Numerical Thermo-Structural Simulations for the Design of the Havar Beam Window of a Beryllium Target for Neutron Beam Production †

Abstract

1. Introduction

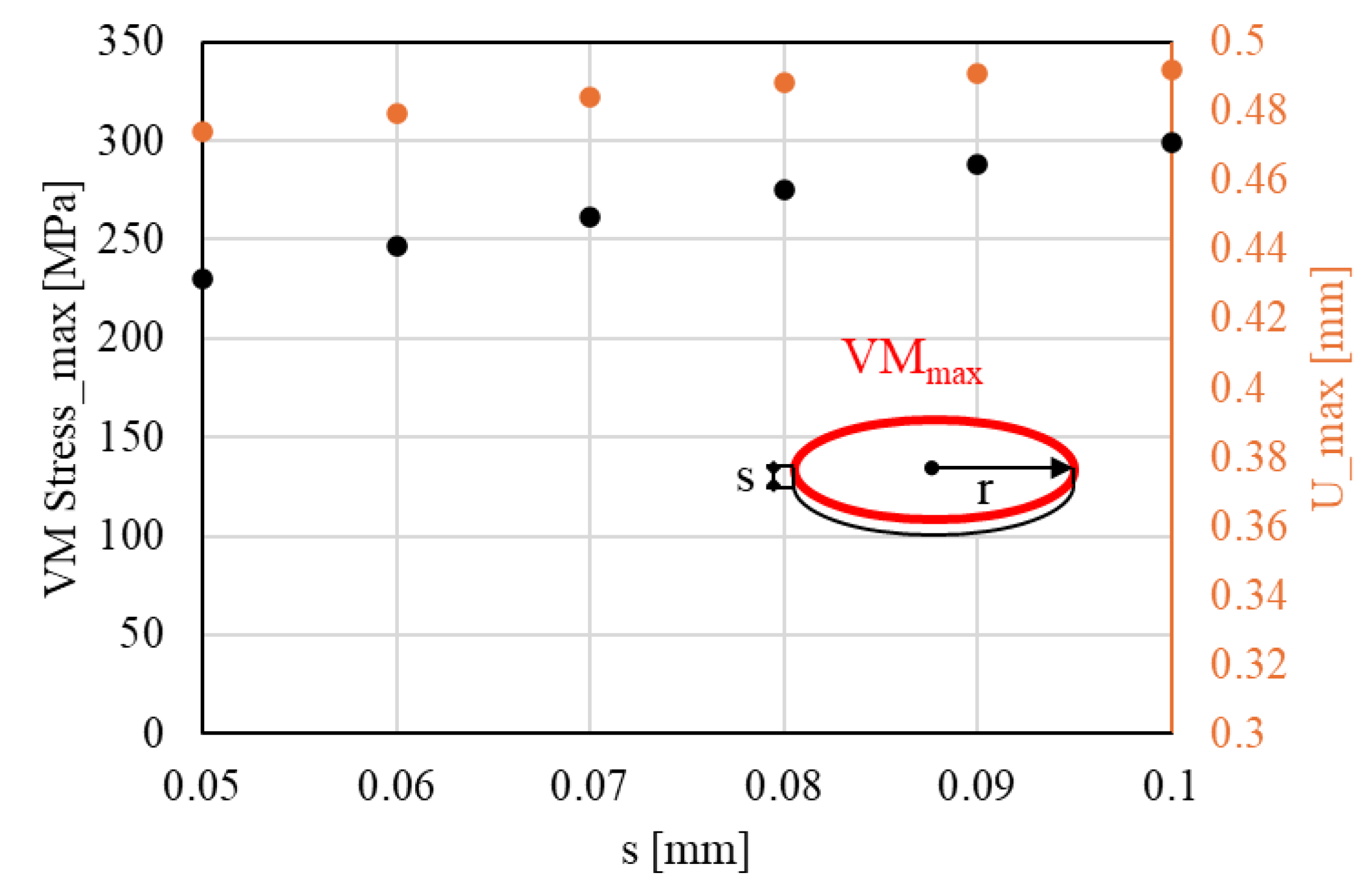

2. Materials and Methods

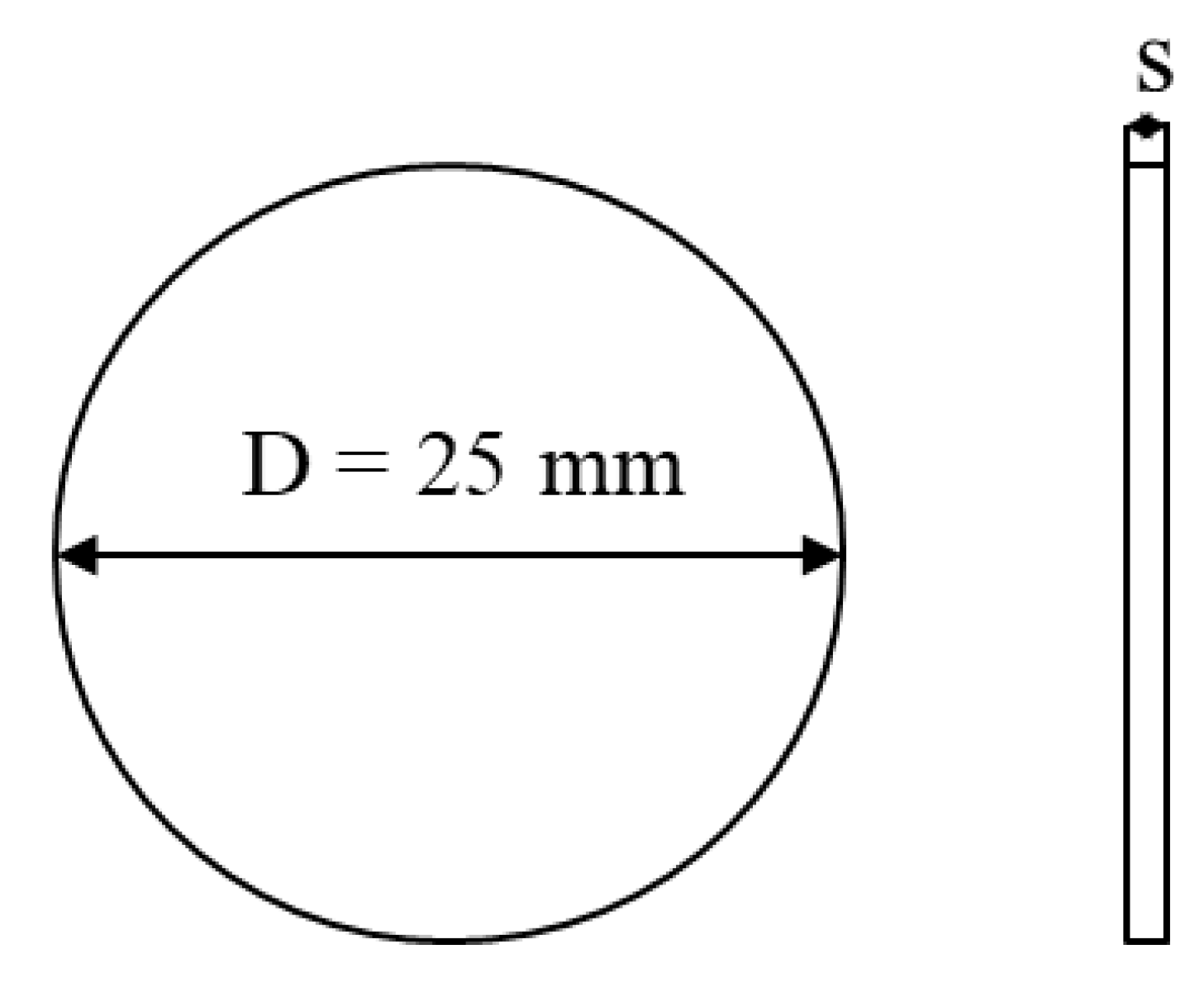

2.1. Case Study

2.2. Loading Conditions

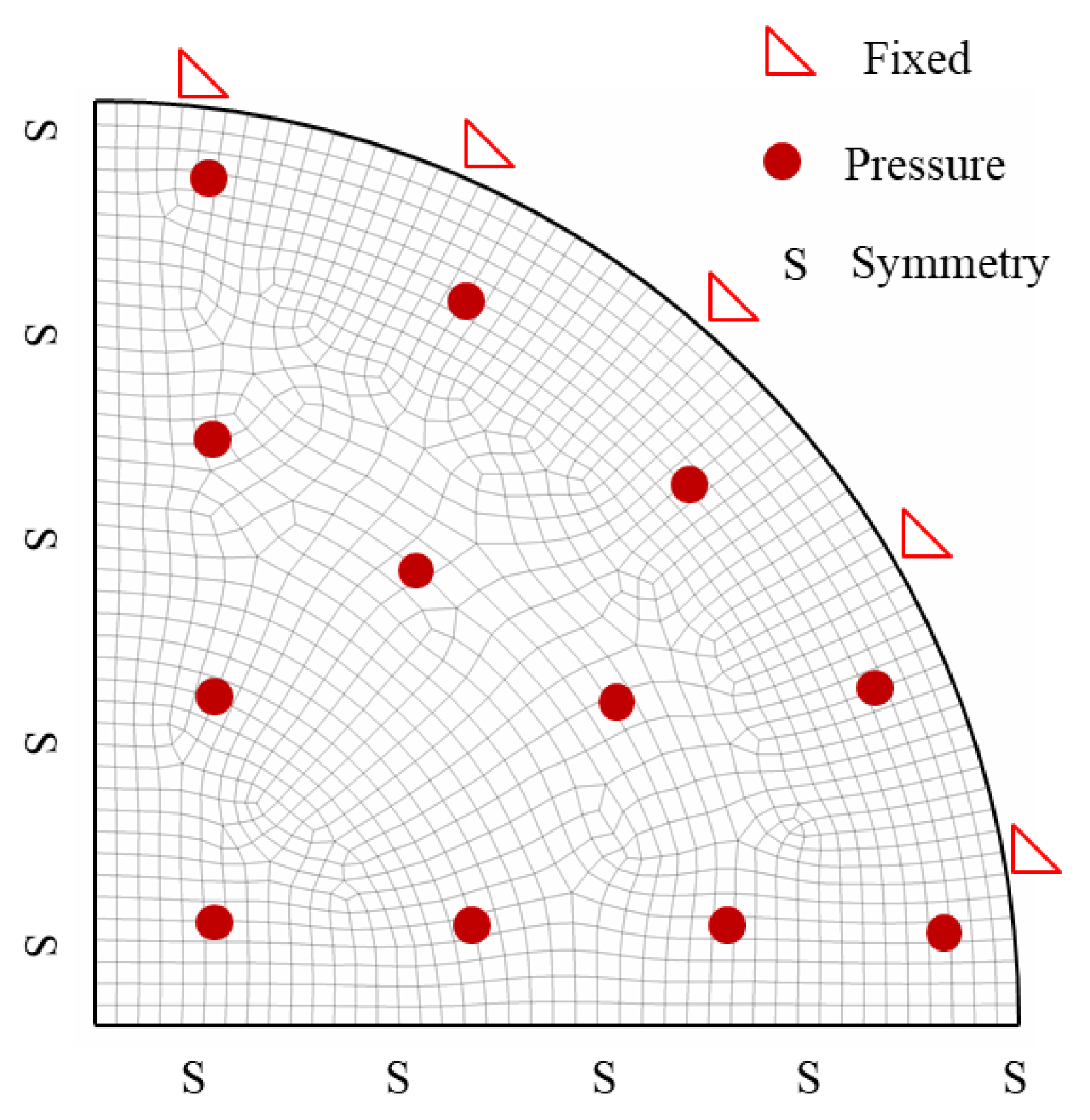

- Atmospheric pressure—applied to the window during the vacuum reduction of the chamber (Figure 3a). Once the entire beam of the facility is under vacuum, this load is no longer active. In this type of application, it is important to maintain the whole beam line under vacuum to avoid possible oxidation of the components.

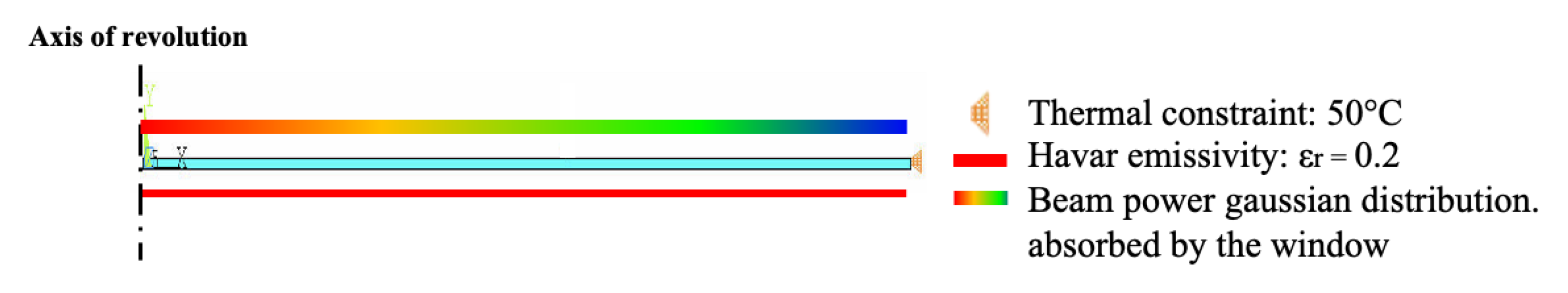

- Thermal load—induced by the proton beam during facility operation (Figure 3b).

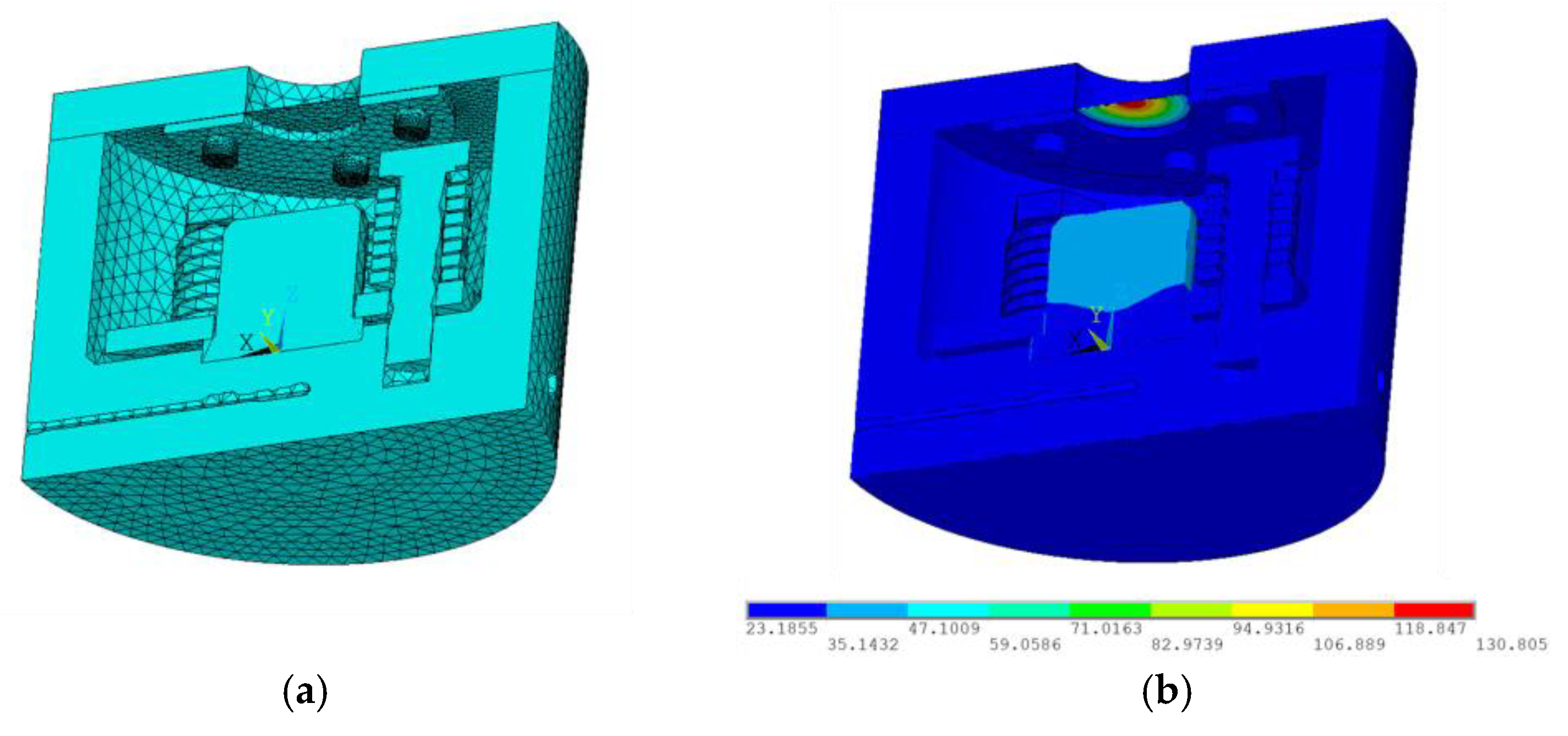

2.3. FE Software

- Structural Analysis: 2D quadrilateral SHELL181 4-node elements were used to enable all analyses to be conducted with the same converged mesh, as the thickness varies.

- Thermal Analysis: 2D quadrilateral PLANE77 8-node axisymmetric elements were utilized.

3. Numerical Results

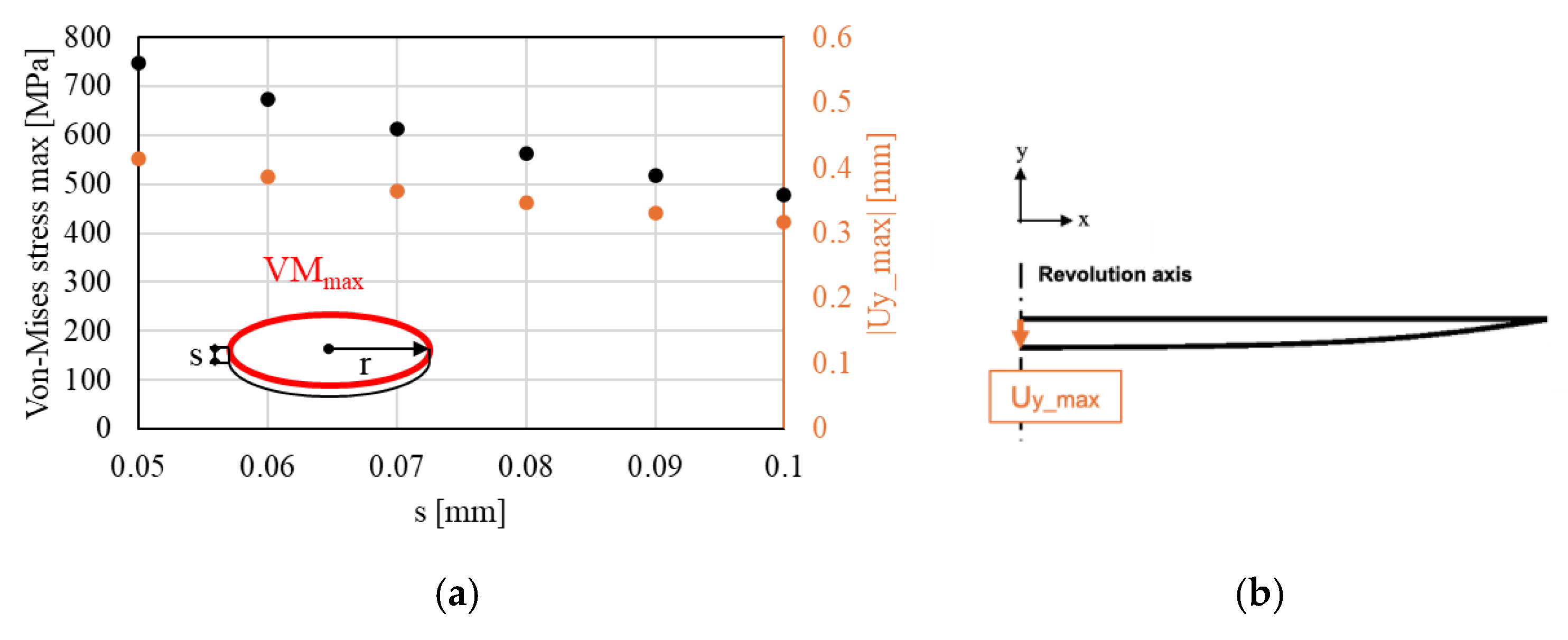

3.1. Structural Analysis Under Vacuum Conditions

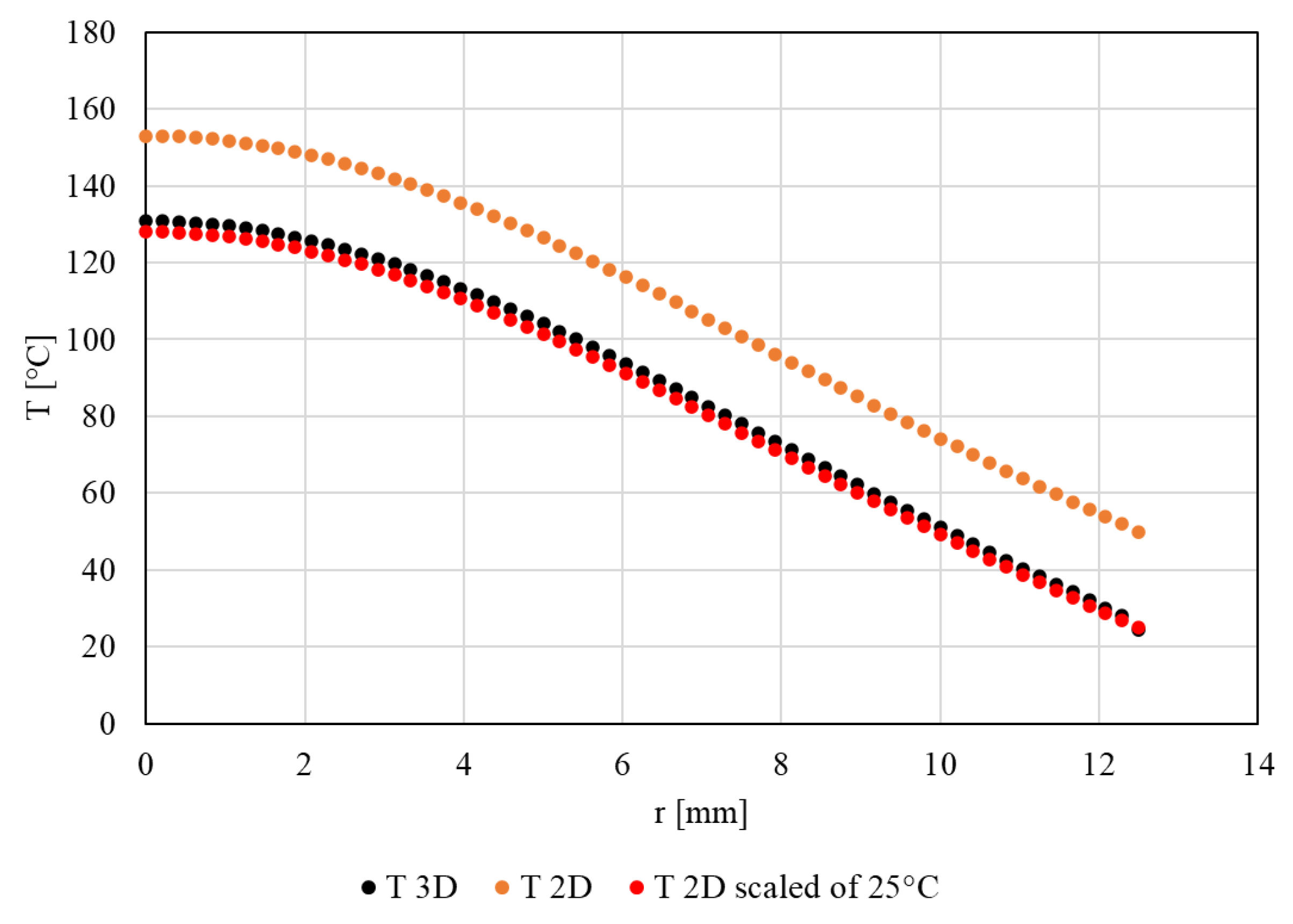

3.2. Thermal Analysis

3.3. Thermal–Structural Analysis

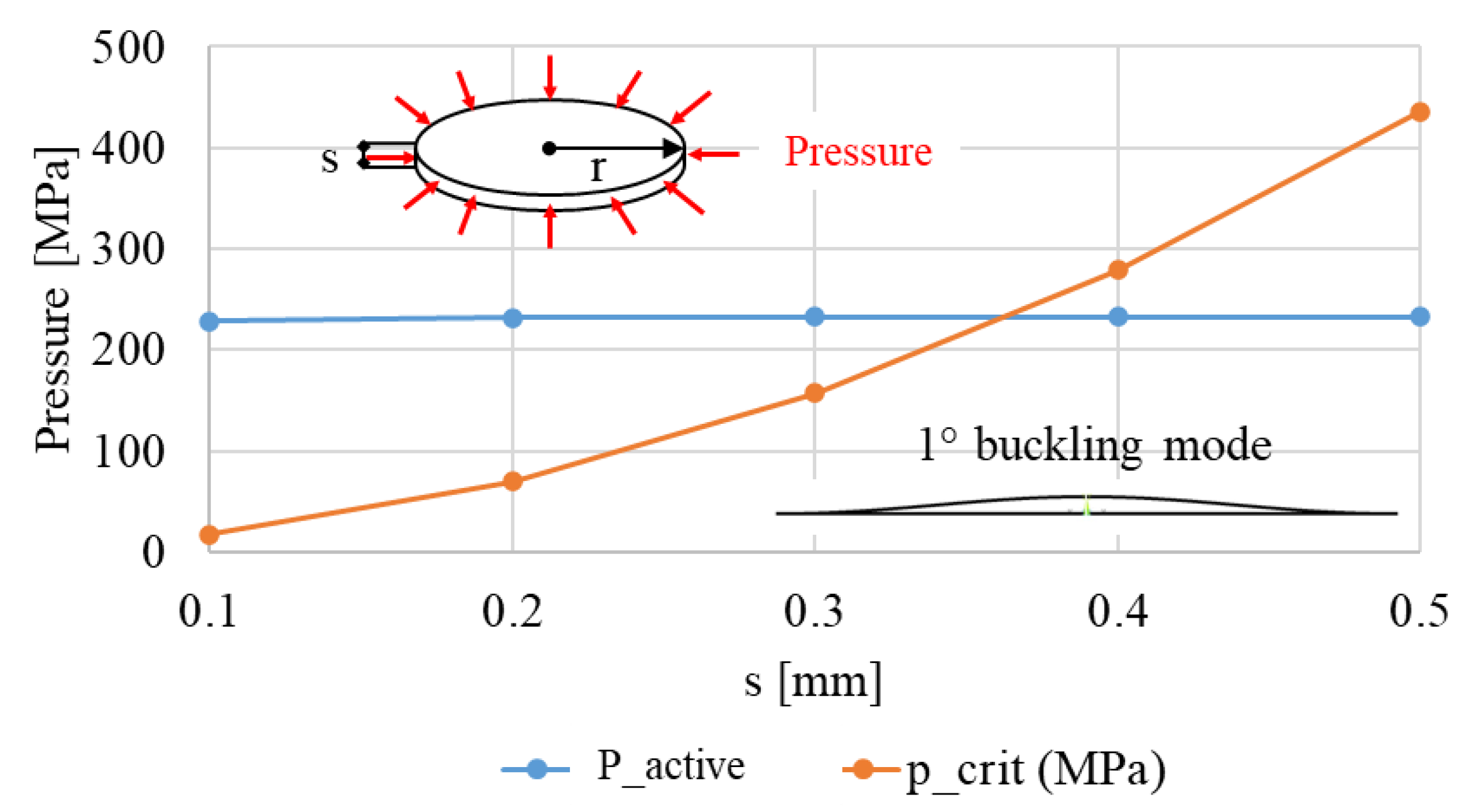

3.4. Buckling Analysis

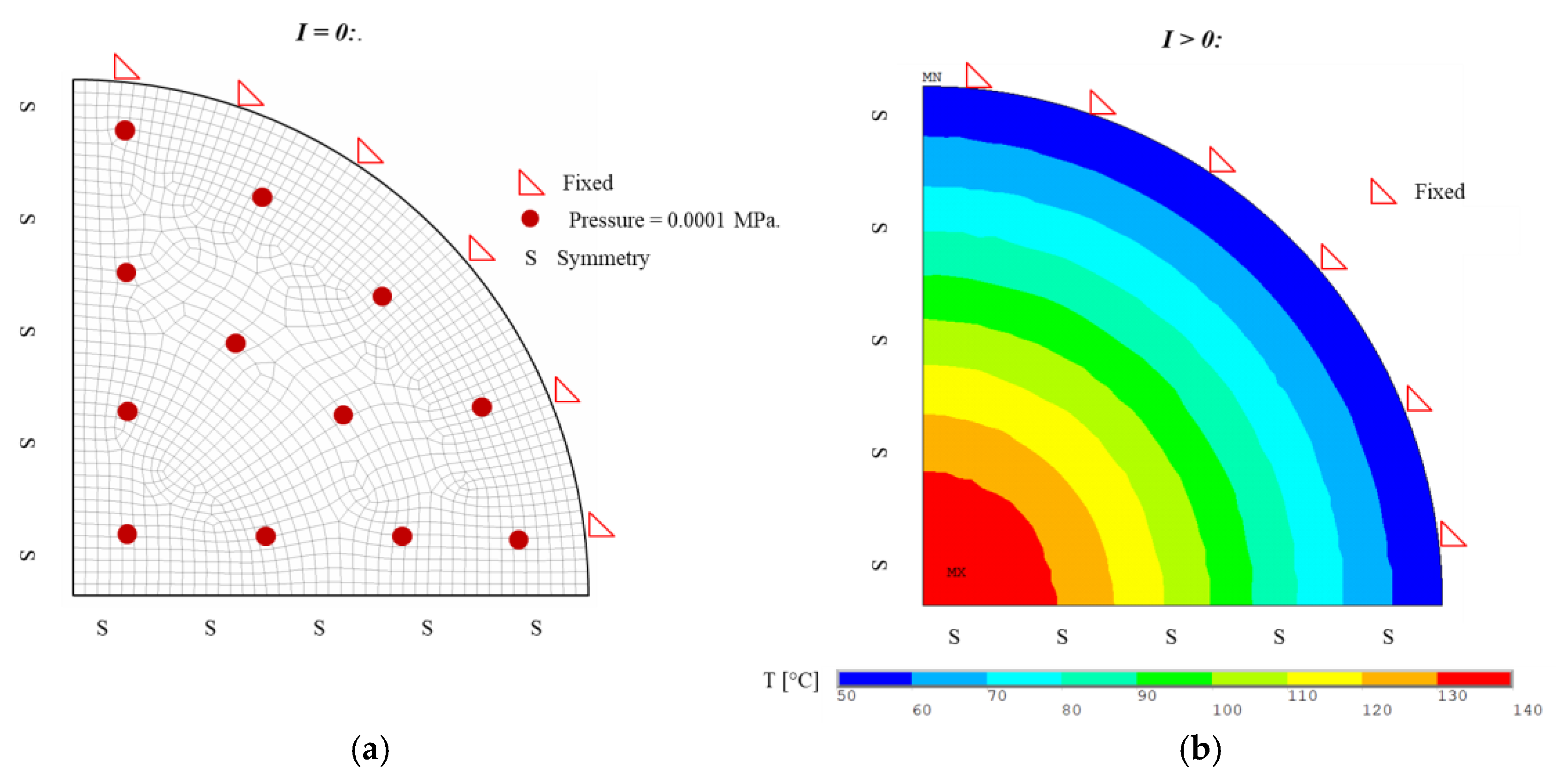

- First iteration (I = 0): A perturbating pressure load is applied, as shown in Figure 12a. This loading allows a small geometric deformation of the window, creating the conditions for the buckling simulation to begin. This load is calibrated so as not to affect the results of the simulation (p = 0.0001 MPa).

- Subsequent iterations (I > 0): As shown in Figure 12b, the thermal load is applied gradually at each iteration until it reaches the output temperature trend of the associated thermal analysis (Section 3.3).

4. Discussion

- Experimental validation of the nonlinear buckling analyses. The predictions made in this paper, particularly regarding the window’s behavior under loads exceeding the critical buckling load, require experimental validation. This validation will ensure the reliability of the design under actual operating conditions.

- Characterization of Havar material properties at high temperatures. To perform reliable thermal–structural simulations, especially under scenarios involving higher proton beam powers, it is crucial to obtain accurate material data for Havar at elevated temperatures (up to 500 °C, the temperature limit often used for the Havar after it loses most of its structural properties). This characterization will enable more precise predictions of the window’s performance under extreme operational scenarios.

- Characterization of Havar material properties after irradiation with a proton beam. This will ensure that the window does not collapse under in-service conditions due to an embrittlement of the material caused by proton beam irradiation.

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barrera, R.A.; Bisello, D.; Esposito, J.; Mastinu, P.; Prete, G.; Silvestrin, L.; Wyss, J. CoolGAL: A Galinstan bathed Be fast neutron production target at the NEPIR facility. EPJ Web Conf. 2020, 231, 03002. [Google Scholar] [CrossRef]

- Mastinu, P.; Bisello, D.; Barrera, R.A.; Porras, I.; Prete, G.; Silvestrin, L.; Wyss, J. Fast neutrons at LNL Legnaro. J. Neutron Res. 2020, 22, 233–247. [Google Scholar] [CrossRef]

- Monetti, A.; Andrighetto, A.; Petrovich, C.; Manzolaro, M.; Corradetti, S.; Scarpa, D.; Rossetto, F.; Martinez Dominguez, F.; Vasquez, J.; Rossignoli, M.; et al. The RIB production target for the SPES project. Eur. Phys. J. A 2015, 51, 128. [Google Scholar] [CrossRef]

- Andrighetto, A.; Manzolaro, M.; Corradetti, S.; Scarpa, D.; Monetti, A.; Rossignoli, M.; Ballan, M.; Borgna, F.; D’Agostini, F.; Gramegna, F.; et al. Spes: An intense source of Neutron-Rich Radioactive Beams at Legnaro. J. Phys. Conf. Ser. 2018, 966, 012028. [Google Scholar] [CrossRef]

- Gramegna, F.; Prete, G.; Andrighetto, A.; Antonini, P.; Ballan, M.; Bellato, M.; Bellan, L.; Benini, D.; Bisoffi, G.; Bermudez, J.; et al. The SPES exotic beam ISOL facility: Status of the project, technical challenges, instrumentation, scientific program. Il Nuovo Cimento C 2018, 41, 195–201. [Google Scholar] [CrossRef]

- Maggiore, M.; Campo, D.; Antonini, P.; Lombardi, A.; Manzolaro, M.; Andrighetto, A.; Monetti, A.; Scarpa, D.; Esposito, J.; Silvestrin, L. SPES: A new cyclotron-based facility for research and applications with high-intensity beams. Mod. Phys. Lett. A 2017, 32, 1740010. [Google Scholar] [CrossRef]

- Havar® • UNS R30004. Hamilton Precision Metal. Available online: https://www.hpmetals.com/-/media/ametekhpmetals/files/havar.pdf?la=en&revision=c2fb2204-9a60-4c3b-b923-7ba40b6f72cd&hash=8B18F671C0462F3388F3989E6472163C (accessed on 6 June 2024).

- Bennett, J.R.J.; Bruno, L.; Densham, C.J.; Drumm, P.V.; Edgecock, T.R.; Fabich, A.; Gabriel, T.A.; Haines, J.R.; Heseroth, H.; Hayato, Y.; et al. A Proposal to the ISOLDE and Neutron Time-of-Flight Experiments Committee. 2004, p. 10. Available online: https://inspirehep.net/literature/856492 (accessed on 10 May 2024).

- Silverman, I.; Kijel, D.; Arenshtam, A.; Gavish, I.; Lavie, E.; Meroz, E.; Weismann, L.; Kreisel, A.; Eliyahu, I.; Zemach, E.; et al. SS316L AS WINDOW FOR PRODUCTION TARGET FOR Ge-68. In Proceedings of the 11th International Topical Meeting on Nuclear Applications of Accelerators, AccApp 2013, Bruges, Belgium, 5–8 August 2013; pp. 226–230. [Google Scholar]

- Cryogenicse, W.V.; Gray, W.H. Thin windows for gaseous and liquid targets: An optimization procedure. Cryogenics 1975, 15, 627–638. [Google Scholar] [CrossRef]

- Gallmeier, F.X. Ge-68 PRODUCTION TARGET USING 30 MEV 1 MA PROTONS AT SARAF. In Proceedings of the 10th International Topical Meeting on Nuclear Applications of Accelerators 2011, AccApp 2011, Knoxville, TN, USA, 3–7 April 2011; pp. 352–356. [Google Scholar]

- Shaiju, V.; Sharma, S.; Kumar, R.; Sarin, B. Target foil rupture scenario and provision for handling different models of medical cyclotrons used in India. J. Med. Phys. 2009, 34, 161. [Google Scholar] [CrossRef] [PubMed]

- Haroush, S.; Moreno, D.; Silverman, I.; Turgeman, A.; Shneck, R.; Gelbstein, Y. The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique. Materials 2017, 10, 491. [Google Scholar] [CrossRef] [PubMed]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM The Stopping and Range of Ions in Matter, 2008; software.

- ANSYS Mechanical APDL® Verification Manual; ANSYS Inc.: Canonsburg, PA, USA, 2020.

- ANSYS Mechanichal APDL® Structural Analysis Guide; ANSYS Inc.: Canonsburg, PA, USA, 2020.

- Young, W.C.; Budynas, R.G.; Roark, R.J. Roark’s Formulas for Stress and Strain, 7th ed.; Reprint in McGraw-Hill international edition, General engineering series; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Kraytermane, B.L.; Fu, C.C. Nonlinear Analysis of Clamped Circular Plates. J. Struct. Eng. 1985, 111, 2402–2415. [Google Scholar] [CrossRef]

- Votawe, J.R.; Nickles, R.J. A theoretical description of the beam induced heating of accelerator target foils. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1989, 281, 216–223. [Google Scholar] [CrossRef]

- Timoshenkoe, S.P.; Gere, J.M. Theory of Elasstic Stability, 2nd ed.; McGraw-Hill International Book Company: New York, NY, USA, 1985. [Google Scholar]

- Snir, Y.; Moreno, D.; Silverman, I.; Samuha, S.; Eisen, Y.; Eliezer, D.; Gelbstein, Y.; Haroush, S. Mechanical properties of proton bombarded SS316L thin foils using the small punch technique. J. Nucl. Mater. 2020, 540, 152340. [Google Scholar] [CrossRef]

| Material Properties of Havar (CR) at Tamb | |

|---|---|

| UTS [MPa] | 1860 |

| Yield Strength [MPa] | 1724 |

| E [MPa] | 203,400 |

| Density [kg/m3] | 8300 |

| Thermal Conductivity [W/(m × K)] | 13 |

| Thermal Expansion Coefficient [K−1] | 12.5 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dattilo, R. Numerical Thermo-Structural Simulations for the Design of the Havar Beam Window of a Beryllium Target for Neutron Beam Production. Eng. Proc. 2025, 85, 28. https://doi.org/10.3390/engproc2025085028

Dattilo R. Numerical Thermo-Structural Simulations for the Design of the Havar Beam Window of a Beryllium Target for Neutron Beam Production. Engineering Proceedings. 2025; 85(1):28. https://doi.org/10.3390/engproc2025085028

Chicago/Turabian StyleDattilo, Roberta. 2025. "Numerical Thermo-Structural Simulations for the Design of the Havar Beam Window of a Beryllium Target for Neutron Beam Production" Engineering Proceedings 85, no. 1: 28. https://doi.org/10.3390/engproc2025085028

APA StyleDattilo, R. (2025). Numerical Thermo-Structural Simulations for the Design of the Havar Beam Window of a Beryllium Target for Neutron Beam Production. Engineering Proceedings, 85(1), 28. https://doi.org/10.3390/engproc2025085028