Innovative Model for Material Selection Within the Automotive Lightweight Eco-Design Field †

Abstract

1. Introduction

2. Materials and Method

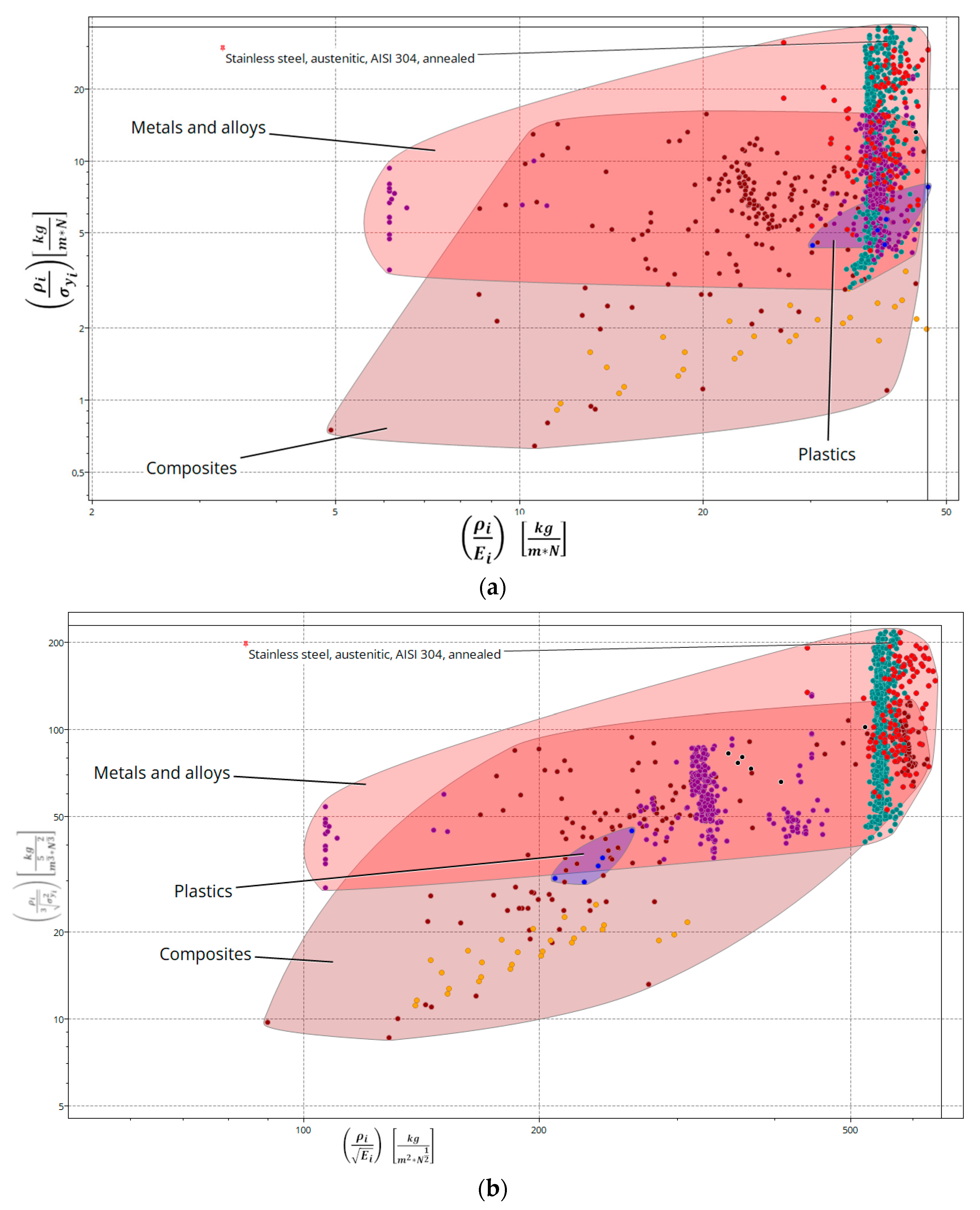

- Material selection: The method originates from the basic idea of Ashby’s approach, which uses performance indices to evaluate materials’ mechanical properties. These indices are calculated based on constraints and objectives that characterize the specific component considered. The primary goal of this work is to identify materials able to optimize design aspects (strength and stiffness) while minimizing component weight. This is accomplished by comparing a broad-spectrum of mechanical features functional to compare new material options to a reference solution by means of mechanical indices such as density, yield strength, and Young’s modulus;

- VIKOR integration: The materials selected by Ashby’s method are ranked through VIKOR’s Multi-Criteria Decision Analysis (MCDA) technique. This stage considers not only mechanical properties but also cost (derived from raw material and manufacturing costs) and environmental impact (calculated using kilograms CO2 equivalent emissions for production, use phase and end-of-life phases). The ranking is carried out on the basis of an innovative comprehensive score that integrates the three main pillars above (design, cost sustainability, environmental sustainability);

- Sensitivity analysis: A sensitivity analysis is performed to evaluate how changes in key parameters (such as weighting factors for design, cost, and environmental impact) affect the final ranking. Such an analysis is useful to assist in evaluating the robustness of the model as well as identifying the most critical factors influencing the material selection process.

2.1. Material Selection

2.2. Integration of Ashby/VIKOR

2.3. Sensitivity Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Ranking | Solution (Material + Primary Process) | [Eur] | Raw Material [Eur] | DEK [Eur/kg] | [kgCO2eq] | [kgCO2eq] | Only Use Phase [kgCO2eq] | ||

|---|---|---|---|---|---|---|---|---|---|

| Ref: Stainless Steel Austenitic AISI 304 Annealed–Press Forming | REF: 8.91 | REF: 67 | REF: 63 | REF: 0 | REF: 105 | REF: 68 | REF: 49 | ||

| 1 | Duralcan Al-20SiC (p) cast (F3K20S).—Squeeze casting | 3.81 | 35 | 28 | −6 | 70 | 49 | 21 | 0.0605 |

| 2 | Duralcan Al-20SiC (p) cast (F3S20S).—Squeeze casting | 3.90 | 35 | 28 | −6 | 73 | 51 | 22 | 0.0755 |

| 3 | Duralcan Al-20Al2O3 (p) (W2A20A-T6).—CIP | 3.99 | 37 | 27 | −6 | 66 | 43 | 22 | 0.0779 |

| 4 | Duralcan Al-20Al2O3 (p) (W6A20A-T6).—CIP | 4.10 | 37 | 28 | −6 | 68 | 45 | 23 | 0.0949 |

| 5 | Low-alloy steel, AISI 9255, oil quenched and tempered at 205 °C.—Press Forming | 4.98 | 13 | 9 | −14 | 40 | 16 | 25 | 0.0961 |

| 6 | Duralcan Al-15Al2O3 (p) (W2A15A-T6).—CIP | 4.11 | 37 | 28 | −6 | 69 | 46 | 23 | 0.0970 |

| 7 | Aluminum, 2024, T8510/T8511.—Press Forming | 4.32 | 23 | 20 | −9 | 88 | 72 | 16 | 0.1041 |

| 8 | Aluminum, 2024, T861.—Press Forming | 4.33 | 23 | 20 | −9 | 88 | 72 | 16 | 0.1055 |

| 9 | Low-alloy steel, AISI 9255, oil quenched and tempered at 315 °C.—Press Forming | 5.07 | 13 | 9 | −14 | 41 | 16 | 25 | 0.1079 |

| 10 | Duralcan Al-10SiC (p) cast (F3K10S).—Squeeze casting | 4.11 | 37 | 30 | −6 | 79 | 55 | 23 | 0.1085 |

| 11 | Duralcan Al-20Al2O3 (p) (W2A20A-T6).—Press Forming | 3.99 | 39 | 36 | −6 | 80 | 58 | 22 | 0.1104 |

| 12 | Aluminum, 5182, H19.—Press Forming | 4.34 | 22 | 19 | −10 | 91 | 75 | 16 | 0.1111 |

| 13 | Low-alloy steel, AISI 5160, oil quenched and tempered at 205 °C.—Press Forming | 5.10 | 13 | 9 | −14 | 41 | 16 | 26 | 0.1116 |

| 14 | Low-alloy steel, AISI 5140, oil quenched and tempered at 205 °C.—Press Forming | 5.11 | 13 | 9 | −14 | 42 | 16 | 26 | 0.1124 |

| 15 | Low-alloy steel, AISI 5160, oil quenched and tempered at 315 °C.—Press Forming | 5.11 | 13 | 9 | −14 | 42 | 16 | 26 | 0.1127 |

| 16 | Aluminum, 2024, T851.—Press Forming | 4.37 | 24 | 20 | −9 | 89 | 73 | 16 | 0.1127 |

| 17 | Low-alloy steel, AISI 4140, oil quenched and tempered at 205 °C.—Press Forming | 5.12 | 14 | 10 | −14 | 42 | 16 | 26 | 0.1151 |

| 18 | Aluminum, 2024, T81.—Press Forming | 4.40 | 24 | 20 | −10 | 89 | 73 | 17 | 0.1160 |

| 19 | Low-alloy steel, AISI 8650, oil quenched and tempered at 205 °C.—Press Forming | 5.12 | 14 | 11 | −14 | 42 | 16 | 26 | 0.1164 |

| 20 | Aluminum, 2014, T6510.—Press Forming | 4.42 | 24 | 20 | −10 | 89 | 72 | 17 | 0.1171 |

| Ranking | Solution (Material + Primary Process) | [kg] | [Eur] | Raw Material [Eur] | DEK [Eur/kg] | [kgCO2eq] | [kgCO2eq] | Only Use Phase [kgCO2eq] | |

|---|---|---|---|---|---|---|---|---|---|

| Ref: Stainless Steel Austenitic AISI 304 Annealed–Press Forming | REF: 8.91 | REF: 67 | REF: 63 | REF: 0 | REF: 105 | REF: 68 | REF: 49 | ||

| 1 | Low-alloy steel, AISI 9255, oil quenched and tempered at 205 °C.—Press Forming | 1.64 | 7 | 3 | −8 | 13 | 5 | 8 | 0.0057 |

| 2 | Stainless steel, martensitic, AISI 440C, tempered at 316 °C.—Press Forming | 1.72 | 8 | 4 | −8 | 18 | 10 | 8 | 0.0126 |

| 3 | Stainless steel, martensitic, AISI 440C, tempered at 316 °C.—Binder Jetting | 1.72 | 11 | 3 | −8 | 15 | 8 | 8 | 0.0132 |

| 4 | Low-alloy steel, AISI 5160, oil quenched and tempered at 205 °C.—Press Forming | 1.82 | 7 | 3 | −8 | 15 | 6 | 9 | 0.0135 |

| 5 | Low-alloy steel, AISI 9255, oil quenched and tempered at 315 °C.—Press Forming | 1.82 | 7 | 3 | −8 | 15 | 6 | 9 | 0.0135 |

| 6 | Stainless steel, martensitic, AISI 440B, tempered at 316 °C.—Press Forming | 1.75 | 8 | 4 | −8 | 18 | 10 | 8 | 0.0139 |

| 7 | Low-alloy steel, AISI 50B60, oil quenched and tempered at 315 °C.—Press Forming | 1.83 | 7 | 3 | −8 | 15 | 6 | 9 | 0.0142 |

| 8 | Low-alloy steel, AISI 5160, oil quenched and tempered at 315 °C.—Press Forming | 1.83 | 7 | 3 | −8 | 15 | 6 | 9 | 0.0142 |

| 9 | Stainless steel, martensitic, AISI 440B, tempered at 316 °C.—Binder Jetting | 1.75 | 11 | 3 | −8 | 16 | 8 | 8 | 0.0145 |

| 10 | Low-alloy steel, AISI 5150, oil quenched and tempered at 205 °C.—Press Forming | 1.87 | 7 | 3 | −8 | 15 | 6 | 9 | 0.0157 |

| 11 | Low-alloy steel, AISI 4150, oil quenched and tempered at 205 °C.—Press Forming | 1.87 | 7 | 4 | −8 | 15 | 6 | 9 | 0.0158 |

| 12 | Low-alloy steel, AISI 81B45, oil quenched and tempered at 205 °C.—Press Forming | 1.87 | 7 | 4 | −8 | 15 | 6 | 9 | 0.0159 |

| 13 | Aluminum, 7068, T6511.—Press Forming | 1.38 | 16 | 12 | −7 | 28 | 22 | 5 | 0.0178 |

| 14 | Low-alloy steel, 300M (high carbon), quenched and tempered.—Press Forming | 1.91 | 9 | 5 | −8 | 15 | 6 | 10 | 0.0184 |

| 15 | Low-alloy steel, AISI 8640, oil quenched and tempered at 205 °C.—Press Forming | 1.92 | 8 | 4 | −8 | 16 | 6 | 10 | 0.0185 |

| 16 | Low-alloy steel, AISI 8650, oil quenched and tempered at 205 °C.—Press Forming | 1.92 | 8 | 4 | −8 | 16 | 6 | 10 | 0.0185 |

| 17 | Low-alloy steel, AISI 4340, oil quenched and tempered at 205 °C.—Press Forming | 1.91 | 8 | 5 | −8 | 16 | 6 | 10 | 0.0185 |

| 18 | Low-alloy steel, AISI 4042, oil quenched and tempered at 205 °C.—Press Forming | 1.93 | 7 | 4 | −8 | 16 | 6 | 10 | 0.0187 |

| 19 | Low-alloy steel, AISI 8740, oil quenched and tempered at 205 °C.—Press Forming | 1.93 | 8 | 4 | −8 | 16 | 6 | 10 | 0.0189 |

| 20 | Low-alloy steel, AISI 6150, oil quenched and tempered at 205 °C.—Press Forming | 1.90 | 7 | 4 | −8 | 18 | 9 | 9 | 0.0190 |

| Ranking | Solution (Material + Primary Process) | [kg] | [Eur] | Raw Material [Eur] | DEK [Eur/kg] | [kgCO2eq] | [kgCO2eq] | Only Use Phase [kgCO2eq] | |

|---|---|---|---|---|---|---|---|---|---|

| Ref: Stainless Steel Austenitic AISI 304 Annealed–Press Forming | REF: 8.91 | REF: 67 | REF: 63 | REF: 0 | REF: 105 | REF: 68 | REF: 49 | ||

| 1 | Low-alloy steel, AISI 9255, oil quenched and tempered at 205 °C.—Press Forming | 4.98 | 13 | 9 | −14 | 40 | 16 | 25 | 0.0000 |

| 2 | Low-alloy steel, AISI 9255, oil quenched and tempered at 315 °C.—Press Forming | 5.07 | 13 | 9 | −14 | 41 | 16 | 25 | 0.0161 |

| 3 | Low-alloy steel, AISI 5160, oil quenched and tempered at 205 °C.—Press Forming | 5.10 | 13 | 9 | −14 | 41 | 16 | 26 | 0.0210 |

| 4 | Low-alloy steel, AISI 5140, oil quenched and tempered at 205 °C.—Press Forming | 5.11 | 13 | 9 | −14 | 42 | 16 | 26 | 0.0221 |

| 5 | Low-alloy steel, AISI 5160, oil quenched and tempered at 315 °C.—Press Forming | 5.11 | 13 | 9 | −14 | 42 | 16 | 26 | 0.0225 |

| 6 | Low-alloy steel, AISI 4140, oil quenched and tempered at 205 °C.—Press Forming | 5.12 | 14 | 10 | −14 | 42 | 16 | 26 | 0.0259 |

| 7 | Low-alloy steel, AISI 8650, oil quenched and tempered at 205 °C.—Press Forming | 5.12 | 14 | 11 | −14 | 42 | 16 | 26 | 0.0279 |

| 8 | Low-alloy steel, AISI 50B60, oil quenched and tempered at 315 °C.—Press Forming | 5.16 | 13 | 9 | −14 | 42 | 16 | 26 | 0.0306 |

| 9 | Low-alloy steel, AISI 5150, oil quenched and tempered at 205 °C.—Press Forming | 5.17 | 13 | 9 | −14 | 42 | 16 | 26 | 0.0336 |

| 10 | Low-alloy steel, AISI 4150, oil quenched and tempered at 205 °C.—Press Forming | 5.17 | 14 | 10 | −14 | 42 | 16 | 26 | 0.0348 |

| 11 | Low-alloy steel, AISI 81B45, oil quenched and tempered at 205 °C.—Press Forming | 5.17 | 14 | 10 | −14 | 42 | 16 | 26 | 0.0353 |

| 12 | Low-alloy steel, AISI 94B30, oil quenched and tempered at 205 °C.—Press Forming | 5.18 | 14 | 10 | −14 | 42 | 16 | 26 | 0.0376 |

| 13 | Low-alloy steel, AISI 4340, oil quenched and tempered at 205 °C.—Press Forming | 5.15 | 17 | 13 | −13 | 42 | 16 | 26 | 0.0380 |

| 14 | Low-alloy steel, AISI 8650, oil quenched and tempered at 315 °C.—Press Forming | 5.18 | 15 | 11 | −14 | 42 | 16 | 26 | 0.0384 |

| 15 | Low-alloy steel, AISI 5140, oil quenched and tempered at 315 °C.—Press Forming | 5.21 | 13 | 9 | −14 | 42 | 16 | 26 | 0.0400 |

| 16 | Low-alloy steel, AISI 4042, oil quenched and tempered at 205 °C.—Press Forming | 5.20 | 14 | 10 | −14 | 42 | 16 | 26 | 0.0404 |

| 17 | Low-alloy steel, AISI 9255, oil quenched and tempered at 425 °C.—Press Forming | 5.21 | 13 | 10 | −14 | 42 | 16 | 26 | 0.0414 |

| 18 | Low-alloy steel, AISI 8640, oil quenched and tempered at 205 °C.—Press Forming | 5.20 | 15 | 11 | −14 | 42 | 16 | 26 | 0.0415 |

| 19 | Carbon steel, AISI 1340, oil quenched and tempered at 205 °C.—Press Forming | 5.22 | 13 | 9 | −15 | 42 | 16 | 26 | 0.0424 |

| 20 | Low-alloy steel, AISI 8740, oil quenched and tempered at 205 °C.—Press Forming | 5.20 | 15 | 11 | −14 | 42 | 16 | 26 | 0.0425 |

References

- Ferreira, V.; Merchán, M.; Egizabal, P.; de Cortázar, M.G.; Irazustabarrena, A.; López-Sabirón, A.M.; Ferreira, G. Technical and environmental evaluation of a new high performance material based on magnesium alloy reinforced with submicrometre-sized TiC particles to develop automotive lightweight components and make transport sector more sustainable. J. Mater. Res. Technol. 2019, 8, 2549–2564. [Google Scholar] [CrossRef]

- Commission European. White Paper: Roadmap to a Single European Transport Area—Towards a Competitive and Resource Efficient Transport System; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Brooke, L.; Evans, H. Lighten up! Automot. Eng. 2009, 117, 16–22. [Google Scholar]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Priarone, P.C.; Catalano, A.R.; Settineri, L. Additive manufacturing for the automotive industry: On the life-cycle environmental implications of material substitution and lightweighting through re-design. Prog. Addit. Manuf. 2023, 8, 1229–1240. [Google Scholar] [CrossRef]

- Lewis, G.M.; Buchanan, C.A.; Jhaveri, K.D.; Sullivan, J.L.; Kelly, J.C.; Das, S.; Taub, A.I.; Keoleian, G.A. Green Principles for Vehicle Lightweighting. Environ. Sci. Technol. 2019, 53, 4063–4077. [Google Scholar] [CrossRef] [PubMed]

- Ashby, F. Multi-Objective Optimization in Material Design and Selection. Acta Mater. 2000, 48, 359–369. [Google Scholar] [CrossRef]

- Ashby, M.F.; Johnson, K. Materials and Design: The Art and Science of Material Selection in Product Design, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2013. [Google Scholar]

- Stojčić, M.; Zavadskas, E.K.; Pamučar, D.; Stević, Ž.; Mardani, A. Application of MCDM Methods in Sustainability Engineering: A Literature Review 2008–2018. Symmetry 2019, 11, 350. [Google Scholar] [CrossRef]

- Kumar, R.; Ray, A. Selection of material for optimal design using multi-criteria decision making. Procedia Mater. Sci. 2014, 6, 590–596. [Google Scholar] [CrossRef]

- Giorgetti, A.; Cavallini, C.; Arcidiacono, G.; Citti, P. A mixed C-VIKOR fuzzy approach for material selection during design phase: A case study in valve seats for high performance engine. Int. J. Appl. Eng. Res. 2017, 12, 3117–3129. [Google Scholar]

- Jahan, A.; Mustapha, F.; Ismail, M.; Sapuan, S.; Bahraminasab, M. A comprehensive VIKOR method for material selection. Mater. Des. 2011, 32, 1215–1221. [Google Scholar] [CrossRef]

- Manalo, M.V.; Magdaluyo, E.R. Integrated DLM-COPRAS Method in Material Selection of Laminated glass Interlayer for a Fuel-Efficient Concept Vehicle; World Congress on Engineering: London, UK, 2018; Volume 2. [Google Scholar]

- Gul, M.; Celik, E.; Gumus, A.; Guneri, A. A fuzzy logic based PROMETHEE method for material selection problems. Beni-Suef Univ. J. Basic Appl. Sci. 2018, 7, 68–79. [Google Scholar] [CrossRef]

- Aziz, C.; Taleb, M.; Zakia, R.; Rajaa, B.; El Haji, M. Electre multicriteria analysis for choosing material concerned by the corrosion problem. J. Appl. Sci. Environ. Stud. 2020, 3, 132–146. [Google Scholar]

- Sen, B.; Bhattacharjee, P.; Mandal, U. A comparative study of some prominent multi criteria decision making methods for connecting rod material selection. Perspect. Sci. 2016, 8, 547–549. [Google Scholar] [CrossRef]

- Rao, R.V.; Patel, B.K. A subjective and objective integrated multiple attribute decision making method. Mater. Des. 2010, 37, 4738–4747. [Google Scholar] [CrossRef]

- Opricovic, S. Multicriteria Optimization of Civil Engineering Systems; Faculty of Civil Engineering: Belgrade, Serbia, 1998; pp. 5–21. [Google Scholar]

- Celik, H.K.; Ersoy, H.; Doğan, A.; Eravci, G.; Rennie, A.E.W.; Akinci, I. Strength-Based Design Analysis of a Damaged Engine Mounting Bracket Designed for a Commercial Electric Vehicle. J. Fail. Anal. Prev. 2021, 21, 1315–1322. [Google Scholar] [CrossRef]

- ANSYS. Available online: https://www.ansys.com/it-it/products/materials/granta-selector (accessed on 17 July 2024).

- Więckowski, J.; Sałabun, W. How the normalization of the decision matrix influences the results in the VIKOR method? Procedia Comput. Sci. 2020, 176, 2222–2231. [Google Scholar] [CrossRef]

- Chatterjee, P.; Chakraborty, S. A comparative analysis of VIKOR method and its variants. Decis. Sci. Lett. 2016, 5, 469–486. [Google Scholar] [CrossRef]

- Del Pero, F.; Berzi, L.; Antonacci, A.; Delogu, M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines 2020, 8, 51. [Google Scholar] [CrossRef]

- Antonacci, A.; Del Pero, F.; Baldanzini, N.; Delogu, M. Holistic eco-design tool within automotive field. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1214, 012045. [Google Scholar] [CrossRef]

| Industrial Processes | |||||

|---|---|---|---|---|---|

| Binder Jetting | 0.05 | 361,000 | 0.98 | 22.4 | 22.4 |

| Cold Isostatic Pressing (CIP) | 1470 | 141,000 | 0.99 | 31.6 | 31.6 |

| Evaporative pattern casting, automated | 2980 | 23,086 | 0.49 | 31.62 | 31.62 |

| Ferro die casting | 44,500 | 393,000 | 0.8 | 54.8 | 54.8 |

| Gravity die casting | 10,500 | 35,200 | 0.69 | 15.8 | 15.8 |

| Green sand casting, automated | 2150 | 39,300 | 0.63 | 77.5 | 77.5 |

| Investment casting, automated (lost wax process) | 6810 | 39,300 | 0.82 | 44.7 | 44.7 |

| Press forming | 78,600 | 278,000 | 0.75 | 77.5 | 77.5 |

| Replicast casting | 5560 | 21,500 | 0.69 | 22.4 | 22.4 |

| Shell casting | 3930 | 5560 | 0.49 | 15.81 | 15.81 |

| Squeeze casting | 22,200 | 393,000 | 0.93 | 30 | 30 |

| Design Scenario | Industrial Process | Family Material | |||||||

|---|---|---|---|---|---|---|---|---|---|

| General Design | 1 | 1 | 1 | 1 | 1 | 1 | 1 | All | All |

| Yield Design | 0 | 1 | 0 | 1 | 1 | 1 | 1 | All | All |

| Wrought Design | 1 | 1 | 1 | 1 | 1 | 1 | 1 | Press Forming | Compatible |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Risaliti, E.; Gabriele, A.; Del Pero, F.; Citti, P. Innovative Model for Material Selection Within the Automotive Lightweight Eco-Design Field. Eng. Proc. 2025, 85, 20. https://doi.org/10.3390/engproc2025085020

Risaliti E, Gabriele A, Del Pero F, Citti P. Innovative Model for Material Selection Within the Automotive Lightweight Eco-Design Field. Engineering Proceedings. 2025; 85(1):20. https://doi.org/10.3390/engproc2025085020

Chicago/Turabian StyleRisaliti, Edoardo, Arcidiacono Gabriele, Francesco Del Pero, and Paolo Citti. 2025. "Innovative Model for Material Selection Within the Automotive Lightweight Eco-Design Field" Engineering Proceedings 85, no. 1: 20. https://doi.org/10.3390/engproc2025085020

APA StyleRisaliti, E., Gabriele, A., Del Pero, F., & Citti, P. (2025). Innovative Model for Material Selection Within the Automotive Lightweight Eco-Design Field. Engineering Proceedings, 85(1), 20. https://doi.org/10.3390/engproc2025085020