1. Introduction

At the beginning, additive manufacturing (AM) was called rapid prototyping, but now it is more commonly known as 3D printing. This technology is used to create prototypes and components with complex geometries such as a mold for investment casting of a turbine blade [

1] or a hip implant [

2], and it could even be used in a reparation process [

3]. In contrast to conventional manufacturing processes, such as injection molding and cutting-based process, AM does not require costly molds or expensive tooling and there is less waste material; however, today it cannot be used as a large production volume process [

4,

5,

6]. Currently, the commercialization of this technology is spreading very rapidly around the world due to the expiry of the patents related to AM devices, so this has led more companies to venture into this technology, and therefore the cost of 3D printers has decreased. 3D printers based on fused filament fabrication (FFF) are the cheapest on the market [

6].

FFF is based on an extrusion process where a thermoplastic filament with a commercially available diameter of 1.75 or 2.85 mm is the feedstock material, which is supplied to a heating chamber by rollers. In the chamber, the filament is heated at a temperature above its melting point and the melted material is pushed through the nozzle die by the solid part of the filament that enters the chamber. The nozzle die deposits the melted material as a thread on a build plate and is moved in the X–Y plane by stepper motors to fill the first layer of the object; after finishing the first layer, the build plate is moved down a thickness in the Z direction, and the printing process continues for the next layer, so the cycle is repeated to form a 3D object layer-by-layer.

To date, not all thermoplastic polymers are printable by FFF; this is mainly due to the particular thermal properties and the low tendency to warp during solidification, which are necessary properties of the polymer for a successful printing process [

7]. Printable polymers such as acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyamide (PA) and polylactide (PLA) can be found on the market in filament forms. The mechanical properties of components fabricated by FFF with pure polymer filaments are low compared to injection molding or other plastic manufacturing processes.

Additive manufacturing of composites is gaining appeal due to the versatility of the properties offered by this class of materials. The introduction of composites in FFF can improve the mechanical properties of 3D printed objects. In recent years, fiber-reinforced polymer composites have been investigated in FFF, showing better mechanical performance, increasing the popularity of this type of composite [

8,

9,

10]. However, particle-reinforced polymer composites in FFF have been very lightly studied. Thus, the aim of this work was to develop 3D printable nanoclay particle reinforced ABS and PLA composites by fused filament fabrication.

2. Materials and Methods

In this section, materials, characterization of pellets, composite filaments, 3D printing and mechanical tests are described in detail.

2.1. Materials

Pellets of ABS (Star Prime Resins ABS448T, Star Plastics Inc., MillWood, WV, USA) and PLA (NatureWorks PLA4043D, NatureWorks LLC, Plymouth, MN, USA) were used as polymer matrices for the particle-reinforced composite filaments. Nanoclay Nanomer I.31 PS (Sigma-Aldrich, St. Louis, MO, USA) was used as the reinforcing particle.

2.2. Thermal Properties of Pellets

The thermal properties of pellets of ABS and PLA were determined by differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) as initial data before the twin-screw extrusion process to produce the composite filaments.

DSC and TGA were carried out in a NETZSCH STA 449 F1 Jupiter. DSC was performed in three stages: the first was heating from 25 °C to 200 °C, the second was cooling from 200 °C to 25 °C, and finally, heating from 25 °C to 200 °C. The cooling and heating rates were 10 °C/min. The TGA samples were heated from 25 °C to 600 °C in an inert atmosphere of N2 at a heating rate of 10 °C/min.

2.3. Composite Filaments

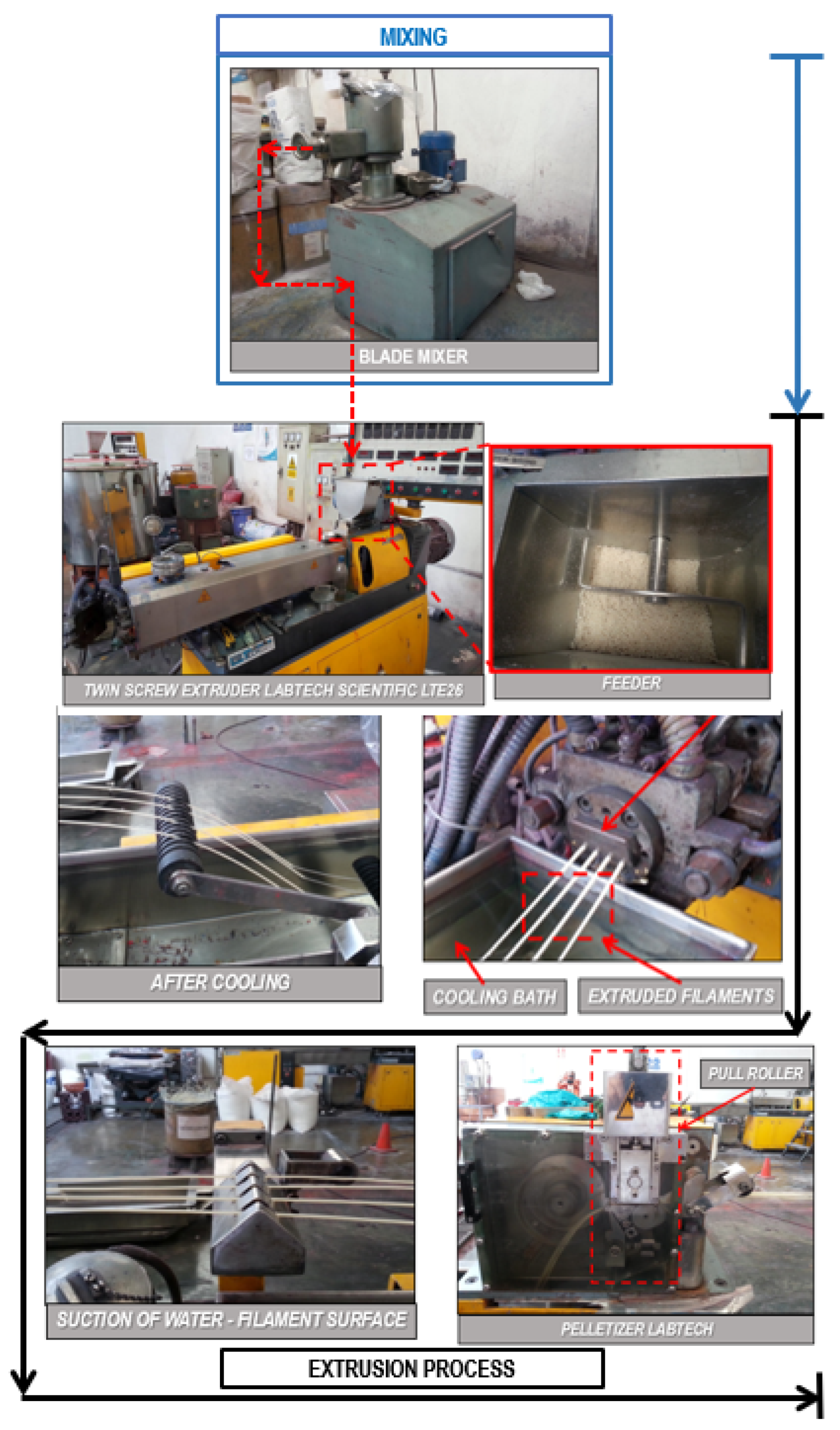

A twin-screw extruder LabTech Scientific LTE26 (Labtech Engineering Co., Ltd., Samutprakarn, Thailand) was used to produce filaments of nanoclay particle reinforced composites.

Table 1 shows the extrusion process parameters in the fabrication of composite filaments. Before the extrusion process, ABS and PLA pellets were dried in a forced convection oven at 85 °C and 55 °C, respectively, for at least 6 h. Nanoclay particles were also dried at 85 °C for 24 h. A blade mixer was used to mix the nanoclay and the matrix (ABS or PLA) for 5 min. The contents of the nanoclay particles in the composite filaments were 0%, 1%, 2% and 3% in weight.

The mixture of nanoclay and thermoplastic matrix were fed into the extruder. The extruded filament was passed through a water-filled cooling bath after exiting the extrusion nozzle. After cooling, a system of suction of water in the filament surface was applied. Pelletizer LabTech (without blades) was used as a pull roller to set the final diameter (Ø1.75 ± 0.5 mm) of the extruded filament.

Figure 1 shows a mixing and extrusion process representation of the fabrication of composite filaments.

The melt flow index (MFI) of the extruded composite filaments was measured using a Zwick/Roell Mflow plastometer at 230 °C for both the ABS and PLA composite filaments. The weights for the MFI measurement were 5 kg for the ABS matrix composite filaments and 2.16 kg for the PLA matrix composite filaments.

2.4. 3D Printing

Similar to other AM methods, FFF starts with a three-dimensional model in a .stl format, which only contains the surface of the object, then a 3D printing software (simplify3D V4.0.0) decomposes the model into slices in order to obtain a set of two-dimensional contour lines, which are the layers of the 3D printed object.

Composite filaments produced by twin screw-extrusion were used as the feedstock material for the 3D printer. MakerBot Replicator 2X (MakerBot Industries, Brooklyn, NY, USA) was the 3D printer used in this study. Tensile and impact specimens were fabricated using an infill of 100%, nozzle temperature of 230 °C, layer thickness of 0.2 mm and raster angle of [45°/−45°].

2.5. Mechanical Tests

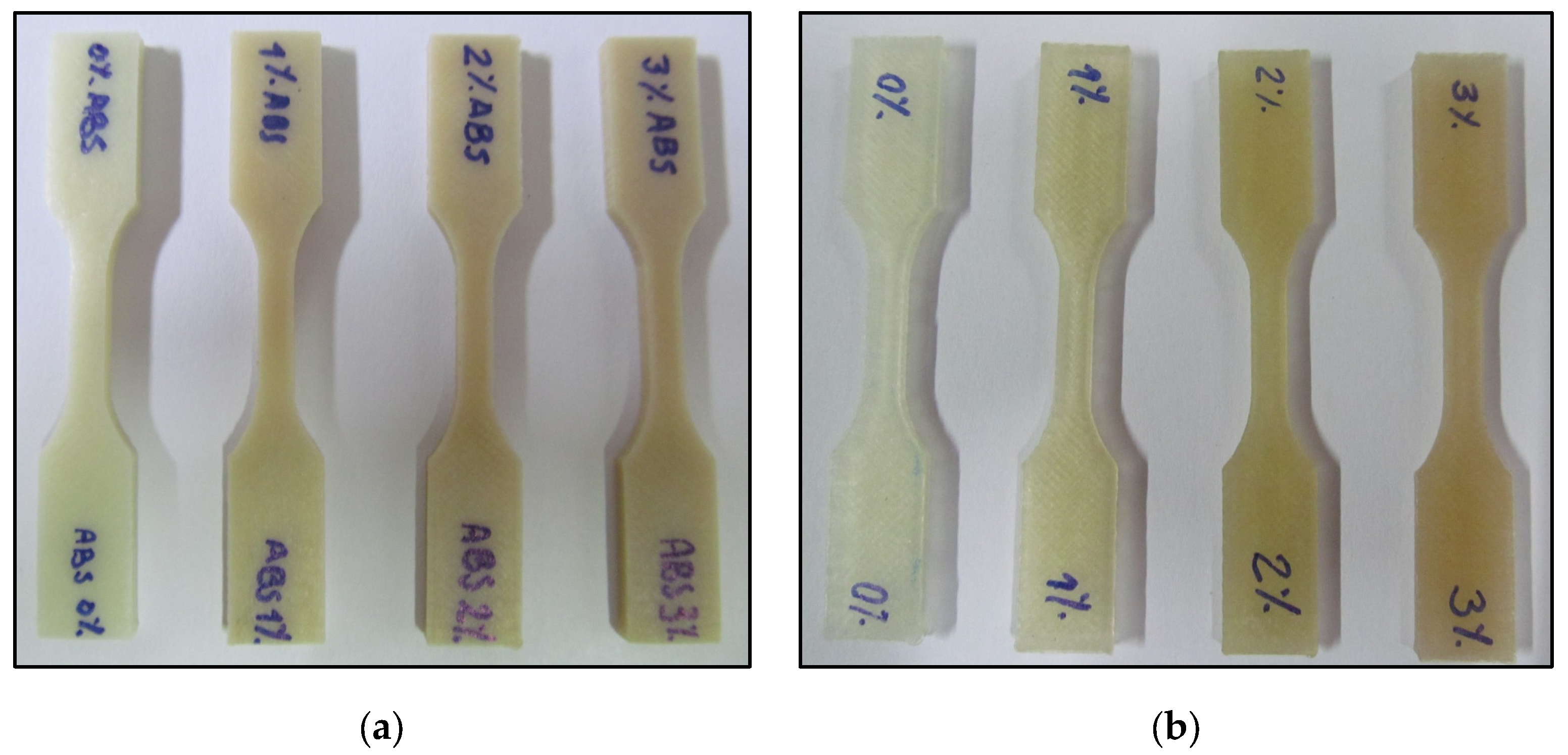

Tensile tests of nanoclay reinforced composites specimens were carried out in a Zwick/Roell Z050 tensile machine at 5 mm/min of speed test. The geometry and dimensions of the 3D printed composite tensile specimens were type V according to ASTM D638-14. The 3D printed tensile specimens are shown in

Figure 2.

In addition to the tensile tests, impact tests were also carried out. The Charpy impact test was based on the ISO 179-1 [

11]. A Zwick/Roell HIT 25P impact machine with a capacity of 25 J was used. The notches of the impact specimens were produced by machining in a Zwick/Roell ZNO automatic cutting machine.

3. Results and Discussion

In this section, the results of the thermal properties of the pellets, the melt flow index of the composite filaments and the mechanical properties of the nanoclay particle reinforced thermoplastic composites fabricated by FFF are discussed.

3.1. Thermal Properties of Pellets

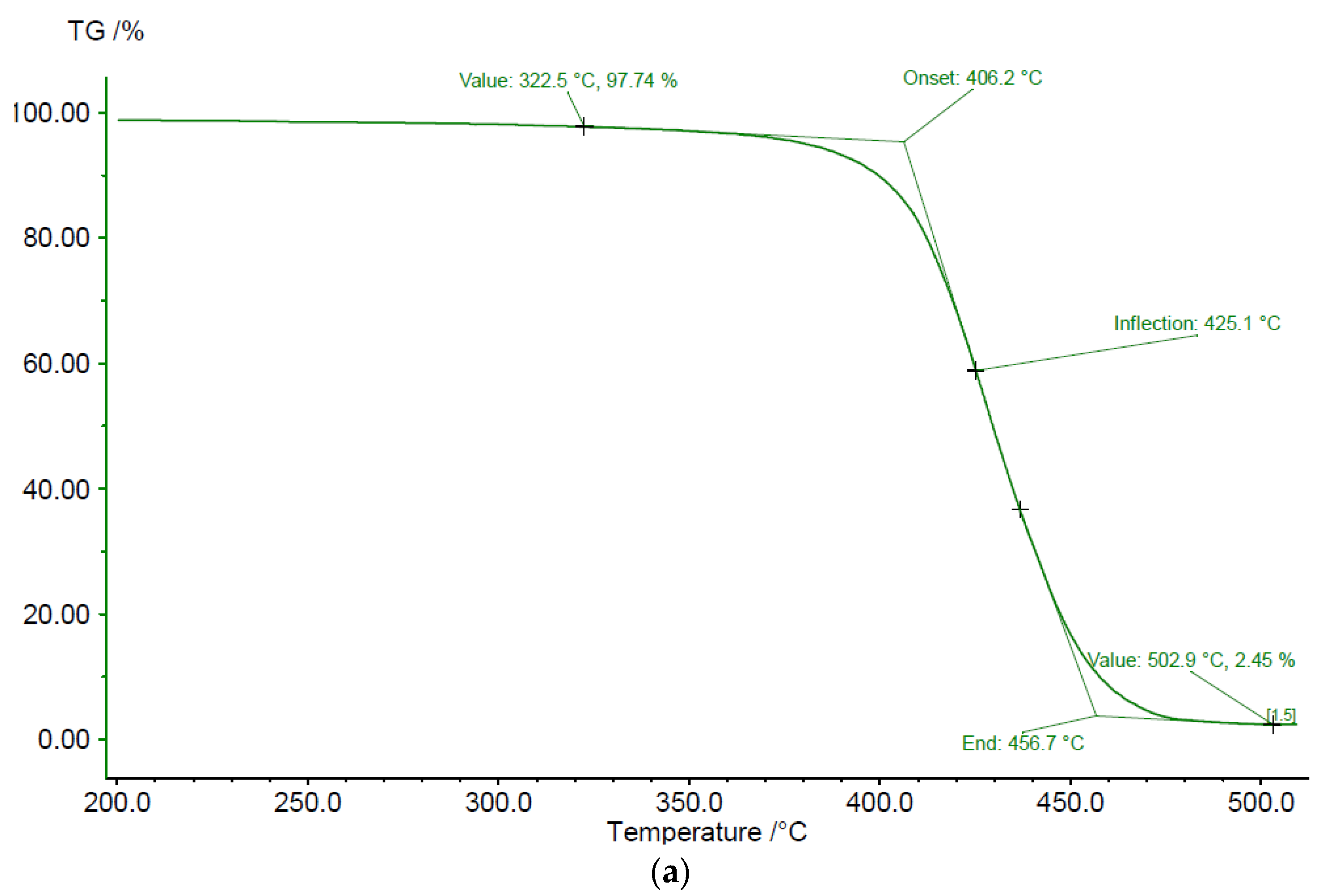

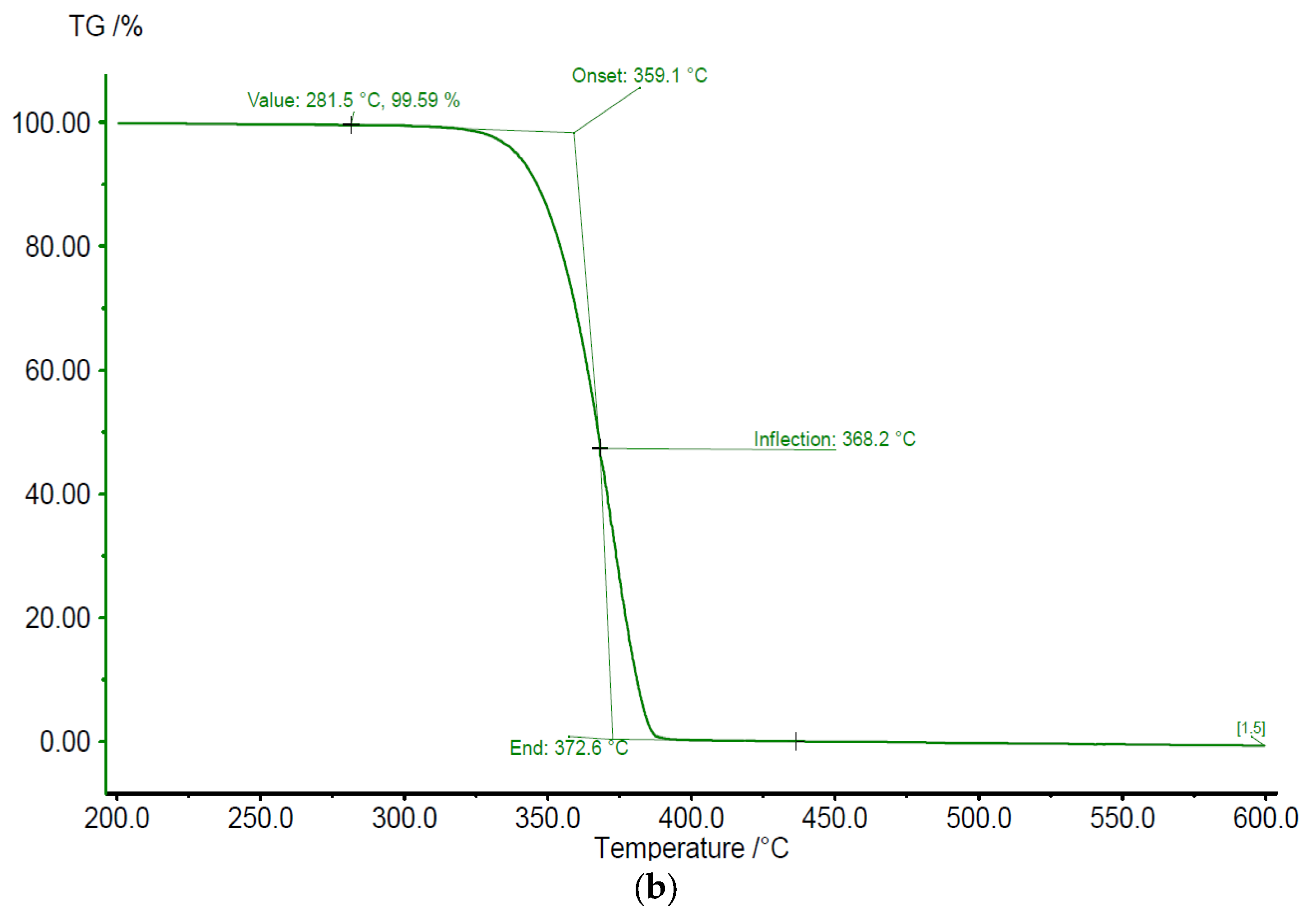

Table 2 shows the results of DSC. A glass transition temperature (Tg) of 110.6 °C and 60.9 °C was observed for the ABS and PLA pellets, respectively. No melting point (Tm) was detected for the ABS pellets because it is an amorphous polymer. A melting point of 153.3 °C was observed for the PLA pellets. The TGA results are shown in

Figure 3. Degradation temperatures of 425.1 °C and 368.2 °C were recorded for the ABS and PLA pellets, respectively. Initial degradation of the ABS pellets was observed at 322.5 °C with a mass drop of 2.3%. For the PLA pellets, a mass drop of 0.4% was observed at 281.5 °C.

The results suggested that the drying temperature used in the forced convection oven, prior to the mixing of the thermoplastics pellets and nanoclay particles, was below the glass transition temperatures for ABS and PLA pellets. Furthermore, in the extrusion process, all heating zones in the extrusion barrels, except the feed zone, were at temperatures above the melting point or glass transition temperatures and below the degradation temperatures for ABS and PLA.

3.2. Melt Flow Index of Composite Filaments

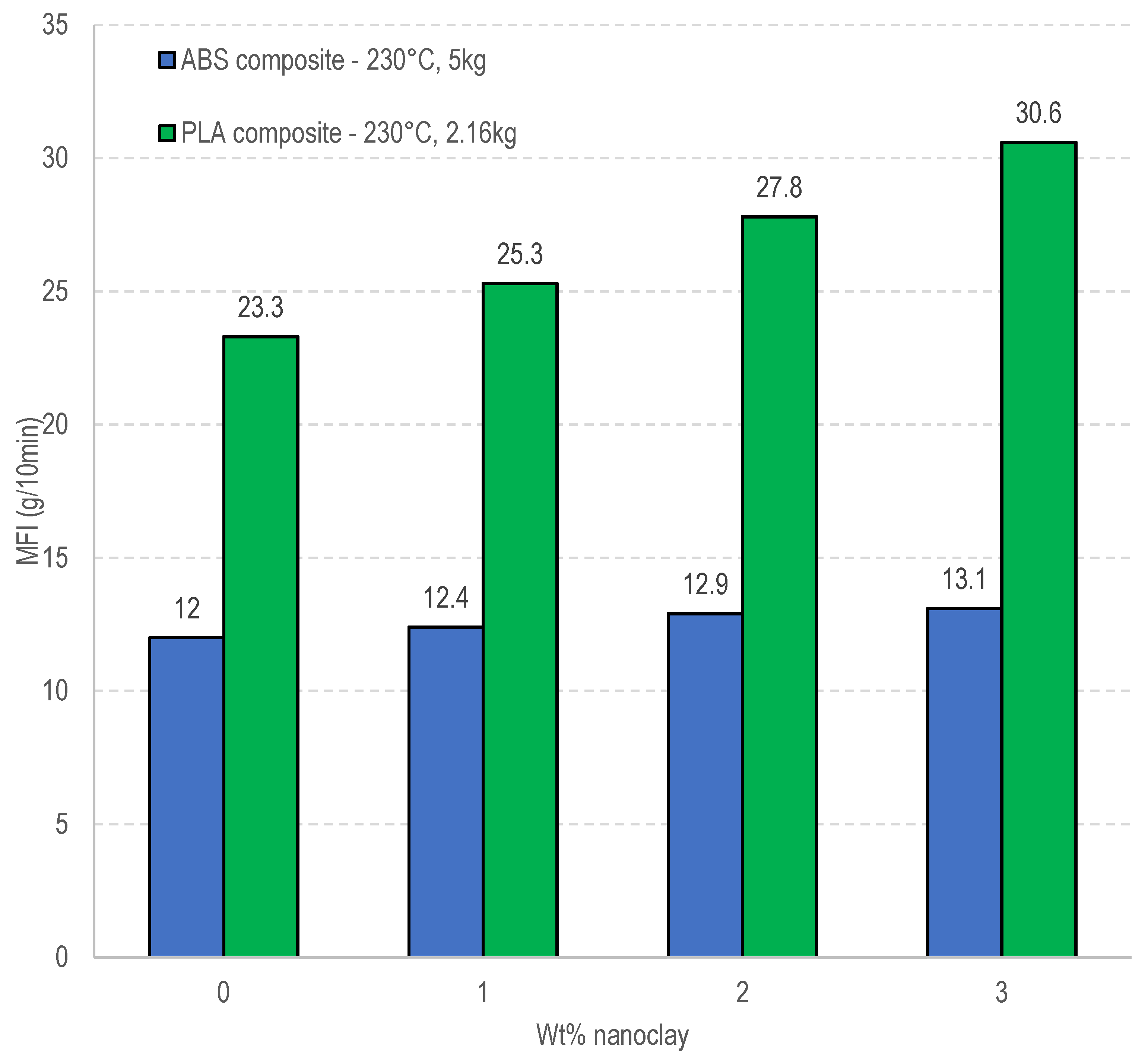

MFI results of the nanoclay reinforced ABS and PLA composites are shown in

Figure 4. It is observed that the addition of nanoclay particles led to an increase in the MFI of the ABS and PLA matrix composites. This increase in MFI would indicate an increase in the mobility of the ABS and PLA polymer chains. Apparently, the nanoclays would act as a plasticizer. Such behavior has also been reported when introducing nanoclays into high density polyethylene (HDPE) [

12]. The MFI results indicated that, during the 3D printing process, the composites had good fluidity at a nozzle temperature of 230 °C (temperature of the MFI test), without clogging of the 3D printer nozzle.

3.3. Mechanical Tests

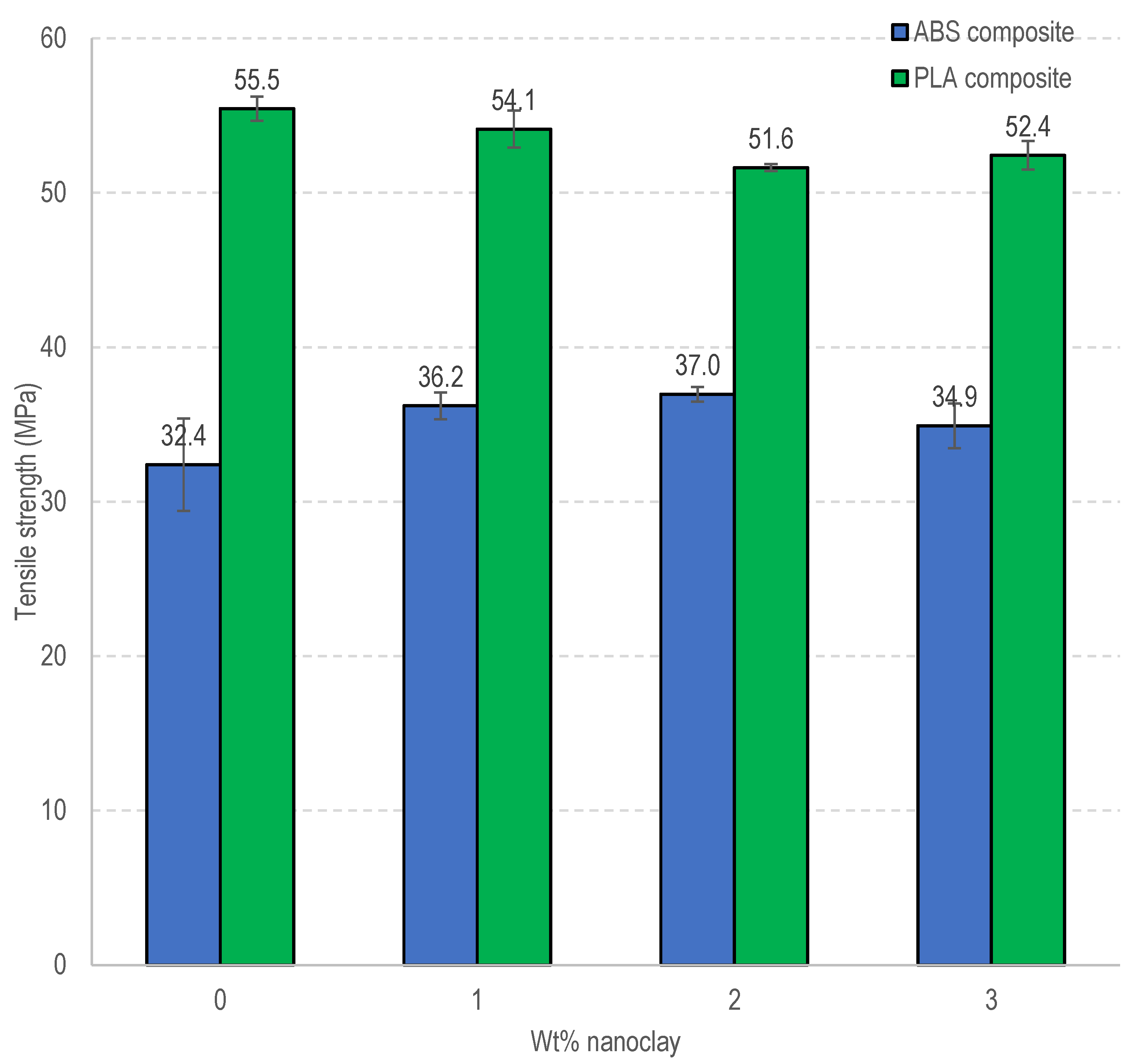

Figure 5 shows the tensile strength of nanoclay-reinforced ABS and PLA composites. It was possible to increase the tensile strength by introducing nanoclay into the ABS matrix. The greatest increase in tensile strength was achieved with a nanoclay content of 2%, thus increasing the tensile strength from 32.4 MPa for the pure ABS matrix to 37.0 MPa for the composite with 2% nanoclay. It can also be observed that the tensile strength of the ABS composite with 3% nanoclay decreased; however, it was still higher than pure ABS. Other research work has also found that the greatest increase in tensile strength is achieved with 2% nanoclay in an ABS matrix [

13].

For the case of PLA composites, a decrease of tensile strength was observed, decreasing from 55.5 MPa for the pure PLA matrix to 51.6 MPa for the 2% nanoclay content. According to the MFI results for the PLA composites, nanoclay in this polymer matrix increased the fluidity of the composites at 230 °C (nozzle temperature in the 3D printing process), which reveals that the nanoclay does not restrict the mobility of the PLA polymer chains. Therefore, an increase in the tensile strength of PLA composites was not achieved since the restriction of the movement of polymer chains plays an important role in increasing their mechanical properties.

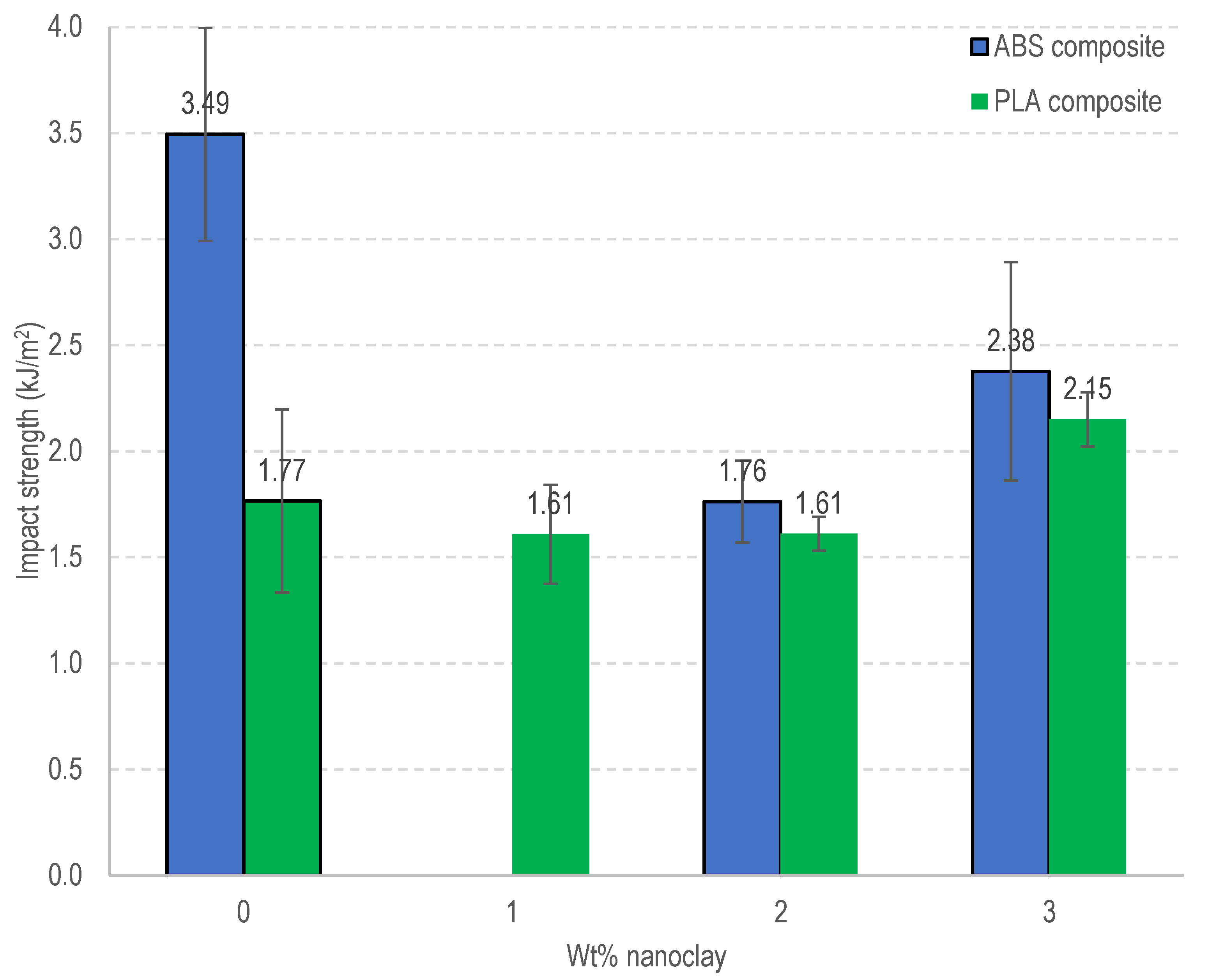

The impact strength of reinforced ABS and PLA composites is shown in

Figure 6. The impact strength of pure ABS matrix was 3.49 kJ/m

2. After introducing nanoclay into the ABS matrix, the impact strength decreased. The ABS composite with a nanoclay content of 2% had the lowest impact strength value. It should be noted that it was not possible to print impact specimens of the ABS composite with 1% nanoclay content. Contrary to the case of ABS composites, an increasing impact strength was observed for PLA composites. The maximum impact strength was achieved with a nanoclay content of 3%.

4. Conclusions

The fabrication of ABS and PLA matrix composite filaments reinforced with nanoclay particles was realized with a twin-screw extruder. Successful 3D printing of nanoclay particle reinforced ABS and PLA was achieved. Nanoclay particles increased the tensile strength of ABS composites up to a maximum of 37 MPa for a content of 2%; however, the impact strength decreased. In the case of PLA matrix composites, the tensile strength decreased when nanoclay particles were introduced. An increase in the impact strength of the PLA matrix composite was observed with a nanoclay content of 3%.

Author Contributions

All authors contributed equally to this work. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data produced in this study are included in the paper.

Acknowledgments

The authors would like to thank VEO-3D PUCP for advice concerning 3D printing technology and assistance in providing the 3D printer used in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wu, H.; Li, D.; Tang, Y.; Guo, N.; Cui, F.; Sun, B. Rapid Casting of Hollow Turbine Blades Using Integral Ceramic Moulds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2009, 223, 695–702. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Krishna, B.V.; Xue, W.; Bose, S. Application of Laser Engineered Net Shaping (LENS) to Manufacture Porous and Functionally Graded Structures for Load Bearing Implants. J. Mater. Sci. Mater. Med. 2009, 20, 29–34. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Azer, M.; Singh, P. Adaptive Toolpath Deposition Method for Laser Net Shape Manufacturing and Repair of Turbine Compressor Airfoils. Int. J. Adv. Manuf. Technol. 2010, 48, 121–131. [Google Scholar] [CrossRef]

- Berman, B. 3-D Printing: The New Industrial Revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. Part B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A. Mechanical Characterization of FDM 3D Printing of Continuous Carbon Fiber Reinforced PLA Composites. Compos. Part B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- ISO 179-1:2000; Plastics-Determination of Charpy Impact Properties-Part1: Non-Instrumented Impact Test. International Standards Organization: Geneve, Switzerland, 2000.

- Sepet, H.; Tarakcioglu, N.; Misra, R. Investigation of Mechanical, Thermal and Surface Properties of Nanoclay/HDPE Nanocomposites Produced Industrially by Melt Mixing Approach. J. Compos. Mater. 2016, 50, 3105–3116. [Google Scholar] [CrossRef]

- Shishavan, S.M.; Azdast, T.; Ahmadi, S.R. Investigation of the Effect of Nanoclay and Processing Parameters on the Tensile Strength and Hardness of Injection Molded Acrylonitrile Butadiene Styrene–Organoclay Nanocomposites. Mater. Des. 2014, 58, 527–534. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).