The Correlation of Pickled Fish and Frequency Response Using Parallel-Coupled-Lines Band-Stop Filter Microstrip †

Abstract

1. Introduction

2. Methods

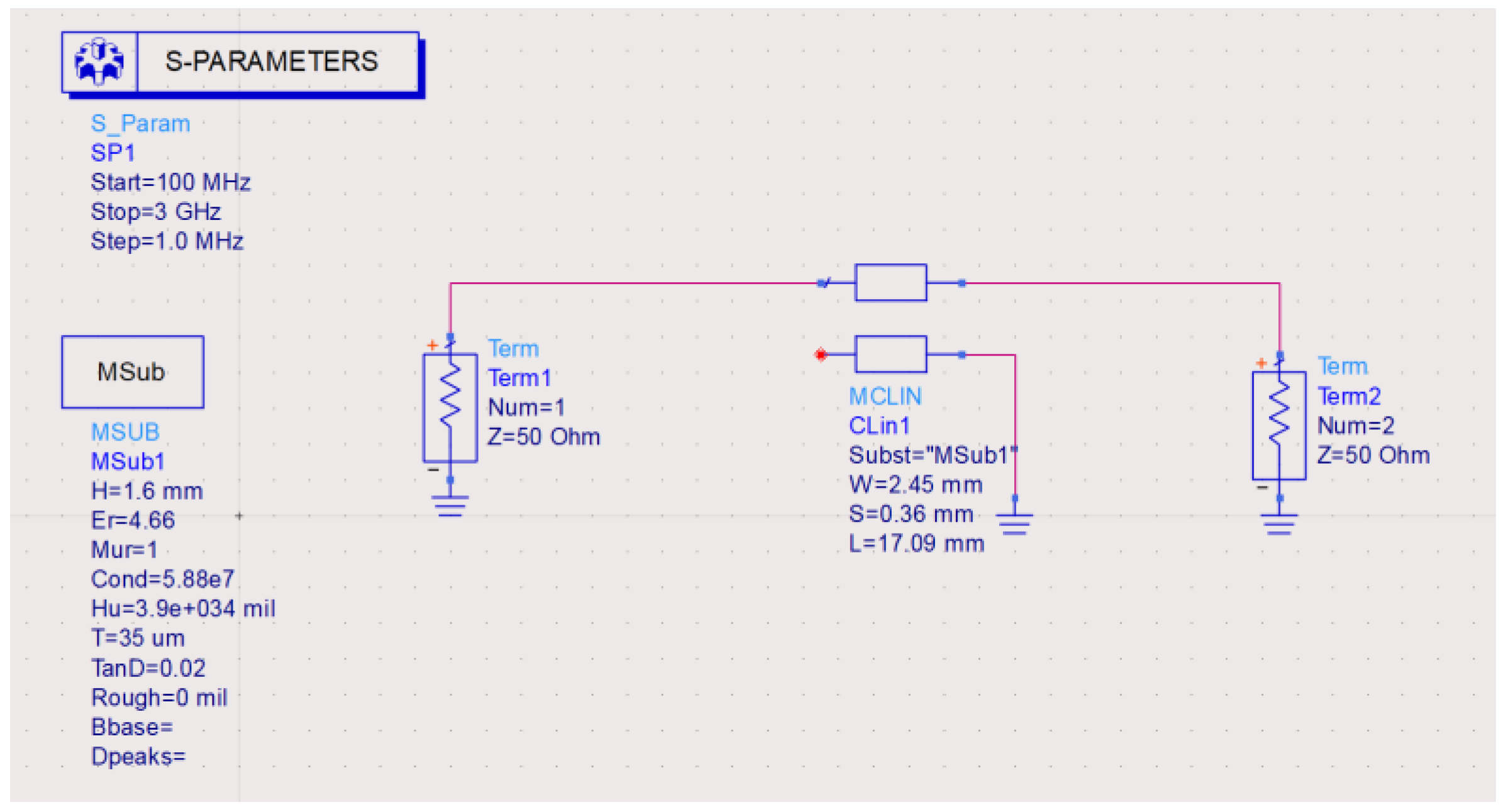

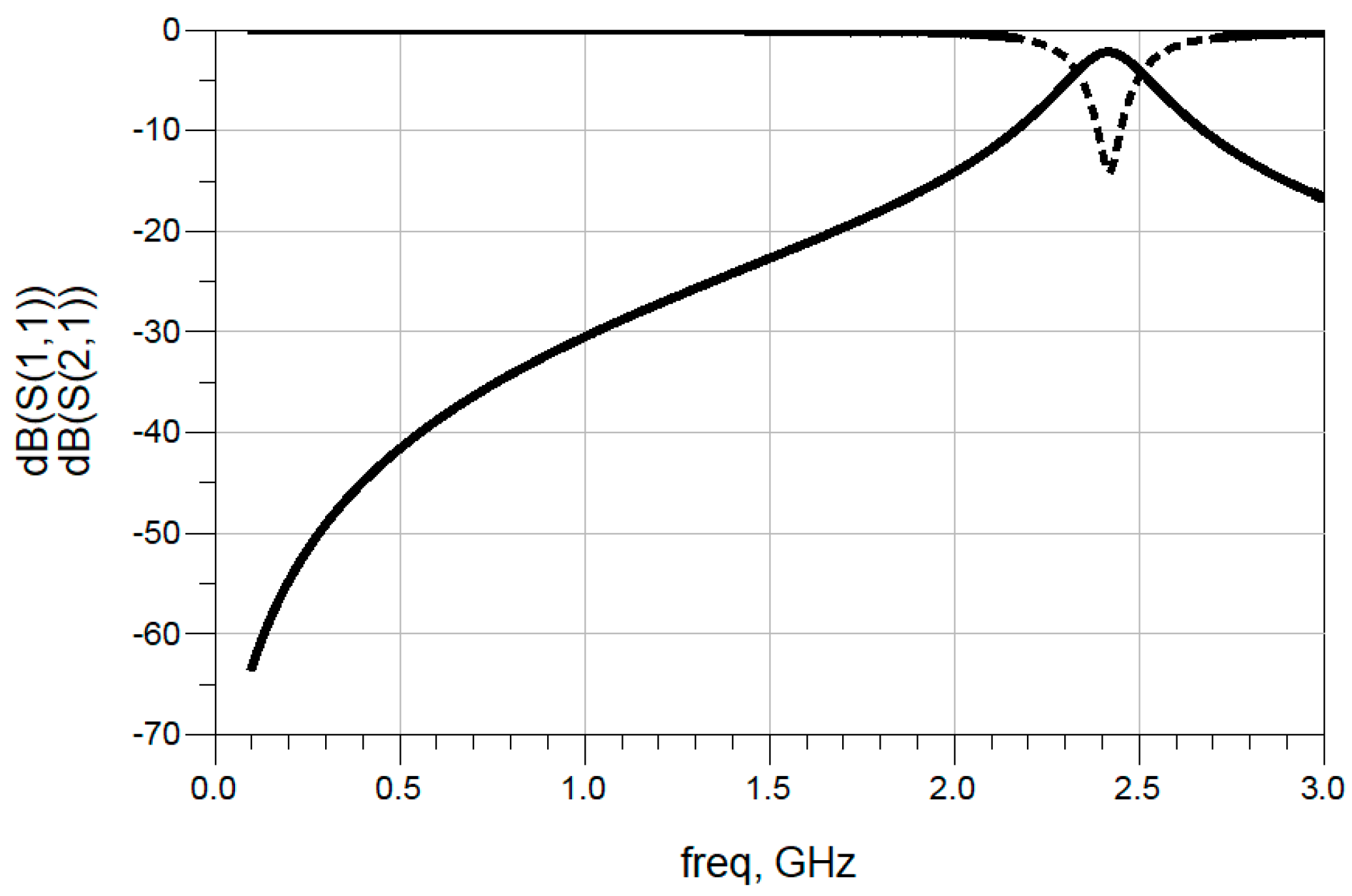

2.1. Design and Analysis

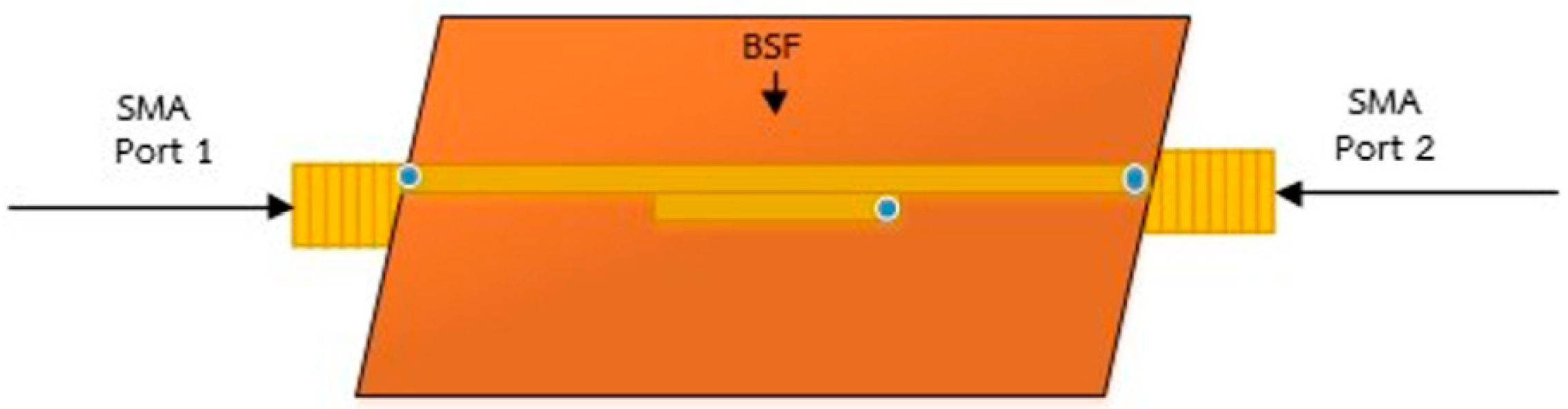

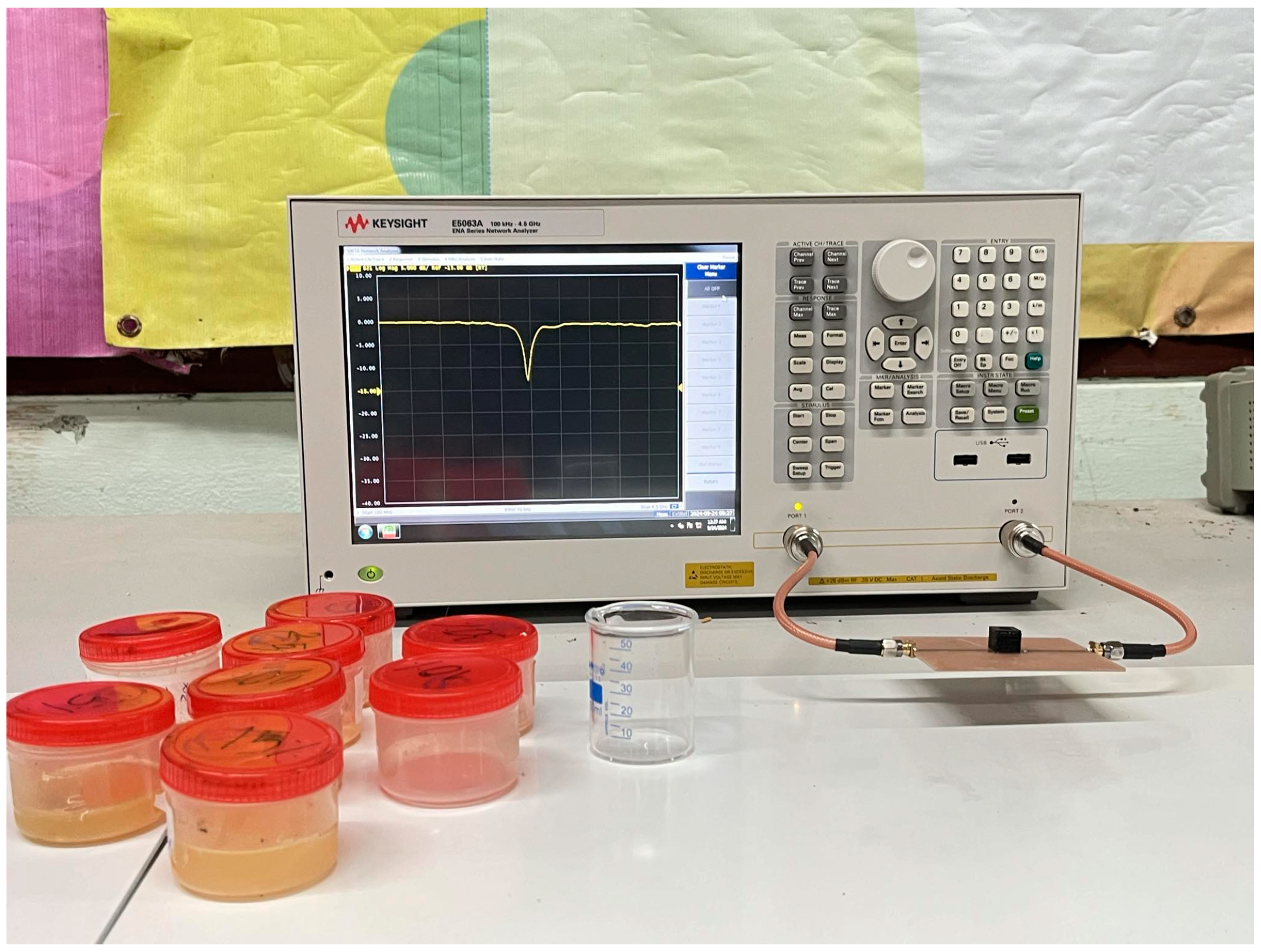

2.2. Experimental Setup

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shahzad, W.; Hu, W.; Ali, Q.; Raza, H.; Abbas, S.M.; Ligthart, L.P. A Low-Cost Metamaterial Sensor Based on DS-CSRR for Material Characterization Applications. Sensors 2022, 22, 2000. [Google Scholar] [CrossRef] [PubMed]

- Jelali, M.; Papadopoulos, K. Inline Inspection of Packaged Food Using Microwave/Terahertz Sensing—An Overview with Focus on Confectionery Products. Processes 2024, 12, 712. [Google Scholar] [CrossRef]

- Haq, T.; Ruan, C.; Zhang, X.; Ullah, S.; Fahad, A.K.; He, W. Extremely Sensitive Microwave Sensor for Evaluation of Dielectric Characteristics of Low-Permittivity Materials. Sensors 2020, 20, 1916. [Google Scholar] [CrossRef] [PubMed]

- S, A.; Menon, S.K.; Donelli, M.; L, M. Development of a Microwave Sensor for Solid and Liquid Substances Based on Closed Loop Resonator. Sensors 2021, 21, 8506. [Google Scholar] [CrossRef] [PubMed]

- Karasaeng, W.; Nualkham, J.; Summatta, C.; Sonasang, S. Measurement of soil moisture using microwave sensors based on BSF coupled lines. Eng. Proc. 2023, 58, 110. [Google Scholar] [CrossRef]

- Saeng-On, P.; Srisawat, S.; Phromloungsri, R.; Summatta, C.; Sonasang, S.; Prabpal, P. Design and analysis of microwave sensor for alcohol concentration with microstrip band stop filter. In Proceedings of the 2023 International Conference on Power, Energy and Innovations (ICPEI), Phrachuap Khirikhan, Thailand, 18–20 October 2023; pp. 52–55. [Google Scholar]

- Pozar, D.M. Microwave Engineering, 4th ed.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Advanced Design System (ADS); 2022 Update 1; License Number 347DF667415C; Keysight Technologies: Santa Rosa, CA, USA, 2022.

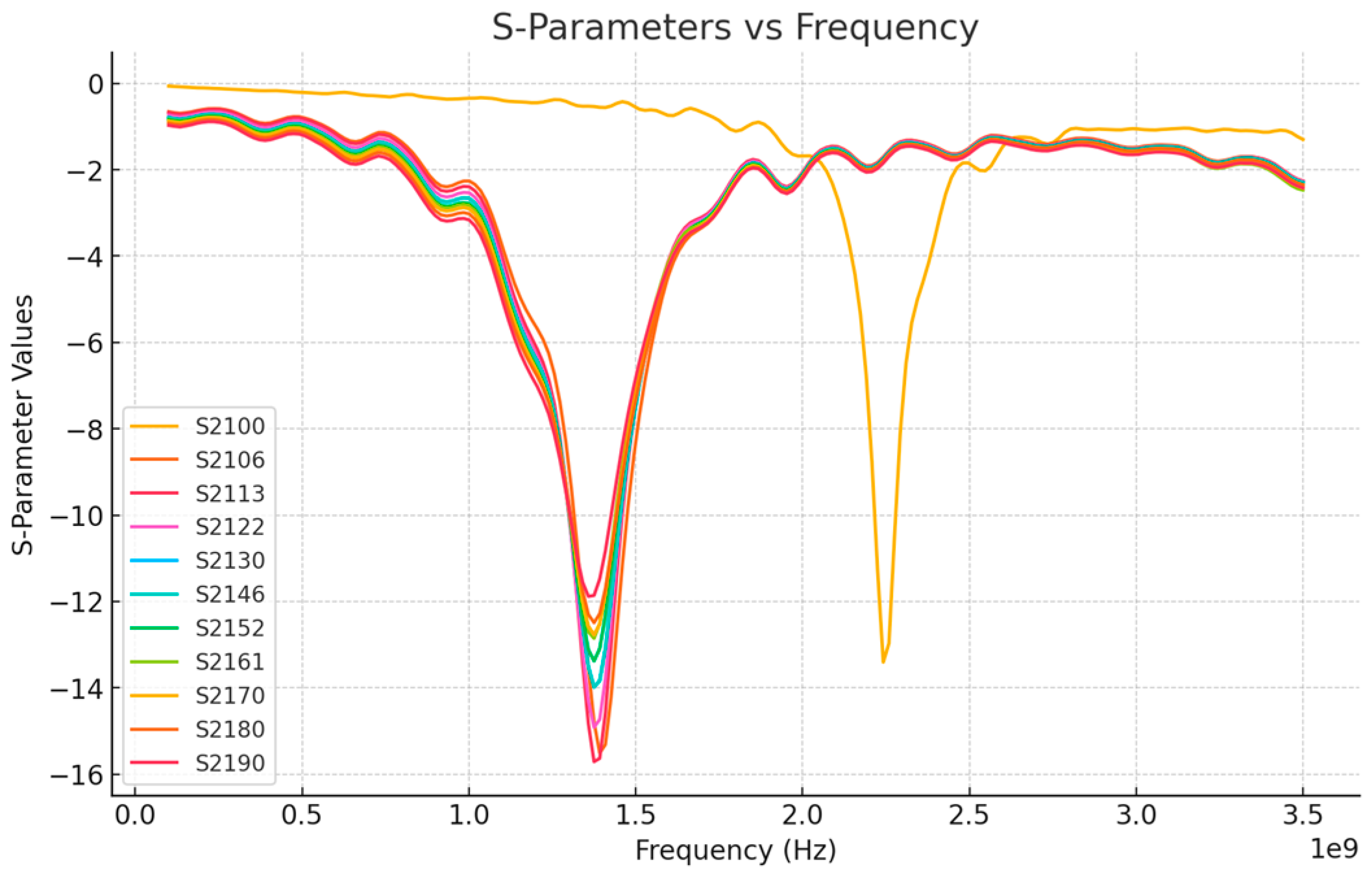

| Salt Concentration (%) | Assigned Variable | Salt Concentration (%) | Assigned Variable |

|---|---|---|---|

| 0 | S2100 | 46 | S2146 |

| 6 | S2106 | 52 | S2152 |

| 13 | S2113 | 61 | S2161 |

| 22 | S2122 | 70 | S2170 |

| 30 | S2130 | 90 | S2190 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karasaeng, W.; Nualkham, J.; Thitimahatthanakusol, P.; Angkawisittpan, N.; Sonasang, S. The Correlation of Pickled Fish and Frequency Response Using Parallel-Coupled-Lines Band-Stop Filter Microstrip. Eng. Proc. 2024, 82, 13. https://doi.org/10.3390/ecsa-11-20508

Karasaeng W, Nualkham J, Thitimahatthanakusol P, Angkawisittpan N, Sonasang S. The Correlation of Pickled Fish and Frequency Response Using Parallel-Coupled-Lines Band-Stop Filter Microstrip. Engineering Proceedings. 2024; 82(1):13. https://doi.org/10.3390/ecsa-11-20508

Chicago/Turabian StyleKarasaeng, Warakorn, Jitjark Nualkham, Phatsakul Thitimahatthanakusol, Niwat Angkawisittpan, and Somchat Sonasang. 2024. "The Correlation of Pickled Fish and Frequency Response Using Parallel-Coupled-Lines Band-Stop Filter Microstrip" Engineering Proceedings 82, no. 1: 13. https://doi.org/10.3390/ecsa-11-20508

APA StyleKarasaeng, W., Nualkham, J., Thitimahatthanakusol, P., Angkawisittpan, N., & Sonasang, S. (2024). The Correlation of Pickled Fish and Frequency Response Using Parallel-Coupled-Lines Band-Stop Filter Microstrip. Engineering Proceedings, 82(1), 13. https://doi.org/10.3390/ecsa-11-20508