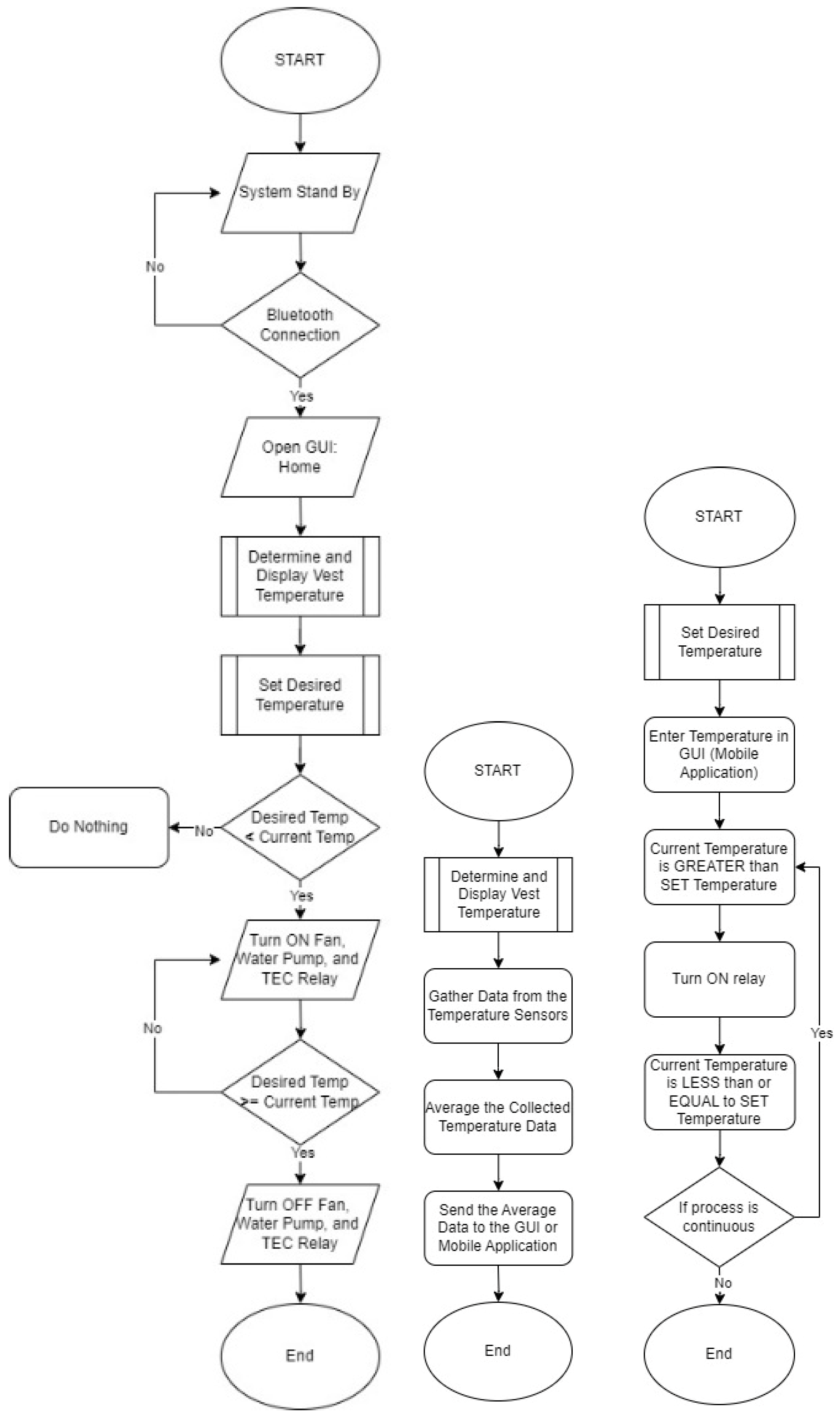

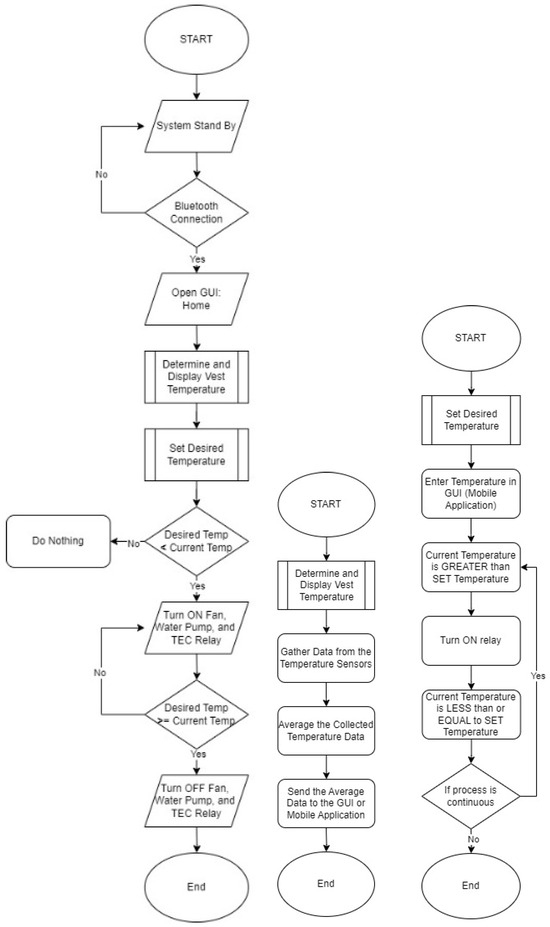

Figure 2 depicts the system’s operational process. A vest equipped with Peltier modules and an array of temperature sensors was developed. The temperature sensors were calibrated to ensure accurate temperature measurements. Usage data were collected to continuously monitor the temperature and control the Peltier cooling system. A target temperature was set for the vest. According to it, the Peltier cooling system was activated or deactivated to maintain the target temperature.

Figure 2.

System process.

2.2. Evaluation

The developed Peltier cooling vest was tested under different environmental conditions. The temperature distribution across the vest was also analyzed to ensure uniform cooling. The response time of the Peltier cooling vest was measured to evaluate its efficiency in maintaining thermal comfort. The power usage of the system was measured for voltage and current.

We installed a temperature sensor array using DS18B20 sensors. This sensor was chosen because of its compatibility characteristics with the Arduino microcontroller. The temperature sensor was configured to a temperature range of 16 to 30 °C on a 1-degree interval and was compared with the readings of a laboratory or medical grade thermometer. Table 1 shows the data gathered for this experiment. The data were analyzed to obtain a Pearson correlation (1). We also examined the temperature stability. We set target temperatures from 16 to 30 °C in a 2-degree interval and measured the deviations from the target temperatures after specific times. The data from 15 to 60 min in a 15 min time interval are shown in Table 2. The difference of the recorded temperature from the set temperature was calculated using the standard deviation (2).

Table 1.

Calibration data of temperature sensor.

Table 2.

Stability of system maintaining temperature.

To measure the cooling response time concerning a given temperature range, three given temperature ranges in an interval of 5° were set. The time taken by the system to reach the target temperature was recorded as shown in Table 3. The temperature data was used to calculate accuracy and error rate ((3) and (4)).

Table 3.

Standard deviation (SD) of readings at different temperatures.

To test the power consumption of the vest, different parameters were used (5) (Table 4).

Table 4.

Tabulation of data for the cooling response of the Peltier cooling vest.

The functionality of the GUI and the reliability of the communication between the smartphone and the cooling device were tested using the one-proportion analysis. The test was conducted for Bluetooth scan, connection/disconnection, temperature display, and temperature settings. The number of expected unsuccessful trials was compared to the total number of unsuccessful trials. The target value was 5%. With the values deviating from the target value, adjustments and modifications were made.

To explore the user experience of the smartphone remote control app, a five-point scale of satisfaction level (very unsatisfactory, unsatisfactory, neutral, satisfactory, and very satisfactory) was used. Different criteria were considered. Forty subjects in the age groups of 9–17 years old and 18–60 years old participated in the survey. Ease of use, intuitiveness with its control application, user-friendliness, no lengthy instructions for operation, responsiveness, and information display were included in the questionnaire for a survey.

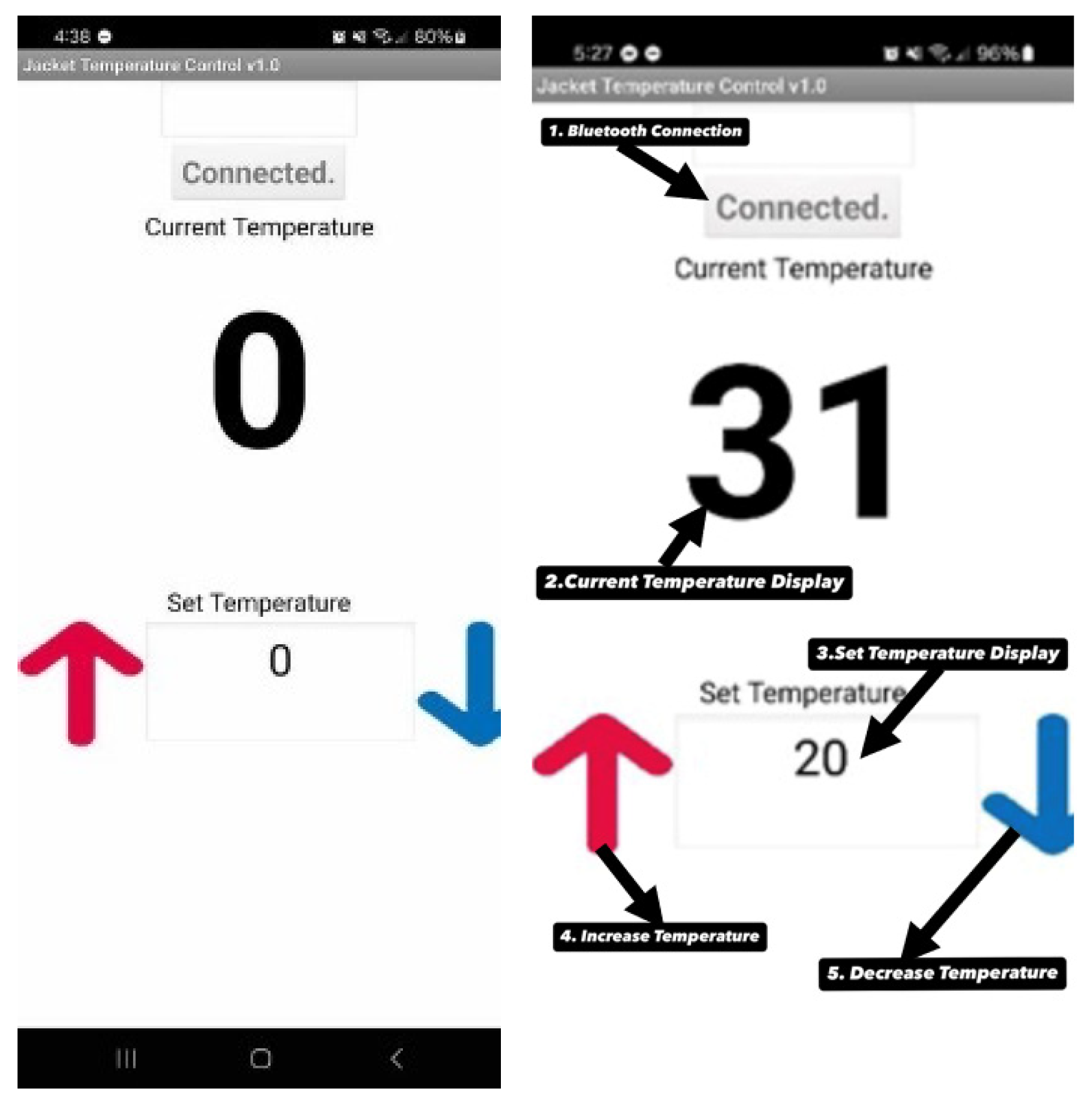

3. Results and Discussion

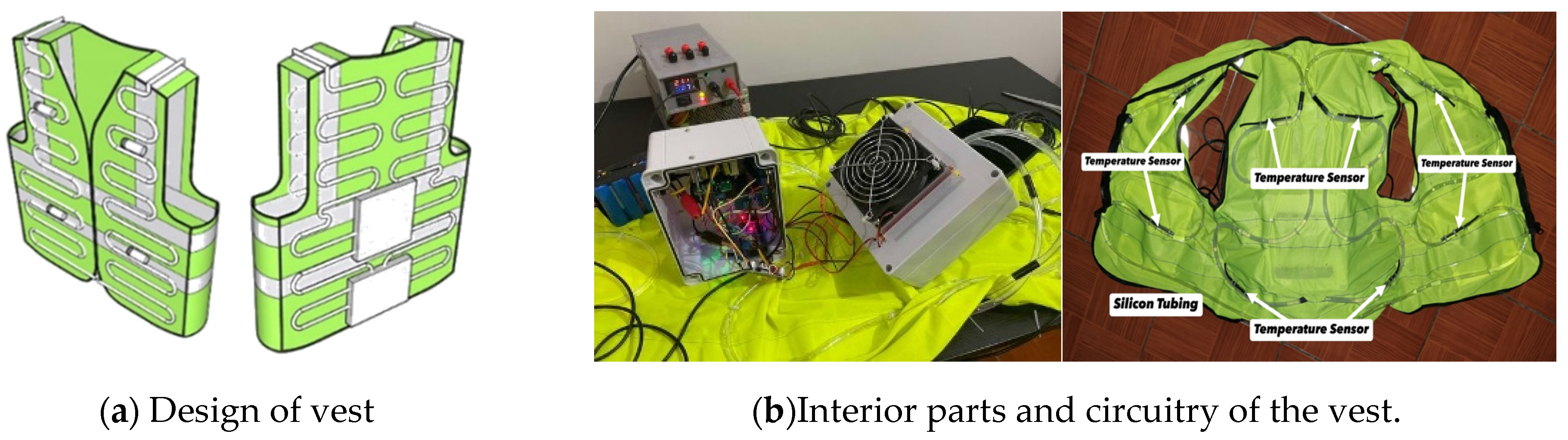

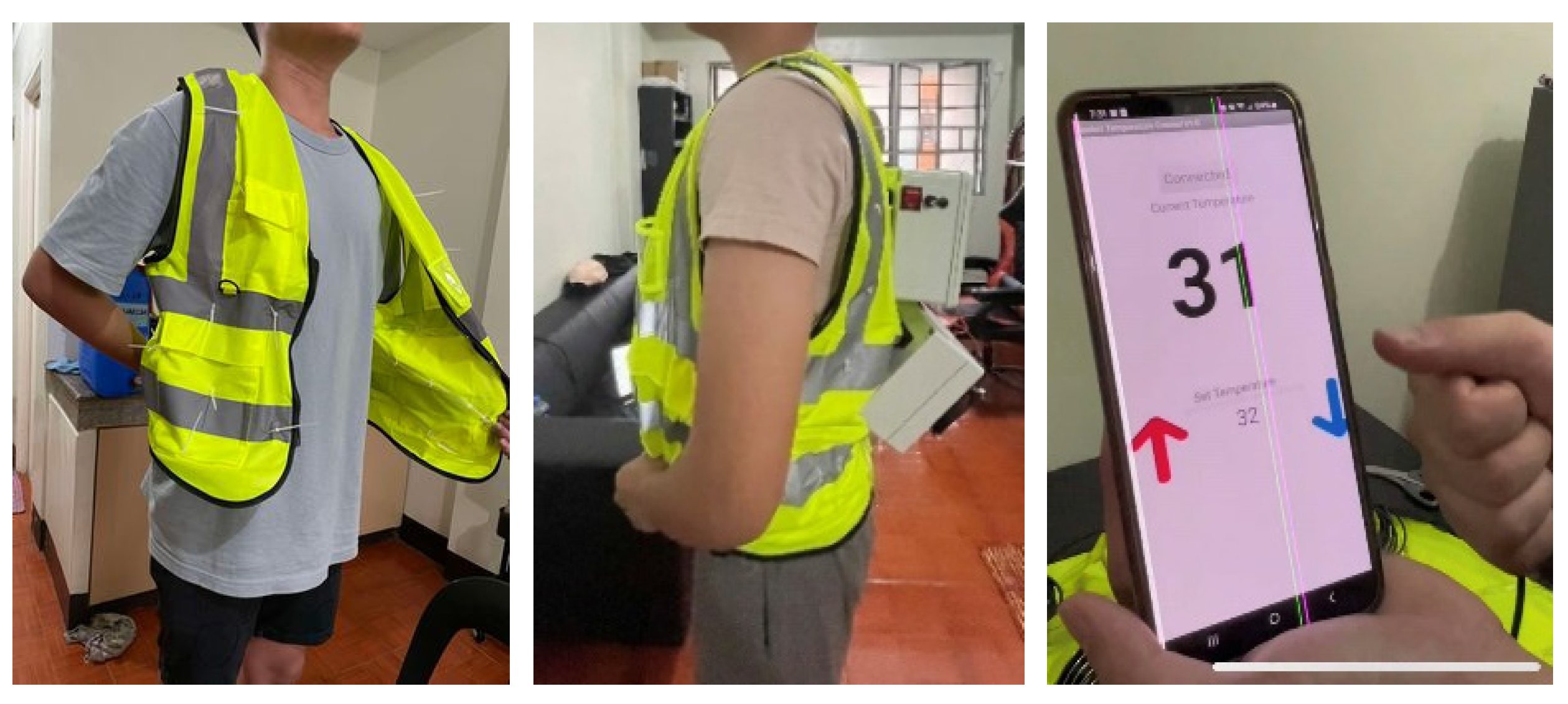

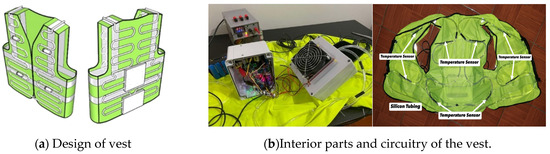

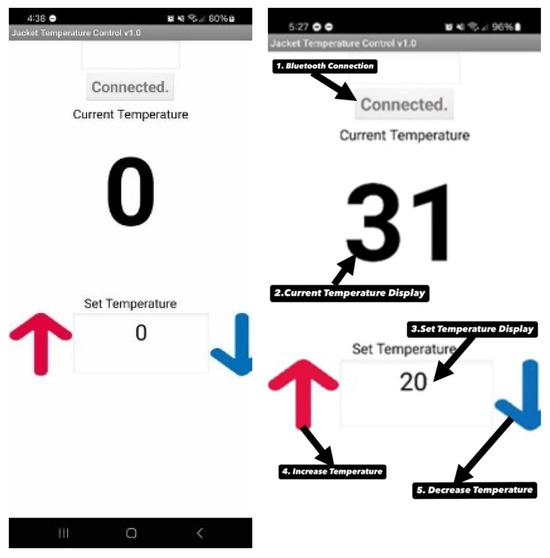

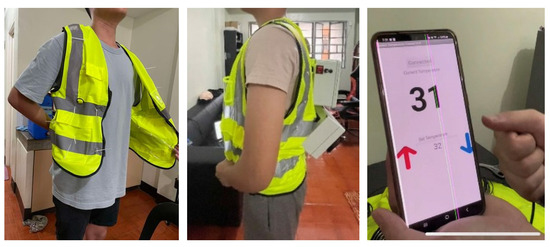

Figure 3a depicts the design of vest and Figure 3b shows the Peltier cooling vest with the Peltier, Bluetooth module, temperature sensors, and other circuitry components. The smartphone GUI application using MIT App Inventor was used as the main interface and for connectivity (Figure 4). Figure 5 shows the actual wearable Peltier cooling vest. The smartphone application ran with the Bluetooth link between the smartphone and hardware configuration (Figure 6). The temperature was displayed to indicate whether the cooling vest reached the target temperature. The temperature was set using a button on the GUI with red or blue arrows.

Figure 3.

Design and components of the vest.

Figure 4.

Smartphone GUI and Bluetooth connectivity depicting temperatures.

Figure 5.

The Actual wearable Peltier cooling vest.

Figure 6.

Peltier cooling vest controlled by the smartphone GUI application via Bluetooth connectivity for temperature control.

3.1. Calibration of Temperature

The average computed value of R across 15 different set temperatures was 0.9979. A positive correlation was observed between the corresponding data. The values of target temperature in 15, 30, 45, and 60 min intervals showed the system’s stability to maintain the temperature. The standard deviation (SD) was computed by comparing the measured temperatures between the given time intervals. The SD increased from 16 to 22 °C. From 24 to 30 °C, the SD decreased. At 22 °C, the highest SD was recorded, while at 30 °C, the lowest SD was observed (Table 1, Table 2 and Table 3).

3.2. Peltier Cooling Vest Cooling Response Time

Cooling from 30 to 26 °C took 10.36 min. From 26 to 21 °C, 8.75 min were spent. From 21 to 16 °C, 9.16 min were spent. The average cooling time for a 5-degree reduction was 9.42 min.

3.3. Temperature Maintainability

The accuracy of temperature across different temperature ranges was calculated (Table 5 and Table 6). From 22 to 16 °C, a lower error rate was obtained. From 22 to 30 °C, a higher cumulative error rate was observed. This showed that the temperature control was more accurate at a lower temperature.

Table 5.

SD at different target temperatures and operation times.

Table 6.

Accuracy of test results.

3.4. Power Consumption

Table 7 depicts the temperature ranges (°C), voltage (V), current (A), and computed power consumption (W) of the Peltier cooling vest.

Table 7.

Power consumption of Peltier cooling vest.

There was a difference in power consumption depending on the target temperatures. An inverse relation between power consumption and the target temperature was observed. This indicated that more power was needed to achieve a lower temperature.

Table 8 depicts the specifications and test results of the GUI interface functionality and functions. The “Bluetooth scan” function failed six times, indicating that the Peltier cooling vest was not detected by the app. The “Bluetooth connection” function failed twice. Other functions did not show any failure.

Table 8.

Interface functionality.

Table 9 depicts the user experience for the smartphone application’s GUI, the control system, and the Bluetooth connectivity were assessed. The ease of use scored 4.18, which showed the satisfaction of users. Intuitiveness, responsiveness, and informativeness scored 4.56, 4.32, and 3.88.

Table 9.

End-user experience.

4. Conclusions and Recommendation

We developed a Peltier cooling vest with a temperature sensor array. The readings of the temperature sensor in the vest and a commercial-grade thermometer showed a strong positive correlation. The temperature control was stable across the measured temperature ranges. The cooling time of the Peltier cooling vest was almost the same across the temperature ranges, with an average of 9.42 min. The accuracy of the temperature control was higher at lower temperatures. The use of the vest was assessed by 40 participants. Bluetooth scanning and connection required improvements. Since the vest was bulky, a more portable Peltier cooling vest needs to be developed.

Author Contributions

Conceptualization, V.K.A.T. and M.J.S.A.Y.; methodology, V.K.A.T., M.J.S.A.Y. and J.R.B.; software, V.K.A.T.; validation, V.K.A.T., M.J.S.A.Y. and J.R.B.; formal analysis, V.K.A.T. and M.J.S.A.Y.; investigation, V.K.A.T. and M.J.S.A.Y.; resources, V.K.A.T. and M.J.S.A.Y.; data curation, V.K.A.T. and M.J.S.A.Y.; writing—original draft preparation, V.K.A.T. and M.J.S.A.Y.; writing—review and editing, M.J.S.A.Y.; visualization, V.K.A.T. and M.J.S.A.Y.; supervision, J.R.B.; project administration, V.K.A.T. and M.J.S.A.Y.; funding acquisition, V.K.A.T. and M.J.S.A.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

All primary contributions in this study are detailed within the article. Any additional information may be addressed to the corresponding author and the School of Electrical, Electronics, and Computer Engineering department of Mapúa University, Manila 1002, Philippines.

Acknowledgments

We are deeply grateful to Jessie R. Balbin, our esteemed thesis advisor, whose unwavering guidance, expertise, and invaluable insights helped to shape the direction and quality of our thesis. We are also extremely grateful to our parents for their unconditional love, unwavering support, and generous financial assistance, which allowed us to complete this thesis. Finally, we want to express our heartfelt gratitude to God for His divine guidance, blessings, and constant presence throughout this journey.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, C.-W.; Xu, K.-J.; Li, L.-Y.; Yang, M.-Z.; Gao, H.-B.; Chen, S.-R. Study on a Battery Thermal Management System Based on a Thermoelectric Effect. Energies 2018, 11, 279. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Wang, J.; Zhang, M.; Jia, M.; Wang, Q. Man-portable cooling garment with cold liquid circulation based on thermoelectric refrigeration. Appl. Therm. Eng. 2022, 200, 117730. [Google Scholar] [CrossRef]

- Hwang, C.O. Development of an adaptive thermoelectric cooling system for smart clothing. Textile Res. J. 2020, 90, 2347–2357. [Google Scholar]

- Wang, L.; Zhang, K. Textile-Based Thermoelectric Generators and Their Applications. Energy Environ. Mater. 2020, 3, 67–79. [Google Scholar] [CrossRef]

- Petsagkourakis, I.; Tybrandt, K.; Crispin, X.; Ohkubo, I.; Satoh, N.; Mori, T. Thermoelectric materials and applications for energy harvesting power generation. Sci. Technol. Adv. Mater. 2018, 19, 836–862. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Warren, K.; Luo, M.; He, X.; Zhang, H.; Arens, E.; Chen, W.; He, Y.; Hu, Y.; Jin, L.; et al. Evaluating the comfort of thermally dynamic wearable devices. Build. Environ. 2020, 167, 106443. [Google Scholar] [CrossRef]

- Smith, A.; Johnson, B. Advances in Wearable Cooling Technology. J. Therm. Eng. 2020, 12, 45–59. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).