Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing †

Abstract

1. Introduction

2. Materials and Methods

2.1. Filaments and 3D Printer

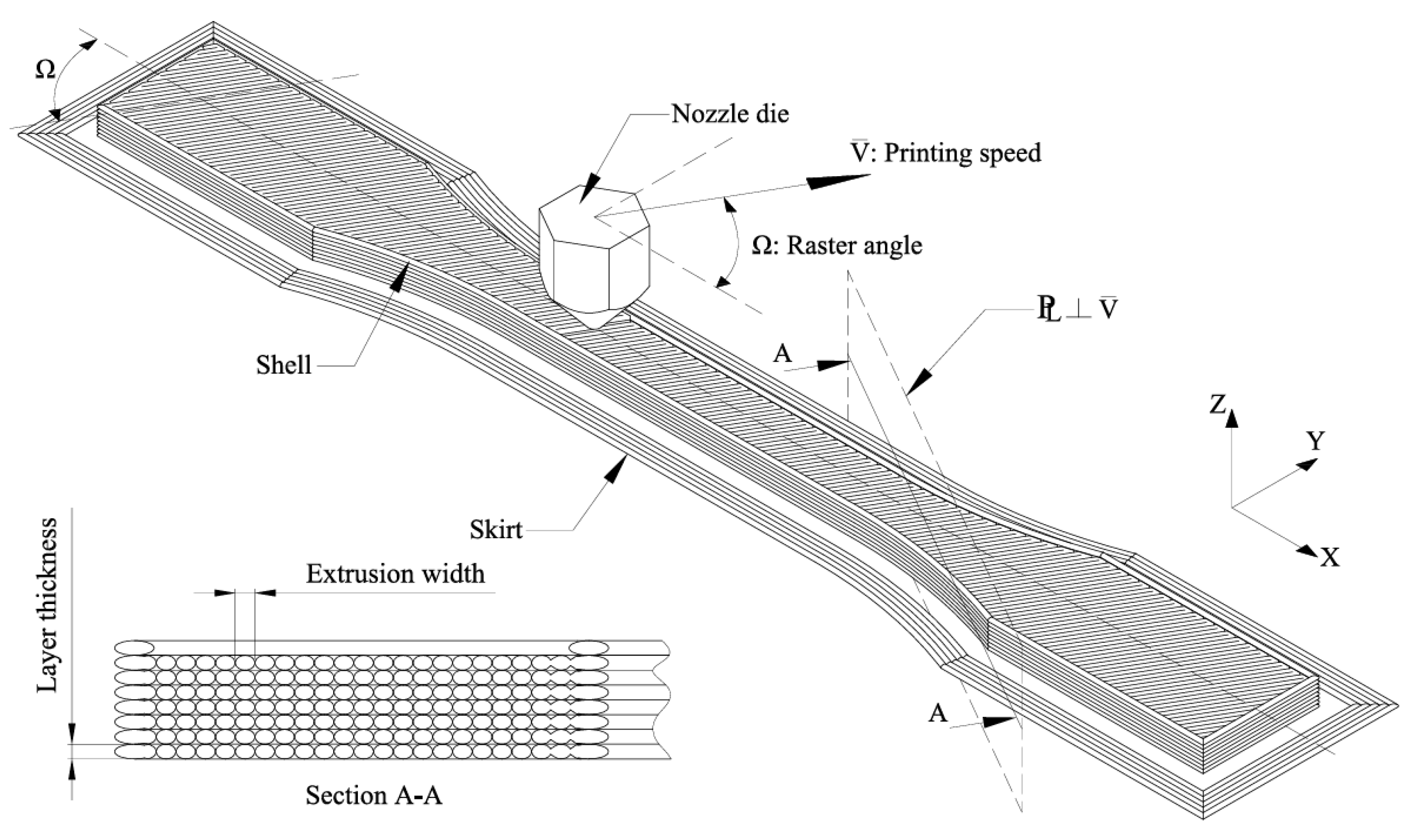

2.2. Process Parameters

2.3. Melt Flow Index

2.4. Scanning Electronic Microscopy (SEM)

2.5. Tensile Testing

2.6. Experimental Plan

3. Results and Discussion

3.1. Filaments

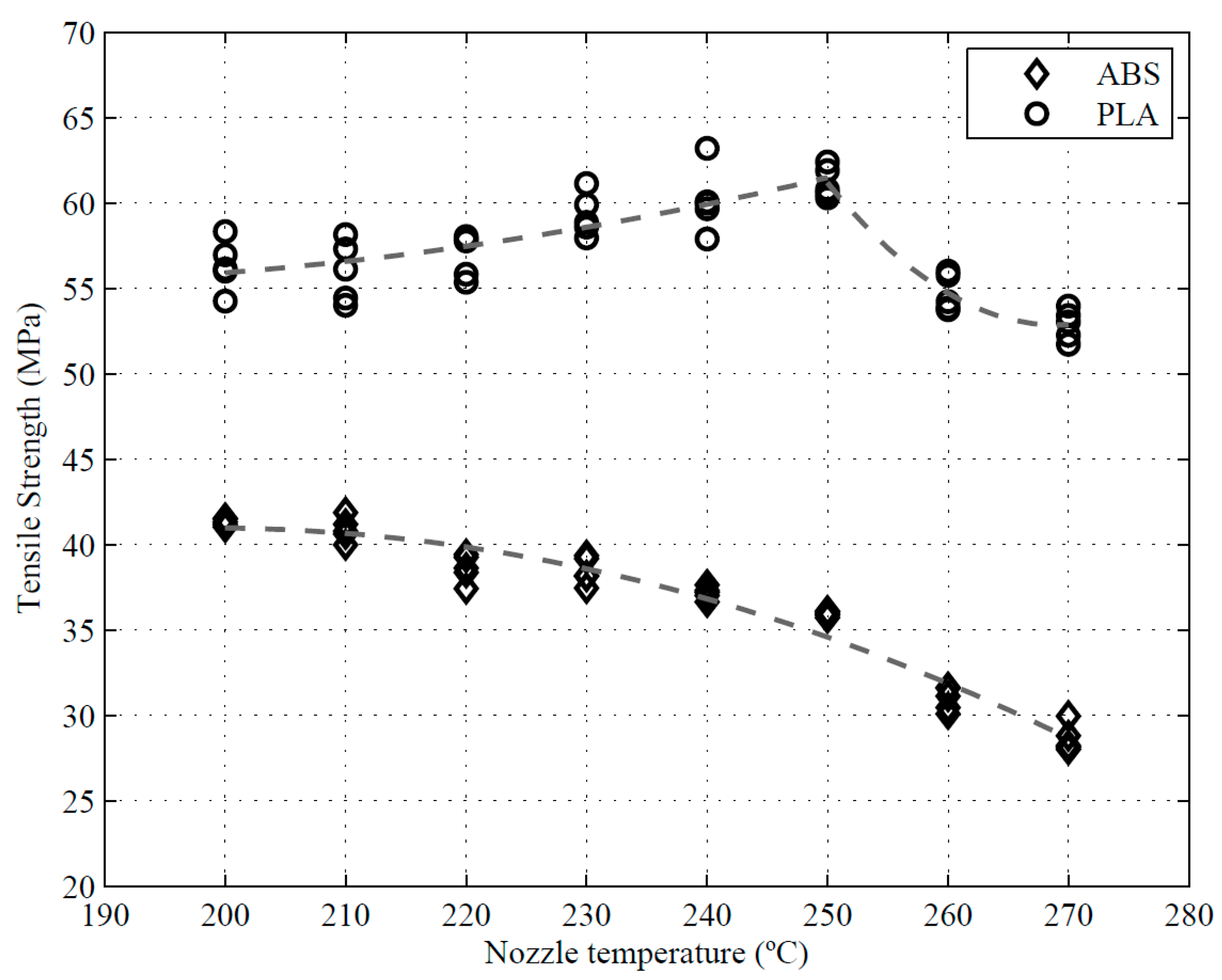

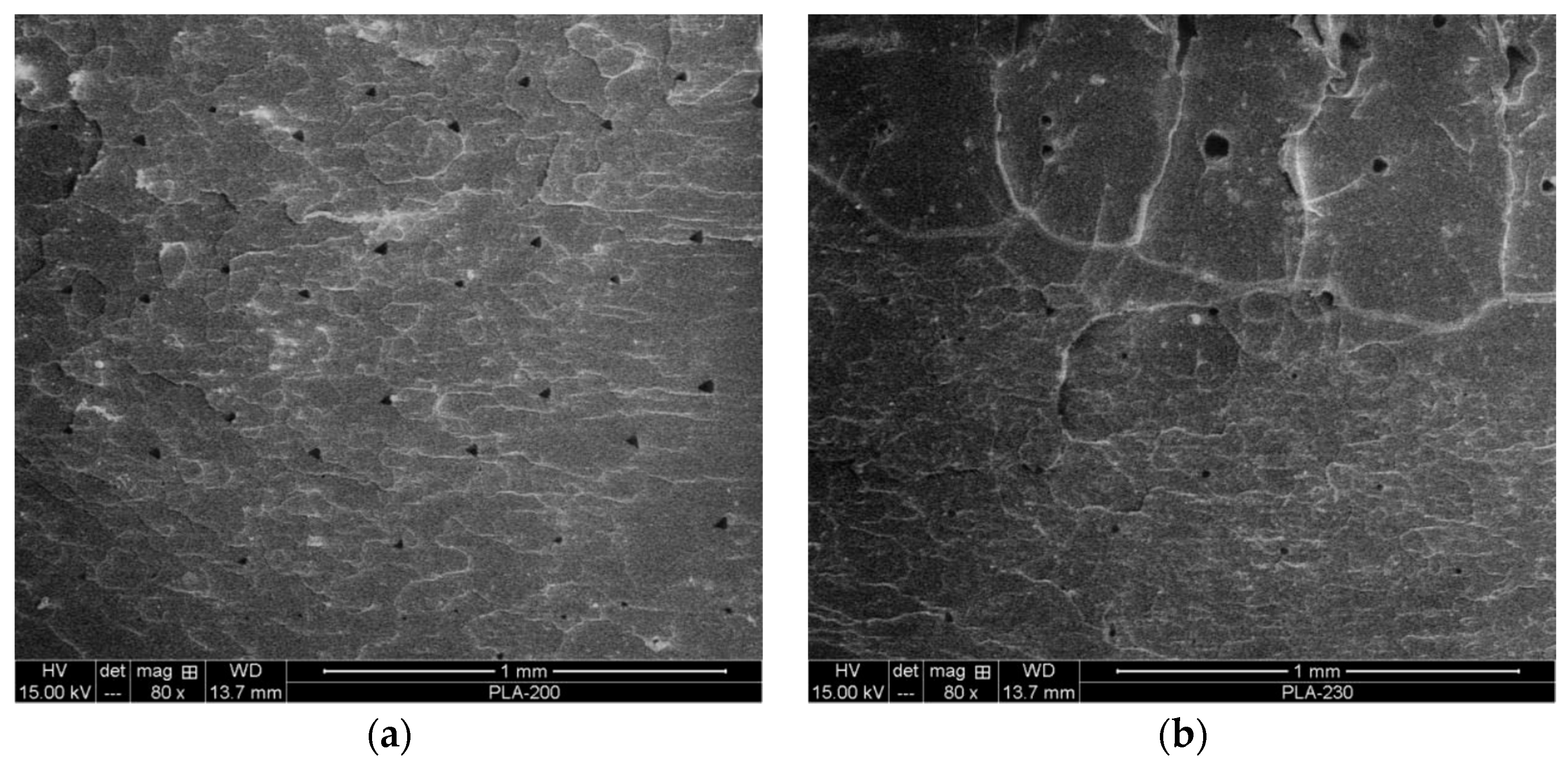

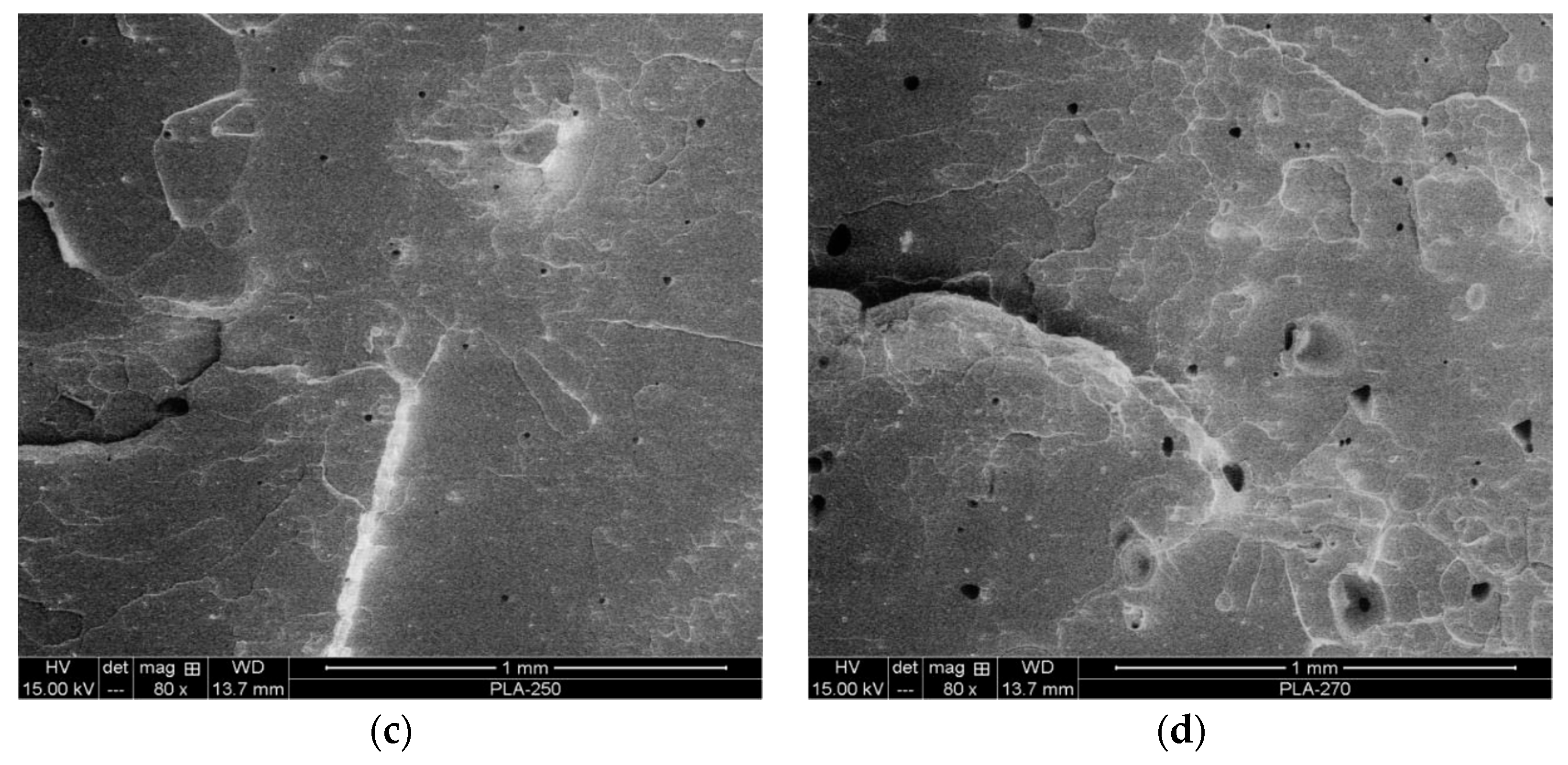

3.2. Effect of the Nozzle Temperature

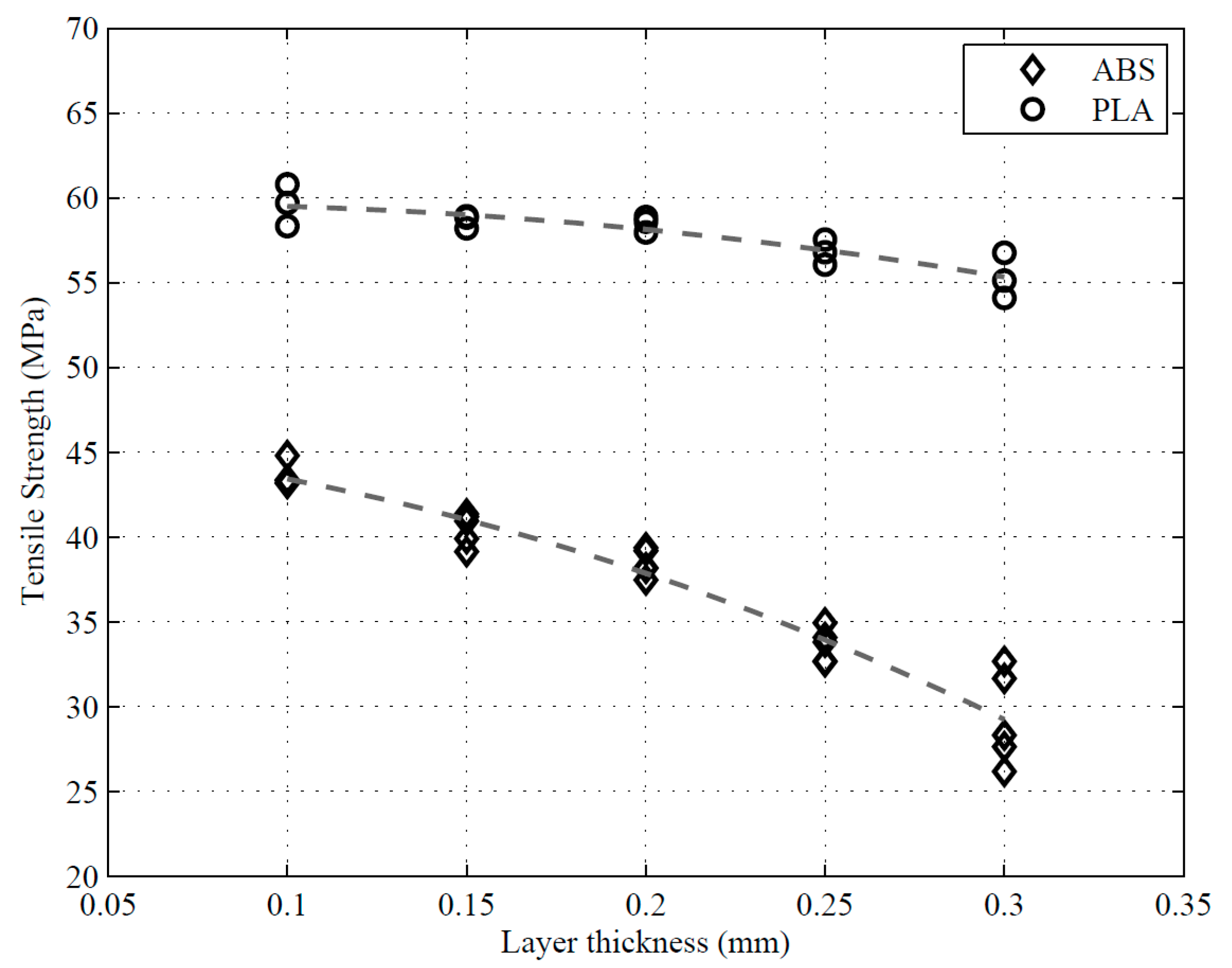

3.3. Effect of the Layer Thickness

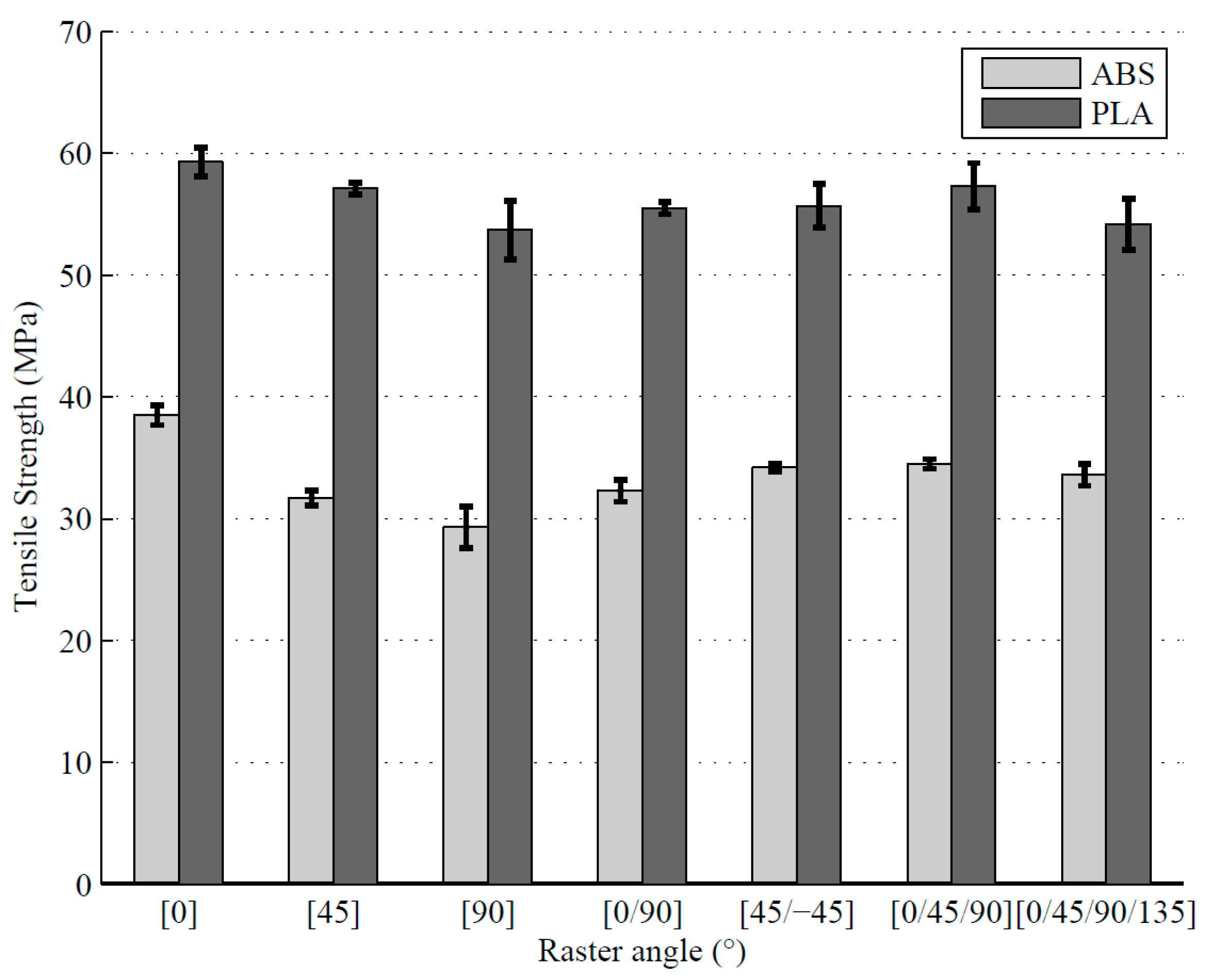

3.4. Effect of the Raster Angle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Standards Organization: Geneva, Switzerland, 2021.

- Berman, B. 3-D Printing: The New Industrial Revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Onwubolu, G.C.; Rayegani, F. Characterization and Optimization of Mechanical Properties of ABS Parts Manufactured by the Fused Deposition Modelling Process. Int. J. Manuf. Eng. 2014, 2014, 598531. [Google Scholar] [CrossRef]

- Durgun, I.; Ertan, R. Experimental Investigation of FDM Process for Improvement of Mechanical Properties and Production Cost. Rapid Prototyp. J. 2014, 20, 228–235. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, M.; Li, S.; Si, L.; Peng, J.; Hu, Y. Mechanical Property Parametric Appraisal of Fused Deposition Modeling Parts Based on the Gray Taguchi Method. Int. J. Adv. Manuf. Technol. 2017, 89, 2387–2397. [Google Scholar] [CrossRef]

- Chacón, J.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive Manufacturing of PLA Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [PubMed]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Zawadzki, P.; Buń, P. Strength of ABS Parts Produced by Fused Deposition Modelling Technology–a Critical Orientation Problem. Adv. Sci. Technol. Res. J. 2015, 9, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Smith, W.C.; Dean, R.W. Structural Characteristics of Fused Deposition Modeling Polycarbonate Material. Polym. Test. 2013, 32, 1306–1312. [Google Scholar] [CrossRef]

- Ahn, S.-H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Ziemian, S.; Okwara, M.; Ziemian, C.W. Tensile and Fatigue Behavior of Layered Acrylonitrile Butadiene Styrene. Rapid Prototyp. J. 2015, 21, 270–278. [Google Scholar] [CrossRef]

- Vega, V.; Clements, J.; Lam, T.; Abad, A.; Fritz, B.; Ula, N.; Es-Said, O.S. The Effect of Layer Orientation on the Mechanical Properties and Microstructure of a Polymer. J. Mater. Eng. Perform. 2011, 20, 978–988. [Google Scholar] [CrossRef]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical Behaviour of ABS: An Experimental Study Using FDM and Injection Moulding Techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Górski, F.; Kuczko, W.; Wichniarek, R. Impact Strength of ABS Parts Manufactured Using Fused Deposition Modeling Technology. Arch. Mech. Technol. Autom. 2014, 34, 3–12. [Google Scholar]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. America Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- Wittbrodt, B.; Pearce, J.M. The Effects of PLA Color on Material Properties of 3-D Printed Components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Shubham, P.; Sikidar, A.; Chand, T. The Influence of Layer Thickness on Mechanical Properties of the 3D Printed ABS Polymer by Fused Deposition Modeling. Key Eng. Mater. 2016, 706, 63–67. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The Effect of Process Parameters in Fused Deposition Modelling on Bonding Degree and Mechanical Properties. Rapid Prototyp. J. 2018, 24, 80–92. [Google Scholar] [CrossRef]

| Nozzle Temperature (°C) | Layer Thickness (mm) | Raster Angle (°) |

|---|---|---|

| 200 | 0.10 | [0] |

| 210 | 0.15 | [45] |

| 220 | 0.20 | [90] |

| 230 | 0.25 | [0/90] |

| 240 | 0.30 | [45/−45] |

| 250 | [0/45/90] | |

| 260 | [0/45/90/135] | |

| 270 |

| Parameter | Unit | Value |

|---|---|---|

| Extrusion width | Mm | 0.48 |

| Infill | % | 100 |

| Number of shells | Lines | 1 |

| Number of skirts | Lines | 4 |

| Printing speed | mm/min | 6600 |

| Filament | Tensile Strength (MPa) | Young Modulus (MPa) | MFI (g/10 min) | |||

|---|---|---|---|---|---|---|

| Average | Std. Dev. | Average | Std. Dev. | Average | Std. Dev. | |

| ABS | 34.4 | 0.5 | 761 | 15 | 5.8 | 0.1 |

| PLA | 55.4 | 1.0 | 1499 | 28 | 25.5 | 3.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina, A.; Acosta-Sullcahuamán, J. Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing. Eng. Proc. 2025, 83, 1. https://doi.org/10.3390/engproc2025083001

Molina A, Acosta-Sullcahuamán J. Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing. Engineering Proceedings. 2025; 83(1):1. https://doi.org/10.3390/engproc2025083001

Chicago/Turabian StyleMolina, Andoni, and Julio Acosta-Sullcahuamán. 2025. "Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing" Engineering Proceedings 83, no. 1: 1. https://doi.org/10.3390/engproc2025083001

APA StyleMolina, A., & Acosta-Sullcahuamán, J. (2025). Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing. Engineering Proceedings, 83(1), 1. https://doi.org/10.3390/engproc2025083001